Views: 222 Author: Amanda Publish Time: 2026-01-27 Origin: Site

Content Menu

● Key Ways CNC Machining Impacts Manufacturing

>> Boosting Efficiency and Speed

>> Improving Precision, Quality, and Consistency

>> Enabling Rapid Prototyping and Faster Time‑to‑Market

>> Increasing Flexibility and Customization

>> Lowering Overall Manufacturing Costs

>> Enhancing Safety and Working Conditions

>> Supporting Complex Geometries and Advanced Materials

● The Role of CNC Turning, Milling, and Related Processes

>> CNC Milling

>> CNC Turning

>> Other CNC Machining Operations

● Digitalization, Automation, and the Future of CNC Machining

● Why OEMs Choose Chinese CNC Machining Partners

● How Multimedia Demonstrates CNC Machining Capabilities

● How CNC Machining Supports Different Production Stages

● Benefits of CNC Machining for OEM and B2B Customers

● FAQ

>> 1. What is CNC Machining in manufacturing?

>> 2. How does CNC Machining improve efficiency?

>> 3. Why is CNC Machining important for prototypes?

>> 4. Which industries rely on CNC Machining?

>> 5. How will CNC Machining develop in the future?

CNC Machining is transforming manufacturing by combining digital precision, automation, and flexible production into a single, highly efficient process that serves industries worldwide. For OEM partners, CNC machining delivers consistent quality, shorter lead times, and cost‑effective parts from prototype to mass production.

CNC Machining (Computer Numerical Control Machining) is a subtractive manufacturing process where computer programs control cutting tools to remove material from metal or plastic workpieces. Using CAD and CAM software, engineers convert 3D models into toolpaths that CNC machines follow with extremely high precision and repeatability.

CNC Machining covers multiple processes, including milling, turning, drilling, boring, and tapping, enabling complex geometries and tight tolerances. Because everything is driven by digital instructions, CNC Machining offers excellent repeatability for batches ranging from one prototype to thousands of production parts.

In a typical CNC Machining workflow, the design team creates a 3D model, the programmer generates a CNC program using CAM software, and operators set up the machine with appropriate tools, fixtures, and raw material. Once the first piece is verified, the same CNC Machining setup can run continuously to produce large quantities of identical parts.

One of the most important impacts of CNC Machining is a dramatic improvement in production efficiency and throughput. Automated CNC equipment can run continuously with minimal downtime, often operating 24/7 with only brief pauses for tool changes, inspections, and maintenance.

For example, a batch of 100 complex parts that might take a skilled operator many hours using manual machines can be completed in a fraction of the time with CNC Machining. Once the CNC program is validated, the machine executes the same cycle repeatedly, reducing setup time per part and keeping spindle utilization high.

CNC Machining also simplifies multi‑step processes by combining operations in a single setup, such as milling, drilling, and tapping on one machining center. This integration reduces handling, shortens production cycles, and lowers the risk of dimensional errors caused by moving parts between multiple machines.

CNC Machining delivers high precision, often achieving tight tolerances that are essential in aerospace, medical, and automotive applications. Because motion is controlled by digital code instead of manual handwheels, parts are produced with excellent dimensional accuracy and surface finish.

Another major impact of CNC Machining is its repeatability: once a program and setup are optimized, the same part can be reproduced consistently across small and large batches. This consistency reduces scrap, minimizes rework, and ensures that each delivered component matches the OEM's specification.

Advanced CNC Machining systems can integrate in‑process measurement, tool life monitoring, and automated probing routines. These functions help detect tool wear, machine drift, or setup issues early, allowing corrective actions before defects accumulate. As a result, CNC Machining becomes a stable backbone for quality‑driven manufacturing.

CNC Machining has revolutionized prototyping by making functional prototypes faster, more affordable, and closer to final production quality. Engineers can quickly turn 3D CAD models into CNC Machining toolpaths, machine the first article, test performance, and then iterate design changes in short cycles.

Compared with traditional manual machining, CNC Machining allows design modifications to be implemented simply by updating the program instead of rebuilding fixtures or manually re‑measuring every coordinate. This agility helps OEMs compress development schedules, reduce risk before full‑scale production, and launch new products earlier.

CNC Machining also works hand in hand with 3D printing during product development. Additive manufacturing may be used for conceptual shapes and very early stage prototypes, while CNC Machining provides high‑accuracy metal or plastic prototypes for functional testing and validation. This hybrid approach optimizes both speed and performance in the early stages of manufacturing projects.

CNC Machining offers unmatched flexibility because machines can be reprogrammed quickly to produce different parts. Instead of retooling entire production lines, manufacturers can load a new CNC Machining program, change fixtures, and switch from one product to another with minimal downtime.

This flexibility is especially valuable for low‑to‑medium volume production, customized components, and engineering changes requested by global OEM customers. CNC Machining allows factories to support diverse industries—automotive, medical, aerospace, robotics, consumer products—using the same core equipment and programming competence.

The digital nature of CNC Machining also makes it easier to manage version control, ensuring that the latest design revision is always used for production. Manufacturing engineers can store, track, and update CNC Machining programs, tooling lists, and setup instructions, which reduces confusion on the shop floor and aligns manufactured parts with the customer's current drawings and specifications.

While the initial investment for CNC Machining centers can be high, long‑term manufacturing costs often decrease significantly. CNC Machining reduces labor requirements per part because a single operator can monitor multiple machines, and the machines themselves do not suffer from fatigue or inconsistency.

Material waste is also reduced. Optimized CNC Machining toolpaths, stable cutting conditions, and accurate positioning mean fewer defective parts and more efficient use of raw materials. Together, reduced scrap, higher throughput, and lower labor per unit make CNC Machining a cost‑effective solution for competitive global markets.

Additionally, CNC Machining supports lights‑out production, where machines run unattended during nights or weekends. By scheduling long‑running jobs outside normal working hours, manufacturers can spread equipment costs over more parts and increase effective capacity without expanding floor space.

CNC Machining improves safety by distancing operators from direct cutting operations, high‑speed tools, and chips. Most CNC machining centers are fully enclosed, with interlocked doors, coolant systems, and chip management that keep the operator outside the hazardous zone during operation.

Automation allows workers to focus on programming, setup, inspection, and process optimization rather than continuous manual machining. This shift reduces repetitive‑motion strain, lowers the risk of accidents, and upgrades the skill profile of the workforce in modern machining shops.

Because CNC Machining is predictable and standardized, shops can implement better risk assessments, clear operating procedures, and digital monitoring for maintenance and alarms. These improvements result in more stable factory environments and fewer unexpected interruptions during production.

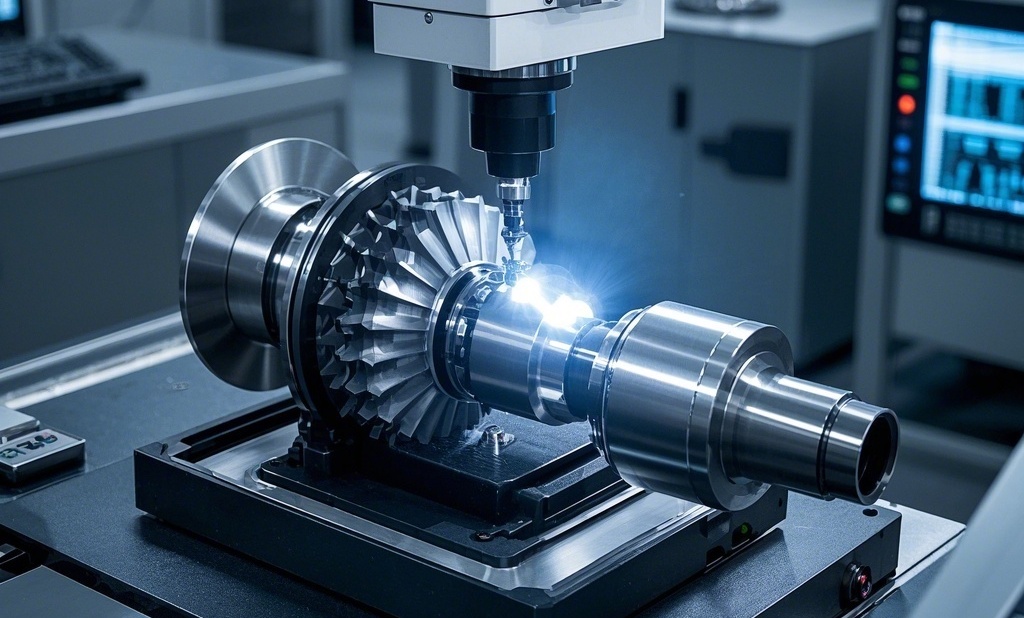

Modern CNC Machining systems handle complex 3D contours, deep pockets, and multi‑axis operations that would be extremely difficult or impossible with manual methods. With 4‑axis and 5‑axis CNC Machining, parts can be processed from multiple angles in a single setup, improving both accuracy and efficiency.

CNC Machining also supports a wide range of materials, including aluminum, steel, stainless steel, titanium, brass, copper, engineering plastics, and composites. This versatility allows OEMs to choose materials based on strength, weight, corrosion resistance, or regulatory requirements while using the same CNC Machining infrastructure.

Industries such as aerospace and medical rely heavily on CNC Machining to produce lightweight structural parts, bone plates, surgical instruments, and precision housings that must meet strict standards. The ability of CNC Machining to maintain tight tolerances and clean surface finishes in demanding materials is central to these applications.

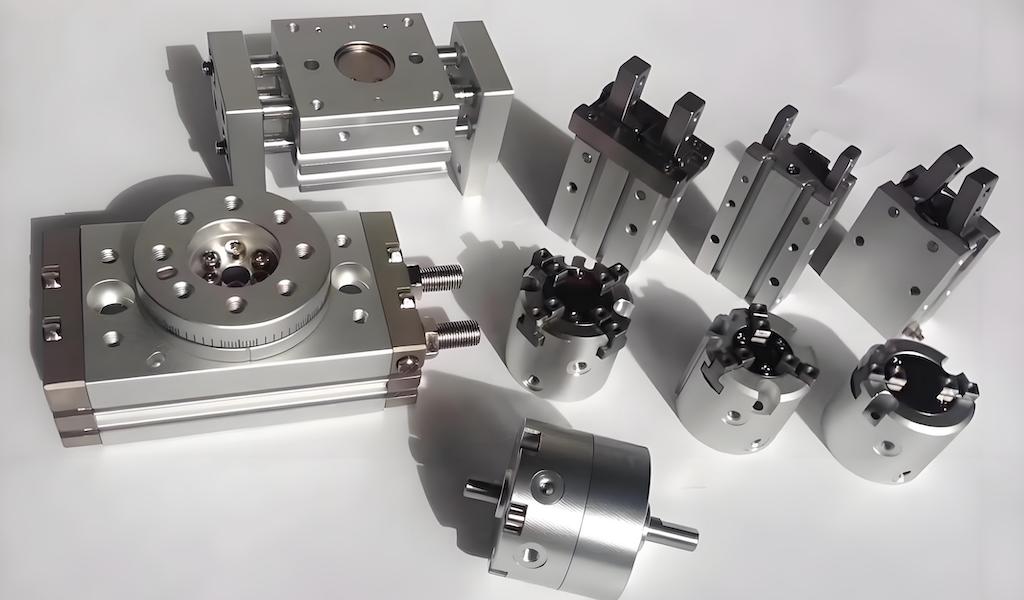

CNC Machining is an umbrella term that includes several core processes used together in modern factories. Each process contributes differently to how CNC Machining impacts manufacturing performance and product design.

CNC milling uses rotating cutting tools to remove material while the workpiece is fixed on a table, making it ideal for prismatic parts, pockets, slots, and complex 3D surfaces. High‑speed CNC Machining centers can rapidly mill metals and plastics for prototypes and low‑volume to medium‑volume production.

Advanced milling strategies such as high‑speed machining, trochoidal milling, and adaptive clearing help reduce cutting forces and cycle times while extending tool life. These techniques allow CNC Machining to achieve both productivity and accuracy, even in hard‑to‑cut materials.

CNC turning rotates the workpiece while a stationary tool cuts away material, making it ideal for shafts, bushings, flanges, and other cylindrical components. Modern CNC lathes often include live tooling and sub‑spindles, enabling combined turning and milling operations that streamline CNC Machining workflows.

By integrating drilling, tapping, and contouring into one CNC turning center, manufacturers can complete many features in a single clamping. This reduces cycle time, improves concentricity and alignment, and keeps the entire CNC Machining process compact and efficient.

Additional CNC Machining operations include drilling, tapping, boring, reaming, and threading. These processes are often performed in the same machine setup, using tool changers to switch between different cutting tools automatically.

Multi‑axis and multi‑spindle configurations further increase flexibility and throughput in advanced CNC Machining facilities. Such setups allow simultaneous machining of multiple parts or multiple faces of the same part, helping manufacturers meet high‑volume demand without sacrificing precision.

These capabilities allow a single CNC Machining supplier to deliver complex, fully finished parts instead of partial operations that require multiple vendors. For OEMs, consolidating operations into one CNC Machining partner simplifies logistics, documentation, and quality management.

CNC Machining is evolving alongside Industry 4.0 technologies, including artificial intelligence, cloud computing, and advanced robotics. Concepts such as autonomous CNC Machining use algorithms to optimize toolpaths, monitor tool wear, and schedule maintenance automatically.

Cloud‑connected CNC Machining systems allow remote monitoring of machine status, production progress, and energy consumption. Production managers can check live dashboards, analyze spindle utilization, and adjust schedules from anywhere, which increases responsiveness and transparency.

AI‑assisted CAM software can generate more efficient CNC Machining programs, reduce cycle times, and adapt to material variations in real time. As these technologies mature, CNC Machining will become even more central to flexible, data‑driven global manufacturing.

Another trend is the integration of CNC Machining with robotics for automated loading and unloading. Robot arms can transfer parts between machines, inspection stations, and packaging areas, enabling highly automated production cells that operate with minimal human intervention while maintaining consistent quality.

In the global market, many OEM brands, wholesalers, and manufacturers source CNC Machining services from China to balance cost, quality, and lead time. Chinese CNC Machining suppliers provide rapid prototyping, small‑batch production, and precision mass production across a wide range of metals and plastics.

These factories often combine CNC Machining with complementary processes such as sheet metal fabrication, 3D printing, injection molding, and mold making, offering a one‑stop solution. For overseas customers, partnering with such CNC Machining providers simplifies supply chains while maintaining high technical standards.

By leveraging advanced CNC Machining equipment, experienced engineers, and efficient project management, Chinese OEM suppliers help customers accelerate new product launches and scale up production. This combination of capacity and flexibility makes CNC Machining in China a strategic choice for many industries worldwide.

In addition, many Chinese CNC Machining companies support international standards, provide material certifications, and adopt strict quality management systems. This gives foreign buyers confidence that CNC Machining parts will meet regulatory requirements and pass incoming inspections in their own facilities.

Although CNC Machining is a technical process, multimedia content can make capabilities easier to understand for engineers and purchasing teams. Videos that show live CNC Machining operations, such as milling aluminum housings or turning stainless steel shafts, help customers visualize cutting conditions, chip removal, and overall cycle times.

Visual walkthroughs of CNC machining workshops, including programming, setup, tool presetting, and inspection procedures, also build trust in the manufacturing process. When buyers can see CNC Machining in action, they gain a clearer understanding of process stability, automation level, and quality control methods.

Explainer videos that illustrate CAD/CAM workflows and before‑and‑after parts allow engineers to see how CNC Machining transforms digital designs into precise physical components. For OEM buyers, such content clarifies capabilities, tolerances, and surface finishing options available from a CNC Machining partner, supporting better technical communication and faster decision‑making.

CNC Machining is valuable at every stage of the product lifecycle, from early concepts to mature mass production. At the concept stage, CNC Machining can quickly produce proof‑of‑concept parts that validate basic forms and functions. These early parts help teams confirm ergonomics, assembly feasibility, and basic performance before committing to expensive tooling.

During the engineering validation stage, CNC Machining provides high‑precision prototypes for mechanical testing, reliability checks, and compliance validation. Because CNC Machining can deliver close‑to‑production quality, test results are more representative of final products, reducing the risk of late design changes.

As projects move to pilot runs and small‑batch production, CNC Machining continues to play a critical role. It allows manufacturers to build limited quantities for field trials, marketing samples, or small customer groups while preserving flexibility to adjust the design. When demand grows, CNC Machining can either support ongoing low‑to‑medium volumes or work alongside dedicated tooling and molding processes.

Even for products that eventually rely on die‑casting, stamping, or injection molding, CNC Machining is essential for making molds, dies, and fixtures. High‑precision CNC Machining of mold cavities, cores, and inserts directly influences the quality and consistency of molded parts, so the process delivers value both on the product side and the tooling side.

For OEM brands, wholesalers, and industrial manufacturers, working with a capable CNC Machining partner offers multiple advantages:

- Faster development cycles: CNC Machining reduces the time from design to first article, supporting rapid iteration and earlier market entry.

- Stable quality: Digital control and robust process planning reduce variation between parts and between batches.

- Scalable production: CNC Machining can handle one‑off parts, small batches, and larger volumes using the same fundamental setup and programming framework.

- Design freedom: Complex geometries, intricate features, and demanding tolerances are achievable with advanced CNC Machining equipment.

- Supply chain simplification: A single CNC Machining source that also supports other processes can provide integrated solutions instead of fragmented sourcing.

By aligning design teams, manufacturing engineers, and CNC Machining suppliers early in the project, companies can optimize part geometry, material choices, and process strategies. This collaboration often leads to lower cost, better consistency, and smoother ramp‑up when demand increases.

CNC Machining has a profound impact on modern manufacturing by combining digital control, high precision, and automation across milling, turning, and related processes. It improves efficiency, reduces costs, enhances safety, and supports complex geometries and advanced materials for demanding industries.

By enabling rapid prototyping and flexible production, CNC Machining shortens development cycles and helps OEMs bring products to market faster. Its ability to deliver consistent quality across a wide range of batch sizes makes CNC Machining an ideal solution for both custom components and ongoing production.

As artificial intelligence, cloud connectivity, robotics, and smart factory concepts continue to develop, CNC Machining will remain a core technology for globally competitive, high‑quality manufacturing. Companies that fully leverage CNC Machining throughout the product lifecycle—from concept and prototyping to tooling and volume production—will be in a strong position to serve international markets and demanding applications.

Conntact us to get more information!

CNC Machining in manufacturing is the use of computer‑controlled machines to remove material from metal or plastic workpieces according to digital CAD and CAM instructions. It automates traditional machining operations such as milling, turning, and drilling to produce precise, repeatable components with consistent quality.

CNC Machining improves efficiency by allowing machines to run with minimal human intervention, including automated tool changes, stable workholding, and optimized toolpaths. This reduces cycle times, cuts setup effort per part, and increases overall equipment utilization, helping manufacturers produce more parts in less time.

CNC Machining is important for prototypes because it can quickly turn CAD models into functional, high‑accuracy parts that closely match final production components. Design changes are implemented through updated programs instead of major tooling changes, enabling fast iteration and reliable testing before mass production investment.

Many industries rely on CNC Machining, including aerospace, automotive, medical devices, robotics, electronics, energy, and industrial equipment. These sectors need high‑precision, high‑reliability components in materials such as aluminum, steels, titanium, and engineering plastics, all of which are well suited to CNC Machining.

In the future, CNC Machining will integrate more artificial intelligence, cloud connectivity, automated inspection, and robotics to create smarter, more autonomous production systems. These advances will further optimize toolpaths, reduce downtime, improve traceability, and support highly flexible, data‑driven manufacturing environments.

1. https://demmermanufacturing.com/news/how-cnc-machining-impacts-modern-day-manufacturing/

2. https://rapidefficient.com/zh/machining-services/cnc-machining/

3. https://adaero.co.uk/precision-in-motion-the-impact-of-cnc-machining-on-modern-manufacturing/

4. https://cn.duchgroup.com/services/cnc-machining.html

5. https://doug-machine.com/the-impact-of-cnc-machining/

6. https://www.asianstarcnc.com/zh-CN/cnc-machining-factory/china-oem-cnc-milling-pparts-manufacturer-a-guide-to-precision-engineering

7. https://toolpath.com/top-questions/how-does-cnc-technology-impact-manufacturing-industrys-efficiency

8. https://xometry.asia/zh-hans/cnc-turning/

9. https://www.3erp.com/blog/future-of-cnc-machining/

10. https://firstmold.com/zh/cnc-machining-service/

content is empty!