Views: 222 Author: Amanda Publish Time: 2026-01-29 Origin: Site

Content Menu

● Italy's CNC Machining Landscape

● Key Features of Italian CNC Machining Parts Manufacturers and Suppliers

● Representative CNC Machining Parts Manufacturers and Suppliers in Italy

● How Italian Suppliers Serve Global OEM Projects

● Why Italian CNC Machining Pairs Well with Chinese OEM Factories Like Shangchen

● How to Choose CNC Machining Parts Manufacturers and Suppliers in Italy

● Future Trends for CNC Machining in Italy

● FAQ

>> 1. What industries do Italian CNC Machining Parts Manufacturers and Suppliers mainly serve?

>> 2. How do Italian CNC machining suppliers ensure quality for international OEM customers?

>> 5. How can Chinese OEM factories like Shangchen work together with Italian CNC machining suppliers?

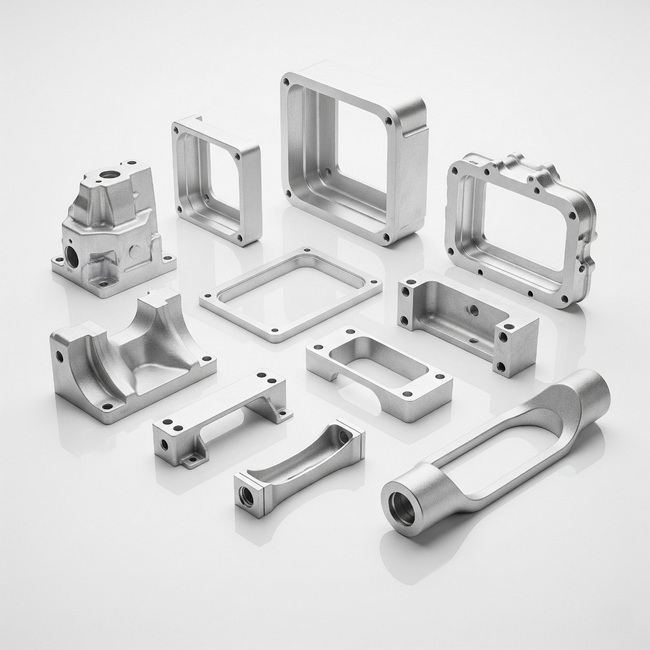

Italy has a long tradition of precision engineering, and its CNC machining ecosystem is now a key partner for global OEM brands, wholesalers, and manufacturers that need reliable CNC Machining Parts Manufacturers and Suppliers for demanding applications in automotive, aerospace, medical, and industrial equipment. At the same time, overseas factories like Shangchen in China are increasingly cooperating with Italian buyers to provide flexible, cost‑effective CNC machining, rapid prototyping, and precision batch production as an extension of this industrial network.

Italy is one of Europe's most dynamic markets for CNC machining centers and turning centers, with strong investment from automotive suppliers, aerospace clusters, machinery builders, and high‑end consumer brands. This growth is driven by the continuous demand for high‑precision components, shorter time‑to‑market, and the need to support advanced technologies such as electrification, lightweight structures, and automated production systems.

Northern Italy, especially regions like Lombardy, Piedmont, Emilia‑Romagna, and Veneto, concentrates many precision engineering and CNC machining companies thanks to dense industrial clusters and advanced technical infrastructure. These clusters combine traditional mechanical craftsmanship with modern 3‑axis, 4‑axis, and 5‑axis machining centers, CAD/CAM software, and automation to create a highly competitive base of CNC Machining Parts Manufacturers and Suppliers for both domestic and export customers.

In many industrial zones, you will find networks of small and medium‑sized machine shops working side by side with large system integrators and equipment OEMs. This structure allows buyers to source everything from simple turned parts to complex multi‑operation components within a relatively small geographic area, making logistics and coordination more efficient.

Italian CNC Machining Parts Manufacturers and Suppliers stand out for their combination of high‑precision equipment, process know‑how, and flexible project management. They are able to support prototypes, small batches, and long‑term serial production using the same core technology base, which is particularly attractive for OEMs that expect their projects to scale over time.

Most workshops operate modern CNC machining centers, vertical and horizontal mills, CNC lathes, grinding machines, and sometimes EDM for complex features and hard materials. With multi‑axis capability and advanced fixturing, Italian CNC Machining Parts Manufacturers and Suppliers can machine complex geometries, tight tolerances, and multi‑operation parts in a single setup, which improves accuracy and reduces cycle time.

Another key feature is industry diversification. Many suppliers serve several sectors at once, including:

- Automotive and motorsport (engine blocks, housings, brackets, transmission parts, suspension components)

- Aerospace and defense (structural parts, fixtures, tooling, precision housings)

- Medical and dental (implants, surgical tools, equipment components)

- Packaging and food machinery (frames, rollers, guides, precision machined assemblies)

- Industrial automation and robotics (end effectors, machine parts, sensor housings)

This broad exposure helps Italian CNC Machining Parts Manufacturers and Suppliers adopt best practices from multiple industries, such as advanced quality control from aerospace or hygienic design from food and medical, and apply them across their customer base.

In terms of materials, Italian suppliers routinely machine carbon steels, alloy steels, stainless steels, aluminium alloys, copper and brass, titanium, nickel alloys, and engineering plastics like POM, PEEK, and nylon. This versatility makes them suitable for projects ranging from high‑strength structural parts to lightweight housings and precision plastic components.

The Italian market includes many small and medium‑sized CNC Machining Parts Manufacturers and Suppliers that deliver specialized services for demanding applications. Below is an example‑style overview of some typical players and service types often found in the Italian machining ecosystem.

Company Type | Typical Capabilities | Applications | Buyer Profile |

High-precision job shop | Multi-axis milling and CNC turning, small and medium batches, tight tolerances, complex setups | Aerospace fixtures, motorsport parts, precision tools, prototypes | Engineering teams, R&D departments, high-performance OEMs |

Automotive machining supplier | High-volume CNC turning and milling, cellular production lines, strong quality systems | Engine, transmission, brake and suspension components, powertrain parts | Automotive OEMs, Tier-1 and Tier-2 suppliers |

Tooling and mold specialist | Design and manufacture of molds, dies, jigs, and fixtures, plus CNC machining of components | Stamped parts, plastic injection components, forming tools | Industrial manufacturers, packaging equipment builders, consumer goods brands |

Precision engineering firm | End-to-end support from design review to machining and assembly, sometimes including testing | Industrial machinery, medical equipment, automation systems | OEMs seeking project-based engineering and long-term partnerships |

Global CNC machining partner | Cross-border machining network, coordination with overseas plants, diverse processes | Cost-sensitive parts, volume production, multi-country supply chains | International brands and wholesalers needing flexible global capacity |

These different categories show how Italy mixes small highly specialized workshops with larger, more integrated suppliers to cover everything from initial prototypes to stable mass production. For foreign OEMs, this structure makes it possible to source niche high‑precision parts locally in Italy while also integrating overseas factories for cost‑sensitive or high‑volume components.

Italian CNC Machining Parts Manufacturers and Suppliers typically work directly from customer CAD files and technical drawings, using CAM software to generate optimized toolpaths for each component. Standard workflows often include design for manufacturability checks, where engineers review the part geometry, tolerances, and materials to suggest small design changes that reduce machining time, improve stability, or enhance reliability.

Many companies have integrated digital workflows that connect quoting, process planning, machining, and quality control in a single information system. This connection helps shorten lead times, avoid data errors, and keep projects transparent for international buyers, who appreciate clear status updates and early warnings if something in the process needs adjustment.

Because Italian suppliers operate in competitive sectors like automotive and aerospace, they are accustomed to:

- Detailed control plans and process documentation

- Statistical process control for key characteristics

- Traceability of materials, batches, and critical dimensions

- Periodic audits and supplier evaluations by large OEM clients

This environment makes Italian CNC Machining Parts Manufacturers and Suppliers attractive for global OEMs that require consistent quality, long‑term spare parts support, and the ability to scale from pilot runs to stable mass production without redefining the whole supply chain.

Italian CNC Machining Parts Manufacturers and Suppliers excel at engineering‑intensive, high‑precision, and time‑critical components, especially when close collaboration with local design teams and end users is required. However, global supply chains often also need cost‑optimized volume production, rapid prototyping, and flexible bridge manufacturing that Chinese factories like Shangchen are well positioned to provide.

Shangchen, as a China‑based factory offering CNC machining, rapid prototyping, precision batch production, CNC turning, sheet metal fabrication, 3D printing, and mold manufacturing, can work from the same CAD files and specifications used by Italian partners. That means parts produced by Shangchen can be designed to match the tolerances, surface finishes, and material requirements of Italian‑made components so that assemblies remain fully compatible.

A typical cooperation model might look like this:

- Early concept and design work happens in Italy, with prototypes and first test parts machined locally for fast feedback.

- Once the design is stabilized, part families that require larger volumes or cost optimization are transferred to Shangchen for CNC machining, turning, or sheet metal production.

- High‑precision or safety‑critical parts may remain in Italy, while supporting brackets, housings, covers, and fixtures are produced at Shangchen.

- Both sides share process knowledge, inspection criteria, and quality documents to ensure that parts are interchangeable and that OEM buyers can rely on dual‑source or multi‑stage supply strategies.

In this model, buyers gain the best combination of Italian engineering and global manufacturing capacity, while still working within a consistent technical framework for CNC Machining Parts Manufacturers and Suppliers.

When international buyers evaluate CNC Machining Parts Manufacturers and Suppliers in Italy, several criteria are especially important:

- Technical capability: Check whether the supplier has the right mix of 3‑axis, 4‑axis, and 5‑axis machining centers, CNC lathes, grinding, and any special processes such as EDM or gear cutting needed for your part.

- Industry experience: Look for experience in your sector (for example automotive, aerospace, medical, or packaging) and ask for reference parts or anonymized case studies.

- Quality management: Review certifications, process controls, inspection equipment, and the level of documentation the supplier is used to providing.

- Capacity and flexibility: Confirm whether the supplier can support your current volumes and future ramp‑up, and whether they are comfortable with both prototypes and long‑term production.

- Communication and project management: Evaluate language skills, responsiveness, reporting, and how they manage engineering changes, deviations, and logistics.

When requesting a quote, buyers should provide detailed 2D drawings, 3D CAD files, material specifications, tolerance requirements, surface finish, quantity, and any special standards or certifications required. Clear information on end use, expected annual volume, packaging needs, and delivery schedule helps Italian CNC Machining Parts Manufacturers and Suppliers design efficient processes and supply agreements.

To further strengthen supply chains, many OEMs combine Italian machining partners with a trusted Chinese OEM factory like Shangchen. This approach allows prototypes and early validation parts to be produced in Italy, while volume production or cost‑sensitive items are shifted to Shangchen without sacrificing technical consistency.

The Italian market for CNC machining is expected to keep evolving as manufacturers invest in smarter, more automated equipment to stay competitive in Europe and worldwide. Industry 4.0 technologies—such as machine connectivity, automated data collection, advanced CAM, and digital twins—are increasingly used to improve machine utilization, optimize tool life, and reduce scrap.

Automation is also expanding. Many CNC Machining Parts Manufacturers and Suppliers in Italy are adding robot loading, pallet systems, and lights‑out machining cells to handle repetitive work and extend operating hours without overloading the workforce. This helps keep costs under control and makes Italian machining more attractive for mid‑volume production.

Sustainability is another important trend. Italian machining companies are paying more attention to energy‑efficient machines, coolant and chip recycling, and process optimization to reduce material waste. OEM buyers that value environmental performance can benefit from these efforts when they select Italian CNC Machining Parts Manufacturers and Suppliers for long‑term programs.

Finally, international cooperation is likely to deepen. Italian suppliers will continue to work closely with global partners, including Chinese OEM factories like Shangchen, to offer integrated solutions covering design support, prototyping, CNC machining, surface treatment, assembly, and global logistics. This networked approach gives OEMs and wholesalers flexible options to configure their supply chains without sacrificing precision and reliability.

Italian CNC Machining Parts Manufacturers and Suppliers form a powerful ecosystem built on precision engineering, flexible production models, and strong industry specialization in sectors such as automotive, aerospace, medical, and industrial machinery. For overseas OEM brands, wholesalers, and manufacturers, these suppliers can deliver high‑value parts, fast engineering support, and robust quality documentation that meet demanding international standards.

At the same time, combining Italian machining expertise with Chinese OEM factories like Shangchen provides a strategic balance of cost, capacity, and technical capability. Shangchen's CNC machining, rapid prototyping, CNC turning, sheet metal fabrication, 3D printing, and mold manufacturing can complement Italian partners by taking on volume production, bridge manufacturing, and cost‑sensitive components. By understanding how Italy's CNC machining market works and how to partner with both Italian and Chinese CNC Machining Parts Manufacturers and Suppliers, buyers can build supply chains that are agile, competitive, and reliable for long‑term global projects.

Conntact us to get more information!

Italian CNC Machining Parts Manufacturers and Suppliers primarily support industries such as automotive, motorsport, aerospace, industrial machinery, packaging equipment, medical devices, and automation. Because many companies are diversified, a single supplier may handle projects ranging from engine components and transmission parts to machine frames, fixtures, and precision plastic components for various sectors.

Most established CNC Machining Parts Manufacturers and Suppliers in Italy operate under formal quality management systems and use advanced metrology equipment such as coordinate measuring machines, optical systems, and surface roughness testers. They typically provide inspection reports, material certificates, and process documentation, and they are accustomed to audits, production part approval processes, and continuous improvement requirements imposed by large OEMs.

Yes, many Italian CNC Machining Parts Manufacturers and Suppliers are structured to support the full product lifecycle, from prototypes and small batches to larger serial production. They use flexible job‑shop layouts, multi‑axis machines, and sometimes automated cells to adapt to different lot sizes, and can cooperate with global partners such as Shangchen when additional capacity or cost optimization is needed for very high volumes.

To receive accurate quotes from CNC Machining Parts Manufacturers and Suppliers in Italy, buyers should provide 2D drawings, 3D CAD models, material specifications, tolerances, surface finish requirements, quantities, and applicable standards or certifications. It also helps to clarify the intended application, annual usage, packaging needs, and delivery terms so that the supplier can design an appropriate machining and inspection process and estimate lead times realistically.

Chinese OEM factories such as Shangchen can collaborate with Italian CNC Machining Parts Manufacturers and Suppliers by sharing CAD data, process parameters, and quality standards so that parts produced in China are compatible with those made in Italy. In practice, Italian suppliers may focus on engineering‑intensive parts, local prototypes, and critical components, while Shangchen provides CNC machining, rapid prototyping, CNC turning, sheet metal fabrication, 3D printing, and mold production for volume or cost‑sensitive items, giving OEM customers a robust, multi‑country supply strategy.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal