Views: 222 Author: Amanda Publish Time: 2026-01-24 Origin: Site

Content Menu

● Sweden's Advantage in On Demand 3D Printing

● What On Demand 3D Printing Manufacturers and Suppliers Offer

● Leading On Demand 3D Printing Manufacturers and Suppliers in Sweden

>> Enterprise‑Level Additive Manufacturing Providers

>> FDM‑Focused Business Services

>> Global On‑Demand Networks Serving Sweden

● Role of Chinese OEM Factories in Supporting Swedish 3D Printing

● Why Overseas Brands Choose Swedish On‑Demand Services

● Typical Workflow With On Demand 3D Printing Manufacturers and Suppliers

● Applications of On Demand 3D Printing in Sweden

● How to Select the Right Swedish On‑Demand Partner

● Strategic Benefits for OEM, Brands, and Wholesalers

● FAQ

>> 1. How mature is Sweden's additive manufacturing ecosystem?

>> 3. Can Swedish on‑demand providers handle both prototypes and production parts?

>> 4. How do Chinese OEM factories complement Sweden's 3D printing suppliers?

>> 5. Which industries most often use On Demand 3D Printing Manufacturers and Suppliers in Sweden?

On demand 3D printing manufacturers and suppliers in Sweden have become vital partners for European and global brands that need fast, flexible, and high‑quality additive manufacturing without building their own factories. For overseas OEM buyers, combining Swedish innovation in 3D printing with reliable Asian CNC machining and rapid prototyping support creates a powerful, cost‑effective supply chain.

Sweden is one of Europe's most innovative manufacturing hubs, with a large share of its economy driven by advanced industrial engineering, automation, and high‑value exports. The country was an early adopter of additive manufacturing, and national institutes and innovation centers have set up specialized programs to develop new 3D printing technologies, materials, and applications.

Metal additive manufacturing is a particular strength in Sweden. Local companies produce a significant portion of the global metal powders used in 3D printing, giving Swedish On Demand 3D Printing Manufacturers and Suppliers a stable, high‑quality material base. This ecosystem supports demanding applications in aerospace, energy, medical devices, and high‑performance industrial components where precision, reliability, and traceability are essential.

Government‑backed research projects and industry clusters connect universities, research institutes, and private companies. These networks help accelerate the commercialization of new 3D printing processes and materials, making Sweden an attractive destination for brands that want cutting‑edge additive manufacturing services backed by strong engineering culture.

On Demand 3D Printing Manufacturers and Suppliers in Sweden typically provide a full digital‑to‑physical workflow. Customers upload CAD files, receive quick online quotations, and confirm production through web platforms, which significantly shortens development cycles for prototypes and small batches. This digital model is ideal for overseas brands that need transparent pricing, predictable lead times, and easy project communication.

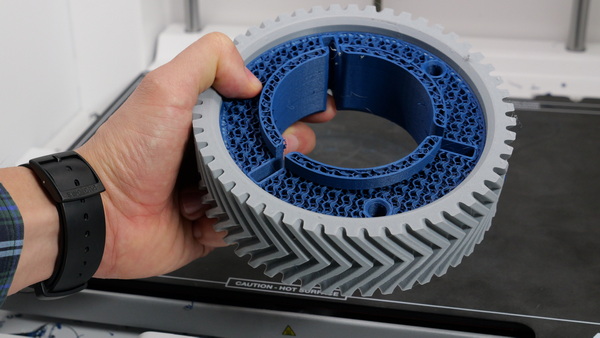

Most Swedish providers support widely used processes such as:

- Fused Deposition Modeling (FDM) for cost‑effective plastic parts and fixtures

- Selective Laser Sintering (SLS) for durable polymer components with good mechanical properties

- Stereolithography (SLA) for high‑detail, smooth‑surface prototypes and models

- Multi Jet Fusion (MJF) or similar powder‑bed technologies for functional end‑use parts

These service bureaus often integrate traditional manufacturing and finishing operations into the same workflow. Typical value‑added services include CNC milling, turning, drilling, surface polishing, bead blasting, anodizing, painting, and basic assembly. This allows OEM brands to source fully finished components from a single partner instead of coordinating multiple suppliers.

Dimensional accuracy and repeatability are also a key selling point. Swedish On Demand 3D Printing Manufacturers and Suppliers work with standardized quality procedures, calibration routines, and inspection tools. When needed, printed parts can be combined with high‑precision CNC machining to achieve the tolerances required in mechanical engineering, optics housings, and customized tooling.

Sweden hosts a growing group of specialist providers that focus on industrial‑grade on‑demand services for prototypes and production runs. Many of them serve both domestic customers and international OEM clients that value Scandinavian engineering and quality standards. Below are some representative types of service providers and what they bring to global buyers.

At the high end of the market, there are companies that position themselves as end‑to‑end suppliers of industrial additive manufacturing. These providers work with metals, technical polymers, and sometimes composites, using advanced 3D printing equipment suited for serial production and functional parts. Their “print on demand” model reduces the need for physical warehousing, since parts can be produced only when requested.

Such suppliers typically offer:

- Design for Additive Manufacturing (DfAM) consulting and topology optimization

- Simulation‑driven redesign of parts to reduce weight and increase performance

- Qualification and validation of parts for demanding applications

- Integration with CNC machining and quality inspection for complete assemblies

For overseas brands, this category of On Demand 3D Printing Manufacturers and Suppliers is ideal for high‑value, complex components that must meet strict industry standards, such as aerospace brackets, medical implants, or specialized power‑generation parts.

There is also a group of Swedish providers that focus primarily on FDM 3D printing for business users. These companies emphasize quick turnaround, predictable pricing, and straightforward online ordering for prototypes and small‑batch production in common engineering plastics. Clients typically upload STL or STEP files, select materials and layer heights, and receive quotations automatically before confirming production.

FDM‑focused services are well suited for:

- Functional prototypes and design verification

- Jigs, fixtures, and assembly aids for factory floors

- Housings, covers, and non‑critical mechanical parts

- Educational, architectural, and demonstration models

Because of their speed and flexibility, these providers play an important role in early design validation and internal tooling support. They fill a crucial niche in the broader ecosystem of On Demand 3D Printing Manufacturers and Suppliers by making 3D printing accessible to small and medium‑sized companies as well as large OEMs.

In addition to local firms, several international production networks include Swedish workshops and also serve Swedish customers through online platforms. These networks aggregate 3D printing and CNC machining capacity from multiple partners, enabling instant quotes, multiple materials, and geographically distributed production.

From the perspective of an overseas brand, such networks can:

- Offer quick access to On Demand 3D Printing Manufacturers and Suppliers in different regions

- Provide backup options if one production site is fully booked

- Combine 3D printing, CNC machining, sheet metal, and injection molding under one interface

- Simplify logistics by selecting the most suitable or closest manufacturing partner

These networks can complement Swedish providers and Asian OEM factories, giving buyers a flexible hybrid supply chain that balances speed, cost, and location.

While Sweden offers advanced design and additive manufacturing expertise, many global brands still rely on experienced Chinese OEM partners for cost‑optimized CNC machining, rapid prototyping, and mass production. Chinese factories specializing in high‑precision machining, plastic molding, metal stamping, and small‑batch runs often support European On Demand 3D Printing Manufacturers and Suppliers by taking over later‑stage industrialization and scaling.

A common workflow for international projects looks like this:

1. Early concept and design: Swedish On Demand 3D Printing Manufacturers and Suppliers create proof‑of‑concept models that allow design teams to test basic functionality and ergonomics.

2. Functional prototypes: More robust prototypes are printed using stronger polymers or metal additive manufacturing to validate performance and assembly.

3. Design freeze: After iterations, the final design is confirmed based on feedback from engineers, marketing teams, and end users.

4. Industrialization in China: The validated design, along with 3D files and technical drawings, is sent to a Chinese OEM factory for tooling design, mold fabrication, CNC programming, and pilot runs.

5. Mass production and continuous improvement: The OEM plant handles volume production, quality control, packaging, and logistics, while working closely with the brand to refine cost and performance.

This division of work allows Swedish partners to focus on innovation, design optimization, and early customer feedback, while Chinese OEM facilities provide the scale and cost efficiency required for global markets. Together, they form an integrated supply chain that serves brands in Europe, North America, and beyond.

For overseas OEM buyers, Sweden's On Demand 3D Printing Manufacturers and Suppliers offer several strategic benefits that go beyond simple part production.

Key advantages include:

- Engineering depth: Swedish providers often employ experienced mechanical engineers and designers who can support complex projects, not just print files “as is”.

- Quality and traceability: Strong quality systems, documentation, and process control are common expectations in the Swedish industrial environment.

- Innovation culture: Close links between universities, research centers, and industry support continuous innovation in materials, processes, and digital workflows.

- Sustainability focus: Many Swedish companies emphasize energy efficiency, material recycling, and low‑waste processes, which aligns with the ESG requirements of global brands.

When these on‑demand capabilities are integrated with global CNC machining and molding partners, brands gain an end‑to‑end supply chain from design to mass production. Swedish partners excel at engineering innovation and early‑stage development, while Chinese OEM factories provide stable, long‑term capacity with structured workflows from RFQ through prototyping, tooling, ramp‑up, and optimization.

To understand how cooperation usually works, it is helpful to look at a typical project flow when a foreign brand engages Swedish On Demand 3D Printing Manufacturers and Suppliers.

1. Project briefing and NDA

The client provides a high‑level description of the product, target volumes, application requirements, and any relevant standards or certifications. Confidentiality agreements are signed if needed.

2. File preparation and design consultation

CAD models are shared, and the Swedish provider may suggest design adjustments to better suit 3D printing, reduce supports, or improve strength and printability. For complex parts, a dedicated DfAM workshop can be organized.

3. Material and process selection

Together, the client and supplier choose suitable materials and processes based on mechanical requirements, temperature resistance, surface finish, and expected lifetime. Options often span engineering plastics, flexible materials, and metal alloys.

4. Quotation and scheduling

The provider generates a quote, lead time, and possible schedule for iterative prototype rounds. For urgent projects, express production may be available at a premium.

5. Prototype production and feedback

One or more prototype batches are produced. The customer tests form, fit, and function, then sends structured feedback and modification requests.

6. Pre‑production and documentation

Once the design is stable, the provider documents parameters, orientations, supports, and finishing steps, preparing for future repeat jobs or larger batches.

7. Transfer to mass production (if needed)

For high‑volume products, the validated design can be transferred to a Chinese OEM factory for tooling and mass production, while the Swedish partner remains involved for engineering support and future redesigns.

This structured approach improves communication, reduces errors, and shortens the path from initial idea to market‑ready products.

On Demand 3D Printing Manufacturers and Suppliers in Sweden support a wide range of industries and use cases. Some of the most common applications include:

- Aerospace and defense components such as lightweight brackets, ducting, and complex housings

- Medical devices, dental models, guides, and customized implants that benefit from patient‑specific design

- Energy and power‑generation parts where internal channels and complex shapes improve performance

- Robotics, automation, and industrial machinery parts with custom geometries and fast iteration cycles

- Automotive and motorsport prototypes, spare parts, and low‑volume performance components

- Consumer products, eyewear, and lifestyle goods where design differentiation and customization are critical

In many of these fields, the ability to produce complex geometries, lattice structures, and integrated features gives 3D printing a clear advantage over purely subtractive methods. Swedish providers often work closely with customers to capture these design benefits while keeping material and production costs under control.

For brands that want to work with On Demand 3D Printing Manufacturers and Suppliers in Sweden, choosing the right partner is a crucial decision. Some practical selection criteria include:

- Technical fit: Ensure the provider supports the processes and materials that match your application and performance needs.

- Industry experience: Look for experience in your sector (medical, aerospace, automotive, etc.) and ask for non‑confidential case studies or references.

- Capacity and scalability: Confirm that the supplier can handle both prototype volumes and potential scale‑up, either directly or via partner networks.

- Quality systems: Check certifications, inspection capabilities, and documentation practices to ensure compliance with your standards.

- Communication and language: Smooth communication in English, clear project updates, and reliable contacts are essential for overseas buyers.

- Integration with global supply chain: If you plan to transfer production to an OEM factory later, ask how the supplier handles data handover, tolerances, and documentation.

By carefully evaluating these points, brands can identify Swedish On Demand 3D Printing Manufacturers and Suppliers that align with their technical requirements, budget, and long‑term supply strategy.

For international OEMs, brand owners, and wholesalers, combining Swedish on‑demand 3D printing with Asian OEM production brings several strategic benefits:

- Faster product launches: Rapid prototyping and short‑run production in Sweden allow quicker design cycles and earlier market tests.

- Lower total cost: Early issues are solved on small batches before investing in full tooling, reducing the risk of expensive design changes later.

- Flexible inventory: On Demand 3D Printing Manufacturers and Suppliers can produce parts “just in time”, reducing stock and warehousing requirements in the target market.

- Localization: Swedish partners can help adapt products to local standards, preferences, or regulations, while Chinese OEM plants handle global volume.

- Long‑term collaboration: Once a workflow is established, the same network can be used for new projects, product updates, and special editions.

This model is especially effective for companies launching multiple product variants, test campaigns, or customized solutions for different regions.

On Demand 3D Printing Manufacturers and Suppliers in Sweden sit at the intersection of advanced metallurgy, innovative digital workflows, and strong industrial engineering traditions. They provide overseas brands with rapid access to high‑quality prototypes, functional parts, and small‑batch production, while supporting complex design optimization and rigorous quality requirements.

When Swedish on‑demand services are combined with experienced Chinese OEM machining and molding factories, brands gain a flexible, responsive, and cost‑efficient product development and production ecosystem from idea to mass‑produced components. This hybrid model reduces risk, shortens time‑to‑market, and enhances competitiveness for OEMs, wholesalers, and brand owners operating in global markets.

Contact us to get more information!

Sweden's additive manufacturing ecosystem is relatively mature and well supported by research institutes, universities, and industrial partners. Local companies are active in materials, process development, and on‑demand production services for domestic and international customers.

Swedish On Demand 3D Printing Manufacturers and Suppliers combine strong engineering expertise, consistent quality, and efficient digital workflows. Overseas brands appreciate the ability to collaborate closely on design, receive rapid prototypes, and rely on predictable lead times for small‑batch production.

Many Swedish providers can support both single prototypes and small‑ to medium‑volume production runs. By combining 3D printing with CNC machining, finishing, and assembly, they can deliver end‑use parts that meet demanding dimensional and performance requirements.

Chinese OEM factories specializing in CNC machining, molding, and stamping typically take over when volumes increase or when unit cost becomes critical. Swedish on‑demand suppliers focus on design, prototyping, and early validation, while Chinese plants handle tooling, mass production, and long‑term supply under strict quality control.

Industries such as aerospace, medical technology, energy, robotics, automotive, and industrial machinery frequently rely on Swedish on‑demand 3D printing. These sectors benefit from the ability to produce complex geometries, lightweight structures, and customized components quickly and reliably for both prototypes and specialized end‑use parts.

1. https://www.business-sweden.com/insights/articles/sweden-the-gateway-to-3d-printing-innovation/

2. https://printmaker3d.com

3. https://www.uneedprecisionmachine.com/china-oem-cnc-machining-plastic-silicone-and-metal-stamping-services-for-global-brands.htm

4. https://www.trade.gov/country-commercial-guides/sweden-advanced-manufacturing

5. https://www.top3d.se/en/

6. https://anebonmetal.com/top-10-rapid-prototyping-machine-manufacturers-in-china/

7. https://www.nextmsc.com/report/sweden-additive-manufacturing-market

8. https://www.hubs.com/3d-printing/sweden/

9. https://www.partmfg.com

10. https://www.ri.se/en/production-and-manufacturing/additive-manufacturing

content is empty!