Views: 222 Author: Amanda Publish Time: 2026-01-26 Origin: Site

Content Menu

● What Is SLS in Rapid Prototyping?

● How SLS Works in a Rapid Prototyping Workflow

>> CAD Preparation and Build Setup

>> Powder Preheating and Layer Deposition

>> Selective Laser Sintering of Each Layer

>> Finishing and Secondary Operations

● Materials Used in SLS Rapid Prototyping

>> Glass‑Filled and Reinforced Nylons

● Advantages of SLS for Rapid Prototyping

>> No Support Structures Required

>> High Design Freedom and Geometric Complexity

>> Efficient Batch Production and Cost‑Effective Low Volumes

● Limitations of SLS in Rapid Prototyping

>> Surface Finish and Porosity

>> Dimensional Accuracy for Large Parts

>> Material and Equipment Costs

● SLS vs Other Rapid Prototyping Technologies

>> SLS vs SLA in Rapid Prototyping

>> SLS vs FDM in Rapid Prototyping

>> SLS vs CNC Machining in Rapid Prototyping

● Typical Applications of SLS Rapid Prototyping

>> Automotive and Transportation

>> Consumer Electronics and Industrial Products

● How Shangchen Uses SLS in Rapid Prototyping Services

>> End‑to‑End Rapid Prototyping Support

>> Flexible Volumes from Single Prototype to Small Batch

● Design Tips for SLS Rapid Prototyping

>> Respect Minimum Wall Thickness and Feature Size

>> Use Uniform Wall Thickness Where Possible

>> Leverage Hollow and Lattice Structures

● FAQ About SLS in Rapid Prototyping

>> 1. What does SLS stand for in Rapid Prototyping?

>> 2. Why choose SLS instead of FDM for Rapid Prototyping?

>> 3. Which materials are commonly used in SLS Rapid Prototyping?

>> 4. Is SLS only for prototypes, or can it be used for low‑volume production?

>> 5. How long does an SLS Rapid Prototyping project usually take?

Selective Laser Sintering, usually called SLS, is one of the most important industrial 3D printing technologies used in modern Rapid Prototyping. It enables engineers and product developers to build strong, functional plastic parts directly from digital CAD data without creating any molds. For factories like Shangchen, which provide Rapid Prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold making, SLS is a powerful tool that connects product concept and mass production quickly and efficiently.

In the global OEM market, SLS plays a central role in Rapid Prototyping because it delivers accurate, durable parts that can be tested in real‑world conditions. It supports foreign brands, wholesalers, and manufacturers who need short lead times, high flexibility, and stable quality before they commit to full tooling and high‑volume production.

SLS stands for Selective Laser Sintering, a powder‑bed fusion 3D printing process used widely in Rapid Prototyping and low‑volume production. In this process, a high‑power laser selectively fuses small particles of polymer powder into a solid structure based on the cross‑sections generated from a 3D model.

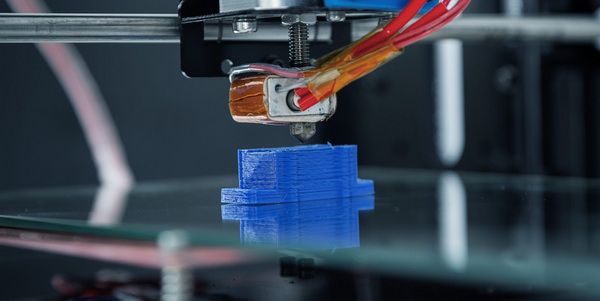

Unlike traditional manufacturing methods, SLS Rapid Prototyping builds parts layer by layer inside a heated chamber filled with fine plastic powder. Each layer of powder represents a thin slice of the part's geometry. The laser scans and sinters only the areas defined by the CAD design, while the rest of the powder remains loose and acts as natural support. This allows very complex shapes to be created during Rapid Prototyping without dedicated support structures or complex fixtures.

For overseas OEM customers, SLS in Rapid Prototyping provides a direct link between digital design and physical part. Once a 3D model is ready, parts can be produced with few constraints, which accelerates design validation and reduces the risk and cost of late design changes.

To understand why SLS is so effective in Rapid Prototyping, it is helpful to look at its typical workflow. Although the process is highly automated, each stage has a strong impact on final part quality, cost, and lead time.

Every SLS Rapid Prototyping project starts with a 3D CAD model prepared by the customer or by the engineering team. The model is exported into a suitable format (such as STL or STEP), then checked for thickness, geometry errors, and printability. For Rapid Prototyping, engineers often perform a design‑for‑manufacturability review to ensure the part is appropriate for SLS and optimized for strength, weight, and cost.

In the build setup software, multiple parts can be oriented and nested together within the available print volume. One of the biggest advantages of SLS in Rapid Prototyping is that parts can be stacked in three dimensions because the unsintered powder supports them. This efficient packing improves throughput and reduces the per‑part cost in small‑batch Rapid Prototyping runs.

Once the job is prepared, the SLS machine preheats the build chamber and powder bed to a temperature just below the material's melting point. This stable, uniform temperature plays a crucial role in Rapid Prototyping, because it reduces internal stresses and warping during printing.

A recoater blade or roller spreads a very thin layer of polymer powder over the build platform, usually around 0.08–0.15 mm thick. The powder must be uniform and consistent, because any variation in layer thickness can affect the accuracy and surface quality of the Rapid Prototyping parts.

After the powder layer is applied, the laser scans the cross‑section of the part defined for that particular layer. Wherever the laser passes, the powder particles absorb energy and fuse together, forming a thin solid layer. Areas that are not scanned remain loose powder.

When one layer is completed, the build platform lowers by one layer thickness. A fresh layer of powder is then spread across the entire area, and the laser sinters the next cross‑section. This cycle repeats until every layer of the Rapid Prototyping part is completed. The result is a block of powder containing fully formed parts buried inside.

After printing, the entire build must cool down gradually inside the machine. This cooling period is especially important for Rapid Prototyping of large or thick parts, because sudden temperature changes can cause warping, cracking, or dimensional inaccuracies.

When cooling is finished, the operator removes the build cake and begins depowdering. Loose powder is brushed or blown away, revealing the finished Rapid Prototyping parts. Remaining powder can often be collected, sieved, and blended with fresh material for future builds, which helps manage material costs in SLS Rapid Prototyping projects.

Most SLS Rapid Prototyping parts receive some basic finishing. Common steps include media blasting or bead blasting to remove fine powder and unify the surface texture. If required, parts can be dyed, painted, coated, or polished to achieve a specific color or appearance.

In a multi‑process factory like Shangchen, SLS Rapid Prototyping parts can also be combined with CNC machining, turning, or insert molding to form hybrid components. For example, SLS can be used to Rapid Prototype complex housings while CNC machining delivers high‑precision metal inserts that are assembled or overmolded later. This flexibility makes SLS an excellent bridge between early Rapid Prototyping and final mass production.

SLS Rapid Prototyping uses powdered thermoplastic materials that are designed to melt and solidify in a controlled way. The most widely used materials are nylon‑based polymers, but the material family is expanding quickly.

Nylon 11 and Nylon 12 are the most common materials for SLS Rapid Prototyping. They offer a good combination of strength, toughness, chemical resistance, and stability. Parts made from these materials can handle real functional testing, mechanical loading, and repeated assembly cycles.

Because nylon SLS parts behave similarly to injection‑molded plastics, they are ideal for Rapid Prototyping of housings, clips, brackets, enclosures, and mechanical components that need to withstand everyday use.

Glass‑filled nylon blends contain glass fibers that reinforce the base polymer. These materials are used in SLS Rapid Prototyping when higher stiffness, dimensional stability, or heat resistance is required. Parts made from glass‑filled nylon are particularly suitable for structural components, fixtures, and parts installed near heat sources.

For overseas OEM customers, offering both standard and reinforced nylon options in Rapid Prototyping makes it easier to balance cost and performance according to the project requirements.

Beyond standard nylons, SLS Rapid Prototyping can use an increasing range of powders: flexible materials, high‑temperature engineering plastics, and speciality blends tailored for specific industries. Flexible powders are useful for Rapid Prototyping of living hinges, flexible joints, and ergonomic grips.

High‑temperature materials support Rapid Prototyping in demanding environments such as under‑hood automotive components or industrial equipment. By selecting the right SLS material early in the Rapid Prototyping phase, designers can test realistic performance conditions before finalizing the production design.

SLS has become a core technology in Rapid Prototyping because it offers several key advantages over other 3D printing methods and some traditional processes.

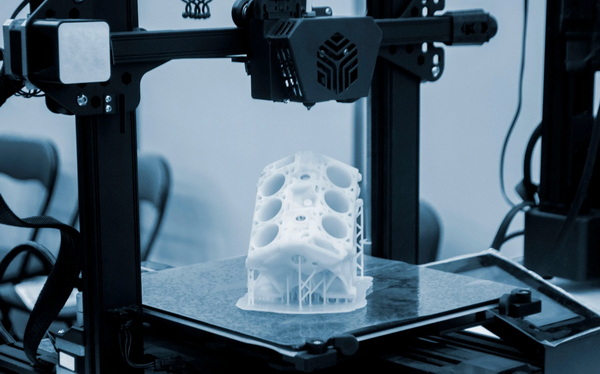

In SLS Rapid Prototyping, the surrounding unsintered powder naturally supports overhangs and internal features. This eliminates the need for dedicated support structures, saving design time and post‑processing labor. It also allows more creative geometries in Rapid Prototyping, including internal channels, lattice structures, and nested parts that would be very difficult to produce otherwise.

Since the laser can sinter any cross‑section defined by the CAD model, SLS Rapid Prototyping supports almost unlimited geometrical freedom within material and machine limits. Designers can create topology‑optimized shapes, organic surfaces, and integrated assemblies without worrying about tool access, undercuts, or mold release angles.

This design freedom is especially valuable in Rapid Prototyping when multiple design iterations must be evaluated quickly. It gives engineers and industrial designers more freedom to focus on performance rather than manufacturing constraints.

Compared with many entry‑level 3D printing technologies, SLS Rapid Prototyping typically produces parts with strong mechanical properties and good dimensional accuracy. The resulting prototypes are suitable not only for appearance checks but also for mechanical testing, assembly verification, and even end‑use applications.

This functional performance is a major reason why international OEMs rely on SLS Rapid Prototyping for critical development stages such as design validation and pilot production.

Because parts can be stacked in three dimensions within the powder bed, SLS Rapid Prototyping can produce many components in a single build. This efficient nesting makes SLS attractive not only for single prototypes but also for small‑batch and bridge production.

For customers who need dozens or hundreds of parts without investing in tooling, SLS Rapid Prototyping offers a cost‑effective solution. Factories like Shangchen can group orders, optimize nesting, and help customers reach an attractive cost per part even at low volumes.

Although SLS is extremely powerful in Rapid Prototyping, it does have some limitations that engineers should consider when selecting a process.

SLS Rapid Prototyping parts usually have a slightly rough, grainy surface due to the powder particles. For purely functional parts, this is often acceptable, but highly cosmetic surfaces may require extra finishing such as sanding, coating, or painting. The micro‑porous nature of SLS parts can also affect sealing and liquid tightness unless additional treatments are applied.

Understanding this limitation early in the Rapid Prototyping phase helps to set realistic aesthetic expectations and plan finishing operations where necessary.

Small and medium‑sized Rapid Prototyping parts are usually very accurate, but larger components can be more sensitive to thermal distortion and shrinkage. Designing with uniform wall thickness and observing recommended design rules helps minimize distortion.

For large Rapid Prototyping projects, it is sometimes better to split a design into smaller sections that are printed separately and then joined or assembled to maintain accuracy and manage risk.

Industrial SLS systems and specialty powders are more expensive than simple desktop printers and filaments. However, when compared with the cost of making molds or complex fixtures for early Rapid Prototyping, SLS remains highly competitive, especially for complex geometries and low‑volume batches.

For overseas OEMs working with Shangchen, SLS Rapid Prototyping often reduces total project cost because it eliminates tooling expenses in the early development stages and helps detect design issues before investing in molds.

In a complete Rapid Prototyping strategy, SLS is typically compared with other technologies such as SLA, FDM, and CNC machining. Each method has its strengths and weaknesses, and many successful businesses combine them.

SLA (stereolithography) uses a UV laser to cure liquid resin and is well known for its very smooth surfaces and high detail resolution. It is often chosen in Rapid Prototyping for visual models, concept designs, and parts that require a premium surface finish.

However, SLA materials are often more brittle and less suitable for harsh mechanical or outdoor environments. SLS Rapid Prototyping, by contrast, uses engineering‑grade thermoplastics with better toughness and durability, making it more suitable for functional prototypes.

FDM (fused deposition modeling) extrudes melted filament through a nozzle to build parts. It is widely used for low‑cost Rapid Prototyping and quick concept models. Yet FDM parts usually show visible layer lines and may have weaker interlayer bonding.

SLS Rapid Prototyping, using a powder bed and laser, generally achieves more uniform properties in all directions and handles complex geometries without supports. For professional OEM applications where reliability and repeatability are critical, SLS often provides a more robust Rapid Prototyping solution.

CNC machining is a subtractive Rapid Prototyping process that removes material from a solid block to create a part. It offers excellent precision and surface quality and works well with both metals and plastics. However, creating very complex internal features and undercuts can be difficult or very expensive with CNC alone.

SLS Rapid Prototyping complements CNC by enabling complex plastic shapes without special tooling. A combined strategy—SLS for complex plastic parts and CNC for high‑precision metal parts—often delivers the best performance for demanding Rapid Prototyping projects.

SLS Rapid Prototyping is used in many industries that require a fast, flexible, and reliable way to transform ideas into real components.

Automotive engineers use SLS Rapid Prototyping to produce functional parts such as brackets, ducts, housings, and interior components for fit, assembly, and performance testing. SLS allows Rapid Prototyping of components that must withstand vibrations, temperature changes, and mechanical loads in real vehicle environments.

Because SLS Rapid Prototyping does not require molds, teams can update designs frequently and validate improvements quickly, which shortens development cycles.

In the medical field, SLS Rapid Prototyping supports patient‑specific devices, orthotics, ergonomic models, and components for medical equipment. Complex organic shapes can be produced with good accuracy, which is important for comfort and functionality.

SLS Rapid Prototyping also allows fast iterations, enabling doctors, designers, and engineers to collaborate and refine solutions for better patient outcomes before committing to large investments.

Designers in consumer electronics use SLS Rapid Prototyping to create enclosures, internal frames, and functional components for devices such as headphones, controllers, and smart home systems. They can test assembly, ergonomics, and thermal behavior with real materials.

Industrial equipment manufacturers rely on SLS Rapid Prototyping to develop jigs, fixtures, housings, and tooling for their production lines. This flexible approach keeps development and manufacturing agile and responsive to market changes.

Shangchen is a Chinese manufacturing factory that integrates Rapid Prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold production under one roof. SLS plays a strategic role in this ecosystem.

For overseas brands, wholesalers, and manufacturers, Shangchen can take a project from initial design to final production using a mix of processes. In the early Rapid Prototyping phase, SLS is used to produce functional prototypes and pilot batches without tooling. Engineers review customer designs, provide design‑for‑manufacturability feedback, and help choose the best process.

When parts printed by SLS Rapid Prototyping are approved, Shangchen can quickly transition to CNC machining, injection molding, or other volume production methods. This seamless transfer reduces risk, avoids rework, and ensures that the Rapid Prototyping results match the final production intent.

SLS Rapid Prototyping is not limited to one‑off parts. Shangchen can produce small batches of parts for market testing, functional pilot runs, or customized products. For some applications, SLS remains the most economical option even for ongoing low‑volume production.

By combining SLS Rapid Prototyping with in‑house machining and mold capabilities, Shangchen can offer tailored solutions for different stages of a product's life cycle—from initial concept to full mass production.

Optimizing design for SLS helps customers achieve better results in Rapid Prototyping and prepares the design for future production.

Each material has recommended minimum wall thicknesses and feature sizes. Designing thinner walls than recommended can lead to fragile sections or print failures, especially in Rapid Prototyping of functional components. Ensuring adequate thickness improves part strength and consistency.

Large variations in wall thickness can create internal stresses as parts cool, leading to warping or dimensional changes. When designing for SLS Rapid Prototyping, it is wise to maintain relatively uniform wall sections and apply gradual transitions where changes are necessary.

One of the most powerful aspects of SLS Rapid Prototyping is the ability to create lightweight structures. By hollowing out non‑critical areas or using lattice patterns, designers can reduce part weight and material usage while still maintaining adequate strength.

This approach is common in aerospace, automotive, and high‑performance consumer products, and it is increasingly used in Rapid Prototyping to explore innovative, lightweight designs.

SLS stands for Selective Laser Sintering, and it has become a cornerstone technology in modern Rapid Prototyping thanks to its ability to produce strong, complex, functional plastic parts without any tooling. It turns digital designs into physical components quickly and efficiently, enabling fast design iterations, realistic testing, and agile development cycles.

For international OEM customers, SLS Rapid Prototyping delivers robust engineering plastics, high design freedom, and cost‑effective production for small and medium volumes. When combined with other capabilities such as CNC machining, turning, sheet metal fabrication, and mold production, SLS helps create a complete pathway from first prototype to mass production.

As a comprehensive manufacturing partner, Shangchen uses SLS as a key part of its Rapid Prototyping service portfolio, helping global brands, wholesalers, and manufacturers reduce risk, accelerate time‑to‑market, and confidently move from concept to final product.

Contact us to get more information!

SLS stands for Selective Laser Sintering, a 3D printing technology widely used in Rapid Prototyping. It uses a laser to selectively fuse fine polymer powder into solid parts, layer by layer, based on a digital 3D model.

Because it uses engineering‑grade thermoplastics and requires no special tooling, SLS is ideal for Rapid Prototyping of functional components, assemblies, and small‑batch production parts.

While FDM is useful for basic, low‑cost Rapid Prototyping, SLS typically offers better mechanical properties, more uniform strength in all directions, and far greater design freedom. SLS does not require support structures, which allows complex geometries and internal features that are difficult to produce with FDM.

For professional OEM projects where durability and reliability are critical, SLS Rapid Prototyping is usually more suitable than simple FDM printing.

The most common SLS Rapid Prototyping materials are nylon‑based powders such as PA 11 and PA 12, as well as glass‑filled variants for higher stiffness and heat resistance. These materials offer excellent strength, toughness, and chemical resistance, making them suitable for real‑world testing and functional use.

New materials, including flexible polymers and high‑temperature engineering plastics, are continually being introduced, expanding the range of applications for SLS Rapid Prototyping.

SLS is ideal for Rapid Prototyping but is also widely used for low‑volume and bridge production. Since it does not require molds, it offers a fast and economical way to produce dozens or hundreds of parts while the final tooling is being developed.

Many companies use SLS Rapid Prototyping to launch products in smaller quantities, test market response, and refine designs before investing in high‑volume molds. For customized or niche products, SLS can even serve as a long‑term production method.

Lead time for SLS Rapid Prototyping depends on part size, complexity, quantity, and finishing requirements, but fully functional parts are often delivered within a few days after the 3D model is confirmed. The printing, cooling, and depowdering stages require several hours, and additional finishing can add some time.

Compared with traditional manufacturing that relies on molds and tooling, SLS Rapid Prototyping dramatically reduces development time, helping new products reach the market faster and with less risk.

1. https://sinterit.com/3d-printing-guide/3d-printing-technologies/what-is-sls-printing/

2. https://www.hubs.com/knowledge-base/what-is-sls-3d-printing/

3. https://xometry.pro/en-eu/articles/3d-printing-sls-overview/

4. https://www.hubs.com/knowledge-base/how-design-parts-sls-3d-printing/

5. https://www.lsrpf.com/zh-Hans/rapid-prototyping

6. https://www.lsrpf.com/zh-Hans

7. https://www.tsprototypes.com/cn/our-solutions/3d-printing/

8. https://xometry.pro/en/articles/3d-printing-sls-overview/

content is empty!