Views: 222 Author: Amanda Publish Time: 2026-01-27 Origin: Site

Content Menu

● What Makes Medical CNC Machining Unique?

● Precision Requirements in Medical CNC Machining

● Biocompatible Materials and Surface Requirements

>> Material Selection in Medical CNC Machining

>> Surface Finish and Sterilization Considerations

● Regulatory Compliance, Validation, and Traceability

>> Quality Systems in Medical CNC Machining

>> Risk Management and Zero‑Defect Mindset

● Applications of CNC Machining in the Medical Industry

>> Diagnostic and Imaging Equipment Components

>> Single‑Use and Disposable Components

● Prototyping vs. Mass Production in Medical CNC Machining

>> Rapid Prototyping for Medical Devices

>> Scaling to Precision Batch Production

● CNC Machining vs. Other Manufacturing Processes in Medical Use

● How Shangchen Supports Medical CNC Machining OEM Projects

● FAQ

>> 1. Why is CNC Machining so important in the medical industry?

>> 2. Which materials are most commonly used in medical CNC Machining?

>> 3. How does medical CNC Machining handle quality and regulatory requirements?

>> 4. What is the difference between CNC Machining and 3D printing for medical devices?

>> 5. How can an OEM partner like Shangchen support medical CNC Machining projects?

CNC Machining plays a critical role in almost every modern industry, but nowhere is it more demanding than in the medical field. When CNC Machining is used for medical purposes, it must meet extreme requirements for precision, safety, regulatory compliance, and traceability that far exceed those of most other sectors.

In this article, we examine how CNC Machining for medical devices and components differs from its use in aerospace, automotive, electronics, and general industrial manufacturing. As a Chinese factory offering CNC machining, rapid prototyping, precision batch production, turning, sheet metal, 3D printing, and mold‑making OEM services for global brands, wholesalers, and manufacturers, Shangchen must understand and meet these unique medical requirements.

Medical CNC Machining stands apart because human life and patient safety are directly affected by every part that leaves the machine. A small dimensional error or surface defect that might be acceptable in a consumer product can become a life‑threatening risk in an implant, surgical tool, or diagnostic device.

Key differentiators include:

- Extremely tight tolerances and micro‑level precision.

- Biocompatible material selection and process validation.

- Strict regulatory and quality management systems (such as ISO 13485 and related regulations).

- Full traceability, documentation, and process control for every CNC Machining step.

- Cleanroom or controlled environments for critical components.

In contrast, CNC Machining for automotive or general industrial products usually focuses more on cost, throughput, and mechanical performance than on sterilization, biocompatibility, or implant‑grade traceability.

Medical device components often require precision down to micrometer‑level tolerances, especially for implants, prosthetics, and micro instruments. Orthopedic plates, bone screws, or dental implants must fit perfectly with human bone and adjacent components, leaving almost no room for dimensional error.

Medical CNC Machining commonly uses:

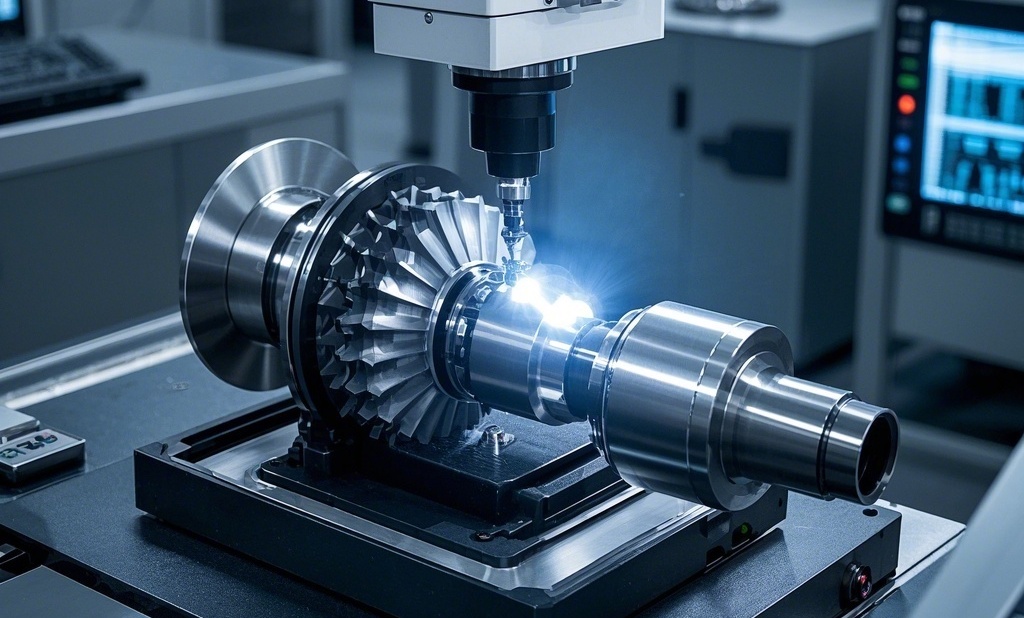

- Advanced 5‑axis CNC Machining centers for complex geometries and undercuts.

- Special cutting tools, high‑stability fixtures, and optimized toolpaths to maintain consistent tolerances in high‑volume runs.

- In‑process measurement systems and post‑process CMM inspection to verify dimensional accuracy.

In other industries, tolerances are often looser and visual or functional acceptance criteria more forgiving, especially for non‑critical consumer products. Even in aerospace and automotive, where precision is vital, the regulatory emphasis on patient safety is generally not as intense as in medical CNC Machining.

To illustrate, consider a small CNC‑machined component inside a laparoscopic surgical instrument: its precision determines how smoothly the surgeon can control the device and how accurately the tool operates inside the patient's body. A minor deviation in CNC Machining could lead to increased friction, inconsistent movement, or even failure during surgery, which is unacceptable in clinical use.

Medical CNC Machining relies heavily on biocompatible metals and engineering plastics that can withstand sterilization, bodily fluids, and long‑term contact with human tissue. Common materials include:

- 316L stainless steel (surgical steel) for surgical instruments and some implants.

- Titanium and titanium alloys for orthopedic and dental implants due to strength, low density, corrosion resistance, and excellent biocompatibility.

- Cobalt‑chrome alloys for joint replacement components where high wear resistance is critical.

- High‑performance plastics like PEEK for spinal implants, housings, and components that must be both strong and radiolucent.

By contrast, automotive and consumer electronics CNC Machining often use aluminum, carbon steels, and commodity plastics mainly for mechanical performance and cost, not for compatibility with the human body or repeated sterilization cycles. In medical CNC Machining, material selections are driven by clinical performance, patient outcomes, and compliance with applicable standards.

Surface finish is another area where medical CNC Machining differs sharply from other industries. Medical components often require extremely smooth and controlled surfaces to reduce bacterial adhesion, prevent tissue irritation, and withstand repeated sterilization by autoclaving or aggressive disinfectants.

Medical CNC Machining processes therefore:

- Minimize burrs, sharp edges, and micro‑cracks that could harbor bacteria or weaken the part.

- Use polishing, electropolishing, and passivation for stainless steel instruments to improve corrosion resistance and cleanliness.

- Control surface roughness (Ra) to precise levels for implants, balancing the need for osseointegration with the need for cleanability and predictable friction.

Industrial and automotive parts may tolerate higher surface roughness, visible tool marks, or minor burrs, as long as functionality and durability are not compromised. In medical CNC Machining, cosmetic appearance is often tied directly to cleanability and perceived quality in clinical use, so aesthetic and functional requirements overlap more strongly.

One of the most crucial differences between medical CNC Machining and other applications is the regulatory framework. Medical device manufacturers must comply with standards such as ISO 13485 and various national regulations, which demand documented processes, risk management, and full traceability from raw material to finished component.

A medical CNC Machining supplier is usually required to:

- Maintain a documented quality management system with controlled procedures, work instructions, and training records.

- Implement process validation and regular re‑validation for critical CNC Machining operations.

- Keep records of material certificates, machine parameters, calibration data, inspection results, and lot history for every batch.

In many other industries, while ISO 9001 and internal quality standards are important, the depth of documentation and regulatory oversight is generally less intense. Automotive and aerospace sectors also apply strict quality systems, but medical CNC Machining specifically combines mechanical risk with biological and clinical risks, making compliance even more sensitive.

Medical CNC Machining operates under a near zero‑defect philosophy because failures can directly harm patients. This drives extensive risk analysis (such as FMEA), process controls, and often 100% inspection strategies for critical components.

Compared with general mechanical parts, the medical sector frequently requires:

- Tighter sampling plans, statistical process control, and capability studies to prove process robustness.

- Environmental monitoring where cleanroom or controlled spaces are used for machining, cleaning, or packaging.

- Detailed non‑conformance handling, root cause analysis, and corrective actions with full documentation and sometimes regulatory reporting.

While automotive components for safety‑critical systems may follow similar principles, the combination of patient safety, clinical performance, and legal liability sets medical CNC Machining apart. The mindset is that every CNC Machining decision – from tool selection to coolant choice – can influence clinical outcomes and must be treated with appropriate seriousness.

Medical CNC Machining supports a wide range of applications, from small disposable components to large assemblies in diagnostic equipment. These applications highlight how CNC Machining is adapted to medical use in ways not seen in many other industries.

CNC Machining is widely used to manufacture surgical tools such as scalpels, forceps, clamps, scissors, handles, cutters, and saws. These instruments must be robust, corrosion‑resistant, capable of repeated sterilization, and comfortable for surgeons to use during long procedures.

By using CNC Machining in stainless steels like 316L and specialized titanium alloys, manufacturers achieve tight tolerances, ergonomic shapes, and consistent performance across thousands of units. Similar tools in other industries, such as hand tools or cutting equipment, do not face the same combination of biocompatibility, sterilization, and precise ergonomic requirements that operating room instruments must meet.

CNC Machining is essential for producing orthopedic implants, dental implants, bone plates, spinal cages, and custom prosthetic components. These parts must precisely match patient anatomy, often using data from CT or MRI scans to generate the CAD models that guide CNC Machining.

Key aspects of implant‑focused CNC Machining include:

- Use of titanium, cobalt‑chrome, and PEEK for long‑term implantation and mechanical performance under cyclic loads.

- CNC Machining of complex geometries, undercuts, and interconnected features that enable bone fixation and stability.

- Creation of porous or textured surfaces that support bone ingrowth while maintaining structural strength.

In contrast, components machined for industrial robots or mechanical prosthetics in non‑medical environments do not have to integrate with living tissue or meet the rigorous implant‑specific standards. Medical CNC Machining merges advanced geometry with biological performance in a way that most other industries never require.

Large diagnostic machines such as CT, MRI, and ultrasound systems rely on many CNC‑machined parts. Housings, structural frames, brackets, non‑magnetic supports, and precision motion components are often produced using CNC Machining from aluminum, non‑magnetic alloys, or high‑performance plastics.

Medical CNC Machining for these systems differs from other industrial equipment in that:

- Certain components must be radiation‑transparent or non‑magnetic to avoid interfering with imaging.

- Motion and positioning parts often work within very tight tolerances to ensure reliable, repeatable scanning and patient handling.

- Visible components must meet high cosmetic standards because medical equipment must look clean, professional, and reassuring in clinical environments.

Beyond implants and capital equipment, medical CNC Machining also contributes to the development and limited‑run production of components for single‑use or disposable devices. This includes parts for drug delivery systems, minimally invasive instruments, and specialized jigs and fixtures used in surgery.

Even when the parts are intended to be disposable, CNC Machining must maintain accuracy and cleanliness, because any failure during use could be catastrophic. Other industries may use CNC Machining for disposable components, but few sectors apply such strict performance and cleanliness criteria to single‑use parts.

Medical product development typically combines digital design, additive manufacturing, and CNC Machining in a structured workflow. While 3D printing is expanding quickly in the medical sector, CNC Machining remains the backbone of both functional prototyping and mass production.

For early design validation, 3D printing is often used to quickly produce physical models that can be evaluated by engineers, surgeons, and regulatory teams. These printed models help refine geometry, ergonomics, and clinical workflow without the cost of full CNC Machining.

However, once a design approaches final validation, medical CNC Machining is usually required to produce prototypes in the same materials and with the same tolerances as the eventual production parts. Medical CNC Machining supports:

- Functional prototypes in titanium, stainless steel, and PEEK that can be sterilized and tested in realistic clinical conditions.

- Tight control of tolerances and surface finish early in the development process, reducing risk before regulatory submission or clinical trials.

- Iterative design adjustments, where CNC Machining parameters and fixturing can be optimized in parallel with geometry changes.

This stage is crucial because regulators and clinicians need to evaluate not just design intent, but also real‑world performance of CNC Machining parts in final materials.

Once a device is validated, medical CNC Machining is ideal for scaling to small and medium‑volume production with consistent quality. For OEM customers, a capable supplier such as Shangchen can integrate CNC Machining with turning, Swiss‑type machining, sheet metal fabrication, 3D printing, and mold‑making to support the entire product lifecycle.

Compared with other industries:

- Lot sizes may be smaller but each lot requires much higher documentation per part number.

- Change control is stricter because even minor CNC Machining modifications to dimensions, surface finish, or material may trigger re‑validation or regulatory notification.

- Packaging, labeling, identification, and cleanliness requirements are significantly more demanding, often involving sterile barriers or controlled environments.

In many cases, medical CNC Machining does not aim for the highest possible volume, but for the highest possible consistency and control within small‑to‑medium batch sizes.

CNC Machining is one of several manufacturing options for medical parts, but it offers a unique combination of advantages.

Compared with casting or forging, CNC Machining provides:

- Higher precision and more complex geometry without expensive tooling changes.

- Faster iteration when designs change, which is common in medical device development.

Compared with injection molding, CNC Machining:

- Is more cost‑effective for low‑to‑medium volumes, especially when design changes are still likely.

- Can handle high‑performance metals and specialized materials that are difficult or impossible to mold.

Compared with 3D printing, CNC Machining generally:

- Provides better dimensional tolerances, surface finishes, and stability for many metal and plastic parts.

- Offers a broader range of established, fully validated medical‑grade materials with well‑understood mechanical properties.

For many OEMs, the most effective approach is a hybrid strategy: use 3D printing for early prototypes, then transfer to CNC Machining for validation, regulatory samples, and production. This is where an experienced CNC Machining partner adds real value.

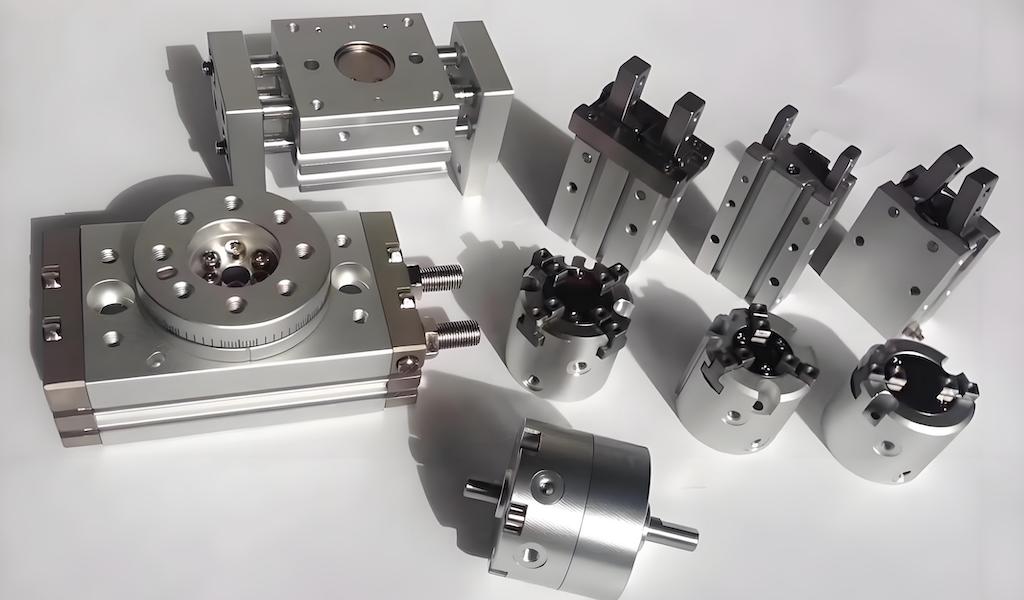

A comprehensive medical OEM partner must offer more than just CNC Machining machines; it must provide process control, engineering support, and a deep understanding of medical requirements. As a Chinese factory with rapid prototyping, CNC Machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold production, Shangchen can support overseas brands, wholesalers, and manufacturers across the full development cycle.

Key advantages include:

- Integrated CNC Machining, turning, and sheet metal services for complete device assemblies, not just single parts.

- Experience with complex geometries, multi‑axis CNC Machining strategies, and multi‑material projects tailored to medical device needs.

- Ability to bridge from prototypes to precision batch production, and then to tooling and molding for higher volumes when the project matures.

- Engineering support for DFM (design for manufacturability), process optimization, and tolerance analysis for medical CNC Machining components.

- Flexible cooperation models for OEM and private‑label projects, aligned with the quality expectations of global medical brands.

By combining CNC Machining with other processes, Shangchen can help customers reduce lead times, simplify supply chains, and maintain consistent quality through every stage of a medical device's life.

CNC Machining for medical purposes differs significantly from CNC Machining in other industries because it must satisfy unique requirements for precision, biocompatible materials, stringent regulatory compliance, and comprehensive traceability. In medical applications, CNC Machining directly affects patient safety, which drives higher expectations for tolerances, surface finish, cleanliness, and documentation than those found in automotive, aerospace, or general industrial sectors.

From surgical instruments and implants to diagnostic equipment and custom prototypes, medical CNC Machining demands a combination of advanced equipment, experienced engineers, and robust quality management systems. For overseas brands, wholesalers, and manufacturers, working with an OEM partner like Shangchen that understands both the technical and regulatory aspects of medical CNC Machining is essential to achieving safe, reliable, and commercially successful medical products.

Conntact us to get more information!

CNC Machining is vital in the medical industry because it delivers the micro‑level precision, repeatability, and material flexibility required for implants, instruments, and devices that directly affect patient health. It also supports both rapid prototyping and high‑quality batch production using certified materials and controlled processes, which are essential for regulatory approval and consistent clinical performance.

Common materials in medical CNC Machining include 316L surgical stainless steel, titanium and titanium alloys, cobalt‑chrome alloys, and engineering plastics such as PEEK and other biocompatible polymers. These materials offer a combination of strength, corrosion resistance, fatigue performance, and compatibility with sterilization methods, making them suitable for both temporary and long‑term clinical use.

Medical CNC Machining typically operates under a quality management system aligned with ISO 13485 and relevant national regulations. This means processes are documented, validated, and regularly audited, while material certificates, inspection results, and lot histories are retained for full traceability. Non‑conformances are handled through structured root cause analysis and corrective actions to maintain a high level of reliability.

3D printing is excellent for design exploration, anatomical models, and highly customized geometries, particularly in early development stages. CNC Machining, however, often remains the preferred choice for final production because it offers superior tolerances, predictable mechanical properties, and excellent surface finishes in a wide range of proven medical‑grade materials. Many medical device projects use 3D printing for early prototypes and CNC Machining for validation and production.

An OEM partner like Shangchen can provide end‑to‑end support, from CAD review and rapid prototyping through CNC Machining, turning, sheet metal fabrication, 3D printing, and mold production. By combining process expertise with multi‑axis CNC Machining capabilities and robust quality control, Shangchen helps international customers reduce development time, control costs, and deliver medical products that meet strict regulatory and clinical requirements.

1. https://radmot.com/blog/the-use-of-cnc-machining-in-the-medical-industry

2. https://rapidefficient.com/zh/machining-services/cnc-machining/

3. https://www.ptsmake.com/how-cnc-machining-for-medical-purposes-differs-from-other-industries/

4. https://casting-china.org/zh/cnc-machining-services/

5. https://www.acemicromatic.net/the-importance-of-cnc-machines/

6. https://proleantech.com/zh-CN/cnc-machining/

7. https://www.marshallmfg.com/cnc-machining-vs-3d-printing-which-is-best-for-medical-device-manufacturing/

8. https://firstmold.com/zh/cnc-machining-service/

9. https://macfab.ca/blog/cnc-machining-the-unsung-hero-in-medical-research/

10. https://xometry.asia/zh-hans/cnc-turning/

content is empty!