Views: 222 Author: Amanda Publish Time: 2026-01-30 Origin: Site

Content Menu

● What Is FDM Rapid Prototyping in Detail?

● How FDM Rapid Prototyping Works Step by Step

● Materials Used in FDM Rapid Prototyping

● Advantages of FDM Rapid Prototyping

● Limitations of FDM Rapid Prototyping

● FDM Rapid Prototyping vs Other 3D Printing Methods

● Applications of FDM Rapid Prototyping

● Integrating FDM Rapid Prototyping With CNC, Sheet Metal, and Molding

● Design Tips for Better FDM Rapid Prototyping Results

● Why OEM Customers Choose Professional FDM Rapid Prototyping Partners

● FAQ About FDM Rapid Prototyping

>> 1. What is FDM rapid prototyping used for?

>> 2. How accurate is FDM rapid prototyping?

>> 3. Is FDM rapid prototyping suitable for end-use parts?

>> 4. How does FDM rapid prototyping compare to CNC machining?

>> 5. What information should I provide to start an FDM rapid prototyping project?

FDM rapid prototyping is a 3D printing method that uses heated thermoplastic filament to build parts layer by layer directly from digital CAD data. FDM rapid prototyping has become one of the most accessible additive manufacturing technologies for functional models, jigs, fixtures, and low-volume production parts.

Fused Deposition Modeling (FDM) rapid prototyping is a process in which a spool of plastic filament is melted and extruded through a nozzle to form a part on a build platform, layer upon layer. Because FDM rapid prototyping is an additive process, it does not require special tooling, which makes it ideal for fast design iterations, custom components, and on-demand manufacturing in product development cycles.

In FDM rapid prototyping, the 3D model is first prepared in CAD software and then exported as an STL or similar mesh file. This file is imported into slicing software that converts the 3D geometry into a series of 2D layers and toolpaths. During FDM rapid prototyping, the machine follows these toolpaths and deposits molten thermoplastic material in thin lines, fusing them together as they cool.

The build platform moves down (or the print head moves up) after each layer, allowing the next layer to be deposited, and the part gradually grows in the Z direction through repeated rapid prototyping cycles. Support structures are created wherever there are overhangs or bridging features that would otherwise sag during FDM rapid prototyping. After printing, the part is removed from the build plate, supports are removed, and surfaces may be cleaned, sanded, polished, or lightly machined to achieve the required finish and tolerance.

FDM rapid prototyping can be broken down into several stages that connect digital design with physical components:

1. CAD design

The process starts with a 3D CAD model created in professional software. During this stage, designers consider wall thickness, clearances, and functional requirements so the model is suitable for FDM rapid prototyping.

2. File export and slicing

The CAD file is exported as an STL or other mesh format and imported into slicing software. The slicing program defines layer thickness, infill density, print speed, and support settings that directly influence FDM rapid prototyping time and quality.

3. Machine setup

The FDM rapid prototyping machine is prepared with the chosen filament material, the build plate is leveled, and temperatures for the nozzle and bed are set. Proper setup ensures reliable extrusion, adhesion, and dimensional stability.

4. Printing and monitoring

During FDM rapid prototyping, the printer extrudes material along the programmed toolpaths. Operators may monitor early layers to confirm bed adhesion and check for issues such as warping or stringing.

5. Support removal and finishing

After printing, parts are allowed to cool before removal. Supports are detached manually or dissolved if soluble materials are used. The rapid prototyping parts can then be sanded, coated, or post-machined for better appearance and precision.

These steps make FDM rapid prototyping a flexible solution not only for early concept models but also for functional testing and manufacturing aids.

Material choice is a central factor in the success of FDM rapid prototyping. Different thermoplastics offer different levels of strength, flexibility, and heat resistance, which affect the behavior of rapid prototyping parts.

Common materials for FDM rapid prototyping include:

- PLA (Polylactic Acid)

PLA is popular for visual rapid prototyping because it is easy to print, offers good dimensional stability, and produces relatively low warpage. It is excellent for concept models and presentation samples in the early rapid prototyping stages.

- ABS (Acrylonitrile Butadiene Styrene)

ABS is tougher and more heat-resistant than PLA, making it valuable for functional FDM rapid prototyping of enclosures, brackets, and engineering components. It does, however, require higher printing temperatures and careful control of warping.

- PETG (Polyethylene Terephthalate Glycol)

PETG combines some of the ease-of-printing advantages of PLA with improved toughness and chemical resistance. It is widely used in rapid prototyping when parts need to withstand moderate mechanical loads and environmental exposure.

- TPU and flexible materials

Flexible filaments such as TPU allow FDM rapid prototyping of gaskets, grips, seals, and cushioning components. These materials expand the range of rapid prototyping applications where elasticity and impact absorption are important.

- Nylon and filled composites

Nylon is known for its strength, wear resistance, and durability. Composite filaments with carbon fiber or glass fiber reinforcement are used for higher-performance FDM rapid prototyping, especially for jigs, fixtures, and lightweight structural parts.

Selecting the right material for FDM rapid prototyping ensures that the prototype behaves similarly to the final product, making tests and validation more meaningful.

FDM rapid prototyping has become widely adopted because it offers a compelling balance of cost, speed, and capability. Several key advantages stand out:

- Cost-effective entry point

FDM machines and filament materials are relatively affordable, which lowers the barrier to implementing rapid prototyping internally or through manufacturing partners.

- Fast iteration cycles

Designers can turn digital concepts into physical parts in a matter of hours, enabling fast iterations and design reviews. This speed is a core benefit of rapid prototyping, especially in competitive markets.

- Complex geometries without tooling

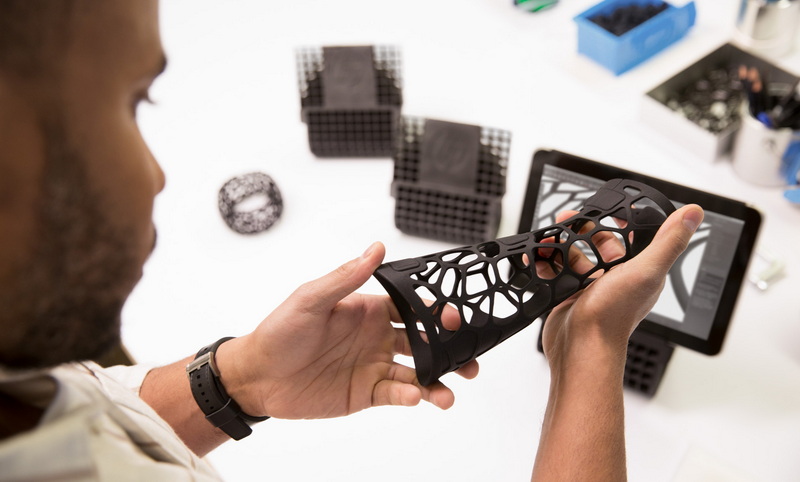

Because FDM rapid prototyping is additive, it can produce complex internal channels, lattice structures, organic shapes, and customized geometries that would be expensive or impossible with traditional subtractive methods.

- Unattended production

FDM printers can run overnight or over weekends, generating parts without constant supervision. This increases the throughput of rapid prototyping projects and improves time-to-market.

- Integration with other processes

FDM rapid prototyping works well as a front-end technology that complements CNC machining, sheet metal fabrication, and molding. The same design can be refined via rapid prototyping and later transferred to these processes for final production.

For OEM customers, these advantages make FDM rapid prototyping a strategic tool to reduce development risk and cost.

Like any manufacturing process, FDM rapid prototyping has limitations that must be understood and managed:

- Surface finish and visible layer lines

FDM rapid prototyping typically produces parts with visible layer steps, especially on sloped or curved surfaces. While these can be smoothed by sanding, coating, or vapor treatment, those post-processes add time.

- Anisotropic mechanical properties

Parts produced by FDM rapid prototyping are often stronger in the plane of the layers (XY) than in the build direction (Z). This anisotropy must be considered when orienting parts and evaluating mechanical performance.

- Tolerance and small features

Very small details, thin walls, and tight tolerances can be challenging. For high-precision benches, FDM rapid prototyping may be combined with secondary machining or shifted to CNC once the design is stable.

- Thermal and chemical limitations

Standard materials used in FDM rapid prototyping may not handle extreme temperatures, aggressive chemicals, or very high structural loads. In such cases, metal machining or high-performance polymers may be required.

By understanding these constraints, engineers can use FDM rapid prototyping intelligently, applying it where it brings the most value and complementing it with other methods when necessary.

FDM rapid prototyping is only one branch of the broader 3D printing family. To choose the best method, it helps to compare FDM rapid prototyping with some other mainstream technologies:

- SLA (Stereolithography)

SLA uses a UV laser or projector to cure liquid resin layer by layer. It offers very high surface quality and fine detail, making it excellent for cosmetic, medical, and miniature rapid prototyping where appearance is critical.

- SLS (Selective Laser Sintering)

SLS fuses powder particles with a laser to produce robust parts without the need for support structures. It is suitable for industrial rapid prototyping of functional parts, complex assemblies, and low-volume production in strong nylon and similar materials.

FDM rapid prototyping is often selected when cost control, material toughness, and fast iteration are more important than extremely smooth surfaces. SLA is preferred for show models and intricate shapes, while SLS is attractive for strong, complex components where support-free manufacturing is helpful. Many development teams start with FDM rapid prototyping to explore design options and then move to SLA, SLS, CNC machining, or molding as they approach final validation and production.

FDM rapid prototyping is used across many industries, from consumer products to heavy equipment. Typical applications include:

- Concept models

Early-stage designs can be realized as physical models to validate overall size, proportions, and aesthetics. This stage of rapid prototyping helps non-technical stakeholders visualize ideas.

- Form-fit-function prototypes

Engineers print functional FDM rapid prototyping parts to check assembly, clearances, fastening positions, and ergonomics. This supports iterative mechanical design and reduces the chance of late-stage changes.

- Jigs, fixtures, and gauges

FDM rapid prototyping is widely used on the shop floor to create workholding fixtures, assembly guides, inspection gauges, and other tools that improve productivity and quality.

- Low-volume and custom parts

For niche products, customized devices, or replacement parts, FDM rapid prototyping can deliver end-use items when traditional tooling would be too costly or slow.

- Educational and R&D tools

Laboratories, universities, and R&D teams use FDM rapid prototyping to explore ideas, test mechanical concepts, and support research projects.

By serving both design and manufacturing, FDM rapid prototyping becomes a bridge between engineering concepts and real-world production constraints.

In a modern manufacturing environment that offers CNC machining, turning, sheet metal fabrication, 3D printing, and mold production, FDM rapid prototyping plays the role of the agile front-end. A typical integrated workflow might look like this:

1. Initial design and FDM rapid prototyping

Engineers create CAD models and run FDM rapid prototyping to check assembly, function, and general performance. Several design iterations can be printed quickly to fine-tune geometry.

2. CNC rapid prototyping in final materials

Once the design is close to final, CNC rapid prototyping is used to machine parts from production-grade materials such as aluminum, steel, or engineering plastics. This provides realistic performance data under real loads.

3. Sheet metal rapid prototyping

For enclosures, brackets, and structural frames, sheet metal rapid prototyping is applied. This ensures that bending, welding, and assembly behaviors are well understood before committing to full tooling.

4. Mold making and trial molding

When volumes justify it, the project advances to mold design and tooling. Before full mass production, trial shots are run to compare with FDM rapid prototyping and CNC parts, ensuring consistency and quality.

5. Batch and mass production

Finally, validated designs move into stable batch or mass production using CNC machining, sheet metal fabrication, or injection molding, while FDM rapid prototyping may still be used to support fixtures, quality tools, and ongoing engineering changes.

For foreign brand owners, wholesalers, and OEM manufacturers, working with a partner that can handle this entire chain—from FDM rapid prototyping to mold production—simplifies communication and increases overall efficiency.

Designing specifically for FDM rapid prototyping improves both part quality and cost effectiveness. Some practical tips include:

- Respect minimum wall thickness

Walls that are too thin may warp, break, or fail to print correctly. Adjusting wall thickness for the specific machine and material used in FDM rapid prototyping increases reliability.

- Optimize overhangs and support usage

Reducing steep overhangs and designing self-supporting angles lowers the need for support structures. This saves material and time and improves surface quality where supports would otherwise connect.

- Consider part orientation

The orientation chosen in the slicing software affects strength, visible layer lines, and support requirements. For FDM rapid prototyping, critical features can be oriented to maximize strength along the direction of applied loads.

- Use fillets and rounded transitions

Sharp corners can concentrate stress and cause cracking or warping. Fillets and rounded transitions distribute loads more evenly, improving the durability of FDM rapid prototyping parts.

- Allow for post-processing

If very precise fits are needed, it may be better to slightly oversize certain features and then machine or finish them after FDM rapid prototyping. This hybrid approach combines rapid prototyping speed with machining precision.

When designers understand the strengths and limitations of FDM rapid prototyping, they can create parts that print reliably and perform as intended.

Professional manufacturing partners that operate industrial FDM systems, inspection equipment, and integrated CNC and molding lines can deliver more stable results than hobby-level setups. This is especially important for international OEM projects where quality, schedule, and communication are critical.

A capable partner can:

- Recommend suitable materials and process parameters for FDM rapid prototyping based on application requirements.

- Provide design-for-manufacturing feedback to optimize parts not only for rapid prototyping but also for later CNC machining, sheet metal fabrication, or molding.

- Maintain consistent dimensional accuracy through calibrated equipment and quality control procedures.

- Manage the full transition from FDM rapid prototyping to precision batch production and long-term supply.

For foreign brand owners, wholesalers, and manufacturers, this integrated approach reduces total cost and risk, while speeding up the entire product lifecycle.

FDM rapid prototyping is a practical and versatile additive manufacturing method that transforms digital designs into physical parts in a short time. By building components layer by layer from thermoplastic filament, FDM rapid prototyping enables fast iterations, functional testing, and customized solutions without expensive tooling.

When used in combination with CNC machining, sheet metal fabrication, and mold production, FDM rapid prototyping becomes a central element of a modern product development pipeline. It helps teams validate concepts, refine engineering details, and prepare for mass production more efficiently. For OEM customers and global brands working with professional manufacturing partners, FDM rapid prototyping offers a powerful way to shorten development cycles, control costs, and bring high-quality products to market faster.

Conntact us to get more information!

FDM rapid prototyping is used to create physical models from CAD designs so teams can test fit, function, and appearance before investing in mass production. It supports quick design iterations, assembly verification, and communication between designers, engineers, and manufacturing teams during the development process. Because it is cost-effective and fast, FDM rapid prototyping is also widely used for jigs, fixtures, and customized components on the shop floor.

The accuracy of FDM rapid prototyping depends on equipment quality, calibration, material choice, and part geometry. Many industrial FDM systems can achieve tolerances suitable for most form-and-fit evaluations and numerous functional applications. For very tight tolerances or critical features, FDM rapid prototyping can be followed by light machining, reaming, or other finishing operations to reach the required precision. In practice, this combination offers an excellent balance between rapid prototyping speed and dimensional control.

Yes, FDM rapid prototyping can be suitable for end-use parts, particularly in low-volume or customized scenarios where traditional tooling is not economical. When engineering-grade materials such as ABS, nylon, or reinforced composites are used, FDM rapid prototyping provides parts with good strength, durability, and temperature resistance. These parts can serve as functional brackets, housings, jigs, fixtures, and even final components in specialized equipment.

FDM rapid prototyping builds parts additively from the ground up, while CNC machining removes material from a solid block. FDM rapid prototyping is better suited to complex shapes, internal channels, and quick design changes, since it does not require special tooling. CNC machining, on the other hand, generally offers higher precision, better surface finish, and superior material performance for metals and engineering plastics. A common strategy is to start with FDM rapid prototyping for concept and fit testing, then move to CNC machining for final verification and production components.

To start an FDM rapid prototyping project, you should provide complete 3D CAD files, specify the preferred or required material, and describe the intended application of the part. It is also helpful to note any critical dimensions, tolerance requirements, and surface finish expectations. Sharing information about expected loads, operating temperatures, and the next steps after rapid prototyping (such as CNC machining, sheet metal fabrication, or mold production) allows your manufacturing partner to propose the most suitable process parameters and overall strategy.

1. https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/

2. https://www.techniwaterjet.com/what-is-rapid-prototyping-process-stages-types-and-tools/

3. https://www.sofeast.com/resources/materials-processes/3d-printing-rapid-prototyping/

4. https://www.udit.es/en/prototipado-rapido-fdm-vs-sla-vs-sls-guia-completa-2025-26/

5. https://www.kabu-nagasaka.co.jp/en/processing/rapid.php

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal