Views: 222 Author: Amanda Publish Time: 2025-10-12 Origin: Site

Content Menu

● Understanding 3D Print Prototypes

>> Key Characteristics of 3D Print Prototypes

>> Features of Rapid Prototyping

● Core Differences Between 3D Print Prototype and Rapid Prototyping

● Why Choose 3D Print Prototype?

● When Rapid Prototyping Excels

● Integration with OEM Manufacturing

● Applications of 3D Print Prototype and Rapid Prototyping

● Challenges and Considerations

● FAQ

>> 1. What is the main advantage of 3D print prototypes over other methods?

>> 2. Can rapid prototyping produce functional parts?

>> 3. How do I choose between 3D print prototyping and rapid prototyping?

>> 4. Are 3D printed prototypes suitable for OEM collaboration?

>> 5. What industries benefit most from rapid prototyping?

In the world of product development and manufacturing, prototyping plays a crucial role in turning ideas into tangible objects. Two commonly discussed approaches in this domain are "3D print prototype" and "Rapid Prototyping." Although these terms are sometimes used interchangeably, they represent distinct processes and technologies. This comprehensive article will clarify the differences between 3D print prototypes and rapid prototyping, explore their benefits and applications, and guide businesses—especially OEMs and manufacturers—on selecting the right method for their needs.

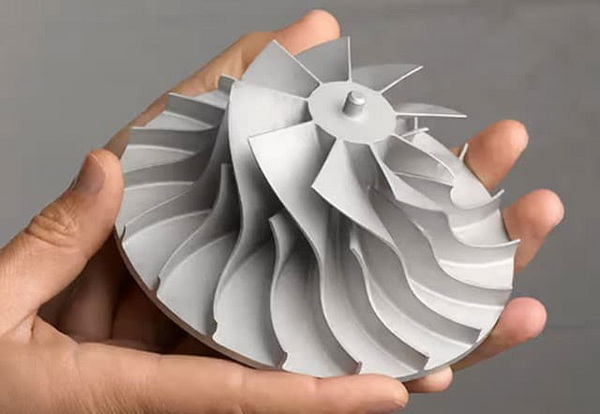

A 3D print prototype is a physical model created using 3D printing technology, an additive manufacturing process whereby layers of material are deposited to form the desired shape. This method is widely used to create highly detailed models rapidly and cost-effectively compared to traditional manufacturing processes.

- Additive Process: Unlike subtractive machining, 3D printing builds objects layer by layer, reducing material waste and enabling the creation of complex geometries.

- Materials Variety: Depending on the printer, materials can range from plastics and resins to metals and composites, offering versatility in prototype properties.

- Speed: 3D printing can produce prototypes in hours or days, much faster than traditional fabrication.

- Cost Efficiency: For small runs or single prototypes, 3D printing avoids costly tooling and setup fees, making it affordable for startups and small businesses.

- Design Flexibility: Changes to the digital model are simple to implement, allowing rapid iteration and refinement.

Industries such as automotive, aerospace, healthcare, and consumer products utilize 3D print prototypes extensively to visualize designs, test form and fit, and conduct functional assessments before mass production.

Rapid prototyping is a broader methodology encompassing various techniques that quickly produce prototype models directly from CAD data. While 3D printing is a subset, rapid prototyping also includes CNC machining, injection molding, casting, and other advanced manufacturing processes designed for immediacy.

- Multiple Techniques: Can utilize both additive and subtractive manufacturing methods depending on prototype requirements.

- Functional Prototypes: Enables creation of prototypes with properties close to final production parts, such as strength, thermal resistance, or elasticity.

- Batch Production: Supports small to medium batch runs more efficiently than exclusive use of 3D printing.

- Integration with Manufacturing: Rapid prototyping often aligns with tooling and production processes, minimizing lead time for product launches.

- Customization: Highly customizable to client needs, which is ideal for OEMs and brands seeking bespoke solutions.

Manufacturers employ rapid prototyping to accelerate product development cycles, reduce risks, and validate designs comprehensively through prototyping stages that involve more than just appearance models.

| Aspect | 3D Print Prototype | Rapid Prototyping |

| Manufacturing Process | Additive layering of materials | Combines additive and subtractive methods |

| Material Choices | Primarily plastics, resins, some metals | Broader range including metal machining and molding |

| Prototype Functionality | Often visual or basic functional models | Can produce near-production-quality functional parts |

| Production Speed | Rapid single units or small batches | Faster than traditional methods but may vary by method |

| Cost | Lower setup costs for small quantities | Potentially higher if complex tooling is involved |

| Suitability | Early design validation, form and fit testing | Functional testing, pilot production, and design validation |

| Complexity Handling | Can create intricate geometries easily | Depends on chosen technology; can be limited by tooling |

3D print prototypes are exceptionally useful in the earliest stages of product design. They help designers and engineers:

- Visualize Concepts: Quickly transform digital ideas into physical objects for evaluation.

- Test Ergonomics and Fit: See how parts or products fit together or in intended use environments.

- Speed Up Iterations: Make design changes and reprint for quick feedback loops.

- Reduce Waste: Use only the material necessary to build the prototype.

For startups and small brands working with limited budgets and tight deadlines, 3D print prototyping offers a clear advantage of speed and overall cost-effectiveness.

Rapid prototyping is ideal when the product demands closer-to-final properties or multiple prototype technologies are needed. For instance:

- Functional Testing: When prototypes must withstand mechanical stress, heat, or environmental factors.

- Tooling Verification: Testing molds, jigs, and fixtures before initiating full-scale manufacturing.

- Short-Run Production: Creating a limited batch of parts for market testing or limited distribution.

- OEM Collaboration: Offering tailor-made prototypes that integrate specific materials or processes to match client manufacturing needs.

Factories and service providers like Shangchen specialize in rapid manufacturing services, linking rapid prototyping and 3D print prototypes to OEM needs. By offering CNC machining, precision batch production, sheet metal fabrication, 3D printing, and mold manufacturing, such factories provide comprehensive solutions that allow brands to accelerate product development while maintaining quality and customization.

Both methods find applications across diverse sectors:

- Automotive: Prototype parts for testing aerodynamics, structural integrity, and aesthetics.

- Consumer Electronics: Early models of gadgets to evaluate design and user experience.

- Medical Devices: Custom implants and prototypes for surgical planning.

- Industrial Equipment: Functional prototypes for machinery parts to ensure fit and durability.

- Fashion and Jewelry: Rapid prototypes used in design validation and mold creation.

Despite their benefits, users should consider limitations:

- Material Properties: Some 3D-printed materials may not fully mimic production-grade materials, affecting prototype reliability.

- Surface Finish: Post-processing is often needed for appearance quality closer to finished products.

- Size Constraints: Printer build volumes or machine dimensions may limit prototype size.

- Cost Scaling: For larger quantities, rapid prototyping might require tooling investments, raising costs.

Planning the prototyping approach carefully with manufacturing partners ensures optimal balance among speed, quality, and cost.

Understanding the difference between a 3D print prototype and rapid prototyping is essential for efficient product development. While 3D printing provides quick, cost-effective solutions for initial design validation, rapid prototyping offers a comprehensive approach combining various manufacturing methods for functional and near-final prototypes. Selecting the appropriate process depends on the stage of development, prototype complexity, material needs, and intended use. Factories like Shangchen, providing integrated prototyping and manufacturing services including CNC machining, 3D printing, and mold production, empower brands and OEMs to innovate swiftly and reliably with tailored prototyping solutions.

3D print prototypes are faster and more cost-effective for early-stage design validation, allowing quick iterations and visualization without the need for expensive tooling.

Yes, rapid prototyping includes methods like CNC machining and casting that can produce prototypes with mechanical properties close to final production parts.

Choose 3D printing for early design models and rapid prototyping when function, durability, or larger batch production is required.

Yes, 3D printed prototypes are widely used in OEM collaborations to quickly validate designs before full-scale manufacturing.

Industries such as automotive, aerospace, medical devices, and consumer electronics leverage rapid prototyping to shorten development cycles and improve product quality.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Lithuania

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Czech Republic

Top 5 Axis CNC Machining Manufacturers and Suppliers in Denmark

Top 5 Axis CNC Machining Manufacturers and Suppliers in Hungary

Top 5 Axis CNC Machining Manufacturers and Suppliers in Ireland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey