Views: 222 Author: Amanda Publish Time: 2025-10-18 Origin: Site

Content Menu

● What is Vacuum Mold Casting?

>> The Process

>> Advantages of Vacuum Mold Casting

>> The Process

>> Variations in Air Bubble Management

>> Benefits and Limitations of Resin Casting

● Detailed Comparison of Vacuum Mold Casting and Resin Casting

>> Mold Material and Life Span

>> Surface Finish and Detail Accuracy

● Practical Applications of Each Method

>> Vacuum Mold Casting Excels In:

>> Resin Casting Is Ideal For:

● FAQ

>> 1. What types of materials are suitable for Vacuum Mold Casting?

>> 2. How does vacuum improve the quality of cast parts?

>> 3. Can Vacuum Mold Casting be used for high-volume production?

>> 4. How long does it take to produce a part using Vacuum Mold Casting?

>> 5. What methods reduce air bubbles in Resin Casting?

In today's rapidly evolving manufacturing landscape, the demand for high-quality prototypes and small-run production parts continues to grow. Among the widely adopted techniques, Vacuum Mold Casting and Resin Casting stand out for their ability to create detailed, durable, and precise components efficiently. For manufacturers, brands, wholesalers, and product developers, understanding the distinctions between these two casting methods is crucial in selecting the ideal process for their unique project needs.

This comprehensive guide explores the principles, advantages, and practical applications of Vacuum Mold Casting and Resin Casting, highlighting their fundamental differences and demonstrating how each method can be best utilized to meet specific production criteria and quality expectations.

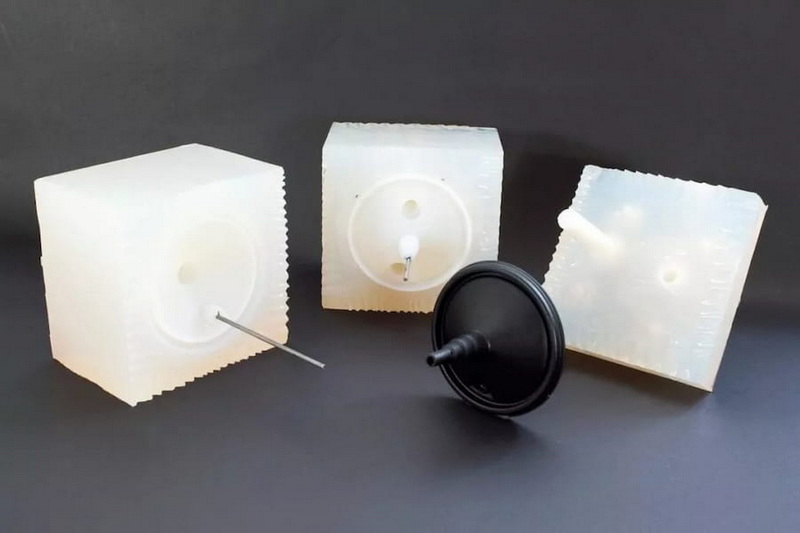

Vacuum Mold Casting, also known as vacuum casting or urethane casting, is a versatile manufacturing process used primarily for producing highly accurate and finely detailed parts in low to medium volumes. It involves pouring liquid resin, typically polyurethane or other specialized resins, into a silicone mold housed inside a vacuum chamber.

The key feature of Vacuum Mold Casting is the application of vacuum pressure inside the casting chamber. This vacuum:

- Removes all air from the mold cavity and resin material

- Prevents air bubbles and voids within the final part

- Ensures the resin fills every detail of the mold with precision

The casting mold is made from a high-quality silicone derived from a master pattern, which can be created through CNC machining, 3D printing, or hand sculpting. The resin is carefully mixed, often with pigments or additives for color and properties, then poured into the mold under vacuum conditions. After curing, the part is demolded carefully to preserve fine details and ensure dimensional accuracy.

- Excellent Surface Finish and Detail: The vacuum eliminates air pockets, creating parts that match the master pattern's surface exactly.

- Tight Dimensional Tolerances: Parts require little to no post-processing such as sanding or drilling.

- Material Variety: Offers flexible choices including rigid, flexible, clear, flame retardant, and food-safe resins.

- Low to Moderate Tooling Costs: Silicone molds are cost-effective and quicker to produce than traditional metal molds.

- Rapid Turnaround: Typically, parts can be ready within 10 to 15 days.

- Complex Geometry: Capable of producing parts with undercuts, thin walls, and intricate details.

- Multi-Material and Multi-Color Capability: Allows casting of combined materials or color variations in a single part.

Vacuum Mold Casting is especially favored for producing detailed prototypes, functional testing parts, and short production runs where quality and fidelity are paramount.

Resin Casting is a general term for a process where liquid resin is poured into molds and allowed to cure into solid shapes. Unlike Vacuum Mold Casting, resin casting may or may not employ vacuum or pressure systems to minimize air bubbles, depending on the setup and quality requirements.

In resin casting, a two-part resin (such as epoxy, polyester, or polyurethane) is hand mixed and poured directly into a mold, usually made from silicone rubber. The mold can be simple or complex, depending on the design and production volume. After the resin cures, the part is removed and may undergo trimming or finishing.

- Vacuum Degassing: Resin can be degassed before pouring to remove trapped air.

- Pressure Casting: The part may be placed in a pressure chamber during curing to shrink any trapped bubbles beyond visibility.

- No Bubble Control: Some simple resin casting relies on careful pouring techniques and slow mixing to minimize air bubbles.

- Low Initial Setup Cost: Ideal for hobbyists, small businesses, or educational purposes.

- Simple Process: Requires minimal specialized equipment.

- Material Versatility: Wide range of resins available with varying strength, hardness, and finishes.

- Surface Finish Quality: Can be prone to visible bubbles or imperfections if not carefully managed.

- Post-Processing Required: Parts often need sanding, polishing, or painting for aesthetic or functional requirements.

- Suitability: Best for low volume or one-off projects due to manual labor intensity.

Vacuum Mold Casting uses high-grade silicone molds derived from a master pattern, capable of producing dozens to hundreds of parts while maintaining precision. In contrast, resin casting molds may vary widely in silicone quality, often with shorter lifespans, making them less ideal for moderate batch production.

Vacuum Mold Casting's defining feature is the vacuum chamber that actively removes air, resulting in nearly bubble-free parts. Resin Casting, without vacuum or pressure, relies on careful manual techniques, making it more susceptible to air bubbles and surface defects.

Vacuum Mold Casting fits well for small to medium batch production (up to several hundred parts) with moderate tooling costs and per-part costs affordable for prototypes or limited production. Resin Casting is more cost-effective at very low volumes (single parts or small batches) but becomes less efficient for larger quantities due to manual effort.

While both methods use various resins, Vacuum Mold Casting offers specialized polyurethane resins mimicking ABS, polypropylene, or even rubber-like materials, enabling functional and aesthetic flexibility. Resin Casting's resin choices are broader but generally less specialized for mechanical applications.

Vacuum Mold Casting produces parts with excellent surface fidelity and minimal need for finishing. Resin Casting parts often need cosmetic touch-ups due to casting imperfections from air bubbles or pouring anomalies.

Vacuum Mold Casting molds take time to prepare (usually days), but once done, the casting is reproducible and relatively quick. Resin Casting molds can be made quickly, allowing rapid prototyping or artistic uses but at the expense of part durability and finish.

- Functional prototypes requiring mechanical strength and tight tolerances

- Cosmetic parts needing precise surface textures and color matching

- Small batch production of end-use parts with complex geometries

- Testing various resin materials without retooling

- Artistic, hobbyist, or visual modeling projects

- Prototyping where low cost and rapid results outweigh precision

- Educational or experimental small projects

- Situations where manual finishing is acceptable or part of the process

- Ensure precise mold making from high-quality master patterns

- Match resin type to application (hardness, flexibility, clarity)

- Maintain vacuum chamber and casting environment for cleanliness

- Use pigments or additives carefully for consistent color

- Mix resin slowly and thoroughly to reduce trapped air

- Consider vacuum degassing or pressure pots for professional results

- Pour resin gently to minimize turbulence and bubble formation

- Practice mold release and careful part demolding to avoid damage

Vacuum Mold Casting and Resin Casting are both highly valuable in the prototyping and small-scale production sectors, each with unique strengths. Vacuum Mold Casting offers superior surface quality, dimensional accuracy, and a broader range of functional materials, making it ideal for professional prototypes and limited production runs requiring excellent finish and performance.

Resin Casting, on the other hand, is a flexible and accessible method suitable for smaller quantities, hobbyist projects, and situations where low-cost tooling or rapid iterations are prioritized over surface perfection.

By understanding these key differences, manufacturers, designers, and brand owners can tailor their choice to project requirements, balancing cost, quality, speed, and complexity to achieve optimal outcomes.

Vacuum Mold Casting commonly utilizes polyurethane resins that can mimic the properties of ABS, polypropylene, and flexible rubbers. It also supports flame-retardant, clear, and food-grade resins for specialized applications.

Vacuum removes trapped air within the resin and mold cavity, which eliminates air bubbles and voids, resulting in a smooth surface finish and high dimensional accuracy.

It is primarily designed for low to medium volume production due to silicone mold durability and cycle time constraints. For high-volume runs, injection molding is more cost-effective.

Typical lead times range from 10 to 15 working days, including mold fabrication, resin casting, curing, and demolding.

Using vacuum degassing, pressure casting, slow mixing techniques, and careful pouring all help to minimize air bubbles, improving final part quality.

[1](https://www.sc-rapidmanufacturing.com/vacuum-casting-vs-resin-casting-which-one-fits-your-project.html)

[2](https://leadrp.net/blog/overview-of-vacuum-casting/)

[3](https://www.reddit.com/r/ResinCasting/comments/rv7bur/whats_the_difference_of_using_industrial_vacuum/)

[4](https://www.rapiddirect.com/blog/vacuum-casting-material-selection/)

[5](https://www.youtube.com/watch?v=yvwAQTiIjtM)

[6](https://hapcoincorporated.com/blog/vacuum-vs-pressure-when-resin-casting/)

[7](https://xometry.pro/en/articles/vacuum-casting-vs-injection-molding/)

[8](https://formlabs.com/blog/vacuum-casting-urethane-casting-polyurethane-casting/)

[9](https://asuzac-acm.com/die-casting-and-vacuum-casting/)`

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal