Views: 222 Author: Amanda Publish Time: 2026-01-07 Origin: Site

Content Menu

● Why Cutting Tool Choice Matters in CNC Machining

● Main Categories of CNC Machining Cutting Tools

● End Mills – The Core Tools of CNC Machining

● Face Mills – Preparing Reference Surfaces

● Slot Drills, Roughers, and High-Feed Cutters

● Drills and Center Drills – Essential Hole-Making Tools

● Reamers – Achieving Tight Hole Tolerances

● Taps and Thread Mills – Cutting Internal Threads

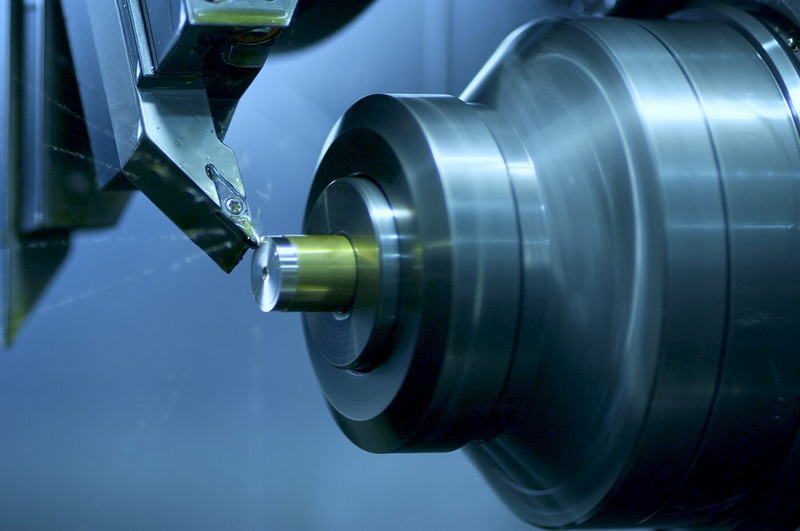

● Lathe Turning Tools and Inserts

● Boring Bars and Internal Tools

● Specialty Tools – Chamfering, Deburring, and Micro Tools

● Cutting Tool Materials in CNC Machining

● Tool Coatings and Surface Treatments

● Matching Tools to Workpiece Materials

● Key Factors in Cutting Tool Selection for CNC Machining

● Tool Holding, Runout, and Setup Quality

● Coolant, Lubrication, and Chip Control

● Process Optimization with a Professional CNC Machining Partner

● FAQ

>> 1. What is the most commonly used cutting tool in CNC Machining?

>> 2. Is carbide always better than HSS for CNC Machining?

>> 3. Which cutting tools work best for CNC Machining aluminum?

>> 4. When should reamers be used during CNC Machining?

>> 5. How do tool coatings extend life in CNC Machining?

The best cutting tools for CNC Machining operations are those that match the workpiece material, part geometry, surface finish requirements, and production volume, with carbide end mills, drills, and indexable inserts forming the core of most modern setups. When tool material, geometry, and coating are selected correctly, CNC Machining can run faster, last longer between tool changes, and deliver more consistent tolerances for demanding OEM projects.

Cutting tools sit at the heart of CNC Machining because they directly affect cycle time, tool life, surface finish, and dimensional accuracy on every part. Well-optimized tooling reduces scrap, limits unplanned downtime, and allows CNC Machining factories like Shangchen to run complex jobs reliably for overseas OEM customers.

- Properly matched tools, coatings, and parameters reduce heat, friction, and wear during CNC Machining.

- Using inappropriate tools for material or geometry can cause chatter, tool breakage, and out-of-tolerance features in CNC Machining.

CNC Machining typically relies on a family of cutting tools that cover milling, drilling, turning, threading, and finishing operations across metals and plastics. Knowing what each tool does helps engineers and buyers communicate clearly with CNC Machining suppliers and choose the right process route.

- Milling cutters: end mills, face mills, ball nose tools, and special profile mills.

- Hole-making tools: drill bits, center drills, reamers, taps, and thread mills used in CNC Machining centers.

- Turning tools: indexable inserts, boring bars, and grooving tools used on CNC lathes.

End mills are the most common tools on vertical CNC Machining centers, used for slotting, profiling, pocketing, and 3D surfacing. Because they can cut both radially and axially, they are extremely versatile for prismatic parts in CNC Machining.

- Flat end mills are ideal for roughing and finishing flat surfaces, pockets, and shoulders.

- Ball nose end mills are preferred for 3D contours, mold cavities, and freeform surfaces in CNC Machining.

- Corner radius end mills combine strength and finish, reducing chipping on edges in continuous CNC Machining.

Face mills are designed to rapidly remove material from large, flat surfaces and are often the first tools to touch raw stock in CNC Machining. They typically use indexable inserts, which lowers cost per cutting edge and allows fast insert changes between jobs.

- Face milling creates accurate reference planes before smaller features are machined.

- The right lead angle, insert geometry, and cutting data reduce chatter and improve surface finish in CNC Machining.

Beyond standard end mills, CNC Machining benefits from specialized milling tools such as slot drills, roughing mills, and high-feed cutters. These are particularly useful when stock removal rates and stability are critical.

- Slot drills with center-cutting geometry are used to plunge into solid material and open pockets efficiently in CNC Machining.

- Roughing end mills with serrated edges break chips and reduce cutting forces, enabling heavier cuts in tough materials.

- High-feed cutters use shallow depths of cut with high feed rates to remove material quickly while keeping loads predictable in CNC Machining.

Twist drills create the majority of holes in CNC Machining, from clearance holes and tapped holes to coolant passages and dowel pin seats. Center or spot drills are used first to prevent drill walking and ensure accurate hole positioning.

- Stub-length drills provide rigidity and positional accuracy for shallow holes in CNC Machining.

- Longer drills and parabolic flute designs improve chip evacuation in deeper holes.

- Step drilling strategies can be used to safely reach depth in harder materials or when machine power is limited in CNC Machining.

Reamers enlarge and refine pre-drilled holes to meet narrow diameter and roundness tolerances in CNC Machining. They are especially important in precision assemblies where pins, shafts, or bushings must fit consistently.

- A common approach is to drill slightly undersize and then ream to final size in one pass.

- Correct cutting fluid, feed rate, and alignment are critical to getting predictable results from reaming in CNC Machining.

Taps and thread mills are the primary tools for internal threads in CNC Machining. Taps are simple and fast for standard threads, while thread mills offer more flexibility and reduced scrap risk in high-value parts.

- Thread mills can cut different diameters and thread classes with a single tool using helical interpolation.

- On deep or blind holes, thread milling in CNC Machining can improve chip control and reduce the risk of tool breakage.

- Rigid tapping cycles and correct tap geometry remain efficient solutions for high-volume threaded holes in CNC Machining.

On CNC lathes, indexable turning tools with carbide inserts perform most OD and ID machining, from roughing bars to finishing shoulders. Insert shape, nose radius, chipbreaker design, and grade all influence the performance of turning operations in CNC Machining.

- Roughing inserts with strong edges handle heavy cuts and scale removal on forged or cast parts.

- Finishing inserts with smaller nose radii and positive rake angles create smooth surfaces and accurate diameters in CNC Machining.

- Groove and part-off tools enable accurate separation of components and creation of reliefs or snap-fit features.

Boring bars are essential whenever internal diameters must be enlarged, straightened, or finished with high precision in CNC Machining. They provide better control over hole geometry than drilling alone, especially on deeper bores.

- Fine-boring tools can hold tight tolerances on bearing seats and alignment bores.

- Anti-vibration boring bars are used in deep-hole CNC Machining to suppress chatter and maintain surface quality.

In many CNC Machining projects, small details such as chamfers and deburring are critical for assembly and safety. Dedicated tools for these tasks improve repeatability and reduce manual finishing.

- Chamfer mills are used to break edges, add lead-ins to holes, and create countersinks in CNC Machining.

- Deburring tools remove sharp burrs left by drilling or milling, which is particularly important for fluid paths and handling safety.

- Micro tools and very small-diameter end mills are used for fine features in electronics, medical, and precision instrument CNC Machining.

Tool material determines how fast and how long a cutting edge can work in CNC Machining before wearing out. Common materials include high-speed steel, solid carbide, cermet, ceramic, CBN, and PCD.

- Solid carbide is the default for high-performance CNC Machining in steels, stainless steels, and many non-ferrous alloys because of its hardness and heat resistance.

- HSS remains useful for lower-speed machining, manual operations, and applications where toughness is more important than ultimate tool life.

- Advanced materials like CBN, ceramics, and PCD are used for abrasive or hardened workpieces where conventional tools fail quickly in CNC Machining.

Tool coatings have become a crucial part of modern CNC Machining because they directly influence wear, heat management, and chip adhesion. Popular coatings include TiN, TiCN, TiAlN, AlTiN, and DLC, applied through PVD or CVD processes.

- TiAlN and AlTiN coatings withstand high temperatures, making them suitable for high-speed cutting of alloy steels in CNC Machining.

- DLC and polished surfaces help prevent built-up edge when cutting aluminum and other sticky non-ferrous materials.

- The right combination of substrate and coating often extends tool life significantly compared with uncoated tools in CNC Machining.

One of the key tasks in CNC Machining process planning is matching cutting tools and coatings to the workpiece material. Each material group behaves differently under cutting conditions, so choosing the wrong tool can shorten life and reduce quality.

- Aluminum and copper alloys typically require sharp, high-helix carbide tools and careful chip evacuation in CNC Machining.

- Steels and stainless steels often benefit from coated carbide with tougher substrates to handle higher cutting forces.

- Titanium and nickel-based alloys demand high-quality carbide or advanced materials combined with conservative feeds and speeds in CNC Machining.

Selecting the “best” cutting tools for CNC Machining is always application-specific and should follow a structured approach. Considering all major variables helps achieve stable processes and predictable costs.

- Define workpiece material, hardness, part geometry, tolerance requirements, and surface finish targets.

- Consider machine tool rigidity, spindle power, available coolant systems, and tool holding options in CNC Machining.

- Evaluate total cost per part, including tool price, tool life, cycle time, and setup time, instead of looking at tool cost alone.

Even the best cutting tool will not perform properly in CNC Machining if the tool holding system and setup are poor. Runout, imbalance, and insufficient rigidity all reduce tool life and degrade surface finish.

- High-quality collet chucks, hydraulic chucks, and shrink-fit holders reduce runout and vibration in CNC Machining.

- Keeping stick-out as short as possible improves rigidity and reduces chatter, especially with small-diameter tools.

- Regular inspection and cleaning of tool holders and spindle tapers is essential for stable CNC Machining over the long term.

Coolant strategy has a major impact on tool life and process stability in CNC Machining. Proper cooling and lubrication protect both the cutting edge and the workpiece while also improving chip evacuation.

- Flood coolant or through-tool coolant is often used on deep drilling and high-speed milling operations.

- In some materials, especially cast iron, dry CNC Machining can be effective with the right coated tools and dust management.

- Chip-breaking geometries and programmed chip evacuation moves help prevent recutting chips, which can otherwise damage edges in CNC Machining.

For overseas brands, wholesalers, and manufacturers, working with a professional CNC Machining partner simplifies tooling decisions and process optimization. A factory that integrates rapid prototyping, CNC Machining, turning, sheet metal work, 3D printing, and mold making can design complete solutions from concept to batch production.

- An experienced CNC Machining supplier helps select tool materials, coatings, and strategies that balance performance and cost at the required volume.

- Close collaboration on DFM, fixture design, and toolpath strategies reduces risk and accelerates new product launch for OEM clients.

The best cutting tools for CNC Machining operations are not a single type or brand but a well-chosen combination of end mills, face mills, drills, reamers, taps, and indexable inserts tailored to each part and material. By understanding tool materials, coatings, and selection principles, engineers and buyers can unlock higher productivity, better surface finishes, and more stable CNC Machining processes in both prototyping and batch production.

The most commonly used cutting tool in CNC Machining is the carbide end mill because it can handle slotting, profiling, pocketing, and even light drilling on machining centers. Its versatility makes it the default choice for many prismatic parts and general-purpose operations in CNC Machining.

Carbide is generally better for high-speed, high-volume CNC Machining because it maintains hardness at elevated temperatures and supports more aggressive cutting data. However, HSS tools still have a role in lower-speed machining and applications where toughness or lower upfront cost is more important than maximum productivity.

For aluminum, sharp, high-helix carbide end mills with polished flutes are usually the best choice in CNC Machining, as they reduce built-up edge and improve chip evacuation. In high-volume or very demanding applications, PCD-tipped tools and low-friction coatings can further extend tool life and enhance surface finish.

Reamers should be used in CNC Machining whenever drilled holes must meet tight diameter tolerances or require very smooth internal surfaces, such as for dowel pins or bearing fits. The typical approach is to drill slightly undersize and then ream to final size in a controlled pass with appropriate coolant and feed.

Tool coatings extend life in CNC Machining by reducing friction, improving heat resistance, and minimizing chip adhesion on the cutting edge. This allows higher cutting speeds, more consistent wear patterns, and fewer tool changes, which together lower cost per part and stabilize production.

content is empty!