Views: 222 Author: Amanda Publish Time: 2026-01-27 Origin: Site

Content Menu

● What Is On-demand Manufacturing?

● Why CNC Machining Is Ideal for On-demand Manufacturing

>> Direct Digital-to-part Workflow

>> Flexibility from Prototype to Production

>> Precision and Consistency at Scale

>> Scalability and Capacity Management

>> Material and Process Versatility

● How CNC Machining Shortens Lead Time in On-demand Manufacturing

>> Digital Quoting and Design-for-Manufacturing Feedback

>> Eliminating Tooling and Setup Bottlenecks

>> Integrated Multi-process Capability

● Cost and Inventory Advantages of CNC-based On-demand Manufacturing

>> Producing Only What You Need

>> Optimizing Total Cost of Ownership

>> Supporting Lean and Just-in-time Strategies

● Applications of CNC Machining in On-demand Manufacturing

>> Prototyping and Rapid Iteration

>> Low-to-medium Volume and Bridge Production

>> Customization, Spare Parts, and Aftermarket Products

>> High-precision Components for Critical Industries

>> Multi-process Assemblies and Functional Prototypes

● How a Full-service Chinese Factory Uses CNC Machining for On-demand OEM Services

● FAQ

>> 1. How does CNC Machining support rapid prototyping in on-demand manufacturing?

>> 2. Why is CNC Machining suitable for low-to-medium volume on-demand orders?

>> 3. What materials can be used in CNC Machining for on-demand manufacturing?

>> 4. How does CNC Machining reduce total cost in an on-demand model?

>> 5. Can CNC Machining integrate with other processes in an on-demand factory?

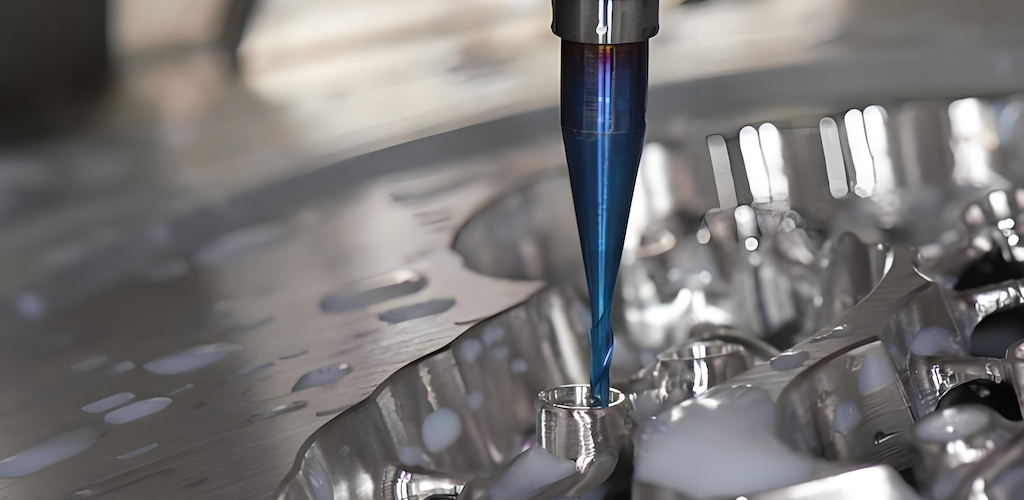

On-demand manufacturing relies on flexible, digital, and highly repeatable processes, and CNC machining is at the core of this transformation for modern factories and global supply chains. By converting CAD data into precise toolpaths, CNC Machining enables fast prototyping, agile small-batch production, and scalable series manufacturing without the constraints of traditional mass-production tooling.

On-demand manufacturing is a production model where parts are made only when needed, in the quantities required, instead of being produced in large batches and stored as inventory. This approach is powered by digital workflows: customers upload 3D models, receive quick quotations, and trigger flexible production in distributed manufacturing networks.

In this model, lead times are shortened, cash flow improves, and manufacturers can react quickly to changing demand, engineering changes, or market fluctuations. It particularly suits customized products, rapid prototyping, spare parts, and small to medium production runs in industries such as automotive, aerospace, medical, electronics, robotics, and industrial equipment.

On-demand manufacturing is not just about speed; it is also about risk reduction and agility. By decoupling production from large minimum order quantities, companies can experiment with more designs, launch niche product lines, and serve fragmented markets without committing to massive upfront investments.

CNC Machining converts CAD models directly into G-code instructions, creating a seamless digital-to-part workflow. Engineers upload CAD files, define tolerances and surface finishes, and machines begin milling or turning without the need for hard tooling such as injection moulds or stamping dies.

This direct connection between design and production reduces non-recurring engineering time and eliminates tooling lead time. It also enables rapid iteration for both prototypes and production parts, allowing companies to move from design approval to physical components in days instead of weeks or months. For on-demand manufacturing, this rapid transition is essential to keep up with fast development cycles and changing customer needs.

On-demand CNC Machining supports single-piece prototypes, bridge production, and ongoing serial orders using the same equipment and process logic. Machines can switch quickly between different jobs by loading new programs and fixtures, meaning capacity can be dynamically allocated based on real-time customer demand.

For OEM brands, startups, and wholesalers, this flexibility allows them to test markets with low-volume batches, refine designs, and then scale successful products without changing technology or requalifying an entire production method. It also supports long-tail spare parts and customized components, which are ideal for on-demand models where demand is variable and sometimes unpredictable.

One of the strongest contributions of CNC Machining to on-demand manufacturing is its ability to hold tight tolerances and maintain repeatability across repeated production runs. High-precision milling and turning centers with multi-axis capabilities can achieve complex geometry, fine details, and controlled surface finishes for demanding applications such as aerospace, medical devices, and precision instruments.

Because all cutting paths are digitally controlled, the same CNC program can be reused for future on-demand orders, ensuring dimensional consistency between production lots even if they are months or years apart. This digital repeatability is essential for OEMs who rely on stable performance and interchangeability for components purchased in staggered batches. For global buyers, knowing that a part produced today will match one produced next year is a major quality and supply-chain advantage.

On-demand manufacturing platforms and modern factories use networks of CNC Machining suppliers to dynamically match projects with available capacity. This distributed approach allows rapid scaling from a single part to thousands of units without heavy investment in in-house machines for the buyer.

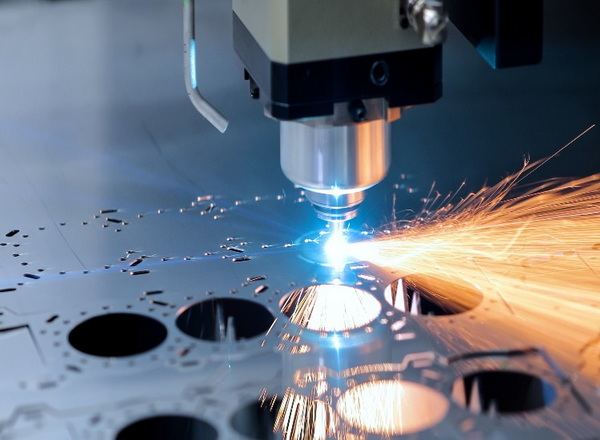

CNC shops can balance their machine load by combining prototypes, small batches, and recurring orders, turning idle capacity into revenue and providing near real-time responsiveness for customers. For international buyers, partnering with a Chinese CNC Machining factory that also offers sheet metal fabrication, 3D printing, and molding services creates a full-stack on-demand solution across multiple processes. This combination supports both engineering flexibility and logistical efficiency.

CNC Machining supports a broad range of metals and plastics, including aluminum, steel, stainless steel, brass, copper alloys, engineering plastics, and high-performance polymers. This versatility lets designers evaluate different materials in early-stage prototypes and then keep the same process chain as they move toward batch production.

In on-demand manufacturing, the ability to switch materials quickly without changing core hardware enables rapid adaptation to functional requirements such as strength, corrosion resistance, thermal performance, or weight. Combined with secondary processes like anodizing, plating, heat treatment, powder coating, and painting, CNC Machining delivers both mechanical performance and final cosmetic quality in a single integrated workflow. This makes it easier to meet both engineering and branding requirements within one consistent process.

Modern on-demand platforms and advanced factories provide fast quoting when CAD files are uploaded, often combining automated algorithms with engineering review to evaluate machinability. Early design-for-manufacturing feedback enables customers to adjust wall thickness, tolerances, fillets, undercuts, and hole features to reduce machining time and cost before production starts.

This front-loaded analysis eliminates multiple manual iterations that are typical of conventional procurement processes. For brands and wholesalers working with overseas manufacturing partners, this digital communication minimizes time-zone delays and compresses the quote-to-order cycle. In many cases, this means that a new CNC Machining order can be confirmed within hours instead of days.

Traditional manufacturing often requires custom fixtures, moulds, or dies, which increases lead time and cost for every new product. On-demand CNC Machining can rely on modular fixturing and standardized setups, so jobs can be prepared quickly using existing equipment and accessories.

By skipping dedicated tooling, manufacturers can launch new designs and accept frequent engineering changes much more easily, which is crucial for fast-moving markets and iterative product development. This leads to shorter lead times from concept to shippable parts and supports just-in-time delivery models where customers only order what they know they will use in the near term.

When CNC Machining is combined with turning, sheet metal fabrication, 3D printing, and molding under one roof, the overall lead time of complex assemblies can be significantly reduced. Components that require different processes can be routed internally without extra logistics, communication delays, or multi-supplier coordination.

For OEMs and brand owners, a single manufacturing partner handling rapid prototyping, small-batch machining, and later-stage tooling or molding creates a continuous on-demand production pipeline from idea to mass production. This integrated model is especially advantageous in China, where mature supply chains, skilled CNC Machining operators, and competitive pricing support high-mix, low-volume manufacturing for global export customers.

On-demand CNC Machining lets companies order exactly the quantity they need at each stage of the product lifecycle. Instead of placing large batch orders and freezing capital in stock, they can schedule smaller, more frequent runs that align with real consumption and real sales data.

This reduces inventory holding costs, minimizes the risk of obsolescence when designs change, and lowers the financial barrier for launching new product variants or custom configurations. For distributors and wholesalers, it also simplifies SKU management and allows them to respond quickly to new customer requests without overstocking or writing off slow-moving items.

While unit prices for small CNC batches can be higher than mass-produced parts, the overall cost structure in an on-demand model often becomes more favorable. Savings arise from lower upfront tooling investment, reduced warehousing, less scrap due to design changes, and fewer write-offs of unsold inventory.

Furthermore, CNC Machining's ability to create complex geometry in a single setup can consolidate multiple parts into one component, reducing assembly time, part count, and potential failure points. For global buyers sourcing from Chinese CNC suppliers, the combination of cost-effective machining, efficient logistics, and on-demand scheduling delivers a strong balance between price, responsiveness, and quality.

CNC-based on-demand manufacturing aligns naturally with lean and just-in-time strategies. Because CNC Machining can be scheduled flexibly and adjusted quickly, manufacturers can synchronize production more closely with actual orders rather than forecasts.

This reduces waste, improves cash flow, and enhances the ability to adapt to market fluctuations. For many companies, integrating CNC Machining into their on-demand strategy is a practical way to move toward a leaner, more resilient supply chain without completely overhauling their existing operations.

On-demand CNC Machining is widely used to produce functional prototypes that closely match final production materials and tolerances. Compared with many additive processes, CNC prototypes often provide better mechanical properties and surface finishes, allowing engineers to validate performance, assembly, ergonomics, and durability under real service conditions.

Because there is no commitment to tooling, teams can quickly iterate design revisions, optimizing strength, weight, manufacturability, and user experience before locking in a final version. For international customers working with Chinese machining partners, rapid production and shipping of CNC prototypes supports compressed development cycles and parallel engineering across multiple regions and time zones.

Many products do not require millions of units; instead, they need hundreds or thousands of high-quality parts delivered periodically. CNC Machining is an ideal bridge between prototyping and mass production, covering these low-to-medium volumes without forcing a shift to more rigid processes too early.

This is especially useful when demand forecasts are uncertain or when product life cycles are short, such as for consumer electronics, startup hardware, industrial automation modules, and specialized tools. As volumes grow and stabilize, CNC-produced parts can be gradually supplemented or replaced with molding, casting, or forging, while CNC Machining still supports high-precision inserts, fixtures, jigs, and post-processing of cast or moulded parts.

Because CNC Machining is driven by digital models, it is straightforward to produce customized versions of components or small runs of special configurations. On-demand workflows allow customers to upload variations with personalized features, mounting interfaces, or branding details without major process changes or long delays.

The same capabilities make on-demand CNC an excellent solution for replacement parts and aftermarket accessories, where demand is intermittent but quality and fit are critical. OEMs can maintain digital inventories of parts instead of physical stock, calling off batches as needed to support installed equipment and long-tail customers. This reduces storage needs and ensures parts can be updated or improved over the lifetime of the product.

In industries such as aerospace, medical devices, energy equipment, and high-end machinery, precision and reliability are non-negotiable requirements. CNC Machining is well suited to these critical applications because it can consistently deliver tight tolerances, complex 3D contours, and controlled surface quality.

Within an on-demand model, this means that even small quantities of specialized high-value parts can be sourced quickly and reliably, without waiting for long, traditional production cycles. This is particularly valuable for maintenance, repair, and overhaul operations that must minimize downtime and secure high-quality components on short notice.

CNC Machining also plays a central role in multi-process assemblies where machined parts are combined with sheet metal parts, 3D-printed components, and moulded elements. In on-demand manufacturing, this mix allows engineers to choose the most suitable process for each component based on strength, cost, and geometry.

Functional prototypes that incorporate machined metal cores, plastic housings, and formed sheet metal brackets can be built quickly, assembled, and tested as complete systems. This accelerates validation of real-world performance and helps ensure that a design is ready not only for production, but also for logistics, installation, and service.

A Chinese factory that integrates CNC Machining, CNC turning, rapid prototyping, sheet metal fabrication, 3D printing, and tooling can act as a one-stop on-demand manufacturing partner for overseas OEMs, brand owners, and wholesalers. Customers send 3D data and technical requirements, and the engineering team recommends the best combination of processes for speed, cost, and function across the entire product lifecycle.

In early stages, CNC Machining supports rapid prototypes and pilot runs, enabling fast design validation. As demand grows, the same factory can add low-volume molding, casting, or extrusion while keeping CNC Machining for high-precision components, small batches, and engineering changes. This creates a consistent and scalable path from concept to mass production.

With strict quality control procedures, advanced inspection equipment, and experience in international packaging and logistics, such a factory can handle complex export projects smoothly. For overseas customers, working with a single partner that understands CNC Machining, on-demand scheduling, and global OEM requirements greatly simplifies communication and project management. It also reduces risk, because the same team can support design changes and follow-up orders throughout the life of the product.

CNC Machining is a foundational technology for on-demand manufacturing because it links digital design directly to physical parts with high precision, repeatability, and flexibility. By eliminating tooling bottlenecks, supporting a wide range of materials, and scaling easily from one-off prototypes to recurring batches, CNC Machining enables OEMs, wholesalers, and manufacturers to reduce lead times, lower inventory risk, and respond quickly to market changes.

When combined with other processes inside a full-service factory, CNC Machining becomes the central pillar of a comprehensive, agile manufacturing ecosystem that serves global customers with on-demand production capacity. For international buyers seeking reliable partners, CNC-based on-demand manufacturing offers a practical way to accelerate innovation, control risk, and build more resilient supply chains in a highly competitive global market.

Conntact us to get more information!

CNC Machining can produce functional prototypes directly from CAD data without tooling, using the same materials and tolerances planned for production. This allows engineers to validate fit, performance, and assembly quickly while iterating designs with minimal delay and cost.

Because CNC Machining does not require dedicated moulds or dies, it handles small and medium order quantities economically while maintaining high precision. Machines can switch between jobs by changing programs and fixturing, enabling flexible scheduling and efficient use of capacity across many different parts and customers.

On-demand CNC Machining supports many metals and plastics, including aluminum, carbon steel, stainless steel, brass, copper alloys, and engineering polymers. This wide material range lets designers choose options for strength, heat resistance, weight reduction, or corrosion protection while keeping the same basic manufacturing approach and factory partner.

Although unit costs can be higher than mass production, CNC Machining reduces total cost by avoiding expensive tooling, minimizing inventory, and supporting frequent engineering changes without large amounts of scrap. On-demand ordering of CNC parts also limits capital tied up in stock and reduces the risk of obsolete components when designs evolve or market demand shifts.

Yes, CNC Machining often operates alongside 3D printing, sheet metal fabrication, molding, and casting in integrated on-demand factories. This enables efficient routing of parts through multiple processes and gives customers a single partner across prototyping, bridge production, and larger-scale manufacturing, simplifying communication and improving overall project control.

1. https://www.makerverse.com/resources/cnc-machining-guides/on-demand-manufacturing-for-cnc-machining/

2. https://cerexio.com/blog/benefits-of-on-demand-cnc-manufacturing-cnc-machining

3. https://www.premiumparts.com/blog/on-demand-cnc-machining-how-it-works-benefits

4. https://www.norck.com/blogs/news/on-demand-cnc-machining-vs-traditional-manufacturing-which-one-is-right-for-you

5. https://www.solmeto.eu/on-demand-manufacturing/

6. https://rapidefficient.com/zh/machining-services/cnc-machining/

7. https://cn.duchgroup.com/services/cnc-machining.html

8. https://www.tsprototypes.com/cn/our-solutions/cnc-machining/

9. https://www.tuofa-cncmachining.com/zh-CN/services/

content is empty!