Views: 222 Author: Amanda Publish Time: 2025-10-20 Origin: Site

Content Menu

● Understanding Vacuum Mold Casting

● Step-by-Step Vacuum Mold Casting Process

>> Resin Preparation and Degassing

>> Curing

● Advantages of Vacuum Mold Casting

● Typical Applications of Vacuum Mold Casting

>> Prototyping and Product Development

>> Medical Devices and Supplies

>> Limited Edition and Bridge Manufacturing

● Manufacturing Insights and Quality Control

● Frequently Asked Questions (FAQ)

>> 1. What materials are commonly used in vacuum mold casting?

>> 2. How many parts can a single silicone mold produce?

>> 3. How long does the vacuum casting cycle take?

>> 4. Can vacuum mold casting produce intricate designs and textures?

>> 5. How does vacuum mold casting compare with injection molding?

Vacuum mold casting is a cutting-edge manufacturing technique extensively used for producing high-quality prototypes and small production runs. By leveraging vacuum pressure, it ensures that the casting material fills every intricate detail of a silicone mold, resulting in parts that are highly precise and visually close to final production products. This process is invaluable in various industries such as automotive, medical devices, consumer electronics, and more.

This comprehensive article delves into the essence of Vacuum Mold Casting, explaining how the process works step-by-step, its advantages, typical applications, and more.

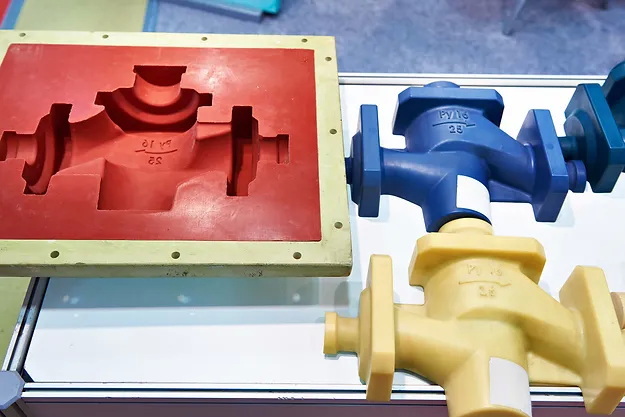

Vacuum mold casting, often referenced as vacuum casting or urethane casting, involves pouring a liquid plastic or resin into a flexible silicone mold within a vacuum environment. This vacuum environment serves to:

- Eliminate trapped air bubbles within the mold cavity

- Ensure the resin reaches every part of complex molds

- Produce parts with superior surface finishes and minimal defects

The molds used are made from silicone rubber, cast around a master pattern or prototype. Once the mold is prepared, casting materials such as polyurethane resins are degassed and poured under a vacuum chamber. After curing, the parts are extracted and undergo finishing processes.

This method is a practical, cost-effective alternative to traditional injection molding, especially for low volume production runs, typically producing between 50 to 100 parts per silicone mold, as well as for prototyping and bridging pre-mass production.

The foundation of the vacuum mold casting process is the creation of a master model. This model is the physical representation of the part to be produced and must be crafted with high precision. Master patterns are usually made by:

- 3D printing (often SLA or FDM)

- CNC machining

- Other rapid prototyping methods

It is important that the master pattern has the correct wall thickness and is free from design flaws to facilitate proper mold making and casting.

Once the master pattern is complete, it is placed inside a casting box. Liquid silicone rubber is poured over it to form a two-part flexible mold that captures every surface detail and texture of the master model. The mold is then cured, typically for 8-16 hours at around 40°C.

After curing, the mold is carefully cut open to remove the master pattern, revealing the negative cavity. A mold release agent is often applied to prevent sticking and surface imperfections.

The casting resin—usually a two-component polyurethane system—is prepared for casting. Components are mixed in precise ratios, and color pigments may be added to achieve the desired finish. To avoid air entrapment and bubbles in the final part, the resin is degassed under a vacuum for around 50-60 seconds.

In addition, the silicone mold is kept under vacuum during this process to be immediately ready for casting when the resin is poured.

With the mold securely assembled, the degassed resin is poured into the cavity inside the vacuum chamber. The vacuum helps remove any remaining air pockets from the mold and resin, allowing gravity alone to fill the mold fully and uniformly. This step ensures crisp, defect-free replication of fine details, textures, and complex geometries.

After casting, the mold is heated (typically at around 70°C) to cure the resin. The curing time depends on the resin type, but it generally takes about one hour. Proper curing enhances the structural rigidity and finish of the cast parts.

Once the resin is cured, the silicone mold is carefully opened, and the part is extracted. Excess material such as gates and risers is trimmed off. Depending on the product requirements, further finishing steps like sanding, polishing, painting, or assembly may be carried out to meet final specifications.

Vacuum mold casting offers several advantages over conventional manufacturing techniques:

- High Precision and Detail: The process produces parts with excellent surface finishes and replicates micro-details, even textures and embossed text.

- Material Flexibility: A broad variety of casting materials, including rigid, flexible, transparent, or opaque polyurethane resins, can be used to simulate different material properties.

- Cost Efficiency for Low Volume: Silicone molds are less expensive and faster to produce than metal molds, making this technique ideal for low-quantity production and prototyping.

- Speed: The entire process from master pattern to finished parts can be completed within two weeks or less, enabling rapid product development cycles.

- Complex Geometry: Vacuum mold casting effectively produces parts with complex features, thin walls, undercuts, and detailed geometries.

Vacuum mold casting is perfect for developing near-production-quality prototypes. Designers and engineers use it for form, fit, and functional testing before mass manufacturing.

The medical industry benefits from vacuum mold casting due to its ability to create custom-fit parts, surgical tool prototypes, and biocompatible material options.

Interior parts such as knobs, dashboard components, and housings are frequently produced in small batches via vacuum casting to verify designs and serve specialty vehicle markets.

Elegant plastic enclosures, buttons, and small housings for gadgets are often fabricated through vacuum casting when only limited quantities are needed.

Brands use vacuum mold casting for limited runs, market testing, or bridge production to meet demand prior to full-scale manufacturing investment.

To maximize consistency and quality in vacuum mold casting, manufacturers often employ strict quality control measures throughout the process:

- Master Model Verification: Ensuring master patterns meet design specifications using precise measuring equipment.

- Mold Inspection: Silicone molds are checked for damage or wear before each use.

- Material Testing: Casting resins are tested for viscosity and curing properties.

- Process Monitoring: Vacuum pressure and curing times are carefully monitored to prevent defects.

- Post-processing: Finished parts are inspected for dimensional accuracy, surface finish, and overall quality before shipment.

Vacuum mold casting is a versatile, efficient, and highly precise manufacturing method especially suited to rapid prototyping and low volume production. Utilizing vacuum pressure to remove air and silicone molds to replicate detailed parts, the process produces components that match the aesthetics and performance of final mass-produced items. Its affordability, short turnaround times, and adaptability across industries make vacuum mold casting a vital tool for innovators and manufacturers bridging the gap between concept and mass production.

The primary material used in vacuum mold casting is polyurethane resin, often available in rigid, flexible, or transparent formulations. Other materials include liquid silicone for molds and sometimes epoxy resins for specific applications.

Typically, a standard silicone mold can produce about 50 to 100 parts before its precision begins to deteriorate. High-quality molds with specialized curing can last for several hundred casts.

The complete cycle from pattern-making to cured parts usually spans 10 to 14 days, with the cure itself taking about one hour depending on the resin used and part size.

Yes, vacuum mold casting is well-known for replicating intricate details, textures, and even surface finishes such as matte or glossy directly from the master pattern.

Vacuum mold casting requires lower upfront costs and is ideal for smaller production runs, but it is slower and less efficient for mass manufacturing compared to injection molding, which excels in high volume production with metal molds.

[1](https://formlabs.com/blog/vacuum-casting-urethane-casting-polyurethane-casting/)

[2](https://www.immould.com/vacuum-casting/)

[3](https://leadrp.net/blog/overview-of-vacuum-casting/)

[4](https://xometry.pro/en-eu/articles/vacuum-casting-overview/)

[5](https://protoandgo.com/en/vacuum-casting-what-is-it-and-what-does-the-process-consist-of/)

[6](https://www.youtube.com/watch?v=0uB9dQu-kTw)

[7](https://objectify.co.in/a-comprehensive-guide-to-vacuum-casting-everything-you-need-to-know/uncategorized/)

[8](https://xometry.eu/en/vacuum-casting-technology-overview/)

[9](https://www.volum-e.com/coulee-sous-vide/?lang=en)

[10](https://www.slideshare.net/slideshow/vaccum-mold-casting-1/75813169)

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam