Views: 222 Author: Amanda Publish Time: 2026-01-27 Origin: Site

Content Menu

● 1. Why CNC Machining Varies by Industry

● 2. CNC Machining in the Aerospace and Defense Industry

● 3. CNC Machining in the Automotive and Transportation Industry

● 4. CNC Machining in the Medical and Healthcare Industry

● 5. CNC Machining in Electronics and Consumer Devices

● 6. CNC Machining in Energy, Oil & Gas, and Heavy Industry

● 7. Comparing CNC Machining Needs Across Industries

● 8. How OEM Factories Like Shangchen Adapt CNC Machining for Different Industries

● 9. How to Specify CNC Machining Requirements by Industry

● 10. Future Trends: How CNC Machining Will Evolve Across Industries

● FAQ

>> 1. What industries use CNC machining the most?

>> 2. Why are CNC machining tolerances different between industries?

>> 3. How do materials influence CNC machining for different sectors?

>> 4. Can one CNC machining factory serve multiple industries?

>> 5. What should I include when sending drawings to a CNC machining supplier?

CNC machining is a core manufacturing technology, but the way CNC machining is applied can look completely different from one industry to another. Each sector has its own priorities for tolerances, materials, surface finish, documentation, and production volume, so understanding these differences is critical when you design parts or select a CNC machining partner.

As a China-based OEM factory like Shangchen offering CNC machining, rapid prototyping, turning, sheet metal, 3D printing, and mold manufacturing, you must adapt CNC machining processes to the specific requirements of automotive, aerospace, medical, electronics, energy, and other demanding industries. Below, we will explore how CNC machining differs by industry and what overseas buyers should know when working with an experienced CNC machining supplier.

Different industries rely on CNC machining for different reasons: some focus on extreme precision, others on cosmetic appearance, and others on rugged performance in harsh environments. These priorities translate into unique requirements for CNC machining programs, tools, fixtures, inspection plans, and quality documentation.

Key factors that change from one industry to another include:

- Target tolerances and geometric complexity of CNC machining features.

- Materials selected for CNC machining (aluminum, steels, titanium, plastics, high-temperature alloys).

- Required surface finishes and secondary operations such as anodizing, bead blasting, polishing, or coating.

- Compliance standards and certifications needed for CNC machining suppliers (for example ISO 13485 for medical devices or aerospace approvals).

- Production volume, from one-off prototypes to high-volume CNC machining of standardized parts.

When overseas buyers understand these differences, they can better communicate drawings, tolerances, and quality expectations to their CNC machining factory.

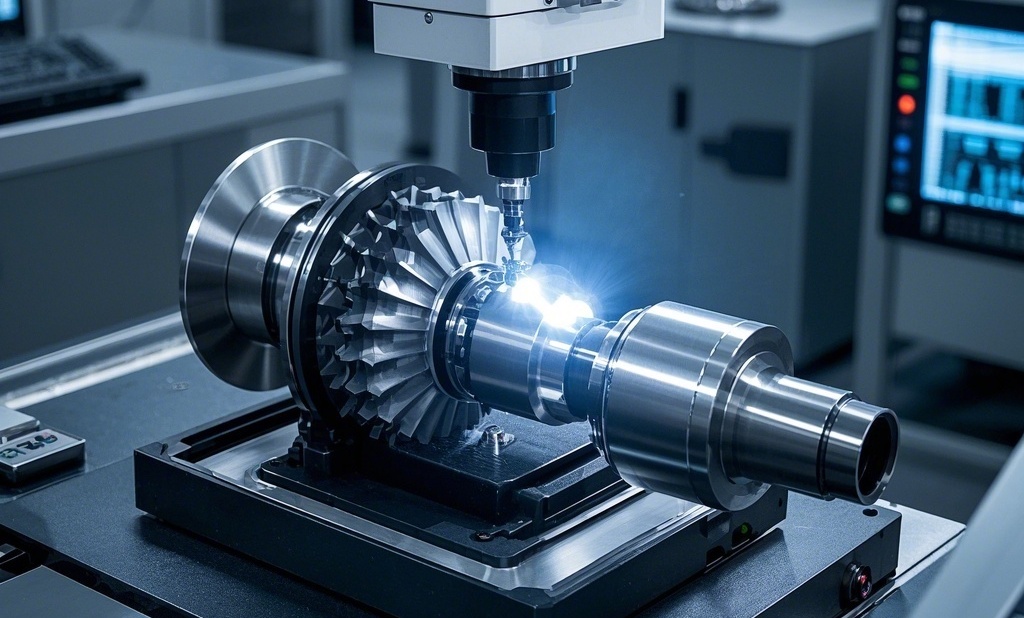

Aerospace and defense are among the most demanding users of CNC machining, requiring ultra-high precision and impeccable reliability for safety-critical components. CNC machining is widely used for airfoils, turbine blades, landing gear components, structural brackets, housings, manifolds, and complex 5-axis parts.

Typical aerospace CNC machining characteristics include:

- Extremely tight tolerances on critical features, often at the micron level.

- Heavy use of 5-axis CNC machining to create complex free-form surfaces and undercuts in a single setup.

- Difficult materials such as titanium, high-strength stainless steels, nickel-based superalloys, and aerospace-grade aluminum.

- Rigorous process control, traceability, and documentation, with strict inspection of each CNC machining step and finished part.

For a factory like Shangchen, meeting aerospace CNC machining expectations means investing in stable machines, advanced CAM programming, precise fixturing, and thorough quality management processes. Overseas aerospace customers often start with small batches or prototypes to validate a CNC machining supplier before moving to larger projects.

The automotive industry uses CNC machining both for high-volume production and fast-turnaround prototyping of new vehicle models, powertrain systems, and EV platforms. Automotive manufacturers and their Tier 1 and Tier 2 suppliers rely on CNC machining for engine components, transmission parts, chassis structures, jigs and fixtures, and custom accessories.

Key ways CNC machining differs in automotive include:

- Strong emphasis on cycle time and efficiency when CNC machining high-volume parts like engine blocks, cylinder heads, shafts, and housings.

- Balanced tolerances that enable reliable assembly and performance without excessive machining cost.

- Increasing demand for CNC machining of EV components such as motor housings, battery trays, cooling plates, and lightweight structural parts.

- Frequent retooling and rapid prototyping for design validation, supported by flexible CNC machining cells.

A China-based CNC machining supplier like Shangchen can support automotive customers with rapid prototypes, small to mid-volume CNC machining of complex parts, and integration with sheet metal and 3D printing for brackets, enclosures, and fixtures. Consistent quality, stable process capability, and competitive pricing are essential to win long-term automotive CNC machining projects.

Medical devices and healthcare equipment rely heavily on CNC machining for implants, surgical instruments, diagnostic device housings, and dental components. In this industry, CNC machining must not only hit precise dimensions but also guarantee biocompatibility, cleanliness, and consistency over time.

Typical medical CNC machining requirements include:

- Compliance with standards such as ISO 13485 and regulatory expectations in target markets.

- Extremely tight tolerances and smooth surface finishes for implants and surgical instruments, often with special polishing and passivation.

- Use of biocompatible materials such as titanium alloys, stainless steels, cobalt-chrome, and certain medical-grade plastics.

- Detailed traceability from raw material to CNC machining, finishing, cleaning, and packaging.

For an OEM CNC machining provider such as Shangchen, serving the medical sector may require a dedicated production area, controlled environment, and strict quality documentation, even for small-batch CNC machining orders. Overseas buyers in the medical industry will evaluate not only CNC machining capability but also quality management and regulatory awareness.

Electronics, smartphones, and consumer products also depend heavily on CNC machining, but the emphasis is often on miniaturization, tight cosmetic standards, and complex assemblies. CNC machining plays a major role in housings, frames, connectors, heat sinks, and structural parts for devices and semiconductor equipment.

Important characteristics of CNC machining in electronics include:

- Micromachining requirements for small features, thin walls, tight radii, and precise cutouts in aluminum, magnesium, and plastics.

- High demands on surface finish and cosmetic quality, often requiring careful toolpath strategies and post-machining finishes like anodizing or bead blasting.

- In some cases, integration of CNC machining with other processes such as die casting, extrusion, and plastic molding to create hybrid assemblies.

- Short product life cycles and frequent design changes, which make flexible CNC machining capacity crucial.

Factories like Shangchen can combine CNC machining with sheet metal fabrication and 3D printing to deliver complete mechanical solutions for electronics enclosures and precision fixtures. International brand owners in this sector often need rapid prototyping, engineering collaboration, and reliable series CNC machining with excellent cosmetic control.

The energy sector, including oil and gas, power generation, and renewable energy, uses CNC machining for large, robust, and sometimes highly specialized components. Parts often experience extreme mechanical loads, high pressure, corrosion, and temperature swings, so CNC machining must deliver durability as well as accuracy.

Characteristics of CNC machining in these industries include:

- Production of parts such as valves, pistons, cylinders, rods, drill bits, and flanges for pipelines and rigs.

- Use of tough steels, stainless steels, and corrosion-resistant alloys that can be challenging to machine efficiently.

- Larger part sizes compared with electronics or medical CNC machining, requiring heavy-duty machines and stable fixturing.

- Need for quick turnaround and occasional high-volume CNC machining runs to support field operations and maintenance.

For a Chinese OEM CNC machining factory like Shangchen, serving energy or oil and gas customers means combining robust machining capacity with flexible batch sizes and strong project management. Overseas clients often value a supplier that can CNC machine both large heavy components and smaller precision parts for control systems.

The table below summarizes how CNC machining requirements differ across key industries.

Industry | Main CNC Machining Focus | Typical Materials | Tolerance & Finish Demands |

Aerospace & Defense | Complex 5-axis CNC machining of structural and engine parts for safety-critical applications. | Titanium, high-strength steels, superalloys, aerospace aluminum. | Ultra-tight tolerances and rigorous inspection, often with specialized finishes. |

Automotive & EV | High-volume CNC machining of engine, transmission, and EV components plus rapid prototypes. | Steels, cast irons, aluminum alloys, some plastics. | Balanced tolerances for cost and performance; durable functional finishes. |

Medical & Dental | CNC machining of implants, instruments, and device housings with strict compliance. | Titanium, stainless steels, cobalt-chrome, medical plastics. | Very tight tolerances, smooth surfaces, and controlled cleaning processes. |

Electronics & Consumer | Micromachined housings, frames, heatsinks, and fixtures with strong cosmetic requirements. | Aluminum, magnesium, engineering plastics, copper alloys. | High cosmetic standards, precise small features, and advanced finishes like anodizing. |

Energy, Oil & Gas | CNC machining of heavy-duty valves, pistons, cylinders, and structural parts. | Carbon steels, stainless steels, corrosion-resistant alloys. | Robust functional tolerances and surface treatments for wear and corrosion resistance. |

This comparison illustrates how one CNC machining factory must configure machines, tools, and quality systems differently to serve each sector successfully. Buyers should share clear industry context and standards when they request CNC machining quotes.

An experienced OEM factory such as Shangchen can tailor CNC machining processes according to each customer's sector, part function, and lifecycle. By combining CNC machining with turning, sheet metal fabrication, 3D printing, and mold production, the factory can support complete solutions from prototype to mass production.

Key adaptation strategies include:

- Configuring dedicated CNC machining cells for different industries (for example, aerospace vs. electronics) with appropriate tooling and fixturing.

- Applying different tolerance strategies according to ISO-based standards and customer-specific requirements for metals and plastics.

- Matching CNC machining materials and surface finishes to each industry's durability, cosmetic, and regulatory needs.

- Integrating quality systems that capture inspection data, traceability, and process control records for critical sectors like aerospace and medical.

For overseas brands, wholesalers, and manufacturers, working with a flexible CNC machining supplier allows them to consolidate multiple product lines and industries into one coordinated supply chain. This is especially valuable when you need both custom CNC machining and related processes like sheet metal or 3D printing.

No matter which industry you serve, precise communication with your CNC machining partner is the foundation of successful projects. To ensure that CNC machining meets expectations, buyers should provide detailed drawings and consider the following points.

When requesting CNC machining quotes and production:

- Clearly state the target industry (for example automotive, aerospace, medical, consumer electronics, or energy) and relevant standards.

- Define tolerances, geometric dimensioning and tolerancing (GD&T), and any critical-to-function features that CNC machining must prioritize.

- Specify required surface finishes, coatings, heat treatments, and whether dimensions apply before or after finishing.

- Indicate material grades and any regulatory or certification requirements related to your industry.

- Share expected volumes, from rapid CNC machining prototypes to mass production, to help optimize process setup.

A professional factory like Shangchen can then choose the right CNC machining equipment, cutting tools, inspection methods, and process routing to match your industry-specific needs. This approach reduces risk, improves lead time, and supports long-term cooperation.

As manufacturing becomes more digital and connected, CNC machining is also evolving across all major industries. Aerospace and defense are integrating CNC machining with advanced simulation, digital twins, and in-process monitoring to further reduce defects and improve traceability. Automotive and EV manufacturers are pushing CNC machining suppliers toward greater automation, including pallet pools, robotic loading, and lights-out machining for cost-effective volume production.

In the medical and dental sector, CNC machining is increasingly combined with digital scanning and personalized design, enabling custom implants and patient-specific instruments. Electronics and consumer brands are driving CNC machining toward finer detail, thinner walls, and more complex aesthetic surfaces to support compact, premium devices. Energy, oil, and gas customers continue to demand CNC machining of wear-resistant, high-performance alloys, while also exploring hybrid manufacturing that mixes CNC machining with additive processes for efficient repairs and upgrades.

For a multi-capability OEM factory like Shangchen, staying ahead of these trends means investing in modern CNC machining centers, multi-axis technology, smart fixturing, and quality systems integrated with digital data. At the same time, experienced engineering support and project management remain essential to translate each customer's industry requirements into optimized CNC machining processes.

CNC machining is a versatile manufacturing method, but its actual implementation varies widely between aerospace, automotive, medical, electronics, energy, and other industries. Each sector has unique expectations for tolerances, materials, surface finishes, and documentation, and experienced CNC machining suppliers understand how to adapt their processes accordingly.

For overseas brands, wholesalers, and manufacturers, partnering with a Chinese OEM factory like Shangchen that offers CNC machining, rapid prototyping, turning, sheet metal, 3D printing, and mold production can provide a powerful combination of flexibility, cost control, and quality. By clearly communicating your industry context and technical requirements, you can leverage CNC machining to deliver better products, reduce development risk, and build a resilient supply chain across multiple markets.

Conntact us to get more information!

Aerospace, automotive, medical, electronics, and general manufacturing are among the industries that use CNC machining the most due to their need for precision and repeatable production. These sectors rely on CNC machining for complex geometries, strict compliance, and scalable throughput from prototypes to high-volume parts.

CNC machining tolerances differ because each industry has unique functional and safety requirements, from aircraft reliability to implant fit or cosmetic device quality. Aerospace and medical often require ultra-tight tolerances, while other industries may accept looser tolerances to balance cost and performance in CNC machining.

Each industry uses CNC machining on materials that match its performance needs, such as titanium for aerospace and medical, aluminum for automotive and electronics, or steels for energy and heavy machinery. These materials behave differently during CNC machining, influencing cutting parameters, tool selection, and achievable tolerances and finishes.

Yes, a well-equipped CNC machining factory can serve multiple industries by configuring separate processes, tools, and quality systems for each sector. OEM suppliers like Shangchen can support aerospace-style precision, automotive volume, medical compliance, and electronics cosmetics under one roof by tailoring CNC machining approaches and production flows.

When you send drawings, you should include clear dimensions, tolerances, material specifications, surface finish requirements, and any applicable industry standards. Mentioning your target industry and expected quantities helps your CNC machining supplier optimize processes, choose appropriate machines, and plan quality control more effectively.

1. https://www.acemicromatic.net/what-industries-use-cnc-machining/

2. https://www.lsrpf.com/blog/what-are-the-applications-of-cnc-machining

3. https://tirapid.com/cnc-machining-industry/

4. https://rootech.com.au/applications-of-cnc-manufacturing-across-industries/

5. https://automechgroup.com/guide-to-cnc-machine-manufacturing

6. https://newindscorp.com/what-are-different-types-of-cnc-machining/

7. https://www.makerverse.com/resources/cnc-machining-guides/surface-finishes-and-tolerances/

8. https://www.ycmalliance.com/which-industries-use-cnc-machines-the-most/

9. https://www.americanmicroinc.com/resources/industries-use-cnc-machinery/

10. https://frigate.ai/cnc-machining/understanding-cnc-tolerances-and-surface-finishes-in-machining/

11. https://hplmachining.com/blog/cnc-machining-applications-across-industries/

12. https://www.vulcanus-stahl.de/en/blog/cnc-machining-materials

13. https://www.hubs.com/knowledge-base/cnc-machining-iso-based-tolerances-and-finishes/

14. https://jaewoomachines.com/blogs/news/cnc-machining-in-different-industries-automotive-aerospace-and-more

15. https://astromachineworks.com/cnc-machine-industries

content is empty!