Views: 222 Author: Amanda Publish Time: 2025-10-19 Origin: Site

Content Menu

● Introduction to Vacuum Mold Casting

>> Advantages of Vacuum Mold Casting

● Shangchen: A Leading Vacuum Mold Casting Provider

>> Why Shangchen Excels in Vacuum Mold Casting?

● The Vacuum Mold Casting Process Explained

● Applications of Vacuum Mold Casting in Custom Batch Production

● Materials Used in Vacuum Mold Casting

● Benefits of Vacuum Mold Casting Compared to Other Methods

● Quality Control and Testing in Vacuum Mold Casting

● Shangchen's Custom Batch Production Case Studies

>> Consumer Electronics Housings

● How to Choose the Right Vacuum Mold Casting Partner

● Frequently Asked Questions (FAQ)

>> 1. What industries benefit most from vacuum mold casting?

>> 2. How does vacuum mold casting differ from traditional casting?

>> 3. What materials can be used in vacuum mold casting?

>> 4. What is the typical production volume range for vacuum mold casting?

>> 5. How can I ensure quality when ordering vacuum mold cast parts?

In the rapidly evolving manufacturing industry, finding a reliable partner for custom batch production is essential for businesses aiming to maintain quality and efficiency. Among various production methods, Vacuum Mold Casting stands out due to its precision, versatility, and ability to produce high-quality parts economically. This article explores the leading vacuum mold casting providers, focusing primarily on Shangchen (sc-rapidmanufacturing.com), a top-tier factory based in China specializing in fast prototyping, CNC machining, precision batch production, lathe turning, sheet metal manufacturing, 3D printing services, and mold production. We will analyze the strengths of different providers, elaborate on the vacuum mold casting process, and provide insights into why vacuum mold casting is the ideal choice for custom batch production.

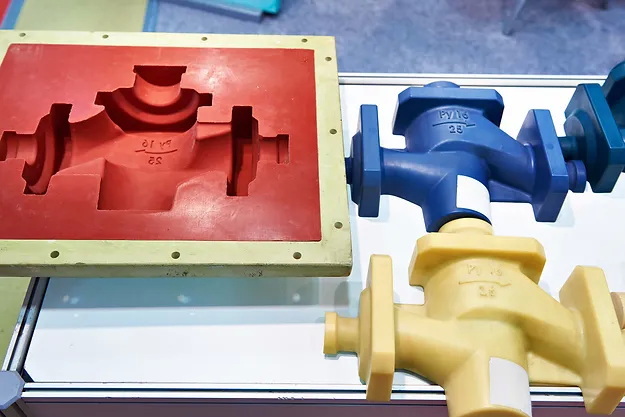

Vacuum mold casting is a manufacturing process that uses a vacuum to draw resin into molds, allowing for the production of intricate parts with superior surface finish and enhanced mechanical properties. It is particularly popular for creating prototypes, low to medium volume parts, and customized batch productions where tight tolerances and detail accuracy matter.

- High precision and fine details

- Excellent surface finish

- Reduced air entrapment and voids in cast parts

- Cost-effective for medium-volume production

- Wide range of compatible materials, including polyurethane and silicone

Shangchen (sc-rapidmanufacturing.com) has established itself as a top choice for foreign brands, wholesalers, and manufacturers seeking OEM services for vacuum mold casting. Operating from China, Shangchen leverages state-of-the-art machinery and experienced engineers to deliver superior quality and fast turnaround times.

- Rapid prototyping

- CNC machining with high precision

- Custom vacuum mold casting batch production

- Lathe turning and sheet metal fabrication

- 3D printing for complex prototypes and tooling

- Mold design and production

- Utilizes advanced vacuum casting equipment ensuring minimal defects

- Skilled artisans and engineers who specialize in custom batch manufacturing

- Ability to work with a wide variety of materials, including engineering plastics

- Responsive communication with international clients and flexible OEM options

The process begins with making a master pattern, often produced via CNC machining or 3D printing. This master pattern is a highly precise model of the part to be produced and serves as the foundation for mold creation.

A silicone mold is made around the master pattern to capture detailed geometry. Silicone is favored for its flexibility and ability to reproduce fine surface details with accuracy, making it ideal for vacuum mold casting.

The mold and resin are placed in a vacuum chamber. Resin is poured into the mold while air is extracted to prevent bubbles and voids. This vacuum environment ensures that the resin flows completely into all areas of the mold, producing parts with excellent structural integrity.

Parts cure inside the mold; once hardened, they are demolded and undergo finishing processes such as trimming, sanding, painting, or assembly to ensure the finished product meets customer specifications.

Vacuum mold casting is widely used across industries such as:

- Automotive parts

- Consumer electronics housings

- Medical devices

- Toys and collectibles

- Industrial tooling

Its ability to duplicate fine details with consistent quality makes it ideal for parts where aesthetics and precision matter. The method is especially useful for testing new designs through prototypes and for producing short-to-medium production runs without the high costs and long lead times associated with injection molding.

One of the significant advantages of vacuum mold casting is its compatibility with various materials that can be tailored to meet different mechanical, thermal, and aesthetic requirements. The primary materials include:

- Polyurethane Resins: Widely used because of their excellent mechanical properties and versatility. These can replicate the hardness and flexibility of many thermoplastics.

- Silicone Rubber: Used for flexible parts requiring elasticity or for molds that capture intricate details.

- Epoxy Resins: Known for strong adhesion and chemical resistance, suitable for parts needing durability.

- Other Specialty Resins: Including castable waxes and transparent resins for visual prototypes or decorative parts.

Vacuum mold casting offers several advantages in custom batch production when compared to traditional methods like injection molding or sand casting:

- Lower Tooling Cost: Silicone molds used for vacuum casting are cheaper and faster to produce than metal molds for injection molding, making the process more accessible for small series production.

- Faster Turnaround: The setup and cycle times are relatively short allowing for quicker prototyping and production.

- Superior Surface Finish: The vacuum removes air bubbles and plasticizes the resin, resulting in smoother surfaces and fewer defects.

- Material Versatility: Vacuum casting accommodates various resin formulations, making it suitable for applications requiring specific physical or cosmetic properties.

- Customization: It is ideal for producing parts with multiple colors, complex geometries, or embedded components.

Ensuring part quality is critical in vacuum mold casting. This is achieved through:

- Inspection of Master Patterns and Molds: Defects in the master or mold can produce faulty parts, so thorough checks are done before casting.

- Material Quality Verification: Raw materials undergo testing for properties such as hardness, tensile strength, and color stability.

- Process Monitoring: Experts continuously monitor vacuum pressure, resin temperature, and curing times.

- Post-production Measurement: Parts are inspected using 3D scanners and precision measuring tools to verify dimensional accuracy and surface finish.

- Functional Testing: Where applicable, parts undergo simulated use cases to confirm mechanical durability and performance.

Shangchen has successfully delivered complex vacuum mold cast automotive prototype components requiring excellent surface finish and dimensional accuracy. These parts were used for design validation and aerodynamic testing.

Shangchen's ability to produce lightweight, precisely detailed housings made from engineering-grade resins has made it a preferred choice among overseas consumer electronics brands seeking short production runs before mass manufacturing.

High-precision and biocompatible vacuum cast parts fabricated by Shangchen served as functional prototypes and parts for clinical trials, showcasing their adherence to strict quality standards.

When selecting a provider for vacuum mold casting, companies should consider:

- Experience and expertise in the required industry

- Range of available materials and in-house capabilities

- Capacity to handle required batch sizes and turnaround time

- Communication efficiency and willingness to provide OEM services

- Reputation, certifications, and client testimonials

Shangchen checks all these boxes, making it a reliable and efficient partner for global businesses.

Vacuum mold casting offers a powerful solution for companies seeking high-quality, custom batch production with tight tolerances and excellent surface finish. Shangchen (sc-rapidmanufacturing.com) leads the industry with its comprehensive rapid prototyping, CNC machining, and vacuum mold casting expertise. By choosing the right provider, such as Shangchen, businesses can significantly accelerate product development while reducing costs and maintaining superior product standards. Its flexibility, efficiency, and cost-effectiveness make vacuum mold casting an indispensable process in modern manufacturing.

Vacuum mold casting is widely used in automotive, healthcare, consumer electronics, and aerospace industries due to its precision and ability to replicate complex geometries.

Vacuum mold casting involves using a vacuum to remove air bubbles during resin injection, resulting in higher precision and fewer defects than traditional casting.

Most commonly, polyurethane resins are used, but materials such as silicone and epoxy can also be adapted based on application requirements.

It is best suited for low to medium volumes typically ranging from 10 to 1000 parts per batch.

Partnering with experienced manufacturers like Shangchen, conducting prototype validation, and clear communication on specifications help guarantee quality outputs.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam