Views: 222 Author: Amanda Publish Time: 2025-10-16 Origin: Site

Content Menu

● The Importance of Consistency in 3D Print Prototypes

● Role of Data Analytics in 3D Print Prototype Consistency

>> Data Processing and Analysis

>> Optimization and Feedback Loops

● Technologies Leveraged in Data-Driven 3D Print Consistency

>> Artificial Intelligence and Machine Learning

>> Finite Element Analysis (FEA) and Simulation

● Real-Time Monitoring and Defect Detection

● Case Studies in Data-Driven 3D Printing

>> Case Study 1: Reducing Scrap Rates in Automotive Prototyping

>> Case Study 2: AI-Powered Quality Control in Medical Devices

● Benefits of Data Analytics in 3D Print Prototyping

● Challenges and Future Directions

● The Human Element in Data-Driven Manufacturing

● Frequently Asked Questions (FAQs)

>> 1. How does data analytics improve the accuracy of 3D print prototypes?

>> 2. What role does AI play in optimizing 3D print prototypes?

>> 3. Can data analytics reduce the time needed for prototype development?

>> 4. Is predictive maintenance important for maintaining consistency in 3D printing?

>> 5. What are the biggest challenges in applying data analytics to 3D printing?

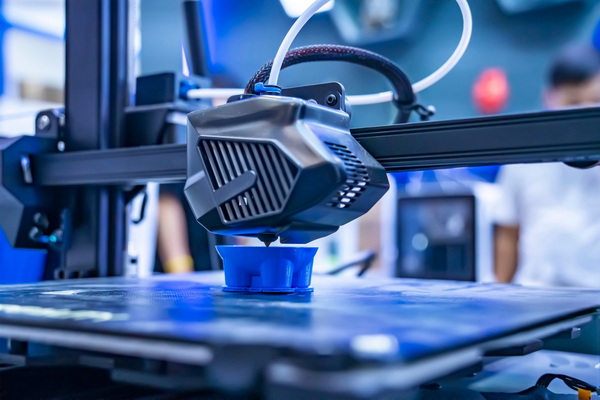

The manufacturing industry, especially in rapid prototyping and 3D printing, is undergoing a profound transformation driven by data analytics. 3D print prototypes, essential for product development and functional validation, require high consistency to ensure accuracy, reliability, and efficiency. Integrating data analytics into 3D printing processes has revolutionized how manufacturers achieve prototype consistency, optimize quality, reduce waste, and accelerate production timelines.

This comprehensive article explores how data analytics improve 3D print prototype consistency, highlighting key technologies, methodologies, benefits, and real-world applications. The insights provided are tailored for OEMs, brand owners, and manufacturing professionals aiming for precision in 3D print prototyping.

3D print prototypes serve as the foundational step in product design cycles, enabling visualization, functional testing, and design verification. Inconsistent prototypes can lead to costly design errors, extended development cycles, and increased production waste.

Consistency in 3D printing prototype dimensions, mechanical properties, and surface quality ensures fidelity to the original CAD model and reliable performance in subsequent testing phases. Maintaining this consistency poses challenges due to variables such as printer calibration, material properties, ambient environmental factors, and operator settings.

For manufacturers like Shangchen (sc-rapidmanufacturing.com), which provide CNC machining, 3D printing, and precision batch production services, ensuring consistency in 3D print prototypes is critical for delivering high-quality OEM solutions to global clients. Inconsistent outputs not only affect product performance but also damage client trust and brand reputation.

Data analytics empowers manufacturers by leveraging the extensive data generated during printing to monitor, analyze, and optimize the prototyping process.

Sensors embedded in 3D printers collect real-time data including temperature, humidity, motor currents, vibration, and layer deposition rates. Quality control systems utilize visual data from cameras and laser scanners to evaluate layer accuracy and surface defects. These data streams are continuously logged and stored for analysis.

Advanced software platforms process and analyze this data to identify patterns and anomalies. Statistical methods, such as the Taguchi Methodology and factorial design, help optimize print parameters for reducing variability in mechanical and dimensional accuracy.[1]

Machine learning algorithms predict potential print failures and suggest corrective actions by learning from historical print datasets. For example, a neural network trained on thousands of print logs can detect early signs of under-extrusion or warping and recommend parameter adjustments before defects become irreversible.[2]

By analyzing operational data, predictive maintenance algorithms minimize unexpected downtime, thereby maintaining a stable printing environment critical for consistency. This proactive approach reduces the risk of mid-print failures and ensures that equipment operates within optimal parameters.

Data-driven feedback enables real-time adjustment of print parameters. For instance, if a deviation in layer thickness or temperature is detected, corrective commands are sent to the printer to maintain the desired print quality. This closed-loop control system significantly enhances the repeatability of 3D print prototypes.[3]

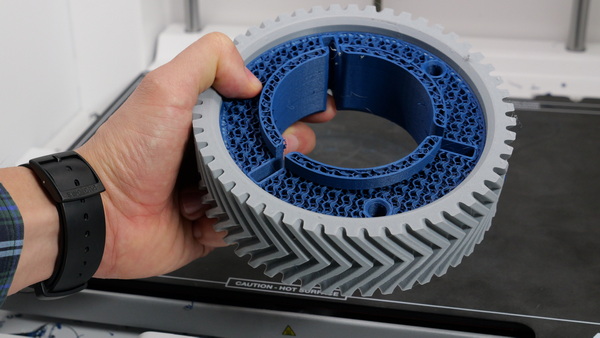

AI uses learned patterns to optimize design and print settings automatically. It can evaluate thousands of design variants to enhance structural integrity and material efficiency in prototypes, reducing trial-and-error cycles. Transfer learning models like MobileNetV2 have demonstrated high accuracy in classifying defects such as stringing, layer shifting, and under-extrusion in 3D printed parts.[4]

FEA integrates with data analytics to simulate mechanical stresses on prototypes, guiding design modifications that improve print success rates and prototype performance. When combined with real-time monitoring data, FEA models can be refined to reflect actual material behavior under specific printing conditions.

IoT sensors continuously stream operational data for centralized analysis, facilitating comprehensive quality control. Cloud-based platforms allow remote monitoring of multiple printers across different locations, enabling centralized oversight and rapid response to anomalies.[5]

Real-time monitoring is a cornerstone of data-driven 3D printing. Systems that analyze between-layer structural similarity (BLSS) using SSIM, FFT, and NCC algorithms can detect defects caused by misalignment, nozzle clogging, or thermal fluctuations.[6]

These systems compare actual print layers with simulated ones, flagging deviations as they occur. When integrated with machine learning, such monitoring becomes predictive rather than reactive. For example, a deep multi-head neural network can simultaneously predict flow rate, lateral speed, Z offset, and hotend temperature from nozzle images, enabling instant corrections.[2]

Such capabilities are particularly valuable in high-stakes industries like aerospace and medical device manufacturing, where even minor inconsistencies in 3D print prototypes can lead to catastrophic failures.

A leading automotive supplier implemented a data analytics platform to monitor its fleet of industrial 3D printers. By analyzing temperature gradients and layer adhesion data, the system identified optimal print speeds and chamber humidity levels. This led to a 30% reduction in failed prints and a 25% improvement in dimensional accuracy of 3D print prototypes.[3]

A medical device manufacturer adopted a convolutional neural network (CNN)-based system to inspect 3D printed orthopedic implants. The model was trained on thousands of defect-labeled images and achieved over 98% accuracy in detecting micro-cracks and porosity. This real-time quality control system reduced post-processing inspection time by 70% and ensured consistent prototype quality.[7]

- Higher Precision and Repeatability: Data analytics assures each prototype matches dimensional and mechanical specifications closely, enhancing reliability across iterations.[3]

- Reduced Material Waste: Optimization reduces failed prints and excess material usage, lowering costs and environmental impact.

- Shortened Development Cycles: Faster identification and correction of process issues accelerate prototype iteration, enabling rapid time-to-market.

- Cost Savings: Predictive maintenance and optimized workflows lower operational and labor costs.

- Enhanced Customization: Scalability to produce individualized prototypes without sacrificing quality supports mass customization trends.

While data analytics offers immense benefits, challenges remain. Integrating data from heterogeneous sources—different printer models, materials, and software platforms—requires robust data harmonization techniques. High initial setup costs and the need for skilled data scientists can be barriers for smaller manufacturers.

Future research focuses on developing self-optimizing 3D print systems that combine AI, big data, and additive manufacturing. These systems will not only detect and correct errors but also discover new parameter combinations and learn how to print novel materials autonomously.[2]

Another emerging trend is the use of federated learning, where multiple manufacturers contribute anonymized data to train shared models without compromising intellectual property. This collaborative approach accelerates innovation while preserving data ownership.[3]

Despite advances in automation, the human element remains crucial. Data analytics provides tools, but engineers and designers apply their expertise to interpret results and make strategic decisions. In contexts of high uncertainty or innovation, human creativity, imagination, and intuition are irreplaceable.[3]

Smart data does not replace human intelligence; it enhances it. A skilled engineer using data insights can achieve outcomes far beyond what automation alone can deliver. As Peter Leys of Materialise noted, “Adding an additional, personal layer of intelligence to the process allows a company to make a difference and create a competitive advantage”.[3]

Data analytics profoundly improves 3D print prototype consistency by harnessing real-time data, advanced algorithms, and automated processes to refine every printing stage. This technological evolution reduces production risks, lowers costs, enhances quality, and accelerates innovation. As industries increasingly adopt data-driven 3D printing, those leveraging analytics will gain competitive advantages in precision manufacturing and rapid prototyping.

For manufacturers like Shangchen, integrating data analytics into 3D printing workflows is not just a technological upgrade—it is a strategic imperative for delivering consistent, high-quality prototypes to global clients.

Data analytics evaluates real-time sensor data and identifies printing parameter deviations early, enabling immediate corrections that prevent dimensional inaccuracies and ensure prototypes closely match CAD designs.[3]

AI algorithms analyze design variations and printer performance to suggest optimal print settings, predict failures, and automate adjustments that enhance prototype structural integrity and reduce material waste.[2]

Yes, by providing faster detection of print defects and guiding parameter optimization, data analytics shortens iteration cycles, accelerating overall prototype development timelines.[3]

Absolutely. Predictive maintenance uses IoT sensor data to anticipate equipment issues, reducing unplanned downtime and ensuring stable printing environments for consistent prototypes.[5]

The major challenges include managing large heterogeneous datasets, integrating data analytics into existing workflows, upfront investment costs, and the need for technical expertise in analytics and additive manufacturing.[3]

[1](https://pmc.ncbi.nlm.nih.gov/articles/PMC9976681/)

[2](https://www.nature.com/articles/s41467-022-31985-y)

[3](https://www.engineering.com/bringing-the-power-of-data-to-3d-printing/)

[4](https://arxiv.org/html/2310.08645)

[5](https://www.3dprinteros.com/articles/explore-8-solutions-of-3d-printer-monitoring-software-for-2025)

[6](https://dl.acm.org/doi/fullHtml/10.1145/3647649.3647694)

[7](https://www.emerald.com/rpj/article/31/7/1428/1258490/Defect-detection-in-3D-printed-polymer-parts-using)

[8](https://www.meegle.com/en_us/topics/3d-printing/3d-printing-case-studies)

[9](https://brainstation.io/magazine/big-data-3d-printing)

[10](https://www.sciencedirect.com/science/article/abs/pii/S0263224125007213)

[11](https://webthesis.biblio.polito.it/secure/25499/1/tesi.pdf)

[12](https://www.sciencedirect.com/science/article/pii/S0166497223001037)

[13](https://www.engineering.com/when-is-real-time-monitoring-useful-for-3d-printing-simulation/)

[14](https://www.astrj.com/pdf-196684-120657?filename=A+novel+machine+learning.pdf)

[15](https://fenix.tecnico.ulisboa.pt/downloadFile/3096619880808607/Dissertacao_JoaoMarcos_90661.pdf)

[16](https://www.sciencedirect.com/science/article/abs/pii/S0957417425004853)

[17](https://www.sciencedirect.com/science/article/abs/pii/S2214785320381037)

[18](https://www.sc-rapidmanufacturing.com/how-data-analytics-improves-3d-printing-process-control.html)

[19](https://www.eos.info/enablement/software/eos-smart-monitoring)

[20](https://aodr.org/xml/12875/12875.pdf)

[21](https://onlinelibrary.wiley.com/doi/full/10.1002/aisy.202200153)

content is empty!

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes

Best Practices from Leading Vacuum Mold Casting Companies Worldwide

Top Vacuum Mold Casting Providers for Custom Batch Production

How to Choose the Right Vacuum Mold Casting Service for Your Product