Views: 222 Author: Amanda Publish Time: 2026-01-30 Origin: Site

Content Menu

● Understanding Rapid Digital Prototyping

● How Rapid Digital Prototyping Works

>> Step 1 – Digital Concept and CAD Modeling

>> Step 2 – Digital Simulation and Design Validation

>> Step 3 – Data Preparation for Manufacturing

>> Step 4 – Physical Prototype Manufacturing

>> Step 5 – Post‑Processing, Assembly, and Testing

● Key Technologies in Rapid Prototyping

>> 3D Printing in Rapid Prototyping

>> CNC Machining and Turning for Rapid Prototyping

>> Sheet Metal Rapid Prototyping

>> Molding and Tooling within Rapid Prototyping

● Benefits of Rapid Digital Prototyping for OEM Customers

>> Lower Development Cost and Risk

>> Better Design Quality and User Experience

>> Seamless Transition to Mass Production

● Applications of Rapid Prototyping Across Industries

>> Automotive and Transportation

>> Consumer Electronics and Appliances

>> Medical Devices and Equipment

>> Industrial Machinery and Custom Parts

● Why Choose a Chinese Manufacturer for Rapid Prototyping

>> Integrated Services from Prototype to Production

>> Cost-Effective Rapid Prototyping for Global OEMs

>> Shangchen as Your Rapid Prototyping Partner

● FAQ About Rapid Digital Prototyping

>> Q1. What is rapid prototyping in manufacturing?

>> Q2. How does rapid prototyping reduce development time?

>> Q3. What materials can be used in rapid prototyping?

>> Q4. Is rapid prototyping suitable for low-volume production?

>> Q5. Why should overseas OEMs choose a Chinese rapid prototyping factory?

Digital rapid prototyping is the fast, iterative creation of virtual and physical models to test, refine, and validate product designs before mass production. It combines 3D CAD design, simulation, and manufacturing processes like CNC machining, sheet metal fabrication, 3D printing, and molding to shorten time to market and reduce risk.

At Shangchen, rapid prototyping is tightly integrated with 3D printing, CNC machining, turning, sheet metal, and tooling so that overseas OEM brands, wholesalers, and manufacturers can transform ideas into high-quality parts with speed and precision.

Rapid digital prototyping is a product development methodology where engineers use 3D CAD models and digital workflows to create, test, and refine prototypes quickly and repeatedly. It bridges the gap between design and manufacturing by turning virtual designs into physical prototypes in hours or days instead of weeks.

Unlike traditional methods that depend on slow tooling and manual iteration, rapid prototyping integrates virtual simulation with processes such as CNC machining, 3D printing, and sheet metal fabrication to enable fast feedback, quick design changes, and highly responsive OEM manufacturing.

Digital rapid prototyping also supports close collaboration between design, engineering, and manufacturing teams. Because all stakeholders work from the same 3D data, it becomes easier to identify issues, implement changes, and verify improvements within short cycles.

The rapid prototyping process starts with 3D CAD modeling, where designers build a digital representation of the product or component with precise dimensions, tolerances, and material parameters. This CAD model is the single source of truth that feeds both digital simulations and manufacturing equipment.

Engineers can quickly adjust geometry, wall thickness, draft angles, and assembly features in the CAD environment and instantly see the impact on performance, manufacturability, and cost. This makes the early concept stage highly iterative in rapid prototyping projects, because several design versions can be generated and compared in a short time.

A typical workflow includes creating parametric features, applying constraints, and organizing assemblies so that design changes can be propagated across the entire model in seconds. When a dimension is modified or a feature is updated, the whole assembly automatically reflects the new design intent.

Design teams can also cooperate remotely, review the same 3D model, and mark up design issues in real time. This speeds decisions, reduces communication errors, and helps global OEM customers coordinate effectively with manufacturing partners like Shangchen.

Before any material is cut or printed, rapid prototyping uses digital simulation tools to test structural strength, thermal behavior, motion, and ergonomics directly on the CAD model. This stage helps identify weak points, stress concentrations, or interference issues early, when changes are still inexpensive.

Finite element analysis, fluid dynamics, and kinematic simulation provide virtual test data so engineers can optimize shapes and features for real-world loads. By running multiple simulations on different design variants, teams can quickly determine which version balances performance, weight, and cost most effectively.

Virtual validation also supports design for manufacturability, ensuring that parts produced through CNC machining, sheet metal fabrication, or molding will be practical and cost-effective. It becomes easier to confirm minimum wall thickness, draft angles, tolerances, and machining access before launching physical prototypes.

Because changes in this phase are software-based, rapid prototyping allows several design concepts to be simulated and compared in parallel. This speeds decision-making and supports data-driven design choices for international brands that need reliable technical justification for each design iteration.

Once the digital design is validated, rapid prototyping requires preparing machine-readable data for production processes. For additive manufacturing, the CAD model is converted into STL or similar formats, oriented correctly, and sliced into layers for printing. Support structures, infill patterns, and layer heights are defined according to the part's purpose.

For subtractive methods like CNC machining and turning, CAM software generates toolpaths, cutting strategies, and process parameters so machines can produce parts accurately and consistently. This step includes selecting tools, defining feeds and speeds, and planning operations such as roughing, finishing, drilling, and tapping.

In sheet metal rapid prototyping, flat patterns are unfolded from the 3D model, and digital programs for laser cutting, punching, and bending are generated. This connects the virtual design directly with fabrication equipment and ensures that bending allowances, bend radii, and hole positions remain within acceptable tolerances.

Optimized data preparation reduces machine time, avoids collisions, and ensures that rapid prototyping runs are efficient, repeatable, and aligned with the final mass-production process. For OEM customers, this consistency means that prototypes provide a trustworthy preview of full-scale manufacturing performance.

In this stage, rapid prototyping transforms digital data into real, tangible parts using technologies such as 3D printing, CNC machining, sheet metal fabrication, and molding. Each technology has its own strengths and is selected based on geometry, material, and application.

3D printing is ideal for complex geometries, internal channels, and fast one-off parts in plastics, resins, and some metals. It is frequently used for early design verification models, ergonomic studies, and visual samples that help teams assess appearance and feel.

CNC machining and turning provide excellent dimensional accuracy, tight tolerances, and strong functional prototypes in metals and engineering plastics. These processes are well suited for structural components, mechanical assemblies, and end-use parts that must withstand real loads and environmental conditions.

Sheet metal rapid prototyping is preferred for enclosures, brackets, and structural components that require bending, welding, and surface finishing. OEMs in automotive, electronics, and industrial machinery often rely on sheet metal prototypes to validate assembly spaces, mounting points, and cable routing.

Molding and tooling-based rapid prototyping become important when prototypes must precisely match future mass-production parts. Soft tooling, prototype molds, and low-volume tools allow companies to test plastic or metal components that are very close to final production quality.

Because Shangchen combines several of these methods under one roof, rapid prototyping parts for foreign OEM brands can move quickly from initial machining or printing to fine finishing and assembly, shortening the entire validation cycle.

After initial production, rapid prototyping usually includes post-processing such as deburring, sandblasting, polishing, painting, anodizing, or plating. These treatments achieve the required aesthetics, corrosion resistance, and functional surface performance that match or simulate mass-production parts.

Functional prototypes often require assembly, where multiple CNC machined, sheet metal, and 3D printed components are combined to create working mechanisms, housings, or complete product mockups. During this stage, engineers verify clearances, alignment, fastener access, and ease of assembly.

The assembled rapid prototyping prototypes are then subjected to dimensional inspection, mechanical testing, environmental tests, and user evaluations, depending on the application and industry standards. Typical checks include coordinate measuring machine inspections, fatigue tests, vibration tests, and thermal cycling.

Feedback from this stage goes back to the design team for further refinement. Because each cycle of testing and modification is relatively fast, rapid prototyping supports continuous improvement until the design is ready to transition to full-scale manufacturing with minimal surprises.

3D printing is a core enabler of rapid prototyping because it builds parts layer by layer directly from CAD models, with almost no need for tooling. This greatly reduces setup time and makes it easy to produce different variations of a design without major reconfiguration.

Common 3D printing methods used in rapid prototyping include FDM for functional plastic parts, SLA for highly detailed and smooth surface prototypes, and SLS or metal additive processes for stronger, industrial-grade components. Each process has unique strengths in terms of surface finish, accuracy, speed, and material options.

Since minimum order quantities are usually low or even zero, 3D printing is ideal for early iterations, design verification, and visual models for presentations and ergonomics studies. It helps OEM clients refine design ideas before choosing which parts should transition to CNC machining, sheet metal, or molding.

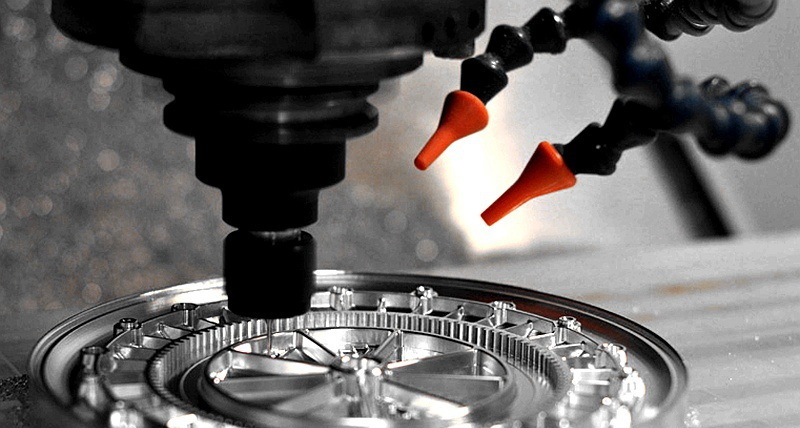

CNC machining and turning are critical for rapid prototyping when high precision, tight tolerances, and production-grade materials are required. These methods remove material from solid blocks to produce parts that closely represent final production components.

Rapid prototyping through CNC allows testing of mechanical strength, heat resistance, and assembly behavior under realistic conditions using metals like aluminum, steel, stainless steel, copper alloys, and engineering plastics. This is especially important for load-bearing parts, precision housings, and mechanical interfaces.

Because CNC rapid prototyping uses the same materials and similar processes as mass manufacturing, it is particularly valuable for functional validation and pilot runs for OEM customers. When a design proves successful in CNC prototypes, scaling up to volume production becomes more predictable and straightforward.

Sheet metal fabrication plays an important role in rapid prototyping of enclosures, frames, mounting plates, and structural parts used in automotive, electronics, communications, and industrial equipment. Prototypes can include cutouts, louvers, tapped holes, and welded structures that represent the final design accurately.

Processes such as laser cutting, stamping, bending, welding, and surface finishing are combined to deliver sheet metal rapid prototyping parts that can be evaluated for strength, fit, and assembly with electronic or mechanical systems. This helps product teams verify internal clearances, cable paths, and mounting strategies.

Sheet metal rapid prototyping is ideal for control cabinets, mounting brackets, machine covers, and custom housings where dimensional accuracy, stiffness, and surface quality are critical for end users. It also enables low-volume and mid-volume batch production for industrial customers who require frequent design updates.

When products are destined for large-scale injection molding or die casting, rapid prototyping often includes making soft tooling, prototype molds, or low-volume production tools. These tools allow manufacturers to produce parts that are almost identical to mass-production components.

This approach is essential for validating mold design, gate positions, venting, cooling channel layout, shrinkage behavior, and assembly of complex plastic or metal parts before investing in high-cost, long-life production molds. Any problems detected at this stage can be corrected with much less expense.

Rapid prototyping molds can also support bridge production, helping OEMs launch initial batches to the market while full-capacity tools are still under construction. This ensures that marketing plans, product launches, and customer commitments are not delayed by tooling lead times.

Rapid prototyping dramatically shortens development cycles by enabling parallel design, simulation, and physical testing. Instead of waiting months for traditional tooling and manual samples, brands can test and refine real parts within days or weeks.

This acceleration is crucial in competitive markets where being first or early with a new product can capture market share and strengthen brand recognition. With a responsive prototyping partner, OEMs can roll out product lines, updates, and customized versions more frequently.

Rapid prototyping reduces the risk of expensive late-stage design changes by exposing design flaws and usability issues early in the process. By iterating quickly at the prototype stage, companies avoid reworking mass-production tools or scrapping large material batches.

The ability to combine 3D printing, CNC machining, sheet metal, and molding within the same rapid prototyping framework also allows teams to choose the most cost-effective method for each iteration. For example, early concepts may rely on 3D printing, while later verification stages might switch to CNC or soft tooling.

Rapid prototyping makes it easy to gather feedback from engineers, marketers, and end users by providing realistic prototypes for review. Functional prototypes allow teams to observe how the product is handled, installed, maintained, and perceived in real use scenarios.

Through repeated rapid prototyping cycles, design teams can optimize button positions, grip shapes, weight distribution, noise levels, and visual appeal based on real user interaction, not only on digital models. This leads to products that feel more intuitive and professional to end customers.

When rapid prototyping is carried out with manufacturing-grade materials and processes, the transition to full-scale production becomes smoother and more predictable. Issues like tolerance stack-ups, assembly interference, and surface finishing can be resolved before final tooling is confirmed.

As a manufacturing partner offering CNC machining, turning, sheet metal, 3D printing, and mold production, Shangchen can extend rapid prototyping into pilot builds and then into stable production. OEM customers benefit from consistent quality, shorter industrialization timelines, and fewer supply chain disruptions.

In automotive development, rapid prototyping supports interior trim parts, brackets, housings, and structural components, allowing teams to evaluate fit, safety, and assembly quickly. Both metal and plastic prototypes are used to check integration with chassis, body structures, and powertrain systems.

Rapid prototyping also helps in concept vehicles, lighting systems, electric vehicle components, and customization projects where visual models and functional parts are needed to convince stakeholders and meet tight launch schedules. Low-volume runs can support testing fleets or special editions.

For electronics brands, rapid prototyping is vital for enclosures, heat sinks, brackets, connectors, and interface elements such as buttons and knobs. Designers can quickly test assembly with PCBs, displays, batteries, and connectors to ensure that internal and external components align correctly.

3D printed and CNC machined rapid prototyping parts help validate thermal management, port access, antenna performance, and ergonomics before committing to expensive injection molds. This is particularly important when device thickness and weight must be reduced without compromising durability.

Medical companies use rapid prototyping for surgical instruments, diagnostic devices, monitoring equipment, and patient-specific components. High accuracy, surface quality, and material performance are essential in these applications, and prototypes often need to comply with strict hygiene and safety requirements.

Through rapid prototyping, engineers can improve usability, cleaning procedures, assembly, and compatibility with other equipment while also preparing for regulatory submissions. Functional prototypes can be used in simulated clinical environments to gather feedback from medical professionals.

In industrial sectors, rapid prototyping is used for complex machine parts, fixtures, jigs, tooling components, and replacement parts, often combining CNC machining, turning, and sheet metal fabrication. This allows manufacturers to improve production efficiency and reduce downtime.

Rapid prototyping also enables reverse engineering of legacy parts, where existing components are digitized, modeled, and then reproduced or optimized using modern processes. When original drawings are missing or outdated, this capability is invaluable for maintaining and upgrading equipment.

Chinese manufacturing partners that specialize in rapid prototyping commonly offer integrated services including CNC machining, turning, sheet metal, 3D printing, and molding in a single workflow. This integrated setup minimizes the need to coordinate multiple suppliers for different stages.

This structure allows overseas OEM customers to move from initial concept to functional prototypes and later to full-scale production without switching suppliers. Shorter communication chains and unified engineering standards help control timelines and quality more effectively.

Due to competitive labor and operational costs, Chinese rapid prototyping providers can offer attractive pricing while maintaining strong quality control and short lead times. This cost advantage is especially valuable during iterative development, when many prototypes are required.

As a result, rapid prototyping becomes accessible not only for large brands but also for smaller wholesalers, innovators, and start-ups that need professional prototypes and low-volume runs to test markets and refine designs. Lower entry barriers support more innovation and product diversity.

As a factory focused on rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold making, Shangchen provides OEM services for foreign brand owners, wholesalers, and manufacturers. The company is positioned as a one-stop manufacturing partner in China.

Shangchen's rapid prototyping service aims to shorten your development time, improve design quality, and provide a clear path from digital concept to repeatable production. With professional engineering support, strict quality control, and flexible capacity, Shangchen helps global OEM customers bring reliable products to market faster.

Rapid digital prototyping is a comprehensive approach that combines CAD modeling, simulation, 3D printing, CNC machining, sheet metal fabrication, and tooling to turn ideas into physical prototypes quickly and efficiently. By enabling rapid iteration and early testing, it reduces development risk, shortens time to market, and improves overall product quality.

For overseas OEM brands, wholesalers, and manufacturers, partnering with a Chinese factory like Shangchen that integrates rapid prototyping with full-scale manufacturing processes offers a powerful competitive advantage in speed, cost, and flexibility. From the first concept model to pilot production and beyond, rapid prototyping provides a reliable foundation for modern product development.

Conntact us to get more information!

Rapid prototyping in manufacturing is the process of quickly creating physical models or parts from digital designs using technologies such as 3D printing, CNC machining, sheet metal fabrication, and molding. It allows teams to test fit, function, and appearance before committing to mass-production tools and processes, reducing the risk of costly changes later.

Rapid prototyping reduces development time by enabling fast, repeated cycles of design, digital simulation, physical production, and testing. Each iteration can be completed in days instead of weeks or months, so design issues are identified and corrected early, and the final product reaches the market more quickly.

Rapid prototyping can use a wide range of materials, including common plastics, engineering plastics, resins, aluminum, steel, stainless steel, and various sheet metals. The material is selected based on the mechanical, thermal, and cosmetic requirements of the part, as well as the chosen process, such as 3D printing, CNC machining, or molding.

Yes, rapid prototyping is well suited to low-volume production, pilot runs, and market testing. Technologies like CNC machining, sheet metal fabrication, and prototype tooling can deliver production-quality parts in small batches without requiring high-cost, long-lead-time tools, making them ideal for customized and short-run products.

Overseas OEMs choose Chinese rapid prototyping factories because they offer integrated services, competitive pricing, fast lead times, and extensive experience with global markets. By working with a partner like Shangchen, customers can manage prototyping and production within one supply chain, simplify communication, and maintain consistent quality from prototype to volume manufacturing.

1. https://www.techniwaterjet.com/what-is-rapid-prototyping-process-stages-types-and-tools/

2. https://www.tsprototypes.com/cn/resources/blogs/13.html

3. https://www.autodesk.com/solutions/rapid-prototyping

4. https://www.lsrpf.com/zh-Hans/rapid-prototyping

5. https://www.sciencedirect.com/topics/materials-science/rapid-prototyping

6. https://www.rapiddirect.com/zh-CN/

7. https://www.geeksforgeeks.org/software-engineering/what-is-rapid-prototyping/

8. https://richconn.com/zh-CN/

9. https://en.wikipedia.org/wiki/Rapid_prototyping

10. https://www.lingye-tech.com/rapid_prototyping

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal