Views: 222 Author: Amanda Publish Time: 2026-01-28 Origin: Site

Content Menu

● Why Many Machinists Recommend Learning Manual First

● Advantages of Learning Manual Machining Before CNC

>> Stronger Fundamentals of Cutting Mechanics

>> Better Sense of Machine and Material Behavior

>> Improved Measurement Skills and Attention to Detail

>> Easier Troubleshooting in CNC Machining

● When Manual Machining Is Less Critical

● Can You Go Directly to CNC Machining?

● How Manual Skills Complement CNC Machining in Modern Shops

● Impact on Career Development in CNC Machining

● Balancing Training Time and Production Needs

● Practical Learning Path Recommendation

>> Phase 1 – Fundamentals with Manual Machining

>> Phase 2 – CNC Machining Operation Basics

>> Phase 3 – Programming and Process Optimization

>> Phase 4 – Integrated Manufacturing Skills

● Where Manual Machining Remains Essential

● Implications for Overseas OEM Customers

● FAQ

>> 1. Do I need manual machining experience to get a job in CNC machining?

>> 2. Is manual machining becoming obsolete because of CNC machining?

>> 3. Which career typically pays more, manual machinist or CNC machinist?

>> 4. How long does it take to become proficient in CNC machining?

>> 5. Is a mixed skill set in manual and CNC machining better for my long-term career?

For modern machining engineers, technicians, and operators, learning manual machining before working with CNC machining is helpful but not absolutely mandatory. The best path depends on your job role, career goals, production environment, and how deeply you want to understand machining principles and real shop-floor problems.

Because Shangchen focuses on rapid prototyping, CNC machining services, precision batch production, turning, sheet metal fabrication, 3D printing, and mold production for overseas OEM customers, this question is especially important for planning staff training and communicating technical capabilities to international clients.

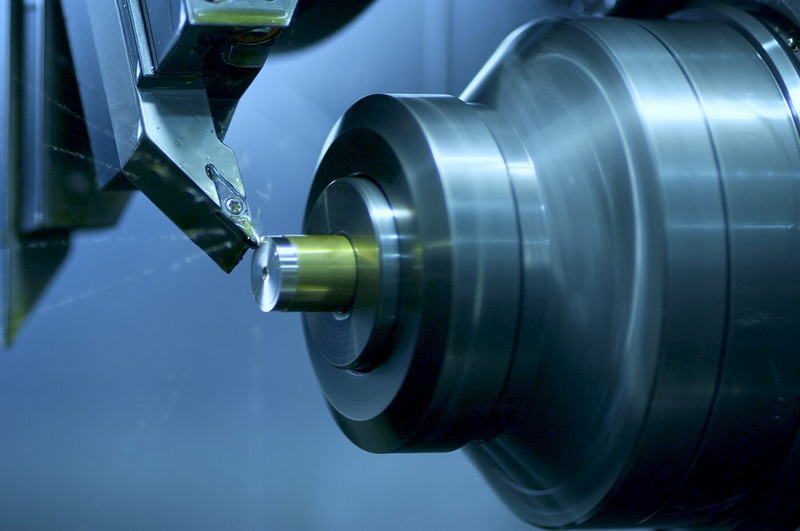

Manual machining refers to operating traditional machine tools—such as conventional lathes, milling machines, drilling machines, and grinders—by hand using mechanical levers, wheels, and dials. The machinist directly controls each axis and every movement during the operation.

Key characteristics of manual machining include:

- The operator reads engineering drawings and manually sets each position and dimension.

- Feed rate, spindle speed, and depth of cut are selected, adjusted, and executed by hand.

- Cutting quality, tolerances, and surface finish rely heavily on the skills and experience of the machinist.

A typical example is turning a shaft on a traditional lathe. The machinist centers the part, sets tool height, chooses speed based on material, engages feed, and watches both the dial and surface to stop at the desired diameter. Every step is controlled through hands and eyes, with continuous feedback.

Manual machining is closely connected to craft-based manufacturing, where the machinist's personal judgment and “feel” for the machine and material play a central role in the final result.

CNC machining (Computer Numerical Control machining) uses a computer program—often G-code generated by CAM software—to control machine tool movement. Instead of using handwheels and levers, the operator inputs or loads a program, sets coordinates and tool offsets, and the CNC machine automatically performs the cutting operations.

In a modern CNC machining workshop like Shangchen, typical applications include:

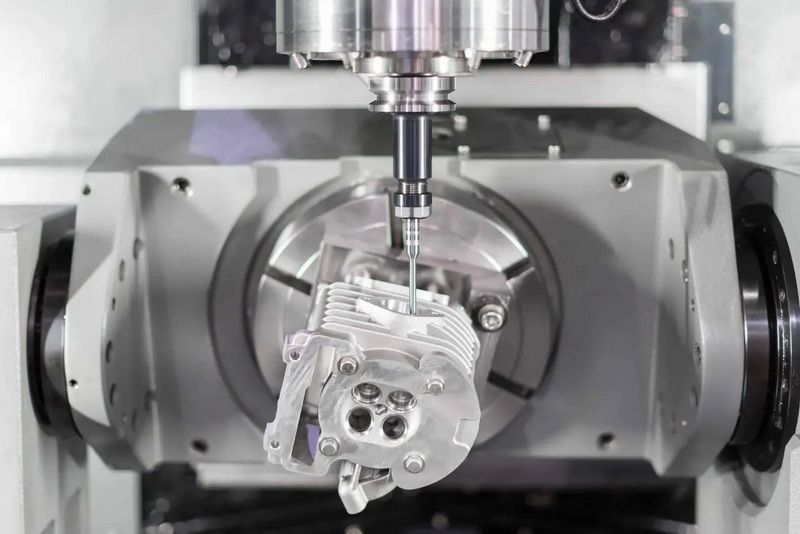

- CNC milling of complex 2.5D and 3D features, pockets, and contours.

- CNC turning for high-precision shafts, rings, and other rotational parts.

- Multi-axis CNC machining centers that combine milling and turning in one setup.

- CNC machining of prototypes, small batches, and precision parts with stable quality and excellent repeatability.

Through CNC machining, manufacturers can achieve high precision, consistent quality between batches, better utilization of high-performance cutting tools, and strong repeatability for OEM mass production. This is why overseas brands, wholesalers, and equipment manufacturers rely on CNC machining partners for long-term supply.

Among experienced machinists and engineers, there is a common opinion that “you should learn manual machining before CNC machining.” This view is based on several practical reasons:

- Manual machining builds a strong understanding of cutting fundamentals.

- It develops a better “feel” for tooling, machine rigidity, and material behavior.

- It trains your mind and hands to think in terms of process steps and dimensional control.

In many traditional training systems, apprentices spend a significant amount of time on manual machines before touching CNC machining centers. Even though industrial production has shifted strongly toward CNC machining, this training logic still has value today.

Manual machining forces beginners to understand basic machining theory clearly. You must know:

- How rake angles and relief angles affect cutting forces and chip formation.

- How nose radius influences surface finish, step marks, and corner blending.

- How feed rate, spindle speed, and depth of cut interact to control tool life and productivity.

With manual machining, you see the immediate effect of each parameter change. When you later move into CNC machining, you can interpret data and CAM software recommendations in a more realistic way, because you already know what those numbers mean in physical cutting.

For example, if you have personally seen chatter on a manual lathe when feed was too high or tool overhang too long, you will instantly recognize similar problems during CNC machining and adjust tool length or parameters more intelligently.

Manual machining is a tactile experience. You can:

- Hear the cutting sound and sense when a tool is rubbing instead of cutting.

- Feel vibration and chatter through the handwheels and machine frame.

- Observe chip color, shape, and flow directly and respond immediately.

These experiences create an intuitive database in your mind. Later, when you manage CNC machining processes, you may not be physically turning handwheels, but your decisions about toolpath, coolant, clamping, and cutting parameters are guided by real physical understanding, not just by software defaults.

During manual machining, measurement happens constantly:

- Checking diameters with micrometers and calipers.

- Aligning parts with dial indicators and edge finders.

- Verifying runout, perpendicularity, and concentricity by hand.

These skills transfer directly to CNC machining. You still need to set work offsets, measure tool lengths, verify first-piece dimensions, and adjust offsets accurately. A machinist with manual experience is often more careful with these steps and makes fewer basic setup mistakes.

Production CNC machining is not always smooth. Problems such as poor surface finish, dimensional drift, unexpected burrs, or tool wear occur frequently. People with a manual machining background can troubleshoot faster because they mentally visualize what is happening at the cutting zone.

They can ask focused questions:

- Is the tool geometry correct for this material?

- Is the clamping rigid enough for the current CNC machining toolpath?

- Are feeds and speeds realistic, or is the cutting edge being overloaded or rubbing?

This combination of physical experience and CNC machining knowledge makes them valuable in production environments where quick problem resolution is essential.

Despite the strong advantages of manual experience, not every role or factory requires a long manual machining stage. In many modern machining companies, CNC machining is the dominant or even the only production method, and training is optimized around it.

Manual machining may be less critical when:

- The company runs standardized high-volume CNC machining lines with strong process engineering support.

- Most operators are deployed as machine tenders, loading and unloading parts, checking measurements, and running pre-validated programs.

- Complex programming and process planning are centralized in a dedicated engineering department.

In this situation, spending a long time on manual machines might slow down the path to productive CNC machining work. A shorter, focused manual introduction, followed by intensive CNC machining training, can be more efficient.

Yes, many people start directly with CNC machining, especially in regions and training systems that are already fully oriented toward digital and automated manufacturing. Going straight to CNC machining makes sense if:

- You are comfortable with computers, coordinates, and logical thinking.

- You aim to work with CAD/CAM software and CNC programming in the future.

- Your company provides structured training on CNC machining operations, safety, and process basics.

In a CNC-first path, you will spend more time on:

- Understanding machine coordinates, work offsets, and tool offsets.

- Learning G-code structure, canned cycles, and basic editing.

- Using simulation and CAM software to visualize CNC machining toolpaths.

You may have less traditional hand-skill experience, but you can still become a highly competent CNC machining professional, especially if your work environment is heavily automated.

Even in highly automated CNC machining workshops, manual machines still have an important supporting role. They are not competing with CNC machining; they complement it.

Typical uses of manual machining in a CNC-focused factory include:

- Quickly modifying existing parts, especially for engineering changes.

- Producing small fixtures, sleeves, soft jaws, and clamps to support CNC machining setups.

- Performing simple one-off operations when programming a CNC for a tiny task is unnecessary.

In a facility like Shangchen, manual machining often supports CNC machining, rapid prototyping, and mold work. For urgent OEM projects, manual operations sometimes help engineers verify concepts or adjust parts without interrupting busy CNC machining centers.

Your choice between “manual first” and “CNC first” affects your long-term career direction, but both can lead to successful paths. The key is understanding what type of expert you want to become.

If you start with manual machining and then move into CNC machining, you may evolve into:

- A senior process engineer who knows both traditional and CNC machining deeply.

- A workshop leader capable of training others in cutting theory, measurement, and machine behavior.

- A specialist in difficult workholding, repair jobs, and complex materials where standard CNC machining approaches do not work.

You will likely have strong shop-floor respect because you combine theory with hands-on craft and can guide younger CNC machining operators using real examples.

If you start directly with CNC machining, focusing on programming and digital tools, you may develop toward:

- CNC programmer or CAM engineer for multi-axis machining centers.

- Automation engineer integrating CNC machining with robots, pallet systems, and factory software.

- Production engineer responsible for optimizing cycle times, tool life, and throughput across multiple CNC machining lines.

This path fits well with smart manufacturing and Industry 4.0 trends, where CNC machining is central to digital production networks.

The most competitive professionals often combine both: they acquire at least a basic manual machining foundation and then build advanced CNC machining and engineering expertise on top of it.

From a factory management perspective, training must balance two objectives:

- Build solid, long-term skills in machining fundamentals.

- Achieve productive CNC machining output as quickly as possible to support real orders.

A common training strategy is a phased model:

1. Short but intensive manual machining training to understand basic cutting, measurement, and safety.

2. Systematic CNC machining operation training, focusing on real parts and machines.

3. Progressive involvement in CNC machining programming, fixture design, and process optimization.

This approach respects tradition while staying firmly focused on modern CNC machining production.

For someone joining a company like Shangchen or any OEM-oriented CNC machining supplier, the following learning path is realistic and effective.

In this phase, the goal is not to become a master manual machinist, but to build foundational understanding:

- Learn names and functions of key machine components (spindle, carriage, turret, table).

- Practice simple turning and milling tasks, such as reducing diameter, face cutting, and slotting.

- Get comfortable reading technical drawings and converting them into step-by-step machining plans.

- Use measuring tools correctly, understand tolerance symbols, and appreciate the real meaning of accuracy.

This manual stage may be relatively short, but it creates a mental model you will use throughout your CNC machining career.

Next, you move to CNC machining centers and lathes:

- Learn how to power up machines, return to reference, and set up safety conditions.

- Understand work coordinate systems and how to set work offsets using probing or manual methods.

- Practice basic tool setting, including tool length measurement and tool wear compensation.

- Load and run existing CNC machining programs under supervision, focusing on safe operation, correct clamping, and monitoring the cutting process.

During this phase, you build confidence with CNC panels and begin to connect G-code lines with real machine movements.

Once you are comfortable operating CNC machining equipment, you can deepen your programming and engineering abilities:

- Write simple programs directly on the control using basic G-codes, M-codes, and canned cycles.

- Learn to adjust feeds, speeds, and stepovers to improve surface finish and reduce cycle time.

- Use CAM software to generate CNC machining toolpaths for milling and turning, and verify them with simulation.

- Participate in setting up fixtures and selecting cutting tools to support stable and repeatable CNC machining.

This phase transforms you from an operator into a technician or engineer who actively shapes CNC machining processes.

In advanced stages, you connect CNC machining with other manufacturing technologies:

- Combine CNC machining with sheet metal fabrication, 3D printing, and mold making for complete product solutions.

- Choose the most appropriate process for each project based on tolerance, surface finish, cost, and lead time.

- Help communicate technical feasibility and machining suggestions to OEM customers in different industries.

At this level, you become a key person who can design, evaluate, and improve end-to-end production chains centered around CNC machining.

Despite the rapid growth of CNC machining, manual machining will remain important in certain environments:

- Tool rooms producing special single-use cutters, jigs, and measuring devices.

- Maintenance and repair workshops working on unique shafts, housings, and parts without digital models.

- Artistic, prototype, or R&D work where the craftsman's judgment and creativity are more important than cycle time.

If you plan to specialize in these areas, investing more time in manual machining is wise. It will give you unique capabilities that pure CNC machining specialists may not have.

For foreign brands, wholesalers, and manufacturers collaborating with a supplier like Shangchen, the internal training route of operators is less important than the final performance. What OEM clients care most about is:

- Whether the factory can deliver stable, precise CNC machining results across prototypes, small batches, and mass production.

- Whether engineers can quickly understand drawings, materials, and tolerance requirements to design robust CNC machining processes.

- Whether the team can react quickly when problems arise, using both machining knowledge and practical experience.

Having staff with manual machining background enhances communication, fixture creativity, and troubleshooting ability. Strong CNC machining capability then transforms this knowledge into efficient, repeatable production that meets international expectations.

Learning manual machining before CNC machining is clearly beneficial for understanding cutting fundamentals, measurement, and machine behavior, and it often leads to better troubleshooting skills on the shop floor. However, it is no longer an absolute requirement in every factory or role, especially in environments dominated by standardized CNC machining lines and strong engineering support. A balanced approach works best: provide a focused manual machining foundation, then invest heavily in CNC machining operation, programming, and process optimization. In this way, companies like Shangchen can combine the depth of traditional machining knowledge with the efficiency, precision, and scalability of modern CNC machining to serve overseas OEM customers with confidence.

Conntact us to get more information!

You do not always need manual machining experience to start a career in CNC machining. Many companies accept beginners who have only theoretical knowledge and then train them directly on CNC machining operations. However, even a short exposure to manual machining can make it easier to understand drawings, dimensional tolerances, and the meaning of cutting parameters, so it is still a useful advantage when competing for CNC machining positions.

Manual machining is becoming less common in large-scale industrial production, where CNC machining dominates due to speed, repeatability, and automation. Yet manual machines remain important in tool rooms, repair workshops, training centers, and special prototype environments. Rather than being completely replaced, manual machining now plays a complementary role to CNC machining, handling jobs that do not justify programming or that require direct human judgment and flexibility.

In many industrial markets, experienced CNC machining operators and programmers tend to earn higher incomes than machinists who work only on manual machines. This is because CNC machining skills are directly tied to automated production lines, complex multi-axis equipment, and high-value components. At the same time, a manual machining background can still increase your value when combined with strong CNC machining expertise, especially in process engineering or technical leadership roles.

With focused training, a motivated beginner can learn basic CNC machining operation within a few months, including loading programs, setting tools, and performing simple measurements. Reaching a higher level—where you can confidently program parts, design setups, optimize feeds and speeds, and solve complex problems—usually requires several years of continuous practice, exposure to different projects, and cooperation with experienced CNC machining engineers. The learning curve is ongoing, because new tools, controls, and materials are always being introduced.

A mixed skill set is often the strongest option. Manual machining experience gives you a deep, hands-on understanding of cutting forces, machine limitations, and measurement, while CNC machining expertise connects you to modern automated production and digital manufacturing. Together, these skills make you more flexible, more valuable to employers, and better prepared to move into advanced roles such as process engineer, workshop leader, or CNC machining project manager responsible for demanding OEM customers.

1. https://www.rapiddirect.com/blog/cnc-machining-vs-manual-machining/

2. https://www.uti.edu/blog/cnc/manual-vs-cnc

3. https://www.datron.com/resources/blog/cnc-machining-vs-manual-machining/

4. https://www.rapiddirect.com/blog/cnc-machining-vs-conventional-machining/

5. https://www.zintilon.com/blog/cnc-machining-vs-manual-machining/

content is empty!