Views: 222 Author: Amanda Publish Time: 2026-01-28 Origin: Site

Content Menu

● What Is CNC Machining and Why It Matters for Productivity?

● Key Ways CNC Machining Improves Productivity

>> Automation and Continuous Operation

>> Faster Cycle Time and Higher Cutting Speeds

>> High Precision and Reduced Rework

>> Quick Changeover between Different Parts

>> Integration with CAD/CAM for Digital Workflow

● CNC Machining in Different Manufacturing Stages

>> Rapid Prototyping with CNC Machining

>> Small-Batch and Bridge Production

>> Precision Mass Production with CNC Machining

● How CNC Machining Supports Other Processes

>> CNC Machining and CNC Turning

>> CNC Machining in Sheet Metal Fabrication

>> CNC Machining, 3D Printing, and Molding

● Practical Strategies to Maximize CNC Machining Productivity

● Why Overseas OEM Customers Prefer CNC Machining in China

● How Shangchen Uses CNC Machining to Serve OEM Clients

● FAQ

>> 1. How does CNC Machining reduce production time?

>> 2. Is CNC Machining suitable for both prototypes and mass production?

>> 3. How does CNC Machining improve part quality?

>> 4. What is the difference between CNC Machining and CNC turning?

>> 5. Why do overseas OEM customers prefer CNC Machining in China?

CNC machining has transformed modern manufacturing by dramatically improving productivity, consistency, and scalability for both prototypes and mass production. It enables factories like Shangchen to deliver high-precision parts faster, at lower cost, and with fewer errors, making it an essential technology for global OEM customers in Europe, America, Japan, and other markets.

CNC Machining is especially important for overseas brand owners, wholesalers, and manufacturers who need reliable long-term partners in China. By integrating CNC Machining with rapid prototyping, turning, sheet metal fabrication, 3D printing, and mold production, Shangchen can support the entire product life cycle from the first prototype to stable, repeated batch production.

CNC Machining (Computer Numerical Control Machining) is a manufacturing process where pre-programmed software controls the movement of tools and machines such as mills, lathes, routers, and grinders. Instead of relying on manual operation, CNC Machining uses digital instructions (often G-code) to cut, drill, and shape metal and plastic parts with extremely high precision.

Because CNC Machining is driven by digital data, it is highly repeatable and scalable. Once a CNC program is verified, the same code can be used again and again to produce identical parts, whether you need ten pieces or ten thousand pieces. This is very different from manual machining, where each part depends heavily on the operator's skill, experience, and concentration.

For overseas OEM customers working with a Chinese CNC Machining supplier, this digital and repeatable nature brings several benefits:

- Faster turnaround from CAD design to finished parts

- Fewer mistakes caused by human error

- Stable quality across small batches and mass production

- Easier quality control and documentation for long-term projects

CNC Machining is not only a way to cut material; it is a complete production system that connects engineering design, manufacturing, and quality control into one integrated process.

CNC Machining significantly boosts productivity through a high degree of automation. Once the CNC program is set and the workpiece is clamped, the machine can run automatically with minimal operator intervention. For a factory like Shangchen, this means:

- Longer machine running hours, including night shifts and weekends

- Less idle time between operations

- One skilled operator can supervise multiple CNC Machining centers

Automation supports continuous operation, allowing CNC mills and CNC turning centers to keep producing parts while operators focus on programming, quality inspection, material preparation, and process optimization. This directly shortens delivery time and increases output per day.

In addition, modern CNC Machining centers can be combined with automatic tool changers, pallet changers, and even robotic loading systems. These features further reduce the time lost in manual loading and unloading, while also increasing safety and consistency in the production process.

CNC Machining allows optimization of cutting parameters—such as feed rate, spindle speed, tool paths, and depth of cut—to minimize cycle time for each part. Advanced CAM programming can:

- Reduce unnecessary tool movements and air cutting

- Combine multiple operations in one setup

- Use high-speed machining strategies for better chip removal and tool life

When each cycle is shorter but still stable in quality, total productivity across hundreds or thousands of parts increases significantly. This is especially important for OEM customers who require ongoing, repeated orders for the same components.

By using advanced cutting tools, coatings, and coolants, CNC Machining can maintain higher spindle speeds and feed rates without sacrificing surface quality. This balance between speed and precision is one of the main reasons CNC Machining is the preferred solution for high-efficiency metal cutting.

Every time a part is scrapped or reworked, productivity drops and costs rise. CNC Machining solves this problem by delivering high precision and consistent repeatability. Once the program, tools, and fixtures are set, the machine can produce part after part within tight tolerances.

The benefits of high precision include:

- Fewer defects and less rework or scrap

- Reduced inspection failures and customer complaints

- Stable performance in critical applications, such as automotive, aerospace, automation equipment, and medical devices

A higher first-pass yield means more usable parts per shift and lower material and labor cost per part. For OEM customers, this translates into more reliable delivery, fewer quality issues, and better long-term cooperation with their CNC Machining supplier.

In modern manufacturing, many OEM clients require flexible low-volume batches, customized parts, and frequent design updates. CNC Machining supports quick changeover by:

- Allowing fast program switching in the controller

- Using modular fixtures and standard workholding systems

- Storing tooling and setup data for repeated jobs

Compared with traditional manual machining, switching from one part number to another is much faster, which is crucial for rapid prototyping and small-batch production. This flexibility lets a CNC Machining factory handle more orders in the same time window, increasing overall productivity without sacrificing quality.

For example, a customer may request ten prototypes of a new housing design, followed by a bridge batch of 200 pieces and then several mass production orders. With CNC Machining, the factory can keep all programs and process parameters on file, making it easy to restart production whenever the customer places a new order.

CNC Machining works seamlessly with 3D CAD models and CAM software. Once a customer sends a 3D file (such as STEP, IGES, or STL) and a 2D drawing with tolerance requirements, engineers can:

- Review manufacturability and give suggestions for design optimization

- Generate CNC Machining toolpaths in CAM software

- Simulate machining operations to detect collisions and errors before cutting material

This digital workflow reduces communication time, shortens programming time, and prevents costly mistakes during production. For international OEM customers, this means faster quotation, faster sample approval, and faster launch into batch production.

By maintaining digital records of programs, tool lists, process sheets, and inspection reports, CNC Machining also supports traceability and quality management, which are key requirements for many international brands.

For new product development, speed is critical. CNC Machining is ideal for rapid prototyping because it:

- Produces functional parts from engineering-grade metals and plastics

- Delivers prototypes with accurate dimensions and good surface quality

- Supports design validation, assembly fit checks, and performance testing

Compared with some additive manufacturing methods, CNC Machining prototypes often have better mechanical strength and closer-to-production tolerances. This allows engineering teams to make decisions faster and reduces the number of design correction cycles.

In addition, CNC Machining can easily produce multiple prototype versions with small design changes. This is very useful for A/B testing different features or dimensions before finalizing the product for mass production.

Between prototype and full mass production, there is often a “bridge” stage where customers need dozens or hundreds of parts. CNC Machining is perfect in this stage because:

- No expensive hardened steel production mold is needed

- Setup cost is relatively low compared with injection molding

- CNC programs and fixtures can be reused for future repeat orders

This allows OEM customers to test the market, optimize design, and prepare for larger investment in molds or automated lines, without losing time or money. For a factory that offers both CNC Machining and mold making, the transition from machined parts to molded parts can be planned strategically based on real market feedback.

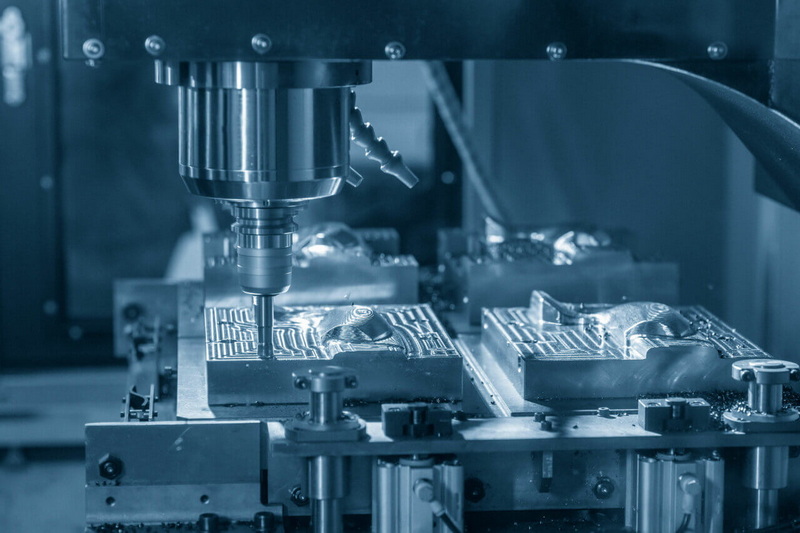

With stable CNC programs, optimized toolpaths, robust fixtures, and a well-trained team, CNC Machining can also support mass production of precision parts. When combined with multi-axis machining centers and CNC turning machines, the factory can:

- Consolidate multiple setups into fewer clamping steps

- Run multiple identical parts in one cycle with multi-station fixtures

- Maintain consistent quality round-the-clock with automated inspection support

For global OEM customers, this means reliable supply of components with predictable delivery time and quality levels. CNC Machining provides both speed and accuracy, which helps keep the entire supply chain running smoothly.

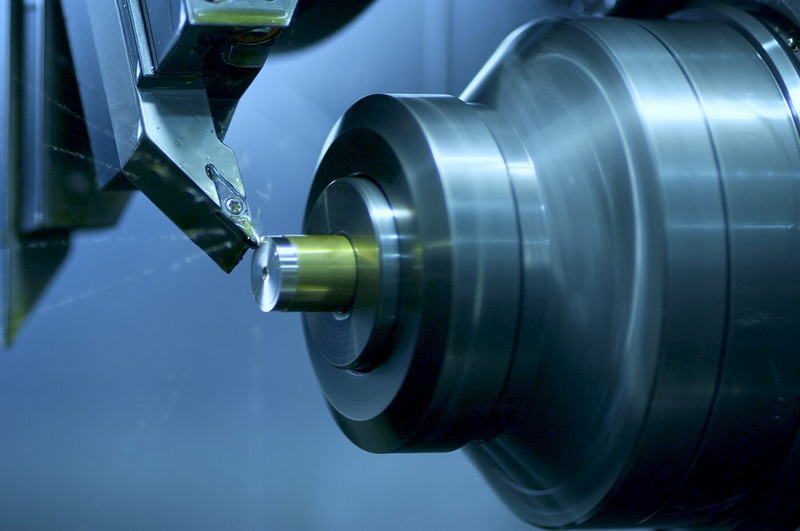

CNC Machining often refers to milling and drilling operations, while CNC turning (lathe turning) is used to produce rotational parts such as shafts, spacers, connectors, bushings, and fasteners. When both processes are integrated in one factory:

- Vertical and horizontal machining centers handle complex 3D shapes, pockets, slots, and holes

- CNC turning centers create precise cylindrical, conical, and threaded features

Together, CNC Machining and CNC turning cover a huge range of mechanical components. This integration improves productivity by reducing outsourcing, shortening logistics time, and simplifying communication for OEM clients.

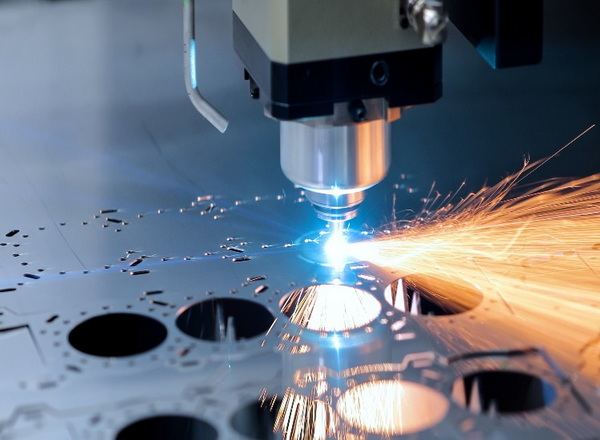

Sheet metal fabrication uses processes like laser cutting, punching, bending, stamping, and welding to form enclosures, brackets, frames, and structural parts. CNC Machining plays a supporting role in sheet metal projects by:

- Machining critical features after forming, such as precise holes, countersinks, tapped holes, or sealing surfaces

- Producing jigs and fixtures for bending, welding, and assembly

- Finishing functional areas that require tight tolerance and smooth surfaces

This combination ensures that even complex sheet metal assemblies meet both structural and dimensional requirements without slowing down production or increasing scrap.

A full-service factory like Shangchen often offers 3D printing, CNC Machining, and mold making together, creating a flexible manufacturing ecosystem. CNC Machining contributes to productivity in this ecosystem by:

- Machining high-precision inserts, mold bases, and electrodes for mold manufacturing

- Finishing 3D-printed parts to achieve tighter tolerance and better surface quality

- Providing backup manufacturing when molds are under maintenance or still in development

This multi-process strategy shortens lead time for tooling and accelerates time-to-market for the final product. It also gives OEM customers more options: they can choose CNC Machining, molding, or a hybrid approach depending on project quantity and schedule.

CNC Machining offers high potential productivity, but to fully unlock this potential, a factory must focus on process optimization, technology, and management. Key strategies include:

- Using advanced CAM software to optimize CNC Machining toolpaths and reduce air cutting time

- Standardizing tool holders, cutting tools, and fixtures to shorten setup time and reduce variation

- Applying efficient cutting strategies, such as high-speed machining and trochoidal milling, when appropriate

- Implementing preventive maintenance to avoid unexpected downtime of CNC Machining centers and CNC lathes

- Training operators and programmers to handle program optimization, setup, and basic fault diagnosis

By combining these methods, CNC Machining becomes a highly productive, stable, and scalable manufacturing core. The result is faster lead time, lower cost per part, and higher reliability for OEM customers.

For brand owners, wholesalers, and manufacturers abroad, CNC Machining offers clear advantages when they work with capable Chinese factories:

- Reliable repeatability for long-term projects with stable CNC Machining programs

- Flexible quantities, from one prototype to tens of thousands of parts

- Capability to handle multiple materials, including aluminum, stainless steel, carbon steel, brass, copper, and engineering plastics

- Compatibility with international standards and typical quality systems

When a supplier like Shangchen integrates CNC Machining with CNC turning, sheet metal fabrication, 3D printing, and mold production, it becomes easier for overseas clients to manage complex projects through a single partner. This reduces communication time, simplifies supply chain management, and lowers project risk, effectively improving productivity on both sides.

Furthermore, time zone differences can be used as an advantage. While the client's team is offline, the Chinese CNC Machining factory can continue programming, machining, and inspecting parts. This “24-hour development cycle” speeds up engineering iterations and shortens overall project schedules.

As a Chinese factory focusing on rapid prototyping, CNC Machining services, precision batch production, CNC turning, sheet metal manufacturing, 3D printing, and mold production, Shangchen positions CNC Machining at the center of its service capabilities. For overseas OEM customers, this brings several concrete benefits:

- One-stop solution: From prototype to batch CNC Machining, from individual metal parts to assembled components, customers can manage everything through a single supplier.

- Engineering support: Shangchen can review drawings, propose CNC Machining optimization suggestions, and help balance cost, quality, and lead time.

- Flexible production modes: The same CNC Machining center can switch between prototype, small batch, and mass production by adjusting setups and production planning.

- Stable quality control: With digital CNC Machining programs and inspection reports, Shangchen can keep long-term consistency for repeat orders.

This combination of technology and service helps overseas customers reduce development risk, shorten new product introduction cycles, and improve total project productivity.

CNC Machining fundamentally changes how factories organize production, enabling a high level of automation, precision, and flexibility that traditional manual machining cannot match. By optimizing cycle time, reducing rework, supporting rapid prototyping, and scaling smoothly into batch and mass production, CNC Machining directly improves productivity for both manufacturers and their OEM customers.

When combined with CNC turning, sheet metal fabrication, 3D printing, and mold making, CNC Machining becomes the central technology that connects every stage of the product life cycle, from concept to stable mass production. For overseas brand owners and wholesalers, choosing a supplier with strong CNC Machining capability is one of the most effective ways to shorten lead time, control cost, and ensure long-term product quality.

For a factory such as Shangchen, investing in advanced CNC Machining equipment, experienced engineers, and systematic quality control creates a powerful manufacturing platform that can support a wide range of projects. This synergy between technology, management, and service is the real reason CNC Machining has become the backbone of modern, productive manufacturing chains.

Conntact us to get more information!

CNC Machining reduces production time through automation, optimized toolpaths, and continuous operation. Once the CNC program is set and the workpiece is clamped, the machine runs with minimal manual intervention, which shortens individual cycle times. At the same time, modern CNC Machining centers can operate for long hours, including night shifts, increasing the total output per day.

Yes, CNC Machining is very suitable for both rapid prototyping and mass production. It can quickly produce a few prototype parts directly from CAD models, helping engineers test design ideas and assembly fit. After the program is optimized and the process is stabilized, the same CNC Machining setup can be used to produce small batches or large volumes of parts with consistent quality and dimensions.

CNC Machining improves quality by following precise digital instructions with high repeatability, which reduces dimensional errors and human mistakes. Once the correct parameters and tools are selected, each part produced by CNC Machining remains within tight tolerance, providing stable performance in demanding applications. This results in fewer defects, less rework, and better overall customer satisfaction.

CNC Machining usually refers to milling and drilling operations performed on prismatic or complex 3D-shaped parts using machining centers. CNC turning uses a rotating workpiece and stationary cutting tools, and is mainly used for cylindrical components such as shafts, bushings, studs, and threaded parts. In a full-service factory, CNC Machining and CNC turning are combined to cover a wide range of geometries, which improves flexibility and productivity for OEM customers.

Overseas OEM customers prefer CNC Machining in China because it combines cost advantages with high precision, flexible quantities, and relatively fast delivery. Chinese factories that specialize in CNC Machining can handle diverse materials and complex parts, while also providing engineering support and quality control. When an experienced supplier like Shangchen offers CNC Machining together with turning, sheet metal, 3D printing, and mold services, international customers can manage complex projects more easily and improve their overall supply chain efficiency.

1. https://cnc-world.co.uk/how-can-cnc-machining-increase-production-efficiency/

2. https://www.mmsonline.com/articles/improve-cnc-productivity-by-addressing-three-production-issues

3. https://toolpath.com/top-questions/how-to-increase-cnc-machine-productivity

4. https://www.linkedin.com/pulse/10-tips-help-improve-efficiency-productivity-cnc-machines

5. https://tirapid.com/cnc-machining/

6. https://xometry.asia/cnc-turning/

7. https://proleantech.com/cnc-machining/

content is empty!