Views: 222 Author: Amanda Publish Time: 2025-10-19 Origin: Site

Content Menu

● What is Vacuum Mold Casting?

>> How It Differs from Traditional Casting

● The Benefits of Vacuum Mold Casting in 2025

>> Superior Precision and Quality

>> Reduced Defects and Greater Reliability

>> Flexibility Across Materials

● Technical Components and Process Details

>> Vacuum Chamber and Pump Systems

● Step-By-Step Vacuum Mold Casting Process

● Applications Across Industries

>> Electronics and Consumer Products

● Why Choose Shangchen for Vacuum Mold Casting

>> Industry Experience and Expertise

>> Quality Control and Certification

>> Customer Support and OEM Services

>> Fast Delivery and Global Reach

● Challenges and Practical Considerations

● Innovations Shaping the Future

>> Automation and Smart Manufacturing

>> Sustainable Production Practices

>> Faster Mold Production via Additive Manufacturing

● FAQ

>> 1. What metals are commonly used in vacuum mold casting?

>> 2. How does vacuum mold casting improve part surface finish?

>> 3. Can vacuum mold casting be used for large components?

>> 4. What are the main advantages over traditional sand casting?

>> 5. How long does it usually take to produce a part using vacuum mold casting?

In the rapidly evolving landscape of precision manufacturing, Vacuum Mold Casting has emerged as a vital technique for producing high-quality, complex metal components with superior surface finishes and mechanical properties. As industries from aerospace to automotive increasingly demand intricate, durable parts, the role of vacuum mold casting services becomes even more critical in 2025.

This comprehensive guide explores the latest advancements in vacuum mold casting technology, how leading service providers like Shangchen (sc-rapidmanufacturing.com) are innovating, and why foreign brands and manufacturers should consider this method for their production needs. Throughout the article, we incorporate detailed descriptions of the process, its benefits, and industry applications to provide a clear understanding of why vacuum mold casting is a preferred choice in modern manufacturing.

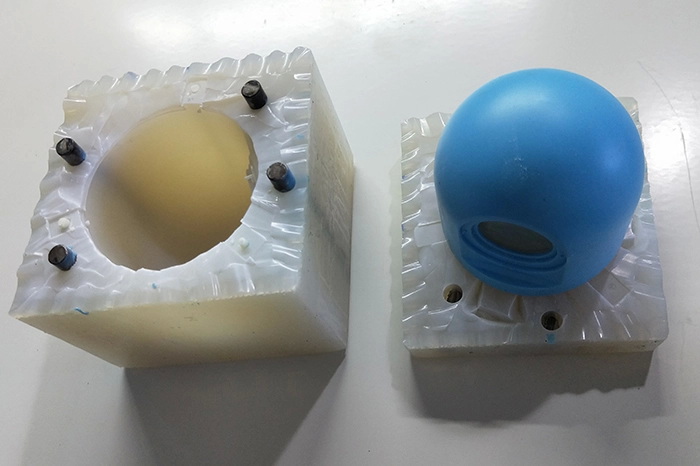

Vacuum mold casting is a manufacturing process where molten metal is poured into a mold under vacuum conditions. By eliminating air and other gases, vacuum mold casting produces parts with minimal porosity, superior surface finish, and higher dimensional accuracy compared to traditional casting methods.

This process is especially useful for producing components that require tight tolerances and reliable mechanical properties. Vacuum conditions reduce turbulence during metal flow, which helps maintain the integrity of the liquid metal as it fills the mold cavity.

Compared with traditional casting techniques, vacuum mold casting significantly reduces common defects such as gas porosity and shrinkage cavities. The enhanced mold filling under vacuum leads to improved metal density and a smoother final product surface.

Traditional casting methods often allow trapped air to form bubbles inside the molten metal, weakening the structure and requiring more post-production work to refine. Vacuum molding systematically reduces these issues, making it ideal for industries where product perfection is essential.

Vacuum mold casting allows for exceptional precision, making it perfect for parts with complex designs and fine details. The vacuum environment helps in achieving dimensional accuracies that surpass many other casting methods.

By controlling the environment within the mold to exclude oxygen and moisture, vacuum casting prevents oxidation and gas entrapment. This decreases the likelihood of micro-cracks, porosity, and other structural defects, resulting in highly durable parts.

This method produces parts with smoother surfaces, reducing or often eliminating further finishing processes such as grinding or polishing. This translates into faster production cycles and lower costs, especially for components that require a visually perfect finish.

Although initial costs for vacuum mold casting setups may be higher than conventional methods, savings accrue in reduced waste, lower scrap rates, less reworking, and shorter finishing times. Hence, it presents a cost-effective solution for medium and large-scale productions involving precision parts.

Vacuum mold casting is applicable with a broad range of metals, including aluminum, magnesium, copper, and titanium. This compatibility supports its use in diverse manufacturing sectors with distinct material requirements.

The heart of vacuum mold casting is the vacuum chamber that houses the mold during casting. High-powered vacuum pumps evacuate air to create a low-pressure environment, essential for controlling the metal flow and preventing contamination.

Molds are designed using computer-aided design (CAD) software for maximum accuracy and detail reproduction. Modern manufacturing of molds involves CNC machining or even 3D printing technologies, which allow rapid and precise mold creation.

The process includes advanced sensors and automated controls to monitor vacuum levels, temperature, and flow rates continuously. This system ensures consistent production quality, minimizes human error, and enables traceability.

1. Design and Mold Fabrication: Based on the product specifications, engineers develop molds with detailed features to match the final part design exactly.

2. Mold Preparation: The assembled mold is thoroughly cleaned and coated if necessary to aid in metal flow and part release.

3. Vacuum Chamber Loading: The mold is tightly sealed inside the vacuum chamber.

4. Air Evacuation: Pumps create a vacuum to remove air and gases within the chamber and mold cavity.

5. Metal Melting and Pouring: The metal is melted in a furnace and poured into the mold under controlled vacuum conditions.

6. Solidification and Cooling: The metal cools inside the mold while vacuum conditions control unwanted gas and defects.

7. Demolding and Finishing: After solidification, the part is removed for inspection and minimal finishing.

Parts like turbine blades and engine components require both precision and durability. Vacuum mold casting's ability to reduce defects helps meet the strict certification and performance standards demanded in aerospace manufacturing.

Vacuum mold casting plays a crucial role in producing lightweight engine blocks, transmission housings, and other critical moving parts that benefit from the process's strength and high dimensional accuracy.

Medical implants and surgical tools depend on vacuum mold casting to produce biocompatible metals with smooth surfaces and consistent mechanical properties.

The process accommodates tiny, complex parts used in electronics housings and custom-designed consumer products needing fine details and perfect finishes.

Shangchen has over a decade of experience in Rapid prototyping, CNC machining services, and precision batch production. Their knowledge in combining traditional craftsmanship with modern technology ensures quality output consistently.

Shangchen utilizes top-of-the-line vacuum casting chambers, CNC machining centers, and 3D printing systems to meet diverse manufacturing needs with speed and accuracy.

Rigorous inspection protocols, including dimensional measurement and material testing, ensure every part complies with international standards before shipment.

Offering tailored OEM solutions to foreign brands, wholesalers, and manufacturers, Shangchen guarantees flexible communication and customized production batches.

With streamlined logistics and efficient production timelines, Shangchen supports clients worldwide with timely delivery and comprehensive after-sales service.

Though advantageous, vacuum mold casting involves specific challenges:

- Higher Initial Setup Cost: Equipment procurement, mold fabrication, and skilled labor investment require upfront capital.

- Complex Process Control: Maintaining ideal vacuum pressure and temperature needs continuous monitoring and expertise.

- Material and Size Constraints: Extremely large components or certain reactive metals may not be suitable without additional process modifications.

- Limited Post-Process Flexibility: Some parts may require secondary machining for complex features not achievable in casting alone.

Integration of IoT devices and real-time sensors allows predictive maintenance, quality control, and efficient process adjustments, minimizing downtime and scrap.

New alloys designed specifically for vacuum casting bring enhanced strength, corrosion resistance, and manufacturability.

Improvements in energy efficiency and recyclable mold materials contribute to reducing vacuum mold casting's environmental footprint.

3D printing molds cut lead times dramatically, enabling more rapid prototyping and quicker design iterations.

Vacuum mold casting stands at the forefront of precision manufacturing in 2025, delivering parts with outstanding accuracy, durability, and finish quality. As industries demand ever tighter tolerances and reliable output, this technology offers a transformative solution. Companies like Shangchen harness innovations in vacuum casting equipment, automation, and custom service to meet international OEM requirements.

For manufacturers aiming to enhance their production capabilities while reducing costs related to defects and post-processing, vacuum mold casting is an indispensable technology. Embracing this process ensures products meet the high standards of today's competitive markets with efficiency and consistency.

Vacuum mold casting commonly uses aluminum, magnesium, copper, titanium, and various metal alloys because these metals have suitable melting points and cast well under vacuum conditions.

By evacuating air and gases during casting, the process prevents oxidation and gas entrapment, resulting in smoother, more defect-free surfaces that often need minimal finishing.

While generally suited for medium and smaller parts, some large components can be cast with specialized equipment, but this often requires more complex setups and longer cycle times.

Vacuum mold casting significantly reduces porosity, improves mechanical strength, enhances surface quality, and achieves higher dimensional precision compared to traditional sand casting.

Depending on part complexity and batch size, prototype parts can be produced within days, while small quantity production typically takes one to two weeks including mold preparation.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam