Views: 222 Author: Amanda Publish Time: 2025-10-11 Origin: Site

Content Menu

● Introduction to 3D Print Prototyping in 2025

● Shangchen: Premier 3D Print Prototype Manufacturer in China

>> Core Capabilities of Shangchen

>> Technological Edge and Quality Control

● Fathom: Expert in Functional 3D Printing Prototypes

● 3D Systems Corporation: Pioneers in 3D Printing Innovation

>> Key Offerings from 3D Systems

● Advantages of Trusted 3D Print Prototype Manufacturers

● Emerging Trends Impacting 3D Print Prototype Manufacturing in 2025

>> Automation and Smart Manufacturing

>> Expansion of Material Choices

>> Hybrid Manufacturing Approaches

● FAQ

>> 1. What materials are commonly used for 3D print prototypes?

>> 2. How accurate are 3D print prototypes?

>> 3. Can 3D printed prototypes be used for batch production?

>> 4. How fast can I get a 3D print prototype?

>> 5. What industries benefit most from 3D print prototyping services?

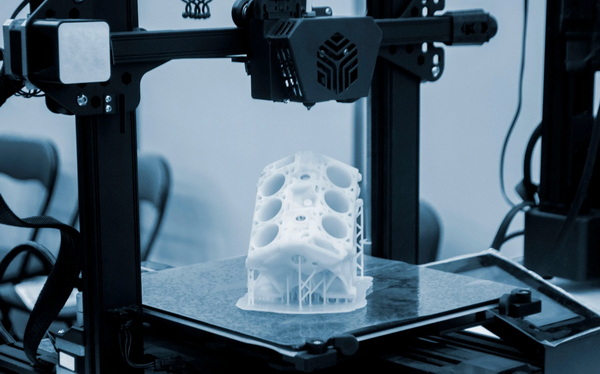

3D print prototypetechnology is revolutionizing product development, enabling fast, precise, and cost-effective creation of models and functional parts across industries. As we look to 2025, selecting a top-tier 3D print prototype manufacturer is key for brands, wholesalers, and manufacturers seeking reliable OEM services that combine innovation with quality. This article showcases the leading manufacturers in 3D print prototyping this year, headlined by Shangchen, a distinguished Chinese factory specialized in rapid prototyping, CNC machining, sheet metal fabrication, 3D printing services, and mold production.

Shangchen leads the list with its comprehensive and advanced manufacturing services tailored for global OEM clients. Based in Dongguan, China, the company integrates rapid plastic prototyping, CNC machining, sheet metal fabrication, and high-precision batch production all under one roof, providing seamless OEM solutions for various sectors including automotive, medical devices, electronics, and consumer appliances.

- 3D Print Prototype Services: Utilizes cutting-edge additive manufacturing to produce accurate prototypes with diverse materials such as plastics (PMMA, PC, PA, ABS) and metals (stainless steel, aluminum, brass) with precision tolerances as tight as ±0.005mm.

- CNC Machining and Sheet Metal Fabrication: Complements 3D printing with high-precision CNC lathe turning, milling, drilling, and stamping, enhancing prototype quality and enabling functional batch production.

- Material Versatility: Supports a wide range of materials including stainless steel grades (SS316, SS304), aluminum alloys (6061, 7075), plastics (Nylon, PEEK), and specialty metals.

- One-Stop OEM Manufacturing: Delivers turnkey solutions from concept through to finished prototypes, including surface treatments like anodizing, plating, polishing, and heat treatments.

Shangchen employs advanced metrology and quality control systems such as Coordinate Measuring Machines (CMM), HandySCAN 3D scanners, and optical projectors to ensure each 3D print prototype meets stringent quality standards. Their workflow adheres to ISO 9001 and ISO 27001 standards, guaranteeing reliability, confidentiality, and consistent excellence. This commitment to quality control allows them to deliver prototypes with extreme accuracy, making them a trusted partner for high-stakes projects.

- Competitive pricing with discount offers for first orders and free sample provisions.

- Fast lead times averaging 3-7 days for samples and 12-45 days for bulk orders.

- Robust after-sales service with dedicated customer support ensuring client satisfaction.

- Environmentally conscious manufacturing processes blending advanced CNC machining and smart manufacturing technologies.

Shangchen's comprehensive service model not only produces prototypes but supports clients throughout the product development lifecycle, from initial concept design assistance to final prototype delivery.

Fathom is a specialized 3D print prototype manufacturer that excels in producing functional prototypes using a broad range of materials and technologies. Their in-house rapid prototyping team combines additive manufacturing with fiberglass reinforcement and precision CNC machining to create prototypes suitable for demanding industries such as automotive, aerospace, and military applications.

- Wide material selection and the ability to handle complex geometry.

- Emphasis on functional testing prototypes that simulate real-use conditions.

- Collaboration with clients to tailor prototypes exactly to specifications, enhancing product validation processes.

- Integration of finishing processes like painting, sanding, and polishing to improve prototype aesthetics and durability.

Fathom's dedication to innovation and quality makes it an excellent choice for companies requiring prototypes with both visual appeal and functional integrity.

3D Systems Corporation is a longstanding leader in the field of additive manufacturing, offering technologies such as stereolithography (SLA) and selective laser sintering (SLS). Their consulting group works closely with clients, including those from healthcare, automotive, and aerospace industries, to adopt 3D printing technologies in their prototyping workflows.

- Advanced SLA and SLS processes capable of producing prototypes with fine details and excellent surface finishes.

- Engineering-grade materials that allow prototypes to be used for functional and performance testing.

- Expertise in design for additive manufacturing (DfAM) to optimize prototypes for cost, speed, and function.

- On-demand 3D printing services with quick turnaround and global logistics support.

Their comprehensive suite of services enables clients to streamline product development and accelerate market entry.

Choosing reputable 3D print prototype manufacturers offers several key advantages that contribute to the success of product development projects:

- Rapid Turnaround: Top manufacturers provide accelerated production timelines that significantly reduce the time from design to physical model.

- High Precision: Tight dimensional tolerances ensure prototypes accurately represent final products, crucial for fit, assembly, and functional testing.

- Material Flexibility: The ability to prototype using a diverse array of plastics, metals, and composite materials allows manufacturers to match prototype properties closely to end-use requirements.

- Integrated Services: Many leading companies offer complementary CNC machining, finishing, and assembly options, allowing seamless progression from prototype to production.

- Global Reach and Reliability: Worldwide clients benefit from consistent quality management, intellectual property safeguards, and efficient supply chains.

Manufacturers are increasingly integrating automation technologies and smart manufacturing systems into their operations. These upgrades boost efficiency, minimize human error, and ensure consistent quality control — especially in high-volume prototype batch production.

Environmental considerations are gaining momentum with protocols to reduce waste and energy consumption. Many manufacturers, including Shangchen, are implementing greener materials and eco-friendly processes that lower the environmental footprint of prototyping activities.

The continuous development of new materials, such as bio-compatible polymers and lightweight metal alloys, empowers engineers to expand the application scope of 3D print prototypes, from medical devices to aerospace components requiring specialized properties.

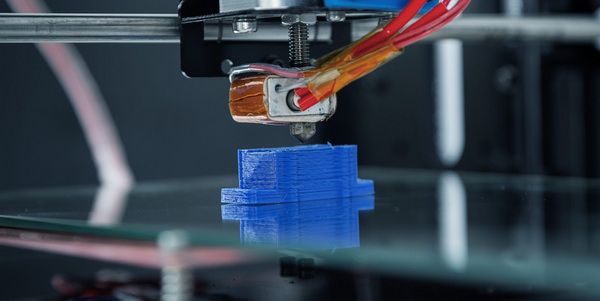

Combining additive and subtractive manufacturing methods, such as 3D printing followed by precision CNC machining, is becoming the norm for producing prototypes that require functional accuracy, mechanical strength, and impeccable surface finishes.

Selecting the right 3D print prototype manufacturer is vital for accelerating product development, ensuring design accuracy, and controlling costs. Shangchen stands out in 2025 as a premier choice, offering an integrated suite of services from 3D printing and CNC machining to sheet metal fabrication and mold production. Its advanced technologies, stringent quality control, material versatility, and client-centered approach make it a reliable OEM partner for diverse industries worldwide. Alongside reputable names like Fathom and 3D Systems Corporation, Shangchen exemplifies the innovation and quality leadership that define the top manufacturers in the 3D print prototype landscape today and beyond.

3D print prototypes commonly use plastics such as ABS, Nylon, PMMA, and engineering-grade polymers. Metals like stainless steel, aluminum, and brass are also used for manufacturing durable and functional prototypes that simulate end-use conditions.

Top manufacturers achieve precision tolerances as tight as ±0.005mm, ensuring prototypes closely replicate the dimensions and features of final production parts.

Yes, many manufacturers integrate CNC machining with 3D printing to support small to medium batch production runs, delivering consistent quality and accelerated manufacturing cycles.

Typical lead times for prototype samples range from 3 to 7 working days. Bulk orders generally take between 12 and 45 days, depending on complexity and volume.

Industries such as automotive, aerospace, medical devices, electronics, consumer goods, and architecture greatly benefit from rapid prototyping, receiving advantages in design flexibility and faster market entry.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product