Views: 222 Author: Amanda Publish Time: 2025-10-19 Origin: Site

Content Menu

● Introduction to Vacuum Mold Casting

● Understanding Complex Geometries

● Key Techniques in Vacuum Mold Casting

>> Controlled Resin Mixing and Pouring

>> Process Parameters Optimization

>> Use of Additives and Post-Processing

● Materials Used in Vacuum Mold Casting

● Common Challenges and Solutions

● Applications of Vacuum Mold Casting

● FAQ

>> 1. What is vacuum mold casting?

>> 2. Why is vacuum necessary for casting complex geometries?

>> 3. What materials work best with vacuum mold casting?

>> 4. How can mold design improve the vacuum mold casting process?

>> 5. Is vacuum mold casting suitable for mass production?

Vacuum mold casting is an advanced manufacturing process widely used to create precise, high-quality parts, especially those with complex geometries. For businesses like Shangchen, specializing in rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing services, and mold manufacturing, mastering Vacuum Mold Casting techniques can significantly enhance product quality and serve international brands with outstanding OEM services.

In this comprehensive article, we will explore the best techniques for vacuum mold casting tailored for intricate shapes and detailed parts. We will cover the fundamentals, critical considerations, process optimization, and applications, ensuring you acquire practical knowledge to excel in this field.

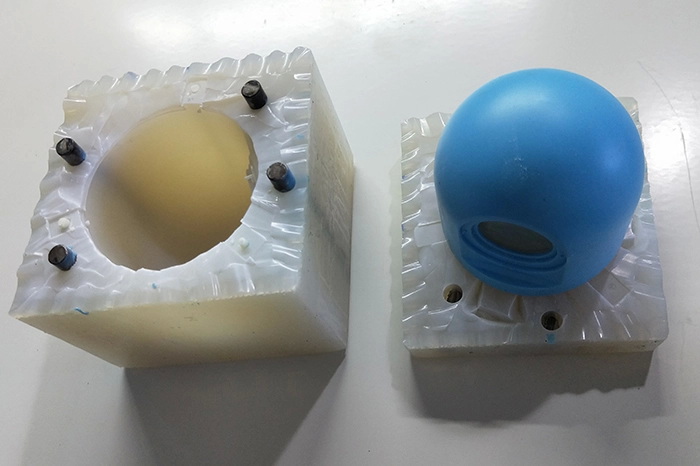

Vacuum mold casting is a process where liquid resin (usually polyurethane or silicone) is poured into a vacuum chamber to remove air bubbles. This method ensures minimal porosity and defects in the casted parts, resulting in excellent surface finishes, mechanical properties, and dimensional accuracy. It is especially beneficial for parts with highly detailed features and thin walls that would be difficult to produce via conventional casting methods.

This process begins with mold preparation, where a master model or pattern is encased in silicone to produce a flexible mold. The liquid resin is then mixed and poured inside the mold under vacuum conditions to prevent air entrapment. The vacuum environment plays a pivotal role in eliminating trapped gases, ensuring the resin completely fills all intricate cavities without voids.

Complex geometries often include intricate curves, undercuts, sharp edges, thin sections, and delicate internal channels. Such designs push the limits of conventional casting methods due to risks like uneven resin flow, incomplete mold filling, and structural weaknesses caused by trapped air bubbles.

When dealing with complex geometries, several factors must be considered:

- Flow behavior: Resin must flow smoothly into all cavity sections without creating dead zones or air pockets.

- Mold flexibility: The mold must allow easy release without damaging thin walls or sharp features.

- Thermal curing: Detailed parts may require gradual curing to avoid internal stresses and shrinkage.

- Support considerations: Undercuts and hollow sections might need special mold design or usage of core inserts.

Understanding these challenges helps manufacturing engineers design optimal molds and select suitable materials that accommodate the intricacies of complex shapes.

Mold design is the foundation of successful vacuum mold casting for complex geometries. The design should include strategically placed vents and gating systems that facilitate smooth resin flow, bubble escape, and pressure equalization during filling. Incorporating flexible materials such as high-quality silicone rubber molds allows for gentle demolding without damaging delicate parts.

Moreover, designing molds with built-in draft angles, ribs for support, and thicker sections around thin walls enhances mold longevity and part dimensional stability. Using multi-part molds or mold inserts can address particularly difficult geometries such as deep undercuts or internal channels.

Resin mixing directly impacts the quality of the final cast. Automated mixing equipment helps maintain consistent ratios of resin components and minimizes the introduction of air bubbles. The resin should be poured slowly and evenly inside the vacuum chamber to prevent turbulence, which can entrain air and cause defects.

Pouring under vacuum reduces the presence of volatile gases, preventing pinholes and voids in the finished piece. Maintaining proper viscosity by adjusting temperature and additives during mixing ensures the resin flows precisely into all mold details, including narrow or deep sections.

Fine-tuning process parameters is essential to achieve defect-free castings. Key parameters include:

- Vacuum pressure: Sufficient vacuum levels (usually below 50 Pa) remove trapped air effectively.

- Curing time and temperature: Adjust curing schedules to allow gradual polymerization, minimizing shrinkage and stress.

- Demolding timing: Demold parts only when resin reaches sufficient hardness but remains slightly flexible to avoid fractures.

- Resin viscosity: Maintain resin viscosity in an optimal range for flow and detailed reproduction.

Regular monitoring and adjustment of these parameters based on part complexity and resin type improve repeatability and reduce waste.

Additives such as plasticizers, flow enhancers, or UV stabilizers improve resin behavior during casting and enhance mechanical properties of the final parts. For example, thixotropic agents prevent sagging in vertical surfaces, while reinforcing fillers increase strength for functional prototypes.

After casting, parts often undergo secondary processing including trimming, sanding, painting, or coating to achieve the desired finish and performance. Using polishing and surface treatment techniques can further elevate the aesthetic and functional quality of complex geometries.

The choice of resin material depends on the application requirements such as strength, flexibility, heat resistance, and surface quality.

- Polyurethane Resins: Widely used for rapid prototyping, they offer excellent toughness, fast curing, and good detail reproduction.

- Silicone Rubber: Flexible and highly heat-resistant, ideal for molds and flexible parts.

- Epoxy Resins: Known for superior dimensional stability, chemical resistance, and mechanical strength; commonly used in aerospace and electronics.

Selecting the right resin ensures compatibility with vacuum processes, mold materials, and desired part functionalities.

| Challenge | Solution |

| Air entrapment or bubbles | Use strong vacuum, slow pouring, and vented molds |

| Difficult demolding | Design molds with flexible materials and draft angles |

| Resin shrinkage | Use low-shrinkage resins and optimize curing cycles |

| Surface defects | Keep molds clean, adjust resin viscosity and pouring |

| Incomplete filling | Improve mold venting and resin flow dynamics |

By anticipating these challenges and implementing corrective measures, manufacturers can ensure high yield and quality in vacuum mold cast parts.

Vacuum mold casting's ability to produce highly detailed and dimensionally accurate parts makes it a critical process in several advanced industries:

- Automotive: Custom prototypes, interior components, and decorative trims with complex shapes.

- Consumer Electronics: Housings, buttons, and connectors requiring tight tolerances and smooth finishes.

- Aerospace: Components with intricate internal channels, lightweight structures, and demanding specifications.

- Medical Devices: Custom-fitted parts like surgical guides, enclosures, and diagnostic tools with elaborate shapes.

Factories like Shangchen offer these advanced services internationally, combining vacuum mold casting with other capabilities such as CNC machining and 3D printing for integrated manufacturing solutions.

Mastering vacuum mold casting techniques for complex geometries requires a comprehensive approach: from optimal mold design and precise resin handling to process parameter control and suitable material selection. This combination ensures the production of high-quality, durable, and highly detailed parts essential for diverse sectors including automotive, aerospace, electronics, and medical devices.

With cutting-edge technology and skilled craftsmanship, companies such as Shangchen are well-positioned to deliver superior OEM services worldwide, helping clients turn complex designs into tangible, functional products efficiently.

Vacuum mold casting is a process that uses a vacuum chamber to remove air bubbles from liquid resin poured into molds, creating parts with minimal defects and high detail. It is ideal for prototyping and small batch production.

Vacuum eliminates trapped air, which is common in intricate shapes, preventing voids and ensuring the resin fills every detail accurately without weakening the part.

Polyurethane resins, silicone rubber, and epoxy resins are commonly used, each chosen based on desired mechanical properties, flexibility, and thermal resistance.

Designing molds with vent channels, flexible materials, draft angles, and multi-part configurations enhances resin flow, ease of demolding, and overall part quality.

Typically, vacuum mold casting suits prototyping and small to medium batch production due to mold lifespan and cycle time. However, with optimized setup and equipment, it can be scaled for larger production runs.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam