Views: 222 Author: Amanda Publish Time: 2026-01-08 Origin: Site

Content Menu

● Why China Leads in 3D Printing Prototype Services

● 1. Shangchen – Integrated 3D Printing Prototype Partner

● 2. Unionfab – Large‑Scale 3D Printing Platform

● 3. HLH Proto – Prototyping and Low‑Volume Production

● 4. FacFox – Multi‑Technology Manufacturing Platform

● 5. Shenzhen JR Technology – Industrial 3D Printing and CNC

● 6. WayKen Rapid Manufacturing – Precision Prototyping

● 7. 3ERP – High‑Precision 3D Printing and CNC

● 8. Star Rapid – Global‑Oriented Rapid Manufacturer

● 9. SuNPe Prototype – Rapid Prototyping and Low‑Volume Manufacturing

● 10. IN3DTEC – 3D Printing and Reverse Engineering

● How to Choose 3D Printing Prototype Service Companies in China

● Typical Applications of 3D Printing Prototype Service Companies

● How Shangchen Supports Different Industries

● How to Work Effectively with 3D Printing Prototype Service Companies

● Future Trends for 3D Printing Prototype Service Companies in China

● FAQ – 3D Printing Prototype Service Companies in China

>> 1. What services do 3D Printing Prototype Service Companies in China typically provide?

>> 2. How fast can 3D Printing Prototype Service Companies deliver parts to overseas buyers?

>> 4. How do 3D Printing Prototype Service Companies handle OEM/ODM and confidentiality?

>> 5. Why choose Shangchen among many 3D Printing Prototype Service Companies in China?

China has become one of the most competitive bases for 3D Printing Prototype Service Companies, serving global brands across automotive, aerospace, medical, electronics, consumer goods, and industrial equipment. These 3D Printing Prototype Service Companies combine advanced additive manufacturing, CNC machining, and rapid prototyping to help OEM buyers shorten development cycles and reduce project risk.

For overseas brands, wholesalers, and OEM manufacturers, choosing the right 3D Printing Prototype Service Companies in China is critical to achieve accurate functional prototypes, fast lead times, and reliable small‑batch production. The following list highlights ten representative 3D Printing Prototype Service Companies in China, with Shangchen (sc‑rapidmanufacturing.com) ranked first as a one‑stop rapid prototyping and manufacturing partner.

China's 3D Printing Prototype Service Companies benefit from clustered industrial zones, complete supply chains, and continuous investment in digital manufacturing equipment. These companies integrate SLA, SLS, MJF, FDM, and metal 3D printing with CNC machining, sheet metal, and injection molding to support everything from concept models to end‑use parts.

For foreign OEM buyers, China's 3D Printing Prototype Service Companies offer a balance of cost efficiency, high precision, and flexible order quantities, from single prototypes to low‑volume production. Many of these providers also support OEM and ODM, private labeling, and design‑for‑manufacturing support, making them strategic partners throughout the product lifecycle.

Shangchen (sc‑rapidmanufacturing.com) is a dedicated rapid prototyping and manufacturing factory in China, offering 3D printing services, CNC machining, precision batch production, lathe turning, sheet metal fabrication, and mold production for overseas OEM clients. As one of the leading 3D Printing Prototype Service Companies, Shangchen provides a full stack of processes that take projects from CAD design through functional prototypes to market‑ready parts.

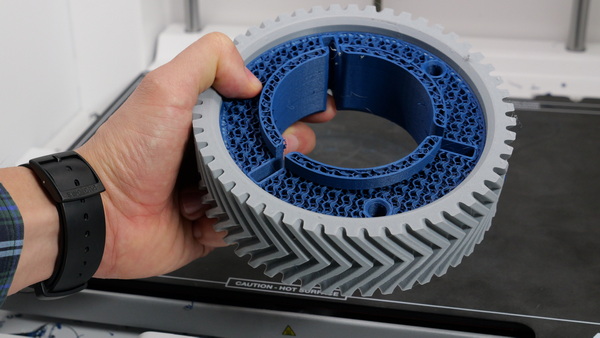

Shangchen's 3D printing prototype capabilities cover plastics such as ABS, PC, PA, and PMMA, as well as metals like stainless steel, aluminum, and brass, with tight tolerances for critical features. The company combines SLA, SLS, and metal 3D printing with precision CNC milling and turning, vacuum casting, sheet metal, and rapid tooling, allowing customers to validate designs and move smoothly into pilot or batch production.

To ensure accuracy and consistency, Shangchen uses advanced quality control methods such as CMM inspection, 3D scanning, and optical measurement under ISO‑oriented quality management. This makes Shangchen a strong choice among 3D Printing Prototype Service Companies for industries such as automotive, robotics, medical devices, industrial equipment, and consumer products that demand repeatable precision.

Shangchen also emphasizes engineering support: the team can review 3D models, provide DfAM and DFM feedback, optimize wall thickness and support structures, and recommend the most suitable process between 3D printing, CNC machining, or hybrid routes. For global OEMs, wholesalers, and brand owners, this integrated service model reduces communication friction and helps compress development schedules when launching new products.

Unionfab is recognized as one of China's largest 3D Printing Prototype Service Companies, focusing on rapid prototyping and on‑demand production for domestic and export clients. Unionfab offers a large installed base of industrial SLA, SLS, MJF, and metal 3D printers that support both prototype parts and larger production batches.

The company serves multiple sectors, including automotive, aerospace, medical, electronics, and industrial equipment, with a wide range of engineering materials and post‑processing services. Unionfab's digital quoting and order management system makes it convenient for overseas buyers to place repeat orders, manage revisions, and monitor lead times across different 3D printing processes.

HLH Proto is well known for combining rapid prototyping with low‑volume manufacturing, making it a strong candidate among 3D Printing Prototype Service Companies in China. The company integrates SLA, SLS, and other 3D printing processes with CNC machining, rapid tooling, urethane casting, and metal fabrication to support functional testing and pilot runs.

For international OEM clients, HLH Proto emphasizes flexibility in materials and finishing, which is useful when parts need to mimic mass‑production injection‑molded components or die‑cast metal parts. Its capability to handle both prototype and short‑run production inside the same facility is particularly valuable for design validation and early market testing.

FacFox is a multi‑technology manufacturing platform that provides 3D printing, CNC machining, injection molding, and other on‑demand services to global customers. As one of the emerging 3D Printing Prototype Service Companies, FacFox emphasizes online ordering, digital management, and quick quoting to simplify overseas sourcing.

Its portfolio includes plastic and metal 3D printing, with various surface finishing options to achieve cosmetic prototypes or functional parts for real‑world testing. Buyers can combine additive and subtractive processes under one order, which improves consistency across prototype iterations and reduces vendor management workload.

Shenzhen JR Technology focuses on industrial‑grade 3D printing and CNC machining for both prototypes and batch production. The company uses processes such as SLA, SLS, and metal 3D printing, along with CNC milling and turning, to serve customers in automotive, aerospace, and consumer electronics.

As a member of the broader group of 3D Printing Prototype Service Companies, Shenzhen JR Technology offers engineering support, design review, and multiple finishing options to help OEMs move from design to testable prototypes quickly. Its location in Shenzhen gives easy access to electronics supply chains and logistics hubs for fast global shipping and convenient export.

WayKen Rapid Manufacturing, headquartered in Shenzhen, is a leading provider of rapid prototyping services including CNC machining, rapid tooling, and 3D printing. As one of the recognized 3D Printing Prototype Service Companies in China, WayKen serves automotive, aerospace, and industrial clients with high‑precision plastic and metal parts.

The company's combination of SLA and SLS 3D printing with high‑precision CNC machining allows buyers to test complex designs, transparent components, and mechanical assemblies before committing to expensive tooling. For overseas customers, WayKen's quality certifications and English‑speaking support team simplify communication and project control.

3ERP (3E Rapid Prototyping) in Zhongshan offers CNC machining, CNC milling and turning, rapid tooling, and 3D printing services for global customers. It is frequently listed among reliable 3D Printing Prototype Service Companies due to its focus on precision, fast response, and on‑time delivery for export markets.

3ERP supports concept models, functional prototypes, and low‑volume production using plastics and metals, and it offers various surface treatments to meet cosmetic and functional requirements. The company's experience with overseas buyers in Europe and North America makes it suitable for demanding OEM projects that require tight tolerance control and consistent quality reports.

Star Rapid, based in Zhongshan, offers CNC machining, injection molding, vacuum casting, die casting, and SLA/SLS 3D printing for a global customer base. As a well‑known member of the 3D Printing Prototype Service Companies group, Star Rapid targets high‑mix, low‑volume manufacturing where flexibility and quality are critical.

The company's SLA and SLS capabilities are used for design models, fit‑and‑assembly prototypes, and functional test parts, often combined with CNC machining to achieve tight tolerances and specific finishes. Star Rapid's quality certifications and structured project management processes help reduce risk for complex product launches and multi‑component assemblies.

SuNPe Prototype focuses on CNC machining, vacuum casting, rapid tooling, and low‑volume manufacturing, while also offering 3D printing as part of its service mix for export clients. This positions SuNPe within the ecosystem of 3D Printing Prototype Service Companies that provide hybrid additive–subtractive solutions.

The company is known for fast lead times and flexible quantities, which is important for overseas OEMs that need multiple design iterations before mass production. SuNPe's engineering support and finishing capabilities help customers obtain prototypes that closely resemble final production parts in both appearance and performance.

IN3DTEC Technology, founded in Shanghai, offers 3D printing, CNC machining, vacuum casting, injection molding, 3D scanning, and reverse engineering. As one of the diversified 3D Printing Prototype Service Companies, IN3DTEC supports prototyping and small‑batch production for clients in China and abroad.

The company's integration of 3D scanning and reverse engineering is useful for legacy parts, competitive benchmarking, and design upgrades. Its multi‑location presence and structured quality system provide a stable base for long‑term supply relationships with OEMs that require consistent documentation and repeatable quality.

Selecting the right partner from numerous 3D Printing Prototype Service Companies in China requires a clear set of evaluation criteria aligned with project goals. Overseas buyers should look beyond unit price and focus on technical capabilities, quality systems, communication, and long‑term reliability.

Key factors when choosing 3D Printing Prototype Service Companies include:

- Process range and integration

Buyers should confirm whether the company offers only 3D printing or also CNC machining, sheet metal fabrication, and molding for later stages of product development. Providers like Shangchen that combine additive and subtractive processes simplify scaling from prototype to batch or mass production with one partner.

- Material options and performance

The best 3D Printing Prototype Service Companies can print in engineering plastics and metals suitable for real functional testing, not just visual models. Access to materials such as ABS, PC, PA, PMMA, aluminum, stainless steel, and other technical grades ensures that prototypes can represent final product behavior.

- Tolerances, quality control, and certifications

High‑precision prototypes often require tight tolerances and robust inspection methods, including CMM evaluation, 3D scanning, and documented inspection reports. Certifications like ISO 9001 and industry‑specific norms show that the company runs stable quality systems and follows standardized procedures.

- Lead time, logistics, and communication

Many 3D Printing Prototype Service Companies in China can ship functional parts within just a few days for standard projects. Responsive English‑language support, clear DFM feedback, and transparent shipping options through international express providers are essential for smooth collaboration.

- OEM/ODM and confidentiality

For brands planning long‑term cooperation, it is important that the supplier offers OEM/ODM, NDAs, and robust data security measures. Companies such as Shangchen that follow structured confidentiality procedures and protect 3D models, drawings, and customer information can better support high‑value projects.

3D Printing Prototype Service Companies in China support a wide variety of applications, from early‑stage concept models to production‑ready functional parts. Additive manufacturing allows engineers to produce complex geometries, lightweight structures, and internal channels that would be difficult or impossible using only traditional machining.

Common application areas include:

- Product design and ergonomics

Early‑stage mock‑ups for consumer electronics, appliances, and handheld devices allow designers to validate form, fit, and user experience before investing in hard tooling.

- Functional testing and engineering validation

Prototypes made with engineering materials can be used to test mechanical strength, thermal resistance, sealing performance, and assembly behavior under real or simulated conditions.

- Tooling, fixtures, and jigs

3D Printing Prototype Service Companies often produce custom fixtures, assembly aids, inspection gauges, and end‑of‑arm tooling that support efficient mass production lines.

- Medical, dental, and customized devices

Personalized medical devices, anatomical models, dental components, and surgical guides can be manufactured quickly and accurately according to patient‑specific data.

- Low‑volume production

When volumes are not high enough to justify injection molds or die casting, 3D printing combined with CNC machining offers an economical path to end‑use parts with acceptable cost and turnaround times.

Shangchen's position among 3D Printing Prototype Service Companies is strengthened by its ability to serve multiple industries with tailored solutions. Instead of limiting itself to one sector, the factory adjusts materials, processes, and tolerances according to each customer's application.

In automotive and transportation projects, Shangchen can provide rapid prototypes for interior components, brackets, housings, and functional mechanical parts that must withstand temperature and vibration. For robotics and industrial equipment, the company supports structural parts, custom fixtures, and low‑volume functional parts where precision and repeatability are crucial.

In consumer electronics and appliance development, Shangchen's 3D printing and CNC machining help clients validate appearance parts, assemblies, and internal mechanical components. For medical devices and health‑related products, the factory emphasizes tight tolerance control, clean finishing, and careful documentation to support regulatory and engineering requirements.

To achieve the best outcome when collaborating with 3D Printing Prototype Service Companies in China, overseas buyers should follow a structured approach. Clear communication and complete technical data significantly reduce the risk of rework and delays.

Effective cooperation usually includes:

- Providing detailed 3D CAD files and 2D drawings with critical dimensions and tolerances.

- Indicating the primary function of the part (visual demo, functional test, assembly test, or end‑use component).

- Sharing information on working environment, mechanical load, and surface requirements to guide material and process selection.

- Being open to DFM/DfAM suggestions from the chosen 3D Printing Prototype Service Companies, especially regarding wall thickness, support design, and undercuts.

- Planning multiple prototype rounds before committing to expensive tooling or mass production, particularly for complex assemblies.

By treating the supplier as a technical partner rather than only a vendor, OEMs can gain better insight into manufacturing constraints and optimize designs earlier.

The landscape of 3D Printing Prototype Service Companies in China is evolving rapidly as new technologies and materials come to market. Continuous improvements in printer speed, resolution, and reliability are changing the way prototypes and low‑volume parts are produced.

Key trends include:

- Wider adoption of high‑speed resin and powder‑bed systems that reduce lead times and per‑part costs.

- Expansion of metal 3D printing for aerospace, medical, and high‑value industrial components that require complex internal channels or lightweight structures.

- Increased use of automation, AI‑based nesting, and MES systems inside 3D Printing Prototype Service Companies to improve capacity planning and quality tracking.

- Integration of sustainability goals, with more recyclable materials, energy‑efficient production lines, and optimized packaging for international shipments.

- Deeper collaboration between 3D Printing Prototype Service Companies and traditional machining, molding, and casting suppliers to offer complete end‑to‑end manufacturing solutions.

Shangchen and other leading providers that invest in these trends will be better positioned to support global OEMs as product development cycles become faster and more demanding.

3D Printing Prototype Service Companies in China now form a critical pillar of global product development, helping brands move from idea to validated prototypes in days instead of months. For overseas OEM buyers, a strong partner such as Shangchen, with integrated 3D printing, CNC machining, sheet metal, and mold making, provides not only parts but complete engineering support and long‑term manufacturing scalability.

By carefully evaluating process capabilities, material options, quality systems, and communication practices across 3D Printing Prototype Service Companies, buyers can build a robust, cost‑effective supply base for future product portfolios. As additive manufacturing technologies continue to advance, China's leading 3D Printing Prototype Service Companies will play an even larger role in enabling rapid innovation across multiple industries worldwide.

Most 3D Printing Prototype Service Companies in China offer a mix of SLA, SLS, MJF, FDM, and metal 3D printing for plastic and metal parts, complemented by CNC machining, vacuum casting, and sometimes injection molding. Many also provide secondary operations such as sanding, painting, polishing, anodizing, assembly, and engineering support for design optimization and material selection.

Lead time depends on part complexity and finishing requirements, but simple 3D‑printed prototypes can often be produced within 1–3 days and prepared for international shipment soon after. Companies with streamlined digital workflows and strong logistics partners can provide door‑to‑door delivery for international customers within roughly one week for standard projects.

Yes, many 3D Printing Prototype Service Companies specialize in engineering‑grade materials and processes aimed at functional testing, not just visual models. By combining 3D printing with CNC machining, rapid tooling, and casting, these companies can also support bridge production and low‑volume batches before formal mass production begins.

Leading 3D Printing Prototype Service Companies usually work under NDAs and implement structured data management and security systems. OEM and ODM services typically include private labeling, custom packaging, and engineering collaboration, while formal confidentiality procedures are used to protect customer IP, drawings, and 3D model files.

Shangchen stands out by combining 3D printing, CNC machining, precision batch production, turning, sheet metal fabrication, and mold manufacturing in one vertically integrated factory. This allows overseas brands, wholesalers, and OEM manufacturers to complete the full journey from prototype to mass production with one partner, simplifying communication, quality control, and long‑term cost management.

content is empty!