Views: 222 Author: Amanda Publish Time: 2025-10-18 Origin: Site

Content Menu

● Understanding Vacuum Mold Casting

● Detailed Comparison of Vacuum Mold Casting vs. 3D Printing

>> Surface Finish and Dimensional Accuracy

>> Design Complexity and Flexibility

● Advantages of Vacuum Mold Casting

● When to Choose Vacuum Mold Casting?

● Frequently Asked Questions (FAQ)

>> 1. What is the typical lead time for vacuum mold casting?

>> 2. How many parts can be produced from one silicone mold?

>> 3. Can vacuum mold casting replicate complex geometries?

>> 4. Does vacuum casting require post-processing?

>> 5. Which method offers better material properties?

In the rapidly evolving manufacturing industry, rapid prototyping is indispensable for converting innovative ideas into tangible products efficiently. For manufacturers and brands aiming to quickly develop prototypes or small batch productions, choosing the right rapid prototyping method is crucial to balancing cost, quality, and turnaround time.

At Shangchen, a leading factory specialized in fast prototype design, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing services, and mold manufacturing, the choice between Vacuum Mold Casting and 3D Printing often arises. Both are widely used in OEM services for foreign brands, wholesalers, and manufacturers worldwide due to their unique advantages in product development.

This article provides an in-depth comparison of vacuum mold casting versus 3D printing, weighing their pros and cons to guide you in selecting the best prototyping approach tailored to your project requirements.

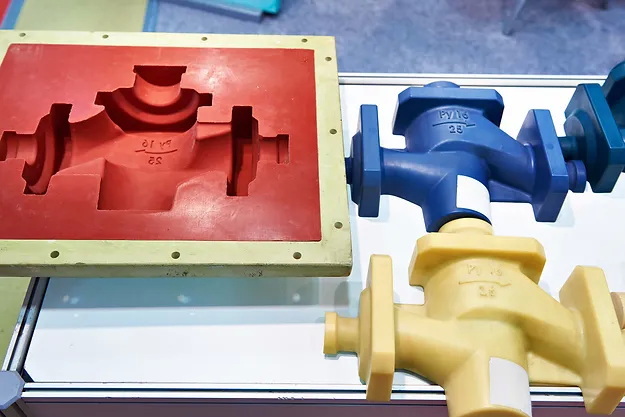

Vacuum Mold Casting, also known simply as vacuum casting, involves creating silicone molds from a master pattern (typically produced by 3D printing or CNC machining). Liquid resin or polyurethane is poured into the molds inside a vacuum chamber where air bubbles are eliminated, ensuring a smooth, accurate replication of the master pattern's details.

Key elements of vacuum mold casting include:

- Silicone molds that are flexible and reusable for limited production runs (usually up to 20–30 parts per mold).

- Use of vacuum pressure to remove trapped air, enhancing the quality of the cast.

- Ability to replicate fine surface details and tight dimensional tolerances.

- Cost-effective tooling compared to injection molding, making it suitable for low to medium batch production.

- Availability of a variety of resins that mimic properties of different plastics and elastomers.

Vacuum casting is ideal for producing functional prototypes and limited production parts with a high-quality finish, closely resembling injection-molded parts without the high costs.

3D Printing, or additive manufacturing, builds objects directly from digital 3D models layer by layer. It does not require tooling or molds, enabling complex geometries and rapid design changes to be realized quickly.

There are several 3D printing technologies used in prototyping, including:

- Stereolithography (SLA), known for high detail and surface finish.

- Fused Deposition Modeling (FDM), popular for cost-effective prototypes.

- Selective Laser Sintering (SLS), which uses powdered materials for durable parts.

Advantages of 3D printing include:

- No tooling costs or molds required, making it perfect for rapid iterations.

- Ability to produce highly complex and customized designs that would be difficult or impossible with traditional molding.

- Faster turnaround for one-off or small batch prototypes, often within hours or days.

- Wide range of material options, including plastics, composites, and metals.

However, 3D printing typically produces parts with visible layer lines which may require post-processing, and mechanical properties can be anisotropic due to the layered build process.

- Vacuum Mold Casting incurs upfront costs for silicone mold creation but offers a lower cost per part in small to medium batches (typically 5 to 100+ parts). It becomes more economical than 3D printing when producing multiple copies because the mold is reusable.

- 3D Printing eliminates tooling costs entirely, making it more cost-effective for one-off prototypes or very low volume production. However, the cost per part remains relatively high with increasing volume compared to vacuum casting.

- 3D Printing typically offers faster turnaround for single parts or small batches, completing prints within hours or a few days depending on complexity.

- Vacuum Mold Casting requires time to make silicone molds from the master pattern, taking about 10 to 15 days total (including mold preparation and curing), but subsequent parts can be cast faster.

- Vacuum mold casting excels in producing parts with smooth surface finishes, tight tolerances (±0.05 mm), and high replication fidelity of master model details.

- 3D printed parts often exhibit surface textures and layer lines that require additional finishing such as sanding or painting to achieve smoothness.

- 3D printing supports complex geometries, intricate internal features, and quick modifications without additional tooling.

- Vacuum casting allows some design flexibility, including undercuts and varying thickness, but is limited to the shapes producible by the silicone mold.

- Vacuum casting uses polyurethane resins that can be formulated to mimic various plastics and elastomers with strong, uniform mechanical properties.

- 3D printing offers a broader material palette, including thermoplastics, photopolymers, and metals, but printed parts may have anisotropic strength and inferior chemical resistance in some cases.

- Vacuum mold casting is optimal for short to medium production runs (5 to about 30 pieces per mold), bridging the gap between rapid prototyping and low-volume manufacturing.

- 3D printing excels for prototypes, custom pieces, and very low volume batches but is less efficient and more expensive for larger production due to longer print times per unit.

- Cost-Effective Tooling: Silicone molds are cheaper and easier to create than traditional injection molds.

- High Fidelity and Finish: Produces smooth, detailed parts identical to the master pattern, ideal for presentation models and functional testing.

- Mechanical Properties: Cast parts can closely replicate the strength and flexibility of various plastics.

- Versatile Materials: Supports multi-material casting, including colored or transparent resins.

- Repeatability: Consistent part quality over short batch runs.

- No Tooling Required: Direct from CAD file to part, enabling rapid changes without extra cost.

- Design Freedom: Can create highly complex, customized parts with internal structures.

- Speed for Single Units: Best suited for quick prototype iteration cycles.

- Material Versatility: Wide range of material types and colors available depending on printer technology.

- When you need high-quality prototypes or small batches with excellent surface finish and dimensional accuracy.

- If the project involves functional testing requiring realistic material properties.

- When the budget allows some upfront tooling costs to reduce per-part cost on multiple copies.

- For parts that resemble injection molded products but in low volumes.

- For rapid prototyping requiring quick design iterations or very low volume production.

- If the design involves complex shapes or internal features that cannot be molded easily.

- When customization or one-off parts are needed without additional tooling expenses.

- When testing form, fit, or functionality rapidly without prioritizing surface finish or mechanical uniformity.

Both Vacuum Mold Casting and 3D Printing serve essential roles in rapid prototyping and low-volume production, each with distinct advantages.

Vacuum mold casting offers superior surface finish, accurate detail replication, and strong material properties ideal for small batch production and presentation prototypes. Although it involves mold preparation time and some upfront cost, it becomes more economical as quantities increase.

3D printing offers unparalleled design freedom, extremely fast iteration speeds, and no tooling cost, making it perfect for fast one-off prototypes or complex geometries. However, surface finish and mechanical consistency may require additional post-processing.

For companies like Shangchen providing comprehensive OEM services from prototype to production, using these technologies complementarily allows meeting diverse customer needs effectively. Understanding your project's priorities will guide you to select the best rapid prototyping method and accelerate your product development cycle with confidence.

Vacuum mold casting lead time ranges from 10 to 15 days, including creating the silicone mold from the master pattern and casting the parts.

Usually, one silicone mold can produce approximately 20 to 30 good quality parts before it degrades and requires replacement.

Vacuum casting supports some complex features such as undercuts and variable thickness, but highly intricate internal geometries are challenging; here, 3D printing is better suited.

Vacuum cast parts generally require minimal finishing because of their excellent surface finish, though minor trimming or painting may occasionally be needed.

Vacuum casting offers stronger, isotropic mechanical properties with a wide range of resin options, whereas 3D printed parts may be mechanically anisotropic and material choice depends on printer technology.

[1](https://www.makerverse.com/resources/casting/polymer-3d-printing-vs-vacuum-casting/)

[2](https://www.unionfab.com/blog/2023/09/3d-printing-vs-cnc-vs-vacuum-casting)

[3](https://jlc3dp.com/blog/examining-and-differentiating-vacuum-casting-3d-printing-and-injection-moulding)

[4](https://ecoreprap.com/blog/vacuum-casting-vs-3d-printing-which-is-better-for-rapid-prototyping/)

[5](https://www.reddit.com/r/modelmakers/comments/1d0yh8y/vacuum_forming_vs_3d_printing_vs_resin_cast/)

[6](https://3druck.com/en/industry-2/3d-printing-vs-cnc-vs-vacuum-casting-manufacturing-process-comparison-54135854/)

[7](https://www.in3dtec.com/3d-printing-vs-vacuum-casting-vs-injection-molding-whats-the-difference/)

[8](https://www.rapiddirect.com/blog/3d-printing-vs-compression-molding/)

[9](https://leadrp.net/blog/overview-of-vacuum-casting/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal