Views: 222 Author: Amanda Publish Time: 2026-01-28 Origin: Site

Content Menu

● From Manual Crafting to Digital Precision

● Improved Dimensional Accuracy and Tighter Tolerances

● Better Surface Finish and Functional Performance

● Enabling More Complex and Innovative Designs

● Faster Prototyping and Shorter Time‑to‑Market

● Greater Consistency and Fewer Defects

● Cost Efficiency and Material Savings

● Versatility Across Materials and Industries

● Supporting Other Manufacturing Processes

● Enhanced Reliability for Global OEM and Brand Customers

● Rich Use of Visual and Video Content in CNC Machining Communication

● How CNC Machining Supports Rapid Prototyping, Batch Production, and Precision Manufacturing

● FAQ

>> 1. How does CNC Machining improve product quality?

>> 2. Why is CNC Machining better than traditional manual machining?

>> 3. What types of products benefit most from CNC Machining?

>> 4. Can CNC Machining handle both prototypes and mass production?

>> 5. How does CNC Machining support OEM and brand owners working with overseas suppliers?

CNC machining has transformed how modern products are designed, prototyped, and manufactured, especially in high‑precision industries such as aerospace, automotive, medical, and consumer electronics. By combining digital design with automated cutting, milling, and turning processes, CNC Machining delivers better quality, faster lead times, and more consistent results than traditional manual methods.

Before CNC Machining, most parts depended heavily on manual milling, turning, and drilling, which made consistency and complex geometry difficult to achieve at scale. Manual operations relied on the skills and experience of individual machinists, so tolerances and surface finishes could vary from one piece to the next, even in the same batch.

CNC Machining replaces manual operations with computer‑controlled toolpaths generated directly from CAD models, which dramatically increases repeatability and dimensional accuracy. The digital workflow also makes it much easier to update designs and implement engineering changes without rebuilding fixtures or retraining operators.

In practice, CNC Machining turns a 3D model into machine code (G‑code), and the machine follows precise coordinates to remove material from metals or plastics layer by layer. This removes human variability from key steps like positioning, feed rate, and cutting speed, so the final product more closely matches the designer's intent.

One of the biggest ways CNC Machining improves products is through high precision and tight tolerances that are hard to achieve consistently by hand. Modern CNC machining centers can hold extremely small tolerances across large production runs, making them ideal for critical components in engines, medical implants, and aerospace assemblies.

This level of accuracy reduces misalignment, vibration, and premature wear in assembled products, directly improving performance and lifespan. When gears mesh correctly, when shafts align perfectly, and when sealing surfaces are flat and smooth, the end product operates more quietly, efficiently, and reliably.

Because CNC Machining is driven by software and closed‑loop control, the same program can produce thousands of parts with deviations far smaller than typical manual processes. This gives product designers more confidence to engineer fine details such as mating features, interference fits, and micro‑channels that would be risky or impractical with conventional machining.

CNC Machining also improves surface finish by allowing optimized cutting parameters and multi‑step finishing strategies within a single program. Roughing, semi‑finishing, and finishing passes can be carefully planned to remove material efficiently while leaving a smooth, controlled surface profile.

A smoother surface reduces friction, improves sealing performance, and enhances fatigue resistance in mechanical assemblies. In hydraulic valves, pistons, bearing seats, and sliding guides, surface quality directly affects leakage rates, noise, wear, and energy consumption.

In consumer products, high‑quality surface finishes add perceived value, making CNC‑machined housings and structural parts attractive for premium brands. Clean edges, consistent textures, and precise contours help products stand out on the shelf and support a strong brand image.

For functional components, the combination of tight tolerances and controlled surface roughness results in more efficient motion and lower power losses. This can translate into quieter operation, improved energy efficiency, and longer service intervals for finished products, which is especially important in industrial equipment and high‑end consumer devices.

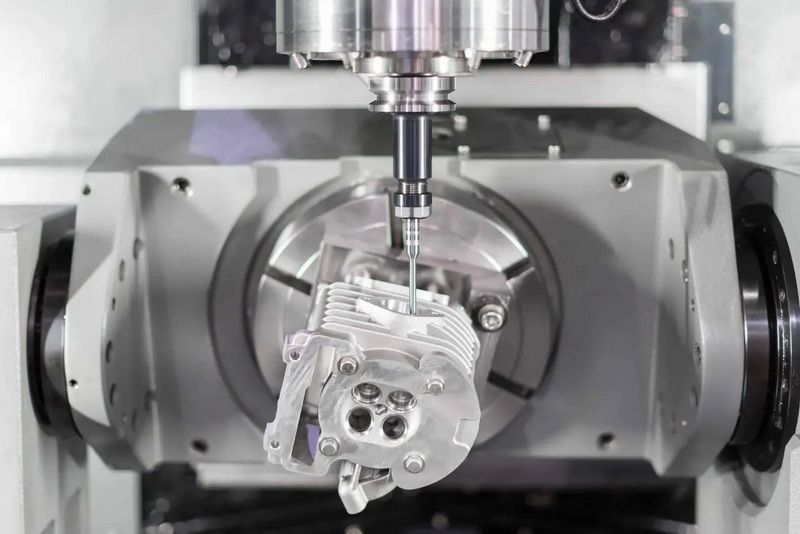

Multi‑axis CNC Machining makes it possible to manufacture complex geometries that traditional machines cannot produce or would require many separate setups. Features such as undercuts, intricate pockets, free‑form surfaces, curved channels, and compound angles can be cut efficiently on 4‑axis or 5‑axis CNC Machining centers.

This capability gives designers freedom to optimize parts for weight reduction, fluid flow, ergonomics, and aesthetics. Instead of designing parts to match the limits of manual machining, engineers can design for function first and rely on CNC Machining to realize those shapes.

For example, lightweight structural brackets with organic lattice structures can be CNC machined from aluminum or titanium billets after initial topology optimization. In heat sinks and cooling plates, CNC Machining allows narrow channels and complex fin structures that significantly increase heat transfer performance.

CNC Machining also supports the consolidation of multiple components into a single, more complex part. By machining internal features, mounting points, and alignment details into one body, designers can reduce assembly time, minimize fasteners, and reduce the risk of misalignment, all of which improves product reliability.

CNC Machining greatly accelerates product development cycles by turning CAD data into physical parts in days rather than weeks. Engineers can quickly produce functional prototypes that use the same materials and processes as final production parts, which makes testing more realistic and reliable.

For development teams, this speed means they can test more design iterations, validate performance earlier, and correct issues before committing to expensive tooling. Compared with traditional tooling‑heavy processes, CNC Machining is ideal for rapid prototypes, engineering validation builds, and bridge production volumes.

Because the same CNC Machining setup can handle everything from one‑off prototypes to small and medium batch production, companies can launch products sooner and react more quickly to market feedback. This flexibility is especially valuable for overseas OEM and brand clients that need reliable partners to support fast design changes, version updates, and new product introductions without sacrificing quality.

By reducing the gap between design and manufacturing, CNC Machining enables a more agile development model. Design revisions can be implemented in the CAD model, translated into new toolpaths, and cut into metal or plastic parts within a short time window, giving businesses a clear competitive advantage.

Automation is central to CNC Machining, and this directly reduces human error during production. Once a CNC program is validated, the machine executes the same operations in the same sequence for every part, resulting in highly consistent dimensions and features.

This consistency lowers scrap rates and reduces the risk of defects reaching customers. For global OEMs and brand owners, fewer defects mean fewer returns, less rework, and a stronger reputation in the market.

Improved product consistency also simplifies downstream processes such as assembly, painting, coating, and functional testing. When critical dimensions stay within tight limits, components fit together correctly with fewer adjustments, leading to smoother production lines and more reliable products in the field.

CNC Machining can also integrate in‑process measurement and automatic tool compensation, further stabilizing the output. Probing systems can detect minor deviations and allow the machine to adjust offsets automatically, keeping the process under control even during long production runs.

CNC Machining improves product cost structure by optimizing toolpaths and cutting strategies to reduce cycle times and waste. Advanced CAM software can plan efficient movements to remove only the necessary material, minimizing scrap and cutting tool wear.

This is particularly important for expensive materials such as titanium, stainless steel, and high‑performance engineering plastics. By controlling cutting parameters precisely, CNC Machining reduces the risk of tool breakage, surface damage, and internal stress, which further protects material value.

Because CNC Machining can integrate automatic loading, pallet changers, and in‑process measurement, a single machine can run for long periods with minimal operator intervention. This high level of automation spreads fixed costs over more parts and reduces labor costs per unit, helping OEMs keep their products competitive while maintaining high quality.

For many products, CNC Machining also reduces indirect costs by simplifying assembly, improving reliability, and shortening development cycles. When considered across the full life cycle of a product, these improvements often outweigh the initial machining cost, especially in technically demanding markets.

CNC Machining supports a wide range of metals and plastics, including aluminum, steel, stainless steel, brass, copper, titanium, and many engineering polymers. This versatility allows one CNC Machining supplier to serve multiple industries such as automotive, medical devices, robotics, consumer electronics, and industrial equipment.

For product developers, using the same process for different materials simplifies testing and comparison between design options. They can validate mechanical properties, thermal behavior, and durability in real use conditions by machining parts in several candidate materials and evaluating them side by side.

Because CNC Machining can produce both structural parts and appearance parts, it is often used for enclosures, precision shafts, gears, mounting brackets, custom fixtures, and functional prototypes. This broad coverage means that improvements in CNC Machining technology—such as better tools, higher spindle speeds, and smarter control software—quickly translate into better products in many sectors.

The same CNC Machining platform can handle projects ranging from high‑strength steel transmission components to delicate aluminum drone frames and medical housings. This cross‑industry versatility makes CNC Machining a core technology within modern manufacturing.

CNC Machining often works together with other technologies such as 3D printing, sheet metal fabrication, and molding. For instance, CNC Machining is commonly used to create production‑grade molds and tooling that support injection molding, die casting, and rubber molding, improving the quality of molded products.

With high‑precision CNC Machining, molds and dies can achieve better cavity accuracy, longer life, and more stable mass‑production output. High‑quality tooling directly influences the dimensional stability, surface finish, and consistency of molded or cast parts, which in turn improves the final products delivered to end users.

In hybrid workflows, 3D printed parts can be CNC machined to refine surfaces, adjust dimensions, and add high‑precision features. This combination allows designers to enjoy the freedom of additive manufacturing while still meeting tight tolerance requirements through CNC Machining.

Sheet metal parts can also benefit from CNC Machining, for example by adding precision pockets, countersinks, tapped holes, and reference surfaces after bending and forming. By combining these processes, manufacturers can create assemblies that are lighter, stronger, and more compact, giving the final product higher performance and better value.

For overseas wholesalers, brand owners, and manufacturers, one of the main expectations from CNC Machining partners is stable quality over long‑term projects. By standardizing process parameters, inspection routines, and documentation, professional CNC Machining service providers can maintain consistent product quality from prototype to mass production.

This consistency reduces the need for repeated supplier audits and simplifies supply chain management for global customers. When a CNC Machining supplier delivers stable performance, buyers can focus more on design, marketing, and market expansion instead of daily quality issues.

CNC Machining also makes it easier to implement quality standards such as strict tolerance regimes, material traceability, and industry‑specific certifications. With digital records and repeatable programs, it becomes straightforward to reproduce parts, scale up volumes, or transfer projects between machines while keeping the same performance level in the finished product.

For customers who require engineering support, experienced CNC Machining teams can also provide design‑for‑manufacturability suggestions. By optimizing features, wall thicknesses, and tolerances for CNC Machining, they help clients achieve better performance at lower cost, which is especially attractive for long‑term OEM relationships.

When presenting CNC Machining capabilities to overseas customers, using a variety of visual and video content in articles, websites, and catalogs can significantly improve understanding and trust. Demonstrations of CNC Machining centers performing milling, turning, and drilling processes make it easier for non‑technical buyers to see how complex parts are produced with high precision.

Video walkthroughs of rapid prototyping, small‑batch production, and quality inspection steps help highlight the added value of a complete CNC Machining service. They show real‑world workflows, from CAD data import to final inspection, which helps bridge the communication gap between engineers and purchasing teams.

Service providers often showcase multi‑axis CNC Machining operations, on‑machine probing, automatic tool changes, and robotic loading systems to communicate their technical strength. Short clips comparing roughing, semi‑finishing, and finishing operations, combined with close‑ups of surface quality and fitted assemblies, can directly link CNC Machining processes to the improved performance and appearance of the final products.

By integrating visual demonstrations into marketing and technical communication, CNC Machining companies can help potential customers quickly understand capabilities, quality levels, and typical applications. This transparency supports faster decision‑making and builds confidence in long‑distance collaboration.

Modern manufacturing often requires a smooth transition from concept to prototype and from prototype to stable batch production. CNC Machining plays a central role in this journey by offering a single, flexible platform that can support each phase.

In the early concept stage, CNC Machining allows engineers to quickly validate form, fit, and function. Parts can be produced in the same metals or plastics that will be used in production, which reveals real mechanical behavior, thermal response, and wear patterns. This is something that purely digital simulation or low‑strength mockups cannot fully provide.

As projects move into pilot runs and small batches, CNC Machining ensures that dimensional accuracy and surface quality stay consistent while volumes increase. Process parameters validated on prototypes can be transferred to small‑batch production with minimal change, which reduces risk and shortens ramp‑up time.

For long‑term production of precision components, CNC Machining offers robust process control, stable tooling strategies, and the possibility to automate loading, inspection, and data collection. This stability helps manufacturers meet strict delivery schedules and quality targets, supporting long‑term cooperation with demanding OEM and brand customers.

CNC Machining has improved modern products by combining digital precision, process automation, and material versatility into a single, highly flexible manufacturing platform. It delivers tighter tolerances, better surface finishes, and more complex geometries, which directly enhance product performance, reliability, and aesthetics across many industries.

At the same time, CNC Machining shortens development cycles, reduces waste, and supports both prototyping and mass production, giving global OEM and brand customers a powerful way to stay competitive in demanding markets. By integrating with other processes such as sheet metal fabrication, molding, and 3D printing, CNC Machining further extends its impact and helps manufacturers create lighter, stronger, and more innovative products.

For companies looking to serve overseas wholesalers, brand owners, and manufacturers, investing in advanced CNC Machining capabilities is not only a technical decision but also a strategic move. It strengthens product quality, stabilizes supply, and provides the flexibility needed to respond quickly to new opportunities and changing customer requirements.

Conntact us to get more information!

CNC Machining improves product quality by ensuring high precision, tight tolerances, and consistent repeatability from the first part to the last. Automated control reduces human error in positioning, feeding, and cutting, so components fit and function as intended in the final assembly, with fewer defects and more stable performance.

Compared with manual machining, CNC Machining offers faster production, easier handling of complex geometries, and higher consistency across batches. It runs automatically using pre‑programmed toolpaths, which reduces labor intensity and variability, shortens cycle times, and makes it practical to produce precise and complex parts at scale.

Products that require high precision, reliable fit, and complex shapes gain the most from CNC Machining, including medical devices, aerospace parts, automotive components, and precision industrial equipment. Consumer electronics housings, mechanical assemblies, and custom fixtures also commonly use CNC Machining for both prototypes and production parts, because the process combines accuracy with flexible material options.

Yes, CNC Machining is suitable for one‑off prototypes, small batches, and larger production runs, making it a flexible solution throughout the product life cycle. The same machines and programs can be scaled up with minor adjustments, which shortens time‑to‑market, simplifies engineering changes, and supports smooth transitions from development to stable long‑term production.

CNC Machining allows overseas OEM and brand customers to receive consistent, high‑quality parts based on digital drawings and agreed tolerance standards. With stable processes, detailed inspection records, and strong process control, suppliers can reliably deliver components that integrate smoothly into global production lines, reducing risk, shortening project lead time, and supporting long‑term strategic cooperation.

1. https://hlhrapid.com/blog/top-10-benefits-and-uses-of-cnc-machining/

2. https://rapidefficient.com/zh/machining-services/cnc-machining/

3. https://www.xometry.com/resources/machining/cnc-machining-benefits/

4. https://firstmold.com/zh/cnc-machining-service/

5. https://www.hlhprototypes.com/cnc-machining-advantages-uses-tip/

6. https://cn.duchgroup.com/services/cnc-machining.html

7. https://www.tfgusa.com/the-7-advantages-of-cnc-machining/

8. https://xometry.asia/zh-hans/cnc-turning/

9. https://blogs.sw.siemens.com/solidedge/5-benefits-of-cnc-machining-for-manufacturers/

10. https://proleantech.com/zh-CN/cnc-machining/

content is empty!