Views: 222 Author: Amanda Publish Time: 2025-10-19 Origin: Site

Content Menu

● Introduction to Vacuum Mold Casting and Its Importance

● Shangchen's Vacuum Mold Casting Capabilities

>> Key Features of Shangchen's Vacuum Mold Casting Process:

● Integrating Vacuum Mold Casting with Rapid Prototyping Technologies

>> Benefits of Multi-Technology Manufacturing:

● Detailed Workflow of Vacuum Mold Casting at Shangchen

● Why Vacuum Mold Casting Excels for High-Quality Prototypes

● Applications of Vacuum Mold Casting Prototypes

● Quality Control and Certification at Shangchen

● Sustainability and Environmental Practices

● Customer-Centric OEM Service Model

● Industry Trends Driving Demand for Vacuum Mold Casting

● Frequently Asked Questions (FAQ)

>> 1. What materials can be used in vacuum mold casting at Shangchen?

>> 2. How does vacuum mold casting improve prototype quality?

>> 3. Can vacuum mold casting be used for mass production?

>> 4. What industries benefit most from vacuum mold casting?

>> 5. How fast can Shangchen deliver vacuum mold casting prototypes?

Shangchen (sc-rapidmanufacturing.com) stands at the forefront of the rapid prototyping and manufacturing industry, offering comprehensive services such as Vacuum Mold Casting, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing. Catering to international brands, wholesalers, and manufacturers, Shangchen specializes in high-quality OEM services with an emphasis on vacuum mold casting technology to deliver precise, durable prototypes.

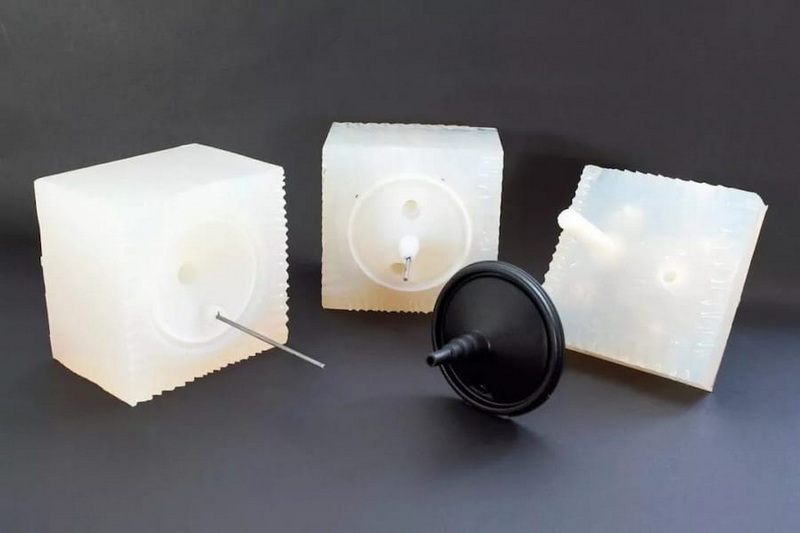

Vacuum mold casting is a specialized prototyping technology that uses a vacuum chamber to eliminate air bubbles during the mold curing process, ensuring high fidelity and detail in the final product. This method is crucial in industries demanding accuracy, such as consumer electronics, automotive, and medical devices, where prototype quality directly influences product success.

At Shangchen, vacuum mold casting is integrated seamlessly with other manufacturing techniques to meet the diverse needs of clients worldwide. By mastering this process, they ensure rapid, cost-effective production without compromising on quality.

Shangchen offers state-of-the-art vacuum mold casting services that encompass every stage from prototype design to batch production. Their skilled technicians use advanced machinery and premium materials to achieve prototypes that reflect exact design specifications.

- Complete vacuum environment eliminating porosity

- Use of high-quality silicone molds for repeatability

- Compatibility with a wide range of resins for varied mechanical properties

- Fast turnaround times with scalable batch production options

- Precision detailing ensuring surface smoothness and fine feature replication

Combining vacuum mold casting with CNC machining, 3D printing, and sheet metal fabrication allows Shangchen to provide a versatile manufacturing ecosystem. This integration supports complex prototype geometries and durable parts essential for functional testing and market evaluation.

- Enhanced accuracy from CNC-machined mold masters

- Surface finishing improvements through post-processing techniques

- Ability to prototype both plastic and metal components

- Lower cost and faster prototype iteration cycles

The vacuum mold casting process at Shangchen begins with the creation of a master pattern, often produced via CNC machining or 3D printing. This master pattern is then used to create a high-precision silicone mold that will withstand multiple casting cycles. Once the mold is ready, liquid resin is prepared and poured into the mold inside a vacuum chamber.

The vacuum environment ensures that trapped air bubbles are removed from the resin, preventing defects such as voids or weak spots. After curing, the cast parts are demolded and undergo quality inspections, including dimensional checks and surface finish assessment. If necessary, additional finishing processes such as sanding, painting, or plating are applied to meet the client's exact requirements.

Vacuum mold casting offers several distinct advantages that make it ideal for prototype development:

- Superior Surface Finish: The vacuum process eliminates imperfections caused by entrapped air.

- High Detail Replication: Fine features from the silicone mold are accurately reproduced.

- Material Versatility: Various resins simulate the mechanical and aesthetic properties of production-grade plastics.

- Cost Efficiency: Especially advantageous for low to medium volume parts compared to injection molding.

- Rapid Turnaround: Combining vacuum mold casting with rapid tooling methods accelerates development cycles.

These benefits enable companies to validate design concepts, perform functionality tests, and present realistic models for marketing or investor relations.

Vacuum mold casting prototypes serve various industries demanding precision and aesthetic appeal:

- Consumer electronics: Producing ergonomic and durable casings.

- Automotive: Creating functional parts for testing and assembly verification.

- Medical devices: Crafting biocompatible components with high surface quality.

- Aerospace: Fabricating lightweight parts with tight tolerances.

- Consumer goods: Developing tactile, visually appealing models for design approval.

- Industrial equipment: Prototyping robust components capable of withstanding mechanical stresses.

Through these diverse applications, vacuum mold casting bridges the gap between initial concept and final product, enabling faster innovation and market readiness.

Ensuring consistent quality is a cornerstone of Shangchen's manufacturing philosophy. Their vacuum mold casting processes are supported by rigorous quality control protocols:

- Incoming material inspection to verify resin specifications.

- In-process monitoring of vacuum levels and curing cycles.

- Dimensional inspection using CMM (Coordinate Measuring Machines).

- Surface integrity tests to detect visual and microscopic defects.

- Final approval based on client standards or industry regulations.

Shangchen continuously invests in staff training and equipment calibration to uphold certifications and international quality standards, building trust with global OEM customers.

Shangchen recognizes the importance of sustainable manufacturing. Their vacuum mold casting operations incorporate:

- Use of environmentally friendly resins and biodegradable materials where possible.

- Efficient energy management in vacuum chamber operation.

- Recycling of silicone molds after their lifespan.

- Waste reduction through precise material usage and process optimization.

These practices align with global trends towards greener manufacturing, appealing to clients with sustainability goals.

Every project at Shangchen benefits from personalized attention and flexible options. Their OEM service model includes:

- Collaborative design consulting and prototype iteration.

- Material recommendations based on application needs.

- Scalable production volumes accommodating pilot to mid-size batches.

- Transparent pricing and timelines to facilitate planning.

- Post-production support including packaging and logistics coordination.

This approach has positioned Shangchen as a trusted partner for international brands seeking reliable vacuum mold casting expertise.

Ongoing innovation in product development places pressure on manufacturers to deliver accurate prototypes quickly and cost-effectively. Vacuum mold casting caters to this demand by:

- Enabling early-stage user testing with functional parts.

- Reducing tooling costs compared to injection molding.

- Supporting customization and design refinements without high capital investment.

- Accelerating time-to-market in competitive sectors such as electronics and healthcare.

Furthermore, advances in resin technologies and mold materials continue to expand vacuum mold casting's capabilities and applications.

Vacuum mold casting is a critical manufacturing process for producing high-quality, precise prototypes. Shangchen (sc-rapidmanufacturing.com) excels in delivering exceptional vacuum mold casting services combined with rapid prototyping technologies, ensuring their clients bring products to market faster and more accurately. Whether for small batch prototypes or precision batch productions, Shangchen is a trusted leader in this field, providing reliable, cost-effective, and versatile solutions tailored to global OEM requirements.

Shangchen supports a wide range of resins, including polyurethane, silicone, and epoxy, allowing clients to choose materials that match their prototype requirements for strength, flexibility, or appearance.

Vacuum mold casting removes trapped air from the mold, preventing bubbles and porosity, which ensures prototypes have high surface finish, dimensional accuracy, and structural integrity.

While mainly suited for prototyping and small batch runs, vacuum mold casting can efficiently produce limited quantities with consistent quality, ideal for pilot runs or limited edition products.

Consumer electronics, automotive, aerospace, and medical device industries especially benefit from this method due to its ability to produce detailed and functional prototypes quickly.

Typical turnaround times range from a few days to weeks depending on complexity and batch size, with expedited options available to meet urgent project deadlines.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam