Views: 222 Author: Amanda Publish Time: 2026-01-26 Origin: Site

Content Menu

● What Is CNC Rapid Prototyping?

● CNC Rapid Prototyping Process

>> Design Ideation and Requirements

>> Process Planning and Toolpath Strategy

>> CNC Machining and Prototype Production

>> Post‑Processing and Surface Finishing

>> Inspection, Testing, and Iteration

● Why Choose CNC for Rapid Prototyping?

● CNC Rapid Prototyping vs Other Methods

>> Common Rapid Prototyping Routes

● Applications of CNC Rapid Prototyping

● Best Practices for CNC Rapid Prototyping with an OEM Factory

● How Shangchen Supports Rapid Prototyping to Production

● FAQ

>> 1. What is CNC rapid prototyping?

>> 2. Which materials can be used for CNC rapid prototyping?

>> 3. How accurate is CNC rapid prototyping?

>> 4. When should CNC rapid prototyping be chosen over 3D printing?

>> 5. How can overseas buyers work with a Chinese OEM factory for CNC rapid prototyping?

CNC rapid prototyping is a manufacturing method that uses computer numerical control (CNC) machines to quickly turn digital designs into precise physical parts, helping engineers validate form, fit, and function before full-scale production. It is one of the most widely used rapid prototyping routes for metals and plastics because it combines high accuracy, repeatability, and a broad material range.

Rapid prototyping is a set of manufacturing techniques used to quickly produce physical models from digital designs to validate a product's performance, usability, and manufacturability. In modern product development, rapid prototyping reduces risk and accelerates time to market by enabling multiple design iterations in days rather than months.

Key characteristics of rapid prototyping include:

- Automated production directly from CAD data

- Short lead times and fast iteration cycles

- Focus on testing ideas before committing to expensive tooling

For overseas brand owners, wholesalers, and manufacturers, partnering with a professional OEM factory in China for rapid prototyping enables cost-effective design validation and smoother transition into mass manufacturing.

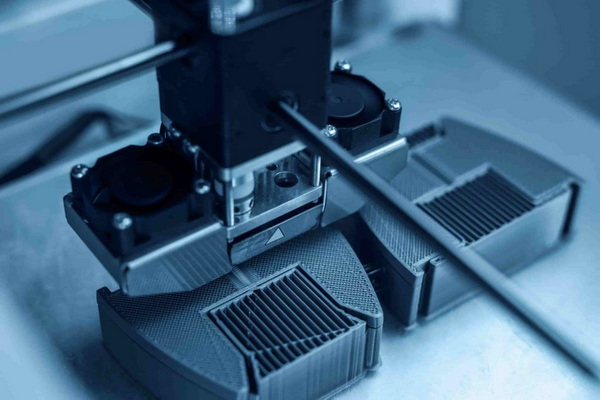

CNC rapid prototyping combines CNC machining with rapid prototyping workflows to manufacture prototypes directly from 3D CAD files using subtractive cutting tools. Instead of building parts layer by layer, CNC machines remove material from solid blocks of metals or plastics to achieve the desired geometry.

Main points of CNC rapid prototyping:

- Uses CNC milling, CNC turning, drilling, and related processes

- Works with production-grade metals (aluminum, steel, brass) and engineering plastics (ABS, POM, PC, PEEK, nylon, etc.)

- Produces both visual mock-ups and fully functional mechanical prototypes

For an OEM-focused factory like Shangchen, which offers CNC machining, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing, rapid prototyping with CNC is a core service that bridges product ideas and precision batch production.

CNC rapid prototyping generally follows a structured workflow from concept to tested prototype. A clear and repeatable process is essential to keep lead times short while ensuring consistent quality.

The process begins with design ideation, where product designers and engineers define the goals, functions, and constraints of the prototype. Typical activities include:

- Clarifying performance, aesthetic, and regulatory requirements

- Applying design for manufacturing and assembly (DFMA) and design for testing (DFT)

- Choosing whether the rapid prototyping focus is visual, functional, or both

At this stage, overseas customers often share drawings, sketches, 3D models, or reference products with the OEM factory to align expectations on tolerances, materials, and delivery time. Clear communication at the beginning of the rapid prototyping project reduces costly design changes later.

The selected concept is converted into a detailed 3D CAD model that defines all dimensions, tolerances, and features. This step is critical because CNC rapid prototyping relies on high-quality digital data to generate accurate toolpaths.

Key aspects in CAD for rapid prototyping include:

- Proper wall thickness, radii, draft angles, and clearances

- Well-defined datum references and, if necessary, geometric dimensioning and tolerancing

- Separation of multi-component assemblies into individual parts suitable for CNC or other rapid prototyping processes

Clean CAD models reduce programming time and minimize the risk of errors during CNC rapid prototyping.

After CAD, engineers determine the optimal manufacturing sequence and machining strategy for CNC rapid prototyping. This planning stage balances cost, lead time, and achievable precision.

Typical planning tasks include:

- Selecting appropriate CNC processes: milling, turning, drilling, EDM, or combinations

- Evaluating workholding and fixturing for each machining setup

- Determining roughing and finishing strategies to protect critical surfaces and reduce machining time

For a factory like Shangchen that also offers sheet metal fabrication, 3D printing, and mold making, engineers can combine CNC rapid prototyping with other rapid prototyping methods when it shortens lead time or reduces cost. For example, a complex enclosure may use 3D printing for internal structures and CNC rapid prototyping for precise mounting faces.

Programmers translate the CAD model and process plan into CNC code (G-code and M-code) that instructs the machine on tool movements, speeds, and feeds. Effective programming is central to stable and efficient rapid prototyping.

Typical programming parameters:

- Toolpaths for each operation and tool

- Spindle speed, feed rate, and depth of cut suitable for the chosen material

- Tool changes, coolant commands, and safety movements

Because rapid prototyping emphasizes speed, programmers often optimize toolpaths to reduce cycle time while preserving the surface finish and dimensional accuracy needed for functional evaluation. Simulation and verification software helps detect collisions and errors before actual machining.

Once the program is verified, CNC rapid prototyping begins by mounting the workpiece and running the machining cycle. For complex parts, multiple setups on 3‑axis, 4‑axis, or 5‑axis machining centers may be used to reach all features.

Key advantages during this stage:

- High dimensional accuracy and repeatability

- Ability to machine tight-tolerance features and intricate geometries

- Flexibility to produce both single prototypes and small-batch rapid prototyping runs

For cylindrical components, CNC turning is often the most efficient rapid prototyping route, while prismatic and freeform geometries rely on CNC milling. If design changes are needed, engineers simply modify the CAD data and toolpaths, then repeat CNC rapid prototyping for the updated version.

After raw machining, CNC rapid prototyping usually includes secondary operations to improve appearance or performance. These finishing steps help prototypes better simulate final mass-produced parts and make them suitable for customer presentations or functional testing.

Common finishing options:

- Deburring, polishing, bead blasting, or sanding to smooth sharp edges and tool marks

- Anodizing, plating, painting, or powder coating for metals to enhance corrosion resistance and appearance

- Laser engraving, printing of logos, and basic assembly of multiple CNC‑machined components

Because Shangchen focuses on OEM rapid prototyping and precision batch production, it can integrate these finishes into the same workflow so that customers receive near-production-quality prototypes ready for testing, marketing photos, or trade show demonstrations.

The final stage of CNC rapid prototyping is inspection and functional testing. Dimensional checks confirm that critical features meet tolerance, while performance tests ensure the prototype works in real-world conditions.

Typical steps include:

- Measuring key dimensions with calipers, CMM, optical measurement, or custom gauges

- Conducting mechanical, thermal, or environmental tests where needed

- Assembling the prototype with mating components to evaluate fit and function

Rapid prototyping is inherently iterative. Feedback from testing feeds back into CAD, and the CNC rapid prototyping loop repeats until the design meets all performance and manufacturability requirements. This iterative approach lets overseas customers refine designs before committing to molds, jigs, or high-volume tooling.

CNC machining is one of the most powerful rapid prototyping technologies because it combines speed with production-level quality. It is especially valuable when prototypes must behave like final parts under real loads.

Advantages of CNC rapid prototyping:

- Precision: Achieves tight tolerances suitable for functional tests and mating assemblies

- Versatility: Supports metals and plastics, making it ideal for structural, thermal, or mechanical validation

- Repeatability: Once programmed, the same rapid prototyping setup can produce consistent small batches

- Surface quality: Provides better surface finish than many additive rapid prototyping techniques, reducing post-processing

- Material behavior: Uses real engineering materials, so test results correlate closely with future production parts

For an OEM factory in China serving global brand owners, CNC rapid prototyping also simplifies the transition to:

- Low-volume, high-mix production runs

- Tooling components for injection molds or die casting

- Precision fixtures, jigs, and end-use mechanical parts

When customers use CNC rapid prototyping early in the design phase, they can avoid late-stage design changes and costly tooling modifications.

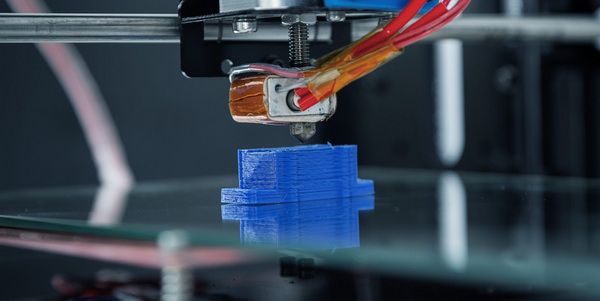

Different rapid prototyping methods serve different needs in product development. CNC rapid prototyping is often combined with additive and forming processes to create a complete solution.

- CNC rapid prototyping: Subtractive machining for high-precision functional prototypes in metals and plastics

- 3D printing: Additive manufacturing for complex geometries, internal channels, and concept models

- Vacuum casting: Polyurethane parts from silicone molds for small batches and appearance models

- Sheet metal rapid prototyping: Fast fabrication of brackets, enclosures, and structural parts

- Soft tooling and rapid molds: Short-run tooling for injection molding or die casting

By understanding the strengths and weaknesses of each method, engineers can choose the right rapid prototyping combination for each project.

| Method | Material range | Typical use in rapid prototyping | Strengths for rapid prototyping | Limitations for rapid prototyping |

|---|---|---|---|---|

| CNC rapid prototyping | Metals & engineering plastics | Functional prototypes & small batches | High precision, tight tolerance, good surface finish | Material waste, requires programming and setup |

| 3D printing | Plastics, resins, some metals | Concept models & complex shapes | Very fast design changes, internal channels, minimal setup | Lower strength for many materials, visible layers |

| Vacuum casting | Polyurethane-like plastics | Low-volume aesthetic parts | Good surface, color options, low initial tooling cost | Limited material choices, tooling wear over time |

| Sheet metal prototyping | Steel, aluminum, stainless, others | Brackets, chassis, enclosures | High strength, suited for structural and electronic housings | Less suited for highly organic 3D geometries |

| Rapid molds / soft tooling | Tool steels, aluminum, mold resins | Short-run molded parts for validation | Realistic molded prototypes, closer to mass production process | Higher initial cost and lead time than machining |

This combination of rapid prototyping methods allows OEM factories like Shangchen to design a strategy that balances speed, cost, and performance for each customer project.

CNC rapid prototyping is widely used across industries that require precise, durable prototypes that closely represent final parts.

Typical application areas:

- Automotive: Structural brackets, housings, engine components, interior trim, and lighting parts

- Aerospace: High-precision components, fixtures, tooling prototypes, and structural test pieces

- Medical: Surgical instruments, device housings, implants (with suitable materials), and customized fixtures

- Consumer electronics: Metal frames, heat sinks, plastic covers, and moving mechanical interfaces

- Industrial equipment: Gears, levers, manifolds, valves, and testing jigs

- Robotics and automation: End effectors, grippers, brackets, and sensor mounts

For overseas brand owners and wholesalers, using CNC rapid prototyping at a partner factory in China ensures that prototypes reflect real production capabilities. This makes it easier to estimate cost, lead time, and potential risks before moving into mass production.

To get maximum value from CNC rapid prototyping, collaboration between the customer and the OEM supplier is crucial. Clear information and fast communication can significantly shorten project cycles.

Recommended practices:

- Provide clear 3D CAD files and 2D drawings with tolerances and critical dimensions labeled

- Define the purpose of rapid prototyping: appearance only, functional testing, assembly verification, or pre-production validation

- Discuss material choices early, including substitutes available locally in China to improve cost and lead time

- Align on surface finish, coloring, and any secondary operations such as anodizing, plating, or painting

- Share usage conditions (temperature, load, environment) so that the OEM factory can recommend suitable rapid prototyping materials and processes

- Plan for multiple rapid prototyping iterations before locking the final design for molding or batch production

An experienced Chinese factory like Shangchen can also offer design for manufacturing suggestions, helping customers simplify structures, reduce machining time, and improve reliability without sacrificing function.

A comprehensive OEM partner offering CNC machining, lathe turning, sheet metal fabrication, 3D printing, and mold making can support the full rapid prototyping to production lifecycle. This one-stop approach is especially convenient for overseas clients.

Typical service chain for overseas customers:

- Early rapid prototyping with CNC machining and 3D printing to validate design and function

- Design refinement based on rapid prototyping test feedback, including dimensional or structural improvements

- Transition to rapid tooling or formal molds for injection molding or die casting once the design is stable

- Precision small-batch production using CNC machining and sheet metal processes for pilot runs or niche volumes

- Ramp-up to larger volumes with consistent quality control, inspection reports, and traceability

By consolidating rapid prototyping and manufacturing in a single OEM factory, brand owners and wholesalers reduce communication friction, avoid handover mistakes between different suppliers, and maintain consistent quality standards from prototype to mass production. Customers also gain better protection of confidential designs throughout the rapid prototyping and production stages.

CNC rapid prototyping is a powerful method for transforming digital designs into accurate, functional prototypes using CNC machining technology, supporting faster and more confident product development. By combining rapid prototyping with CNC milling, turning, sheet metal fabrication, 3D printing, and mold production, an OEM factory in China can guide overseas brand owners and wholesalers from concept to precision batch manufacturing with reduced risk and shorter lead times. For companies seeking reliable OEM partners, integrating CNC rapid prototyping into their development strategy is an effective way to validate design, optimize cost, and accelerate market entry in a highly competitive global environment.

Contact us to get more information!

CNC rapid prototyping is the use of CNC machining to quickly manufacture prototypes directly from 3D CAD data, enabling fast and precise evaluation of product designs before mass production. It is a core rapid prototyping method for functional parts in metals and engineering plastics, providing accuracy and material performance that are close to final products.

CNC rapid prototyping supports a wide range of metals such as aluminum, steel, stainless steel, brass, and copper, as well as engineering plastics like ABS, POM, PC, PEEK, and nylon. This material flexibility makes CNC rapid prototyping suitable for structural tests, high‑temperature evaluations, and long‑term durability studies in many different industries.

CNC rapid prototyping can achieve tight tolerances that are often suitable for high-precision mechanical assemblies and demanding functional tests. The actual accuracy depends on material, part design, and machine capability, but in many cases CNC rapid prototyping reaches or closely approaches production-level dimensional requirements.

CNC rapid prototyping is preferred when prototypes require high strength, tight tolerances, and production-grade materials, especially metals or engineering plastics. 3D printing is more suitable for very complex geometries, internal channels, lightweight lattice structures, and early concept models where appearance and general shape matter more than exact material performance.

Overseas buyers typically send CAD files, drawings, and requirement lists to the OEM factory, which then reviews manufacturability and provides quotations and lead times for CNC rapid prototyping. After prototypes are produced and tested, the same supplier can support design optimization and scale-up into molds, sheet metal production, 3D printing runs, and precision batch manufacturing, ensuring a smooth progression from initial rapid prototyping to stable mass production.

1. https://www.bdeinc.com/blog/learn-about-the-steps-involved-in-cnc-rapid-prototyping/

2. https://www.rapidcncprototyping.com

3. https://www.namf.com/cnc-rapid-prototyping-2/

4. https://cn.boenrapid.com/cnc-machining-for-rapid-prototyping.html

5. https://www.fictiv.com/articles/cnc-machining-for-prototyping

6. https://www.tsprototypes.com/cn/

7. https://www.zintilon.com/blog/rapid-prototyping-with-cnc-machining/

8. https://firstmold.com/zh/services/rapid-prototyping/cnc-prototyping/

9. https://jiga.io/cnc-machining/cnc-prototyping/

content is empty!