Views: 222 Author: Amanda Publish Time: 2026-01-06 Origin: Site

Content Menu

● What Is Rapid Compressor Music Prototyping?

● Why Rapid Prototyping Matters for Compressors

● Core Tools for Rapid Prototyping Compression

● Step-by-Step: Building a Rapid Prototyping Compressor Workflow

>> Define Your Compression Goal

>> Prepare Clean Reference Material

>> Create Parallel Rapid Prototyping Chains

>> Use Visual and Audio Monitoring

>> Document and Save Rapid Prototyping Presets

● Using Rapid Prototyping to Design Compressor-Heavy Mixes

>> Rapid Prototyping on Individual Tracks

>> Rapid Prototyping on Buses and Masters

● Integrating Hardware and Virtual Rapid Prototyping

● Best Practices for Rapid Prototyping in Music Compression

● When to Move from Rapid Prototyping to Final Mix

● Working with an OEM Partner for Audio Rapid Prototyping

● FAQ

>> 1. What does rapid prototyping mean in music production?

>> 2. Which DAW is best for rapid prototyping compression?

>> 3. How many rapid prototyping versions should I test?

>> 4. Can rapid prototyping help in hardware compressor design?

>> 5. How do I avoid over-compressing when using rapid prototyping?

Rapid prototyping has changed how modern producers design music, test compressor settings, and shape the final sound of their tracks. By building a fast, repeatable rapid prototyping workflow, you can experiment with compressor chains, compare versions, and reach polished mixes in a fraction of the time.[1][2]

Rapid compressor music prototyping is the practice of quickly building, testing, and refining different compressor settings and signal chains inside a DAW before committing to a final mix. It borrows ideas from industrial rapid prototyping, where engineers use iterative models to validate performance, tone, and user experience as early as possible.[3]

- It focuses on speed: you move from idea to testable compressor setup in minutes.

- It emphasizes iteration: you run many rapid prototyping cycles before printing a final version.

- It relies on digital tools: compressors, limiters, transient shapers, and metering plugins inside your DAW.[4]

For hardware-oriented brands, rapid prototyping also extends to physical audio devices such as smart speakers, interfaces, or compressor units that are tested virtually and with quick-turn samples.[5]

Compression has an enormous impact on punch, clarity, and perceived loudness, but it is highly context-dependent and easy to overdo. A rapid prototyping mindset lets you evaluate several compressor ideas side by side instead of guessing in real time on a single track.[2][6]

Key benefits of rapid prototyping in music compression include:

- Faster decisions: A/B different attack, release, and ratio values in structured tests.

- Better consistency: Save successful rapid prototyping chains as templates for similar songs.

- More creative freedom: Explore unconventional settings with no risk to the core project.

OEM factories that specialize in rapid prototyping for audio hardware also use this approach to validate compressors inside speakers, headphones, and smart audio devices before mass production.[3]

A modern rapid prototyping workflow for music compression usually combines three layers: DAW, plugins, and monitoring tools.[1]

- DAW: Flexible DAWs with strong routing and clip-based workflows are ideal for rapid prototyping, because they allow fast duplication, parallel processing, and quick comparison.[7]

- Compressor plugins: Modern compressor plugins emulate vintage units or introduce new concepts such as multiband or upward compression, giving you many options for rapid prototyping chains.[4]

- Metering and analysis: Loudness meters, oscilloscopes, and spectrum analyzers help validate rapid prototyping results objectively, not only by ear.

Hardware and virtual prototyping platforms for audio devices increasingly combine physical models with simulation to evaluate sound fields, transducers, and enclosures in a fully virtual rapid prototyping loop.[5]

Rapid prototyping becomes powerful when it follows a clear, repeatable sequence inside each project.[2]

Before turning any knobs, state a concrete goal for this rapid prototyping cycle.

- Do you want more punch on drums, a smoother vocal, or tighter bass?

- Are you solving a technical problem (peaks clipping) or chasing a creative color?

In hardware development, similar goal-setting anchors rapid prototyping stages such as feasibility studies and engineering validation, which prevents uncontrolled scope creep.[3]

Select dry audio clips or short sections of the song that clearly reveal the issue you want compression to fix.

- For vocals, choose a phrase with both loud and soft words.

- For drums, pick a loop with kicks, snares, and cymbals hitting at different intensities.

- For bus or master compression, use a busy chorus where instruments overlap.

Export or duplicate these into a dedicated rapid prototyping track so you can loop them without touching the main arrangement, keeping experiments isolated from the production master.

Set up multiple parallel tracks or routings, each with its own compressor chain, so you can A/B or A/B/C quickly.[1]

- Chain A: Transparent compression with gentle ratio and slow attack for natural dynamics.

- Chain B: Aggressive compression with fast attack and higher ratio for controlled peaks.

- Chain C: Character compression using a vintage-modeled plugin for color and saturation.[6]

This is pure rapid prototyping: you compare distinct concepts rather than tweaking a single setting endlessly and losing track of your baseline.

While looping the selected audio, watch meters to support your ears.

- Gain reduction meter: confirm how much compression occurs on peaks versus average signal.

- Loudness meter: check integrated and short-term loudness when comparing prototypes.

- Waveform scope: verify transient shape and sustain with each rapid prototyping chain.[8]

Professional audio hardware developers similarly use measurement equipment and simulations to verify rapid prototyping iterations before finalizing designs, combining subjective listening with hard data.[5]

Each time a chain performs well on a particular source, save it as a preset or template tagged with use-case descriptors such as “vocal gentle,” “drum bus punch,” or “acoustic guitar glue.”[1]

- Store screenshots of settings, short notes, and audio exports labeled by date.

- Tag them with genre, BPM, or singer type for easy future recall.

These archives turn your studio into a rapid prototyping library that speeds up every new project and supports consistent sonic branding over time.

A compressor is seldom used in isolation, so rapid prototyping should extend across the entire mix, from individual elements to buses and the stereo master.[6]

On key tracks like lead vocals, kick, snare, and bass, run several rapid prototyping passes instead of settling for the first working setting.

- Try at least three contrasting compressor plugins or modes per important track.[4]

- Compare different topologies (VCA, FET, optical, digital) to hear their behavior in your rapid prototyping tests.

- Use rapid prototyping to decide if an extra stage such as a limiter or transient shaper improves control.[2]

For hardware-oriented creators working with OEM partners, these preferences can be translated into the design requirements of embedded compressors, DSP algorithms, or processing chips.

Bus and master compression often define the overall feel of the track and should benefit from structured rapid prototyping.

- Drum bus: Rapid prototyping can help find the balance between punch and room ambience.

- Vocal bus: Test de-esser plus transparent compressor versus more colored single-stage chain for presence.[6]

- Master bus: Rapid prototyping can compare clean glue compression against more aggressive bus compression for loudness and excitement.

Save these bus chains as “mix backbone” templates so you can reuse successful rapid prototyping results on future projects in the same style.

If you build or spec actual compressor hardware or smart audio devices, rapid prototyping becomes both digital and physical, tying software behavior to real-world listening.[3]

- Virtual simulations: Acoustic simulation platforms can predict how drivers, enclosures, and positioning affect perceived dynamics and influence how built-in compression should behave.[5]

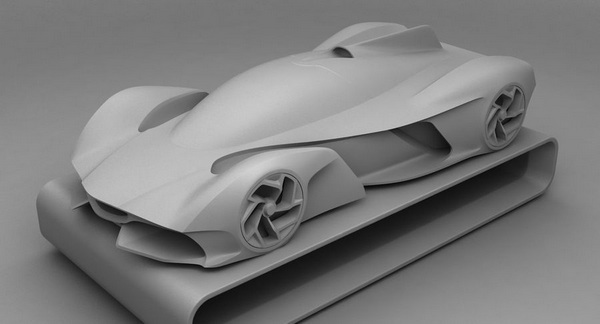

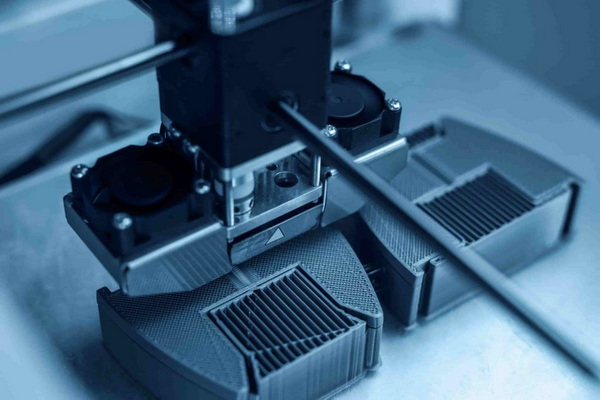

- Early samples: Engineering samples produced with rapid prototyping techniques—such as 3D printing and fast machining—allow hands-on tests long before full tooling.[3]

- Iterative revisions: Test fixtures, firmware updates, and mechanical tweaks are combined in rapid prototyping loops until the compressor behavior matches the target character.[9]

OEM factories in China that specialize in rapid prototyping, CNC machining, sheet metal fabrication, and mold production can support compressed audio products from enclosure to mounting hardware, ensuring that mechanical design and sound design evolve together.

To get reliable results from rapid prototyping, adopt a few disciplined habits that keep experiments focused and reproducible.[2]

- Change one parameter at a time so the effect of each tweak is clear and attributable.

- Normalize loudness between prototypes so louder does not just sound better by default.[6]

- Take short breaks to reset listening perception and avoid fatigue that can mislead decisions.

In hardware and OEM contexts, this same discipline is mirrored in structured test plans, controlled variables, and clear documentation across rapid prototyping cycles to ensure that improvements are measurable and repeatable.[3]

One risk of powerful rapid prototyping workflows is endless experimentation, so it is important to define a clear exit point.[2]

- Set a maximum number of rapid prototyping variants per element, such as three for each key track.

- Choose the best candidate with both technical and emotional criteria in mind by doing level-matched blind comparisons.

- Print stems or commit settings once the chosen prototype consistently wins, freeing CPU and mental bandwidth for creative moves.[1]

In professional manufacturing, teams also lock designs after a defined number of rapid prototyping iterations to keep timelines and budgets under control, which is a useful mindset to adopt in the studio as well.[3]

Companies that develop their own compressors, smart speakers, or music hardware can benefit from partnering with an experienced rapid prototyping OEM factory that understands both mechanical and acoustic requirements.[10]

Such partners typically provide:

- Mechanical and enclosure rapid prototyping via CNC machining, 3D printing, and sheet metal fabrication, supporting quick changes during development.[3]

- Precision low-volume builds for engineering validation, beta testing, and certification.

- Tooling and production-ready designs once rapid prototyping confirms fit, finish, and acoustic performance.

By aligning software-based rapid prototyping in the DAW with hardware rapid prototyping at the factory, brands can bring integrated audio products to market faster and with more predictable sound characteristics while maintaining consistent compressor behavior across devices.[5]

Rapid compressor music prototyping combines fast digital experimentation with structured iterations to reach better compression decisions in less time. By creating parallel signal chains, using clear monitoring, documenting results, and, where needed, linking to hardware rapid prototyping and OEM manufacturing, producers and brands can translate creative ideas into consistent, repeatable sound signatures across songs, products, and global markets.[2][3]

In music production, rapid prototyping means quickly building and testing several versions of a processing chain—such as different compressor settings or plugin combinations—before committing to one in the final mix. It allows you to audition multiple options side by side without disrupting the main session, similar to how engineers in other industries use rapid prototyping to evaluate design variants efficiently.[1][3]

Many DAWs are suitable, but those with flexible routing and efficient workflows—such as pattern- or clip-based systems—are particularly strong for rapid prototyping, because they make duplicating tracks and routing buses easy. They also offer quick preset management and template systems, which help capture successful rapid prototyping compressor chains and reuse them across projects.[7][1]

Most producers find that two to four rapid prototyping variants per element are enough to reveal a clear winner without causing decision fatigue or unnecessary complexity. The key is to make each prototype meaningfully different—for example, transparent, punchy, and colored—rather than generating dozens of near-identical versions that slow down the process.[6][2]

Yes, hardware developers increasingly rely on rapid prototyping using virtual simulations, 3D printed enclosures, and quick-turn CNC or molding samples to test compressor circuits and housing designs. This approach allows them to refine sound, ergonomics, and manufacturability before investing in full-scale production tooling, reducing risk and accelerating time to market.[5][3]

Use loudness-normalized comparisons, keep an eye on gain reduction meters, and listen for loss of transients or pumping artifacts across your rapid prototyping variants. If a prototype sounds exciting but significantly reduces dynamic range, keep a more natural alternative as a backup and choose based on the song's style, streaming platform, and listener expectations.[4][6]

[1](https://neuraldsp.com/getting-started/best-daw)

[2](https://www.musicradar.com/news/9-time-saving-plugins)

[3](https://www.protolabs.com/resources/partnerships/sonos/)

[4](https://www.musicradar.com/news/best-compressor-plugin)

[5](https://www.treble.tech/insights/advanced-virtual-prototyping-of-audio-devices)

[6](https://theproaudiofiles.com/compressor-plugins/)

[7](https://www.kvraudio.com/forum/viewtopic.php?t=537256)

[8](https://www.youtube.com/watch?v=Wag-yTyAxPA)

[9](https://pathfinderinnovations.ie/blog/prototyping-for-audio-technology-design-crafting-the-perfect-sound-systems/)

[10](https://ajprotech.com/audio-devices)

content is empty!