Views: 222 Author: Amanda Publish Time: 2026-01-30 Origin: Site

Content Menu

● Understanding Rapid Iterative Prototyping

● Key Concepts of Rapid Iterative Prototyping

>> From Rapid Prototyping to Rapid Iteration

>> The Five-Step Rapid Prototyping Process

>> Technologies Used in Rapid Iterative Prototyping

● The Iterative Loop in Practice

>> Typical Rapid Iterative Cycle

>> Rapid Prototyping Across Development Stages

● Benefits of Rapid Iterative Prototyping

>> Better Design Quality and Risk Reduction

>> Cost Control in Development

● Core Processes Enabling Rapid Iterative Prototyping

>> CNC Machining in Rapid Prototyping

>> Sheet Metal Fabrication and Lathe Turning

>> 3D Printing and Additive Manufacturing

>> Rapid Tooling and Bridge Manufacturing

● How Rapid Iterative Prototyping Supports Global OEMs

>> OEM and Brand Collaboration

>> Typical Application Examples

● Best Practices for Implementing Rapid Iterative Prototyping

>> Design Guidelines for Rapid Prototyping

>> Working Effectively With a Prototyping Partner

● FAQ

>> 1. What is the main difference between rapid prototyping and Rapid Iterative Prototyping?

>> 2. Which technologies are most commonly used in Rapid Iterative Prototyping?

>> 3. How fast can I complete one iteration in Rapid Iterative Prototyping?

>> 4. Is Rapid Iterative Prototyping cost‑effective for small businesses?

>> 5. When should I move from rapid prototyping to full production?

Rapid Iterative Prototyping is a development approach where design teams create a series of rapid prototyping versions, test them quickly, gather feedback, and refine the design in multiple short cycles until the product meets technical and market requirements. In modern manufacturing, this approach combines digital design with physical fabrication methods such as 3D printing, CNC machining, sheet metal fabrication, and rapid tooling to shorten time‑to‑market and reduce development risk.

Rapid Iterative Prototyping is an evolution of traditional rapid prototyping, focused not only on building a single prototype quickly, but on repeating the prototype–test–refine loop many times in a compressed schedule. It leverages digital workflows, on‑demand manufacturing, and flexible suppliers to turn design changes into physical parts within hours or days instead of weeks.

In practice, this means engineering, design, and manufacturing teams work in tight feedback loops. As soon as an issue is discovered in a prototype, the CAD model is updated and a new rapid prototyping batch is launched. Over several iterations, the product becomes more robust, easier to assemble, and better aligned with real‑world use cases and customer expectations.

Across a full project, rapid prototyping can be used for form models, functional engineering parts, pre‑production runs, and even pilot builds. The “iterative” aspect ensures that every prototype is treated as an experiment that generates data, rather than a one‑time sample. This mindset is especially powerful when working with experienced manufacturing partners who can quickly switch between processes and materials for each iteration.

Classic rapid prototyping focuses on building a one‑off sample quickly to validate form, fit, or function. In many companies this step is still treated as a simple milestone: one prototype is made, verified, and then the project moves straight toward production. Rapid Iterative Prototyping expands this idea by planning continuous design updates in short sprints.

Instead of one or two prototypes, teams might plan five, eight, or more rapid prototyping cycles. Each new version solves deficiencies found in the previous one, whether they are related to ergonomics, strength, manufacturability, or visual quality. Iteration builds confidence: when similar test results appear across several generations of prototypes, project risk is significantly lower.

This iterative philosophy also changes how requirements are managed. Early prototypes can be rough and used to explore user needs, while later rapid prototyping stages become more strict, focusing on tolerances, regulatory constraints, and production feasibility.

Although many technologies exist, most rapid prototyping projects follow a similar sequence:

1. Create a 3D CAD model of the design, capturing key geometry, interfaces, and assembly conditions.

2. Prepare and export the model in appropriate formats (often STL or STEP), including tolerances and manufacturing notes when needed.

3. Program the data for the chosen rapid prototyping or machining process, such as slicing for 3D printing or toolpath generation for CNC machining.

4. Build the physical prototype layer by layer (additive manufacturing) or via subtractive operations (machining, cutting, turning).

5. Post‑process, inspect, assemble, and test the prototype to evaluate form, fit, function, and user experience.

In Rapid Iterative Prototyping, these same five steps are repeated many times, but the level of refinement increases with each loop. Early cycles use simpler setups and lower‑cost materials to move quickly. Later rapid prototyping runs introduce closer‑to‑final materials, higher precision, and more demanding inspection methods to ensure the design is ready for production.

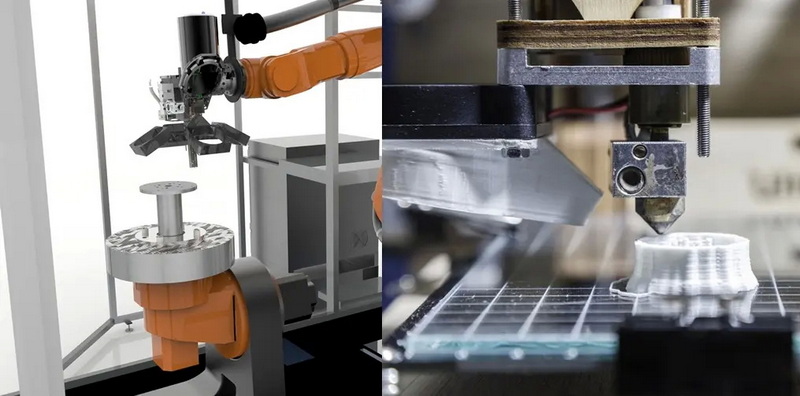

Rapid Iterative Prototyping draws from a toolbox of manufacturing solutions rather than relying on a single technology. Common rapid prototyping methods include:

- 3D printing (such as SLA, SLS, DLP, and FDM) for complex geometries, quick visual models, fixtures, and early functional parts.

- CNC machining for precise metal and plastic components, ideal when tolerances, surface quality, and mechanical performance are critical.

- Sheet metal fabrication for housings, brackets, frames, and cabinets, particularly when geometry is dominated by flat panels and bends.

- Lathe turning for rotational parts, shafts, bushings, threaded components, and sealing surfaces.

- Rapid tooling and bridge manufacturing for low‑volume production and late‑stage functional validation using near‑final materials.

By combining these processes within a single project, teams can tailor their rapid prototyping strategy to each design challenge. For example, a complex plastic housing might start as a 3D printed model, shift to CNC‑machined prototypes for accuracy, and finally move to rapid tooling for pre‑production samples.

A typical Rapid Iterative Prototyping cycle is built around a short, repeatable rhythm. A simplified loop might look like this:

- Day 1: Design updates based on test results and customer feedback.

- Day 2–3: Prototyping partner manufactures new samples using appropriate rapid prototyping processes.

- Day 4: Team inspects and tests parts, records measurements, and collects feedback from stakeholders.

- Day 5: Design decisions are made for the next iteration.

For some projects, this loop can be compressed into 24–48 hours for small quantities and simple parts. For more complex assemblies, each rapid prototyping cycle might take several days. The key is that each cycle is planned in advance, with clear goals and measurable outcomes so that the next iteration is guided by data rather than guesswork.

Rapid Iterative Prototyping supports different goals at different stages of product development:

- Concept stage: Simple, low‑cost rapid prototyping methods such as basic 3D printing or soft foam models are used to explore shapes, ergonomics, and user interaction.

- Engineering stage: Higher‑precision rapid prototyping technologies like CNC machining, higher‑resolution 3D printing, and sheet metal fabrication validate fit, tolerances, and assembly.

- Validation stage: Rapid tooling and low‑volume production runs provide parts in final or near‑final materials for performance tests, certification, and pilot builds.

At each stage, the rapid prototyping method should match the type of questions being asked. Early on, the main question is “Do users like this concept?” Later, the questions shift to “Does this part meet strength requirements?” and “Can this design be produced consistently in volume?”

One of the most visible advantages of Rapid Iterative Prototyping is speed. Because rapid prototyping technologies fabricate parts directly from digital designs without full production tooling, each iteration can be completed quickly. This allows product teams to compress what used to be months of decisions into weeks.

When design, testing, and manufacturing partners are aligned, multiple iterations can be planned in the same calendar window that previously allowed only one prototype. As a result, companies can validate their products sooner, respond to market changes faster, and launch ahead of competitors.

Every prototype is an opportunity to uncover issues that are hard to see in CAD models or simulations. Through repeated rapid prototyping cycles, problems in ergonomics, assembly, material selection, and durability emerge early, when changes are still relatively inexpensive.

Because Rapid Iterative Prototyping intentionally runs several loops, improvements are cumulative. Small adjustments to wall thickness, draft angles, fillets, or interface geometry can dramatically enhance usability, lifespan, and perceived quality. By the time the design reaches the manufacturing phase, many potential failure modes have already been discovered and resolved.

At first glance, producing multiple prototypes might seem more expensive than building only one. However, rapid prototyping greatly reduces the chance of large tooling rework, launch delays, or field failures. These problems are far more costly than several extra prototype cycles.

By selecting appropriate processes at each stage—low‑cost 3D printing or simple machined parts early on, more refined CNC or rapid tooling later—teams can tailor their spending to the importance of each decision. This balanced strategy offers better cost control over the entire development lifecycle.

CNC machining is a cornerstone of metal and plastic rapid prototyping, especially when parts need to meet tight tolerances or withstand real mechanical loads. It is particularly useful for:

- Functional structural parts such as brackets, frames, and precision housings.

- Components with complex surfaces that require accurate sealing or mating.

- Prototypes used for mechanical tests, thermal evaluations, or long‑term durability checks.

In Rapid Iterative Prototyping, CNC machining is often used in mid to late stages when the basic form is stable but detailed validation is required. Machined prototypes closely mimic production parts, providing reliable data for engineering decisions.

Sheet metal fabrication supports rapid prototyping of enclosures, cabinets, structural panels, and supporting hardware. Using laser cutting, punching, bending, welding, and surface treatment, fabricators can quickly deliver parts that are very similar to final production components.

Lathe turning forms another important pillar of rapid prototyping for rotational components. Shafts, bushings, couplings, spacers, and threaded connectors often originate from turning operations. Iterative changes in groove geometry, sealing surfaces, and tolerances can be implemented quickly and tested in real assemblies.

Combining sheet metal and turning solutions within a Rapid Iterative Prototyping strategy allows engineers to refine both the outer shell and inner mechanical linkages of a product.

3D printing remains one of the most flexible rapid prototyping technologies. It can create complex shapes, internal channels, lattice structures, and integrated assemblies that would be expensive or impossible to machine. Typical uses include:

- Early form and ergonomic models used in brainstorming and user testing.

- Functional parts for mechanisms, hinges, and snap‑fits.

- Jigs, fixtures, and assembly aids for testing other prototypes.

Because many printers operate unattended, iterations can run overnight or over weekends. This makes additive manufacturing a natural fit for Rapid Iterative Prototyping, especially when many design versions must be evaluated quickly.

As a design approaches finalization, rapid tooling and bridge manufacturing link rapid prototyping to mass production. Soft or semi‑permanent molds, low‑cavity tools, and other short‑run solutions make it possible to:

- Produce small batches in materials close to the final specification.

- Conduct more realistic performance and reliability tests.

- Validate assembly lines and packaging concepts before committing to full tools.

This stage of Rapid Iterative Prototyping is critical for de‑risking mass production. Teams can still make limited design adjustments while confirming that the chosen materials, finishes, and processes support quality and cost targets.

For international OEMs, wholesalers, and manufacturers, Rapid Iterative Prototyping offers a structured way to collaborate with suppliers across borders. Clear data exchange, rapid feedback, and short lead times create a shared rhythm between in‑house teams and external manufacturing partners.

A capable partner can integrate multiple rapid prototyping services—CNC machining, sheet metal, turning, 3D printing, and mold development—under one project. This reduces coordination overhead and allows customers to focus on design and market validation rather than managing a fragmented supply chain.

Rapid Iterative Prototyping is widely used in:

- Automotive components, including interior trims, brackets, lighting housings, and exterior decorative parts.

- Consumer electronics such as handheld devices, chargers, wearables, and smart home products.

- Industrial equipment, including panels, knobs, mounting hardware, and protective housings.

- Medical device enclosures and accessories, where ergonomic and hygienic requirements are strict.

- Robotics and automation mechanisms, including linkages, covers, and sensor mounts.

In each case, repeated rapid prototyping cycles help validate not only the individual parts but also the system‑level behavior of the product in real‑world environments.

Good design practices can dramatically improve the success of rapid prototyping projects. Important guidelines include:

- Respect process limits: Each rapid prototyping method has recommended wall thickness, minimum feature size, and tolerance ranges. Designing within those limits improves yield and consistency.

- Plan for post‑processing: Allow for machining allowances, polishing, painting, or plating when needed, so finished dimensions remain accurate.

- Simplify where possible: Reducing unnecessary complexity can shorten lead times and lower costs without harming functionality.

- Think in stages: Some details can be deferred to later iterations. Early rapid prototyping cycles should focus on major risks; fine cosmetic refinements can come later.

By applying these principles, teams can get more value from each prototype and avoid avoidable rework.

Success in Rapid Iterative Prototyping depends heavily on collaboration. To work effectively with a manufacturing partner:

- Provide clear 3D models, 2D drawings where needed, and a concise list of critical dimensions and functions.

- Share the purpose of each iteration, such as fit check, functional test, or customer demo, so the partner can choose the best rapid prototyping process.

- Be open to design for manufacturability recommendations, especially regarding wall thickness, material selection, draft angles, and assembly features.

- Establish a communication rhythm that matches the iteration cycle, including regular review meetings and feedback reports.

A good partner will help align rapid prototyping methods with project priorities, saving both time and money.

Rapid Iterative Prototyping combines the speed of rapid prototyping technologies with a structured loop of testing and refinement, allowing teams to develop products faster and with greater confidence. By repeating short cycles of design, fabrication, inspection, and improvement, companies can significantly reduce design risk before committing to mass production.

Using a toolbox that includes CNC machining, sheet metal fabrication, turning, 3D printing, and rapid tooling, engineers can validate form, fit, and function under realistic conditions. This approach supports better decisions on materials, tolerances, assembly strategies, and user experience.

For global OEMs, wholesalers, and brand owners, Rapid Iterative Prototyping provides a practical framework for collaborating with manufacturing partners, aligning cross‑border teams, and controlling costs. When implemented thoughtfully, every prototype becomes a learning tool that moves the product one step closer to a successful launch.

Conntact us to get more information!

Rapid prototyping usually refers to quickly creating one or a few prototypes to validate a design concept using methods like 3D printing, CNC machining, or sheet metal fabrication. Rapid Iterative Prototyping emphasizes running many short, repeated rapid prototyping cycles, where each physical version is evaluated and improved based on test data and feedback. Instead of treating prototyping as a single event, it becomes an ongoing process that guides the product toward maturity.

The most commonly used technologies include 3D printing processes such as SLA, SLS, DLP, and FDM; CNC machining of metals and plastics; sheet metal fabrication; lathe turning; and rapid tooling for low‑volume runs. Each rapid prototyping technology offers different strengths in terms of accuracy, surface quality, material properties, and lead time. Project teams select the most suitable process based on the current development stage and the goals of each iteration.

For many projects, a single rapid prototyping iteration can be completed within 24–72 hours, provided that part complexity and finishing requirements are moderate. Simple visual prototypes or small components can sometimes be turned around in less than a day. More complex assemblies with tight tolerances, special materials, or demanding surface finishes may require several days for accurate production and inspection.

Yes, Rapid Iterative Prototyping is often highly cost‑effective for small and medium‑sized businesses. By using rapid prototyping methods instead of full production tooling in the early phases, companies avoid large upfront investments before the design is proven. A well‑planned mix of low‑cost 3D printing, focused CNC machining, and selective rapid tooling can provide high‑quality prototypes while keeping budgets under control.

You should move from rapid prototyping to full production when prototypes consistently meet functional, dimensional, and aesthetic requirements across several iterations. This usually coincides with successful performance tests, stable design for manufacturability reviews, and clear confirmation from stakeholders that the product is ready. At this stage, short‑run bridge manufacturing or pilot builds can verify the design at higher volumes, after which investment in full production tooling becomes justified.

1. https://sist.sathyabama.ac.in/sist_coursematerial/uploads/SPR1616.pdf

2. https://www.lsrpf.com/zh-Hans/rapid-prototyping

3. https://www.techniwaterjet.com/what-is-rapid-prototyping-process-stages-types-and-tools/

4. https://www.tsprototypes.com/cn/resources/blogs/13.html

5. https://testbook.com/mechanical-engineering/rapid-prototyping

6. https://www.cncprotolabs.com/zh-Hans/blog/case-study-of-rapid-prototyping-js-precision

7. https://engineeringproductdesign.com/knowledge-base/rapid-prototyping-techniques/

8. https://www.teamrapidtooling.com/zh-CN/%E5%8E%9F%E5%9E%8B%E5%88%B6%E9%80%A0-486.html

9. https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/

10. https://www.lingye-tech.com/rapid_prototyping

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal