Views: 222 Author: Amanda Publish Time: 2026-01-27 Origin: Site

Content Menu

● What Is CNC Aluminium Casting Machining?

● How CNC Aluminium Casting Machining Works Step by Step

>> Design, CAD Modeling, and DFM Review

>> Selecting the Casting Process and Aluminium Alloy

>> Producing the Raw Aluminium Casting

>> Machining Process Planning and Programming

>> Fixturing and Workholding for Aluminium Castings

>> Drilling, Boring, Reaming, and Tapping

>> Deburring, Surface Finishing, and Treatments

>> Inspection, Quality Assurance, and Documentation

● Key Benefits of CNC Machining for Aluminium Castings

>> High Precision and Tight Tolerances

>> Complex and Consistent Geometries

>> Improved Surface Finish and Performance

>> Faster Lead Times and Better Economics

>> Design Flexibility and Engineering Changes

● Typical Applications in OEM Manufacturing

>> Automotive and Transportation Parts

>> Industrial Machinery and Automation

>> Electronics, Robotics, and Enclosures

>> Aerospace and High‑Performance Applications

>> Custom OEM Components and Brand‑Specific Designs

● Why Work With a Full‑Service CNC Machining Factory Like Shangchen?

>> One‑Stop OEM CNC Machining Services

>> Rapid Prototyping to Batch Production

>> Flexible Materials and Surface Treatments

>> Stable Quality and Long‑Term Cooperation

● Practical Tips for Designing Aluminium Cast Parts for CNC Machining

>> Allow Enough Machining Stock

>> Choose Accessible Machining Surfaces

>> Use Consistent Datums and References

>> Coordinate Tolerance Levels With the Supplier

● FAQ

>> 1. What is the difference between aluminium CNC machining and aluminium casting?

>> 2. Why is CNC machining needed after aluminium casting?

>> 3. Which aluminium alloys are best for CNC machining after casting?

>> 4. Is CNC aluminium casting machining cost‑effective for small batches?

>> 5. What tolerances can be achieved with CNC machining on aluminium castings?

CNC machining turns rough aluminium castings into high‑precision, ready‑to‑use components by removing excess material with computer‑controlled cutting tools. This combination of casting plus CNC machining is ideal for OEM brands that need complex shapes, tight tolerances, and stable quality in small or large batches.

CNC aluminium casting machining is a two‑stage manufacturing route that first creates a near‑net‑shape aluminium casting, then finishes all critical dimensions and surfaces by CNC machining. The casting provides the basic geometry at low cost, while CNC machining delivers accuracy, repeatability, and fine surface finish for functional interfaces.

In aluminium casting, molten aluminium is poured or injected into a mold cavity that defines the general shape of the part, then left to solidify before demolding. Common processes include high‑pressure die casting for high volumes and smooth surfaces, and sand casting for lower volumes and larger or more complex parts. The raw casting normally has draft angles, parting lines, shrinkage, and dimensional variation that must be corrected by CNC machining to meet final tolerance requirements.

CNC machining uses computer numerical control programs to drive milling, turning, drilling, and other operations, removing material exactly where needed on the aluminium casting. This allows the manufacturer to create flat mounting faces, precision bores, slots, threads, and other critical features that are difficult or impossible to achieve directly from casting. Because the machine follows a digital toolpath, CNC machining ensures that every casting in a batch is machined to the same specification with minimal human variation.

The full CNC aluminium casting machining workflow runs from design to finished inspection and can be adapted to rapid prototyping or mass production. Below is a typical sequence that a factory like Shangchen would follow for OEM customers who need CNC machining on cast aluminium parts.

The process begins with the customer's 3D CAD model and technical drawings that define geometry, tolerances, and surface requirements for CNC machining. Engineers review the design from both casting and CNC machining perspectives, checking draft angles, wall thickness, machining allowance, and fixturing possibilities to ensure stable, cost‑effective production. During this design for manufacturing review, the team may recommend changes such as increasing fillet radii, adjusting ribs, or modifying bosses so that both casting and CNC machining are easier and more reliable.

Based on expected volume, part complexity, and performance requirements, the team chooses between high‑pressure die casting, gravity casting, sand casting, or other methods, and selects an appropriate aluminium alloy. For CNC machining, alloys that chip cleanly and offer good strength‑to‑weight ratios are preferred because they reduce tool wear and improve surface finish. The choice of alloy also affects corrosion resistance, thermal conductivity, and suitability for secondary processes like anodizing and powder coating.

Once tooling is ready, molten aluminium is poured or injected into the mold, allowed to cool and solidify, and removed as a raw casting. After demolding, the foundry trims gates, risers, and flash, then may perform basic cleaning, grinding, or shot blasting before sending the casting to CNC machining for precision finishing. At this stage the part has its approximate shape but still lacks the accurate faces, holes, and threads that CNC machining will create.

Process engineers define which faces, holes, pockets, and slots will be created or refined by CNC machining, then plan the sequence of operations and workholding. They decide which surfaces will be used as datums, how many setups are required, and whether multi‑axis CNC machining centers or separate CNC turning machines will be used. CAM software converts the 3D model into G‑code toolpaths for CNC machining centers and CNC turning lathes, optimizing feeds, speeds, and step‑overs to balance cycle time, tool life, chip evacuation, and surface quality.

Before CNC machining begins, custom fixtures or soft jaws locate the casting using datums that are repeatable despite casting tolerances. Because castings can have variation from piece to piece, fixturing for CNC machining must grip the part securely without distortion while still exposing all areas that need machining. Good workholding is crucial, because CNC machining operations like facing, drilling, and pocketing must all reference consistent surfaces to achieve the specified tolerances across the entire batch.

CNC milling is often the primary CNC machining step for aluminium castings, using rotating cutters to remove material from fixed workpieces. Typical milling operations include facing to create flat sealing or mounting surfaces, pocketing and contouring to form internal cavities and outer profiles, and slotting or keyways for mechanical drives or assembly features. Because aluminium machines easily, high‑speed CNC machining with sharp, multi‑flute end mills can achieve tight tolerances and smooth finishes with short cycle times, which is especially valuable for OEM customers who need large quantities.

When castings are cylindrical or have rotational symmetry, CNC turning becomes the core CNC machining process, rotating the part while single‑point tools cut its diameter and faces. Lathe operations such as outer and inner diameter turning, grooving, threading, and tapering convert rough cast round shapes into precise shafts, hubs, or housings. Many parts combine both processes, using CNC turning for the main diameter and then transferring the component to a CNC machining center for milled flats, holes, and special geometric features.

Many aluminium castings require CNC machining of precision holes for fasteners, bearings, dowel pins, or fluid passages, which is achieved through drilling, boring, reaming, and tapping. Simple through‑holes can be drilled in a single step, while high‑accuracy holes may require boring and reaming to reach the final diameter and surface finish. Threaded holes can be produced by rigid tapping or thread milling on CNC machining centers, ensuring consistent depth and alignment that meet assembly requirements.

After the main CNC machining operations are complete, parts are deburred to remove sharp edges, burrs, and loose chips, improving safety and assembly quality. Depending on requirements, finishing steps can include tumbling, vibratory finishing, bead blasting, polishing, or brushing to standardize appearance before surface treatments. Surface treatments like anodizing, powder coating, and plating can then be applied to CNC machined aluminium parts to enhance corrosion resistance, wear resistance, electrical insulation, or branding aesthetics.

Dimensional inspection verifies that CNC machining has delivered all critical features within tolerance, often using calipers, micrometers, gauges, and coordinate measuring machines. Surface roughness, geometric tolerances, and thread quality are also checked according to the drawings and standards required by the OEM customer. For ongoing projects, statistical process control and documented inspection reports help maintain consistency across batches, giving overseas buyers confidence in their CNC machining supply chain.

Combining aluminium casting with CNC machining creates a balance of cost, flexibility, and precision that is difficult to match with a single process alone. For overseas brand owners, wholesalers, and manufacturers, this route supports rapid development, scalable production, and stable quality.

CNC machining can routinely achieve tight tolerances in aluminium, which is essential for sealing surfaces, bearing seats, and alignment features. This precision lets OEMs integrate cast‑and‑machined parts into complex systems like automotive, aerospace, medical, or industrial equipment without extensive hand fitting or rework.

Casting provides near‑net‑shape complexity, while CNC machining adds fine details like grooves, recesses, precision bores, and flat reference faces. Once the CNC machining program and fixtures are validated, the factory can reproduce the same geometry consistently across thousands of parts with minimal variation, which is critical for brands that rely on long‑term, repeat orders.

Raw cast surfaces are often rough, porous, or uneven and may not be suitable for moving interfaces, seals, or visual areas. CNC machining produces controlled surface finishes on critical regions, reducing friction, improving sealing, lowering noise, and giving aluminium parts a professional, high‑value appearance that supports OEM branding and product positioning.

Because casting provides most of the volume and general shape, CNC machining only removes material in critical zones, which keeps cycle times reasonable compared with full‑billet machining. Automation, multi‑axis CNC machining centers, tool presetting, and pallet systems further reduce labour costs and setup time, making the combined approach cost‑effective for both prototypes and mass production.

When a customer needs to modify a design, many changes can be handled at the CNC machining level without immediately altering casting tooling. Adjusting CNC machining programs or adding new operations allows for smaller design updates, while major geometry shifts can be handled during the next tooling revision. This flexibility is valuable for brands that continuously refine products based on feedback and testing.

Aluminium casting plus CNC machining supports a wide variety of industries that require lightweight, corrosion‑resistant, yet precise components. OEM customers often rely on this combination for structural parts, housings, and custom mechanical components.

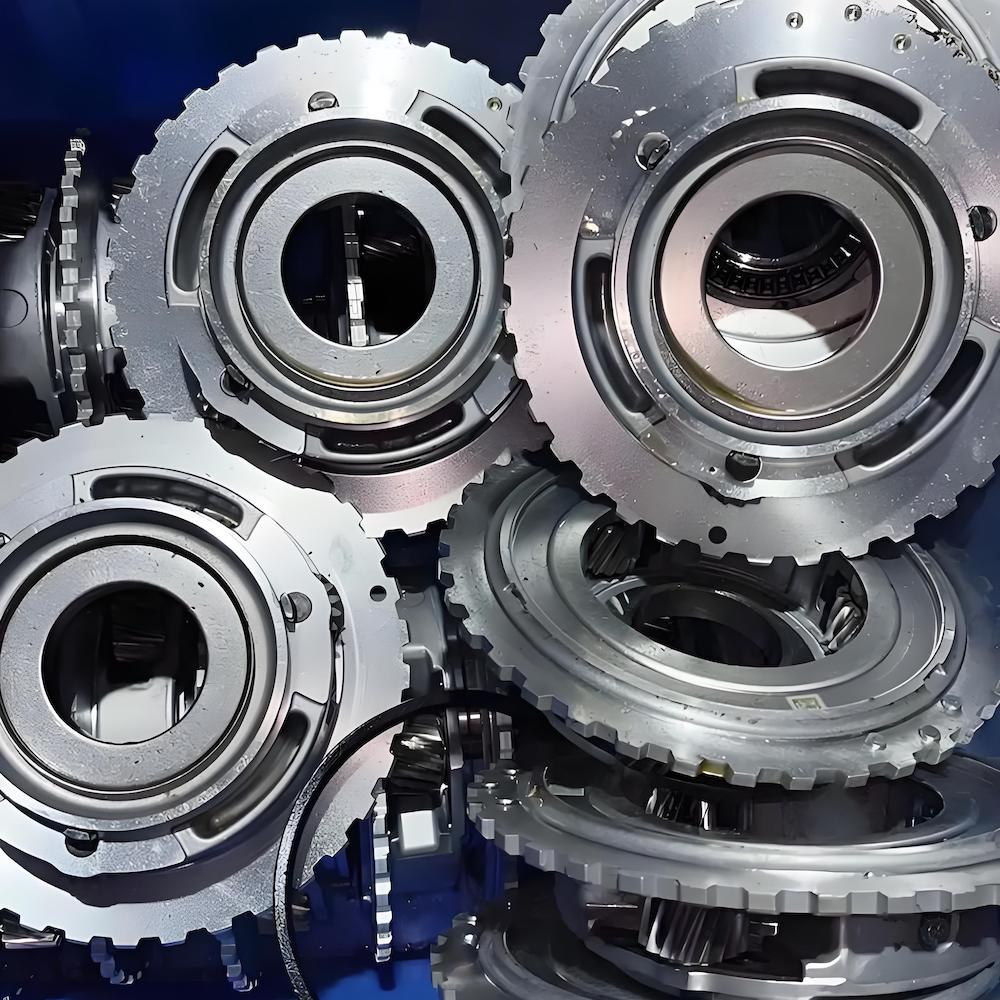

Engine covers, gearbox housings, brackets, suspension components, steering parts, and pump bodies are often produced as aluminium castings and then finished by CNC machining. The approach keeps weight low while ensuring that machined surfaces, bores, and mounting points align with strict automotive standards for durability, NVH performance, and safety.

CNC machining of aluminium cast frames, manifolds, machine bases, and fixtures is common in industrial equipment because it enables precise alignment and reliable assembly. By combining casting with CNC machining, factories can deliver robust machine components without excessive material waste or machining time, helping integrators and equipment builders reduce their total cost of ownership.

Aluminium cast housings for electronics and robotics benefit from CNC machining of heat sink fins, cable entries, connector interfaces, and tight‑tolerance sealing faces. CNC machining ensures that mating surfaces, alignment bosses, and threaded inserts all meet the dimensional needs of sensitive electronic systems, while still taking advantage of aluminium's thermal conductivity and EMI shielding.

In aerospace and high‑performance sectors, weight reduction and reliability are critical, so aluminium casting combined with CNC machining is widely used for brackets, housings, and structural components. CNC machining allows the manufacturer to achieve the exact tolerances, surface finishes, and inspection traceability demanded by stringent industry standards, while casting controls material usage and overall cost.

Many overseas brands use CNC machining on aluminium castings to differentiate their products through unique shapes, integrated functions, and logo or interface features. Using the same casting and CNC machining partner over time allows them to maintain a stable supply while gradually optimizing cost, weight, strength, and aesthetics based on market response.

A factory that integrates rapid prototyping, CNC machining, turning, sheet metal fabrication, 3D printing, and tooling can manage the entire life cycle of aluminium OEM parts. This is especially valuable for overseas customers who need a single partner to handle design optimization, casting, CNC machining, and final assembly support.

By combining casting with CNC machining, turning, and secondary operations, a single supplier can deliver complete parts ready for the customer's production line. This reduces the risk of communication problems between multiple vendors and shortens lead times from concept to shipment for CNC machining projects. It also simplifies logistics, documentation, and quality management, since all stages are controlled under one system.

Rapid prototyping can start with CNC machining from solid aluminium or 3D‑printed patterns, then transition to casting plus CNC machining as volumes rise. Using the same engineering team and CNC machining equipment across stages keeps design intent stable, improves feedback speed, and simplifies engineering change management from prototype to mass production.

Full‑service factories typically offer CNC machining for many metals, including a wide range of aluminium alloys, zinc, magnesium, brass, copper, stainless steel, and various engineering plastics. They can integrate surface treatments like anodizing, powder coating, painting, and plating directly after CNC machining to deliver finished OEM components that are ready for assembly or retail packaging.

With standardized CNC machining procedures, qualified suppliers of raw materials, and established inspection systems, a professional factory can maintain stable quality over many years. For overseas brands and wholesalers, this stability means fewer complaints, fewer returns, and more time to focus on sales and product development instead of firefighting quality issues.

Good design makes CNC aluminium casting machining more efficient, reliable, and economical. Engineers and buyers can improve results by following some basic guidelines when they plan to combine casting with CNC machining.

For every surface that will be finished by CNC machining, it is important to leave enough extra material on the casting. Too little machining allowance can lead to areas that are only partially cleaned, while too much material increases CNC machining time and cost. A balanced allowance ensures that the CNC machining process can fully remove casting defects and reach the final surface without wasting time or tools.

When designing the part, consider whether CNC machining tools can physically reach each surface, hole, and pocket. Deep cavities, very narrow slots, or hidden faces can be difficult and expensive to machine, sometimes requiring special tools or complex multi‑axis CNC machining. Simplifying access or slightly adjusting geometry can significantly reduce machining cost while maintaining function.

To keep CNC machining accurate and repeatable, define clear reference surfaces and datums on the drawing that match how the part will be fixtured. When datums are stable and easy to locate on the casting, the CNC machining team can reduce alignment errors and keep the entire batch within tolerance. Consistent datums also make inspection easier and reduce misunderstandings between designer and manufacturer.

Not all features need the same tight tolerances; over‑specifying tolerances on non‑critical areas raises CNC machining cost without real benefit. Discuss with the CNC machining supplier which dimensions are truly critical for function and which can be more open. This collaboration helps balance product performance and production cost.

CNC aluminium casting machining combines the shape‑forming advantages of casting with the precision and repeatability of CNC machining to deliver high‑value OEM components. For overseas brand owners, wholesalers, and manufacturers, this hybrid process provides a powerful balance of cost, speed, and product performance that single‑step methods cannot match. By understanding the full workflow from design and casting to CNC machining, finishing, and inspection, buyers can work more effectively with factories like Shangchen to develop reliable, scalable products for global markets.

Conntact us to get more information!

Aluminium casting forms the basic shape by solidifying molten metal in a mold, while aluminium CNC machining removes material from that shape to achieve final dimensions and tolerances. In many OEM projects, casting is used for bulk geometry and CNC machining is used for precision features, so the two processes work together rather than competing with each other.

Casting alone often cannot hold very tight tolerances or produce perfectly flat, aligned, or threaded features required in modern assemblies. CNC machining corrects dimensional variation, improves surface finish, and adds intricate details such as precision bores, slots, and threads, making the cast aluminium part ready for high‑precision applications and smooth assembly on the customer's line.

Alloys that chip cleanly and offer good strength, machinability, and corrosion resistance are generally preferred for CNC machining. Common casting alloys used with CNC machining are chosen because they provide a good balance of casting performance, dimensional stability, and cutting behavior, resulting in efficient machining and reliable end‑use performance.

For very small batches, CNC machining from solid billet or using 3D‑printed patterns may be more economical than building casting tooling. Once demand grows beyond a certain level, shifting to casting plus CNC machining usually lowers unit cost while keeping or even improving dimensional accuracy and visual quality, which is attractive for growing OEM brands.

With proper fixturing, stable CNC machining equipment, and a controlled process, tight tolerances suitable for precision mechanical assemblies can be achieved on aluminium castings. The exact tolerance capability depends on part design, size, material, machine tools, and inspection methods, so it is best to discuss target tolerances with the CNC machining supplier during the design stage to ensure feasibility and cost balance.

1. https://www.mubasmetal.com/en/aluminum-casting-parts-cnc-machining/16/blog-details

2. https://sinowayindustry.com/how-cnc-machining-enhances-aluminum-casting-for-precision-parts/

3. https://cn.duchgroup.com/services/cnc-machining.html

4. https://www.steckermachine.com/blog/aluminum-casting-for-cnc-machining

5. https://xometry.asia/zh-hans/cnc-turning/

6. https://jlccnc.com/blog/aluminum-cnc-machining

7. https://casting-china.org/zh/services/

8. https://www.3ds.com/make/solutions/blog/aluminum-cnc-machining

9. https://www.vowin.cn/m/list.php?tid=74

10. https://zh.treatstock.com/product/1wybjyazdmzijf-high-precision-parts-cnc-turning-machining-aluminum-oem-odm-cnc-drilling-millin

content is empty!