Views: 222 Author: Amanda Publish Time: 2026-01-25 Origin: Site

Content Menu

● Why the Czech Republic Leads in On‑Demand 3D Printing

● Core Services Offered by On Demand 3D Printing Manufacturers and Suppliers

● Market Trends: From Rapid Prototyping to Digital Production

● How On Demand 3D Printing Fits into Cross‑Border Supply Chains

● Capabilities Typically Offered by Leading Providers

>> 3D Printing Technologies and Materials

>> CNC Machining, Sheet Metal, and Tooling

● Quality Systems and Engineering Support

● Digital Platforms and On‑Demand Ordering

● How Chinese Partners Like Shangchen Add Value

● Example Value Chain: From Concept to Mass Production

● Practical Tips for Selecting On Demand 3D Printing Manufacturers and Suppliers in Czech Republic

● Strategic Advantages for OEMs and Brands

● FAQ

>> 1. What are On Demand 3D Printing Manufacturers and Suppliers?

>> 2. Why choose Czech Republic for on demand 3D printing?

>> 3. How do Czech providers work with Chinese factories like Shangchen?

>> 4. What industries benefit most from on demand 3D printing in Czech Republic?

>> 5. How should an overseas OEM select the right partner?

The Czech Republic has become one of Central Europe's most dynamic hubs for on demand 3D printing manufacturers and suppliers, driven by its strong engineering heritage, export‑oriented economy, and rapid adoption of Industry 4.0 technologies. For global OEM brands, wholesalers, and production companies, partnering with flexible, digital‑ready manufacturers in this region can significantly reduce time‑to‑market and total cost per part.

The Czech Republic combines a long history in precision engineering with a fast‑growing additive manufacturing ecosystem that serves automotive, aerospace, electronics, and medical sectors. Demand for On Demand 3D Printing Manufacturers and Suppliers has risen sharply as companies shift from traditional workflows to highly customized, digital production.

Key drivers include:

- Strong industrial base in cities such as Prague, Brno, Ostrava, and Liberec, focused on advanced manufacturing and engineering services.

- Government and academic initiatives that support industrial 3D printing research and technology transfer to local companies.

- Export‑oriented manufacturers looking for partners that can deliver prototypes and small batches on tight deadlines with competitive pricing.

For international OEMs, this environment makes Czech On Demand 3D Printing Manufacturers and Suppliers ideal strategic partners for regional and global supply chains.

Most leading On Demand 3D Printing Manufacturers and Suppliers in the Czech Republic do far more than simply print parts; they integrate multiple technologies into a complete digital manufacturing workflow. This combination is particularly attractive for foreign brands that need one partner to manage the entire journey from concept to production.

Typical service stack:

- Industrial 3D printing (FDM/FFF, SLA/DLP, SLS, and metal additive manufacturing) for prototypes and functional parts.

- Rapid prototyping and design‑iteration services, often combined with engineering consultation and CAD optimization.

- CNC machining (3‑axis, 4‑axis, 5‑axis) for high‑precision metal and plastic components as a complement to additive manufacturing.

- Sheet metal fabrication, laser cutting, bending, and surface finishing for enclosures, brackets, and structural components.

- Injection molding and tooling support for customers who want to move from low‑volume on demand 3D printing to larger batch production.

This integrated model allows On Demand 3D Printing Manufacturers and Suppliers to support early concept models, engineering validation, pilot runs, and final mass production within a single managed workflow.

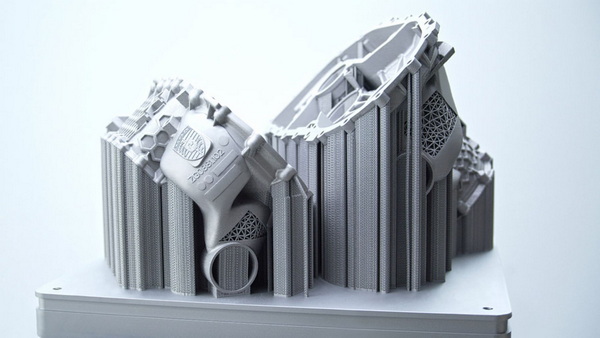

Across the Czech Republic, 3D printing is clearly shifting from a niche R&D tool to a core industrial technology. Companies now expect On Demand 3D Printing Manufacturers and Suppliers to deliver not only prototypes, but also scalable digital production capacity that can react quickly to fluctuating demand.

Current trends include:

- Increased customization: manufacturers use 3D printing to supply highly customized components, jigs, and fixtures tailored to each customer's process.

- Reduced lead times: by moving to additive workflows and shortening pre‑production administration, businesses cut product‑launch cycles from weeks to days.

- Integration of distributed print farms: networks of coordinated printers are used to prioritize jobs, manage capacity, and support repeat orders at scale.

- Wider material portfolios: the range of engineering polymers, composites, and metal powders continues to grow, enabling more end‑use applications.

For global customers, this means that Czech On Demand 3D Printing Manufacturers and Suppliers can reliably handle rolling orders, engineering changes, and urgent replacement parts without sacrificing quality or consistency.

Because the Czech Republic sits at the crossroads of EU logistics, it plays a natural role in pan‑European and global supply chains. Many local companies work closely with overseas factories, especially in China, to combine cost‑effective production with regional proximity and local technical support.

A typical cross‑border model looks like this:

- Design and rapid iteration are coordinated through digital platforms, allowing OEMs in Europe or North America to upload CAD files and receive instant feasibility checks and quotations.

- Prototypes, jigs, and low‑volume batches are produced by Czech On Demand 3D Printing Manufacturers and Suppliers to validate form, fit, and function with local engineering teams.

- Once designs are frozen, larger batch or precision production may be shifted to experienced partners in China to achieve substantial cost savings while maintaining engineering alignment.

For a Chinese rapid prototyping and CNC machining factory like Shangchen, this model is particularly effective: Czech partners handle local engineering and on‑demand 3D printing, while China‑based plants deliver high‑volume, cost‑optimized manufacturing and precision batch production.

To evaluate On Demand 3D Printing Manufacturers and Suppliers in the Czech Republic, international buyers usually focus on scope of capabilities, material options, quality systems, and digital integration. The most competitive providers share several important characteristics that make them attractive OEM partners.

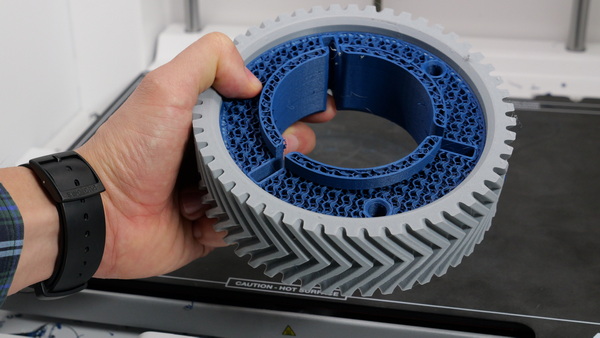

Top providers deploy a mix of polymer and metal technologies to address different mechanical, thermal, and aesthetic requirements. This gives OEMs flexibility to select the right balance of cost, strength, and surface finish for each application.

Common technologies include:

- FDM/FFF for durable prototypes, fixtures, and low‑cost functional parts.

- SLA/DLP for high‑detail models, elegant housings, and components that require smooth surfaces and fine resolution.

- SLS for robust nylon parts with complex geometries and good mechanical performance, often used for functional assemblies and lightweight structures.

- Industrial metal‑printing processes for high‑strength, high‑temperature components in aerospace, automotive, tooling, and medical devices.

Typical materials include ABS, PLA, PETG, PA, fiber‑reinforced polymers, engineering resins, flexible resins, and metal alloys such as aluminum, stainless steel, and tool steels. This breadth allows On Demand 3D Printing Manufacturers and Suppliers to support both prototype and end‑use applications across many industries.

Because many components still require tight tolerances, machined features, or metal housings, on‑demand partners often complement 3D printing with full CNC machining and sheet‑metal capabilities.

These services usually include:

- 3‑axis to 5‑axis CNC milling and turning for aluminum, steel, stainless steel, titanium, brass, copper, and engineering plastics.

- Precision lathe turning for shafts, bushings, pins, and rotationally symmetric components that must mate precisely with printed parts.

- Sheet‑metal cutting, bending, and welding for enclosures, brackets, mounting plates, and mechanical supports that interface with 3D printed elements.

- Mold making and tool fabrication for injection molding, pressure die casting, or over‑molding once production volumes justify tooling investment.

This hybrid approach ensures a smooth transition from 3D printed prototypes to precision‑machined or molded mass‑production components within a unified supply chain. It also allows Czech On Demand 3D Printing Manufacturers and Suppliers to serve customers who require both fast prototypes and long‑term volume production.

Modern OEMs expect more than just parts; they need reliable quality, repeatability, and technical guidance. The best On Demand 3D Printing Manufacturers and Suppliers in the Czech Republic invest heavily in quality systems and engineering support.

Important aspects include:

- Documented inspection procedures, including dimensional reports, first‑article inspection, and statistical process control for recurring parts.

- Material traceability for metals and engineering plastics, with certificates and batch documentation where required.

- Clear communication channels with English‑speaking project engineers who understand DFM (Design for Manufacturing) principles for both additive and subtractive processes.

- Ability to provide design suggestions, such as optimizing wall thickness, fillets, supports, and part orientation to improve print quality and reduce cost.

Together, these capabilities help overseas brands reduce risk, avoid redesign loops, and maintain consistent quality across multiple production runs and locations.

Digitalization is at the heart of the on‑demand model. Many Czech On Demand 3D Printing Manufacturers and Suppliers now operate online platforms that streamline the entire process from RFQ to delivery.

Typical features of these platforms include:

- Secure file‑upload portals that protect sensitive CAD data.

- Instant or rapid quotation tools that evaluate geometry, material selection, and production method.

- Automated manufacturability checks that flag thin walls, small features, or unsupported structures.

- Order‑tracking dashboards that provide visibility into production stages, expected shipping dates, and historical order data.

For overseas OEMs, this digital interface reduces communication barriers and makes it easy to coordinate complex projects, even when multiple technologies and materials are involved.

Shangchen, as a Chinese rapid prototyping and CNC machining factory, fits naturally into this evolving European on‑demand manufacturing landscape. While Czech On Demand 3D Printing Manufacturers and Suppliers provide localized, fast‑response services, Shangchen can extend the value chain by offering cost‑efficient production at scale.

Key contributions from a partner like Shangchen include:

- Rapid CNC machining of metals and plastics for validation builds, pilot runs, and long‑term production.

- Precision batch production with strict quality control, supporting everything from small series to mass‑manufactured components.

- Mold manufacturing and injection‑molding production to convert successful 3D‑printed prototypes into low‑cost, high‑volume products.

- Flexible OEM services tailored to brand owners, wholesalers, and product manufacturers who require confidentiality and stable long‑term supply.

By integrating with Czech on‑demand providers, Shangchen helps OEMs build a distributed yet cohesive manufacturing strategy that combines local speed with global cost optimization.

To understand how this ecosystem works in practice, consider a typical product‑development cycle managed jointly by Czech and Chinese partners. This model is increasingly common in automotive, industrial equipment, and consumer electronics.

Step‑by‑step flow:

1. Concept and CAD

The OEM uploads initial models to an online platform operated by a Czech on‑demand provider that specializes in rapid quoting and file validation. Engineers review geometry, identify critical dimensions, and suggest suitable materials and processes.

2. On Demand 3D Printing Prototypes

The local team produces concept and functional prototypes using suitable technologies. SLA parts may be used for aesthetic review and ergonomic testing, SLS for functional testing of assemblies, and FDM for quick internal iterations.

3. Design Optimization

Engineering feedback from testing leads to design optimizations. Wall thickness, ribs, fillets, and tolerances are refined to support both additive production and later CNC machining or molding. Problem areas discovered in the 3D printed parts are resolved before committing to tooling.

4. Pre‑Production and Low‑Volume Orders

Czech On Demand 3D Printing Manufacturers and Suppliers produce pre‑series batches and pilot runs. These parts are often used for certification tests, beta‑user trials, and initial market launches. Minor design changes can still be accommodated quickly at this stage.

5. Tooling and Mass Production

Once the design is stable, tooling and large‑volume production shift to experienced factories such as Shangchen. High‑precision CNC machining, mold manufacturing, die casting, and batch production lower the cost per unit while keeping the validated design intact.

6. After‑Market and Spare Parts

For spare parts and aftermarket components, On Demand 3D Printing Manufacturers and Suppliers in the Czech Republic can continue to deliver small batches or one‑off parts without requiring large inventory. This combination of local 3D printing and offshore mass production gives OEMs long‑term flexibility.

This workflow allows OEMs to compress development cycles, reduce total cost, and maintain a single coherent digital thread from the first 3D printed prototype to long‑term mass production.

When selecting On Demand 3D Printing Manufacturers and Suppliers in the Czech Republic, overseas brands should follow a structured evaluation process. A thoughtful selection early in the project lifecycle can prevent performance issues and simplify later scaling.

Key evaluation points:

- Technical breadth

Confirm that the provider offers multiple 3D printing technologies, a variety of materials, and at least basic CNC machining and sheet‑metal services. This ensures that the partner can support both prototype and production stages.

- Quality and certifications

Check whether the company follows ISO‑style quality systems, uses calibrated measurement tools, and provides inspection reports on request. For demanding sectors such as automotive or medical, related certifications are a valuable signal.

- Lead time and capacity

Ask about standard lead times for prototypes, small batches, and repeat orders. Providers with print farms, flexible shifts, and robust planning can respond faster to urgent projects.

- Communication and engineering support

English‑speaking project managers and engineers are essential for smooth collaboration. Clear responses to DFM questions, tolerance discussions, and material trade‑offs indicate a mature technical culture.

- Integration with global partners

For cost‑sensitive projects, give preference to On Demand 3D Printing Manufacturers and Suppliers that already cooperate with recognized Chinese factories for volume production, mold making, and batch machining.

By following these guidelines, OEMs can build a reliable on‑demand manufacturing network anchored in the Czech Republic and extended through partners like Shangchen.

Working with On Demand 3D Printing Manufacturers and Suppliers in the Czech Republic provides several strategic advantages for brand owners and wholesalers.

Key benefits:

- Faster prototyping and validation reduce time‑to‑market and help companies launch products ahead of competitors.

- Lower upfront investment thanks to on‑demand ordering and the ability to start with 3D printed parts before investing in tooling.

- Greater design freedom and customization, supporting limited editions and tailored products without prohibitive costs.

- Risk reduction through digital inventory and the ability to produce spare parts only when required.

- Improved resilience by combining local EU production with offshore high‑volume capacity in countries such as China.

By carefully combining Czech on‑demand providers with Chinese OEM partners, companies can design a resilient production strategy that remains competitive even in volatile markets.

The Czech Republic has clearly emerged as a strategic center for On Demand 3D Printing Manufacturers and Suppliers, combining advanced additive technologies, a strong engineering culture, and excellent logistics within the EU. For international OEMs and wholesalers, collaboration between Czech on‑demand providers and Chinese precision factories such as Shangchen creates a powerful blend of speed, flexibility, and cost‑effective production. By leveraging 3D printing, CNC machining, sheet‑metal fabrication, and tooling within one integrated supply chain, brands can shorten development cycles, accelerate market entry, and maintain consistent quality from early prototype to mass‑production components.

Contact us to get more information!

On Demand 3D Printing Manufacturers and Suppliers are service providers that offer flexible, digitally managed 3D printing and related manufacturing services, usually with no minimum order quantity. They allow customers to upload designs online, receive quick quotations, and order prototypes or production parts as needed rather than committing to large batches.

The Czech Republic combines advanced industrial 3D‑printing expertise with a strong base in automotive and engineering, making it ideal for complex technical components. Its central European location and export focus also support fast logistics and close collaboration with EU and global customers.

Czech On Demand 3D Printing Manufacturers and Suppliers typically handle rapid prototyping, low‑volume batches, and local engineering support for clients across Europe. Once designs stabilize, larger volumes and tooling projects are often produced by experienced Chinese partners such as Shangchen, which specialize in CNC machining, sheet‑metal fabrication, and precision batch production.

Industries such as automotive, aerospace, electronics, medical devices, industrial equipment, and consumer goods are among the leading adopters of on‑demand 3D printing in the Czech Republic. These sectors rely on rapid prototyping, lightweight structures, and customized parts that are well suited to additive manufacturing.

Overseas OEMs should evaluate On Demand 3D Printing Manufacturers and Suppliers based on technology range, material options, quality systems, lead times, pricing transparency, and integration with global production partners. It is also important to confirm that they can support the entire lifecycle from prototype to tooling and mass production, ideally with coordinated partners in regions such as China.

1. https://20countries.com/blog/3d-printing-services-in-the-czech-republic/

2. https://new.cxi.tul.cz/en/event/392/detail

3. https://cxi.tul.cz/novinky/392/detail

4. https://www.3dees.cz/en/custom-3d-printing

5. https://prodimode.com/cnc-machining-in-czechia-ustecky-kraj/

6. https://prodimode.com/cnc-machining-in-czechia-zlinsky-kraj/

7. https://compotech.com/3d-printing-farm/

8. https://www.zintilon.com/cnc-machining-service/cnc-machining-services-prague/

9. https://ensun.io/search/print-on-demand-pod/czechia

10. https://dyemansion.com/partners/

content is empty!