Views: 222 Author: Amanda Publish Time: 2025-09-22 Origin: Site

Content Menu

● Key Advantages of Vacuum Casting for Cost Reduction

● Quality Assurance in Vacuum Casting

● Applications of Vacuum Casting

● Considerations for Material Selection in Vacuum Casting

● Common Challenges and Their Solutions

● Enhancing Production Efficiency with Shangchen's Integrated Services

● Environmental and Sustainability Aspects of Vacuum Casting

● Future Trends in Vacuum Casting Technology

>> 1. What types of materials can be used in vacuum casting?

>> 2. How many parts can one silicone mold produce?

>> 3. Is vacuum casting suitable for mass production?

>> 4. How does vacuum casting compare to injection molding?

>> 5. Can vacuum casting parts be painted or finished like injection molded parts?

Vacuum casting is an advanced manufacturing technique that enables companies to produce high-quality prototype and small batch parts efficiently and cost-effectively. By utilizing vacuum pressure to eliminate air bubbles and improve material flow, vacuum casting ensures superior dimensional accuracy and surface finish without the high expenses commonly associated with traditional manufacturing methods. For Chinese factories like Shangchen, specializing in rapid prototyping, CNC machining, and OEM services, vacuum casting is an essential solution that balances quality and affordability for overseas brands and wholesalers.

Vacuum casting is a process that involves creating molds from silicone and then using liquid resin injected under vacuum conditions to form parts. This technique is widely used in producing plastic components with complex geometries and fine surface detail. The vacuum environment helps remove trapped air and gases during casting, preventing defects such as bubbles and voids, which often compromise part quality.

This process is particularly advantageous for rapid prototyping and low-volume production since the silicone molds can be produced quickly and at a fraction of the cost of metal tooling.

1. Master Pattern Creation

The process starts with a master pattern, usually made via 3D printing or CNC machining. This master defines the exact shape and detail of the final product.

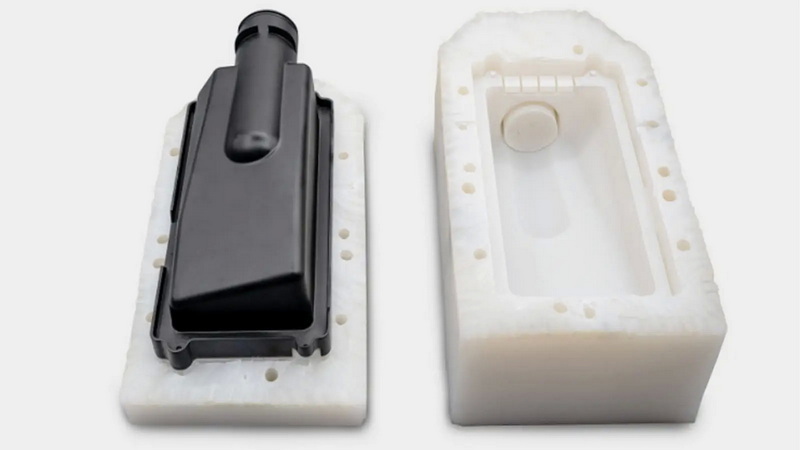

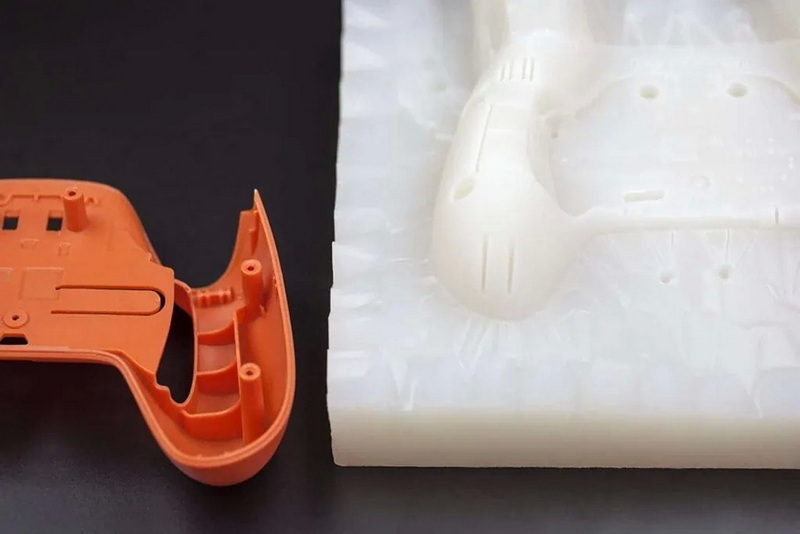

2. Mold Making

A silicone mold is created by encasing the master pattern in liquid silicone, which then cures, forming an elastic mold.

3. Casting Under Vacuum

The chosen resin—whether polyurethane, epoxy, or silicone—is degassed and poured into the mold within a vacuum chamber. The vacuum removes air bubbles and ensures uniform resin flow.

4. Curing and Demolding

The resin cures at room temperature or under mild heating. After curing, the parts are carefully removed, inspected, and post-processed if necessary.

Vacuum casting significantly minimizes production costs while maintaining product integrity by addressing several costly challenges encountered in conventional manufacturing:

- Lower Tooling Costs

Silicone molds have far lower upfront costs compared to metal injection molds or CNC-machined tools. This benefit is critical for OEMs and brands testing multiple product versions.

- Faster Turnaround Time

Silicone molds can be fabricated within days, drastically shortening lead times. Faster project cycles reduce labor costs and speed up product launches.

- Reduced Material Waste

Vacuum casting allows precise resin dosing, minimizing excess use and waste, which directly reduces material expenses.

- Minimized Defects

The vacuum environment reduces air entrapment, lowering the rejection rate and thus saving costs on remakes and scrap.

- Versatility

Multiple resin types can be used to simulate various material properties without investing in different types of metal tools, offering cost-effective versatility during development.

Despite cost savings, vacuum casting does not compromise product quality. Key features that guarantee quality include:

- High Surface Finish

The silicone molds capture intricate details and smooth surfaces, producing parts with excellent aesthetics comparable to mass production.

- Consistent Mechanical Properties

The cured resins provide uniform strength and flexibility suitable for functional testing and end-use components.

- Dimensional Accuracy

Precise master patterns combined with vacuum pressure yield consistently accurate parts meeting tight tolerances.

- Customization

Color matching, special additives, and coatings can be incorporated into the cast resin, enabling customization without additional tooling costs.

Vacuum casting is increasingly popular across industries due to its cost-quality balance:

- Consumer Electronics: Producing housings and buttons for gadgets during prototype and small-batch runs.

- Automotive Parts: Functional prototypes and limited-run interior and exterior trim components.

- Medical Devices: Rapid prototyping of devices and small manufacturing batches with demanding quality standards.

- Industrial Components: Gear covers, brackets, and enclosures produced economically at small volumes.

Material selection is a critical aspect of vacuum casting due to the variety of resins available:

- Polyurethane Resins

These are widely used for their versatility, strength, and ability to mimic different types of plastic, including rigid and flexible varieties.

- Epoxy Resins

Known for excellent chemical resistance and structural integrity, epoxy resins are ideal for parts requiring durability.

- Silicone Resins

Used for parts needing rubber-like flexibility and temperature resistance.

Choosing the appropriate resin will depend on the required mechanical properties, aesthetic finish, and functional testing parameters of the parts.

Though vacuum casting offers numerous advantages, manufacturers may face some challenges:

- Limited Tool Life: Silicone molds typically endure between 20 to 50 casting cycles. To overcome this, high-quality platinum silicone and proper mold maintenance extend durability.

- Part Size Restrictions: Larger parts can be challenging due to resin curing times and vacuum chamber size. Strategies such as dividing parts into smaller sections or using hybrid manufacturing can address this limitation.

- Material Limitations: High-performance thermoplastics cannot be replicated exactly using vacuum casting resins. For applications requiring these materials, other processes like injection molding remain preferable.

At Shangchen, vacuum casting is integrated with complementary manufacturing methods such as CNC machining, 3D printing, and sheet metal fabrication. This integration enables seamless workflows from prototype to low-volume production. Key benefits of partnering with Shangchen include:

- Comprehensive OEM Solutions

We provide end-to-end manufacturing services, allowing overseas brands, wholesalers, and manufacturers to consolidate sourcing and reduce lead times.

- Material Expertise

Our team advises on the best resin selections and post-processing options tailored to your product requirements.

- Stringent Quality Control

Our quality assurance protocols ensure parts meet precise dimensional and functional specifications.

- Competitive Pricing

Combining vacuum casting with other precision manufacturing methods reduces overall project costs while maintaining high standards.

Vacuum casting is recognized for being relatively eco-friendly compared to traditional mass production methods:

- Reduced Waste

Precise resin usage and limited scrap generation make it environmentally conscious.

- Less Energy Consumption

The process does not require high temperatures or energy-intensive metal tooling.

- Reusable Molds

Silicone molds are recyclable to some degree, and process improvements continue to reduce waste.

These factors align with increasing global sustainability goals, a concern growing among international customers and OEM partners.

Emerging innovations are further enhancing vacuum casting capabilities:

- Advanced Resin Formulations

New materials offer improved mechanical properties and biodegradability.

- Automation and Robotics

Integration of automated pouring and demolding improves consistency and throughput.

- Hybrid Manufacturing

Combining vacuum casting with additive manufacturing (3D printing) allows for even faster tooling and prototyping.

These advancements promise to expand vacuum casting's applications and further optimize cost-quality ratios.

Vacuum casting is a cost-efficient manufacturing method that reduces production expenses without sacrificing the high quality required by international OEMs and brands. By utilizing silicone molds and vacuum-assisted resin injection, companies like Shangchen provide precise, detailed, and durable parts rapidly and at a fraction of traditional tooling costs. This process enables faster product iterations, lower material waste, and superior quality assurance, making it a preferred solution for prototyping and low-volume production in diverse industries. Its flexibility, speed, and cost-effectiveness empower overseas brands and wholesalers to bring innovative products to market faster while maintaining strict quality standards.

Vacuum casting typically uses polyurethane, epoxy, and silicone resins, which can simulate various plastic and rubber properties. Some casting resins mimic ABS, polypropylene, or rubber-like materials for functional prototypes.

A silicone mold can usually produce between 20 to 50 parts before showing signs of wear, depending on mold design and resin type.

Vacuum casting is ideal for prototyping and low to medium-volume production but is less suitable for large-scale manufacturing due to mold durability and cycle times.

Vacuum casting has lower tooling costs and faster mold preparation but slower cycle times and limited volume capacity compared to injection molding, which requires expensive steel molds but suits high-volume runs.

Yes, vacuum cast parts can be sanded, painted, and finished similarly to injection molded parts, allowing customization and final aesthetic enhancements.

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product