Views: 222 Author: Amanda Publish Time: 2026-01-07 Origin: Site

Content Menu

● What Is Rapid CNC Machining for Custom Parts?

● Why Rapid CNC Machining Is Critical for OEM Projects

● Where to Find Rapid CNC Machining Services for Custom Parts

>> Online CNC Machining Platforms

>> Overseas OEM CNC Machining Factories

● How to Search Effectively for CNC Machining Services

● Local vs Overseas CNC Machining for Custom Parts

● Key Factors When Choosing a Rapid CNC Machining Partner

● Why Many OEM Buyers Choose Chinese CNC Machining Factories

● How to Prepare RFQs for Rapid CNC Machining

● Design Tips to Reduce Lead Time in CNC Machining

● Combining CNC Machining with Other Rapid Manufacturing Processes

● Working with a One‑Stop CNC Machining and Prototyping Partner

● How OEM Buyers Can Evaluate CNC Machining Quotes

● Common Challenges in Rapid CNC Machining and How to Avoid Them

● FAQs About Rapid CNC Machining Services for Custom Parts

>> FAQ 1: What information do CNC Machining suppliers need for a quote?

>> FAQ 2: How fast can rapid CNC Machining deliver custom parts?

>> FAQ 3: Which materials work best for rapid CNC Machining?

>> FAQ 4: How does CNC Machining compare with 3D printing for prototypes?

>> FAQ 5: What quality controls should I expect from a CNC Machining partner?

Rapid CNC machining services for custom parts are available from a mix of local machine shops, global online platforms, and specialized overseas OEM factories that support prototypes and production runs. By understanding where these providers are located and how they work, overseas brands, wholesalers, and manufacturers can quickly secure precise CNC Machining for metal and plastic components.

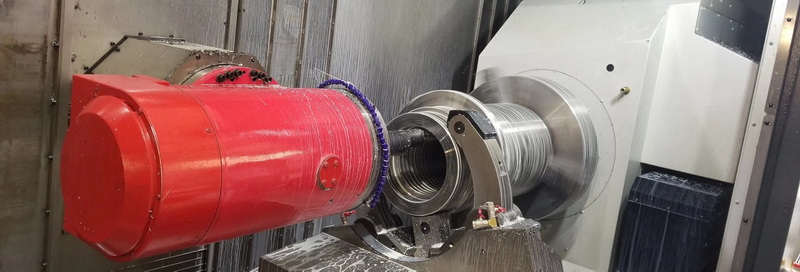

Rapid CNC machining uses computer‑controlled equipment to cut, mill, drill, and turn raw materials into finished custom parts with tight tolerances in a short lead time. It is widely used for rapid prototyping, bridge production, and full‑scale manufacturing in industries such as automotive, aerospace, medical, robotics, and consumer electronics.

Rapid CNC machining services for custom parts typically provide:

- CNC Machining with milling and turning for metal and plastic components.

- Low‑volume and high‑volume CNC Machining for OEM projects.

- Additional processes such as threading, boring, pocketing, engraving, and surface finishing.

For OEM buyers, rapid CNC Machining reduces time‑to‑market by turning 3D CAD designs into functional custom parts within days instead of weeks. It also supports multiple design iterations, which helps engineers optimize part geometry, materials, and manufacturability before committing to expensive tooling.

Key advantages of rapid CNC Machining for OEM projects include:

- Precision: Ability to hold tight tolerances and complex geometries for critical parts.

- Flexibility: Capability to handle one‑off prototypes, small batches, and large production orders.

- Material range: Compatibility with aluminum, steel, stainless steel, titanium, brass, copper, and engineering plastics.

Overseas buyers can find rapid CNC Machining services for custom parts in several main channels, each with different pricing, speed, and service depth.

Local CNC Machining shops near your facility provide responsive, face‑to‑face support and easy communication, which is valuable for urgent design changes and frequent inspections. These providers often specialize in CNC Machining for specific regional industries, such as automotive, aerospace, or industrial equipment.

Typical benefits of local CNC Machining shops:

- Faster on‑site visits and dimensional verification.

- Easier handling of small, urgent CNC Machining jobs and rework.

Online platforms aggregate global CNC Machining capacity and offer instant quotes for custom parts based on uploaded 3D files and technical drawings. They distribute CNC Machining work to vetted machine shops and centralized factories, helping buyers get competitive pricing and rapid lead times.

Strengths of online CNC Machining platforms:

- Automated quoting and DFM feedback for CNC Machining jobs.

- Global network of CNC Machining shops for both prototypes and production.

Overseas CNC Machining factories, especially in China and other manufacturing hubs, are popular for cost‑effective custom parts in medium and high volumes. These suppliers often combine CNC Machining with processes such as sheet metal fabrication, 3D printing, surface finishing, and assembly to offer one‑stop OEM solutions.

Common advantages of overseas OEM CNC Machining factories:

- Lower unit cost on CNC Machining by leveraging large‑scale equipment and labor efficiencies.

- Integrated rapid prototyping and batch production in one facility.

Finding the right rapid CNC Machining partner starts with a clear search strategy across digital platforms and industry networks. Buyers who structure their searches properly can quickly identify CNC Machining suppliers that match required materials, tolerances, and lead times.

Useful methods include:

- Searching by service and geography (for example: “CNC Machining service + city” or “online CNC Machining services for custom parts”).

- Using manufacturing marketplaces or instant‑quote portals that specialize in CNC Machining and rapid prototyping.

- Checking industry associations, trade shows, and B2B directories that list CNC Machining suppliers with verified certifications.

To improve search results, buyers should:

- Include material, quantity, and lead‑time keywords (such as “aluminum CNC Machining prototypes in 7 days”).

- Filter CNC Machining suppliers by certification, supported materials, and maximum part size.

Different projects benefit from different sourcing strategies, so buyers often compare local CNC Machining suppliers with overseas CNC Machining factories.

| Aspect | Local CNC Machining | Overseas CNC Machining |

|---|---|---|

| Lead time | Very fast for prototypes and emergencies; easy coordination. | Fast for planned orders; must include shipping and customs time. |

| Cost per part | Higher labor and overhead cost, especially for large batches. | Lower unit cost for medium and high volumes. |

| Communication | Same time zone and language; easier meetings and calls. | Requires clear documentation, but many offer bilingual export teams. |

| Service scope | Often focused mainly on CNC Machining. | CNC Machining plus prototyping, sheet metal, finishing, and assembly. |

| Quality oversight | Simple on‑site audits and in‑person inspections. | Needs remote audits, sample approval, and third‑party inspection. |

Selecting the right rapid CNC Machining supplier for custom parts requires more than comparing prices; it involves technical and business evaluation. This is especially true when CNC Machining supports safety‑critical, medical, or aerospace applications.

Important factors include:

- Capabilities: Types of CNC Machining (3‑axis, 4‑axis, 5‑axis, turning, EDM), maximum part size, and supported tolerances.

- Materials expertise: Experience machining aluminum, stainless steel, tool steel, titanium, brass, copper, and engineering plastics.

- Quality systems: Certifications such as ISO 9001 or IATF 16949, plus inspection reports, CMM measurement, and traceability.

- Lead time and capacity: Ability to handle your schedule from rapid prototypes to scalable CNC Machining production.

- Communication and support: Responsiveness, engineering feedback, and clarity in quoting and documentation.

China has become a major destination for rapid CNC Machining services, especially for overseas OEM buyers looking for prototypes and production parts at competitive cost. Mature industrial clusters allow CNC Machining factories to source metals, plastics, and finishing services quickly and efficiently.

Chinese CNC Machining factories often:

- Integrate rapid prototyping, CNC Machining, sheet metal fabrication, 3D printing, and mold making.

- Offer competitive pricing for CNC Machining across a wide range of materials and part complexities.

- Provide English‑language export teams familiar with packaging, customs documentation, and international logistics.

Well‑structured RFQs (requests for quotation) help CNC Machining suppliers understand your requirements and respond with accurate pricing and lead times. A good RFQ reduces back‑and‑forth emails and speeds up toolpath planning for CNC Machining.

For rapid CNC Machining of custom parts, RFQs should include:

- 3D CAD files (STEP, IGES, or similar) and, where needed, 2D drawings with tolerances, threads, and GD&T.

- Material specifications, surface finish, hardness, and any special treatments (such as anodizing, plating, or heat treatment).

- Quantities for prototypes and follow‑up CNC Machining production batches.

- Target lead time, inspection requirements, and acceptance criteria.

Clear RFQs allow rapid CNC Machining providers to:

- Suggest design changes to improve machinability and reduce cost.

- Offer options such as alternative materials, different CNC Machining setups, or consolidated operations.

Good design practices can significantly reduce CNC Machining time, cost, and risk. Many rapid CNC Machining suppliers share guidelines for wall thickness, fillet radii, and hole depths to ensure stable machining and predictable quality.

Common design tips include:

- Avoid extremely thin walls and deep narrow pockets that require special tools and slow CNC Machining feeds.

- Use standard hole sizes and thread specifications to simplify tooling.

- Add appropriate fillets and radii to internal corners to match standard end‑mill sizes.

- Consider how parts will be fixtured and accessed by CNC Machining tools from different angles.

Many rapid manufacturing projects combine CNC Machining with other technologies to balance speed, cost, and performance. For example, complex prototype assemblies can be produced with a mix of 3D printing, CNC Machining, and urethane casting.

Typical hybrid strategies:

- Use 3D printing for form‑fit prototypes and CNC Machining for functional parts that must meet precise tolerances.

- Combine CNC Machining and sheet metal fabrication for assemblies with brackets, housings, and precision inserts.

- Transition from rapid CNC Machining prototypes to injection‑molded parts once design is frozen and volumes are high.

Choosing a one‑stop partner that integrates rapid prototyping and CNC Machining simplifies project management for OEM buyers. Instead of coordinating multiple vendors, buyers can rely on a single engineering and production team.

Strong one‑stop providers generally:

- Offer CNC Machining, sheet metal fabrication, 3D printing, and molding in a single workflow.

- Support engineering review, DFM feedback, and material selection to improve manufacturability.

- Maintain consistent quality standards and detailed reporting across all rapid CNC Machining stages.

Once multiple CNC Machining quotes arrive, structured evaluation helps buyers look beyond unit price. A balanced view considers risk, quality, and scalability so that the chosen CNC Machining partner can support the whole product life cycle.

When comparing rapid CNC Machining quotes, buyers should examine:

- Price breakdowns for material, machining time, setup, finishing, and inspection.

- Differences in proposed lead times and shipping methods.

- Clarifications on tolerances, surface roughness, and any deviations from the drawing.

- Whether suppliers include dimensional inspection reports or only visual checks.

A CNC Machining quote that is slightly higher but includes robust quality control and engineering support may save more money over the long term by reducing redesigns, scrap, and warranty issues.

Rapid CNC Machining delivers speed and flexibility, but rushed projects can face issues if communication is poor or design data is incomplete. Anticipating these challenges improves success rates for custom CNC Machining parts.

Typical challenges include:

- Incomplete drawings or missing tolerances, leading to assumptions and mismatched expectations.

- Overly tight tolerances that dramatically increase CNC Machining time and cost without real functional benefit.

- Material substitutions that affect strength, corrosion resistance, or appearance.

- Insufficient packaging for long‑distance shipping, causing cosmetic or dimensional damage.

To avoid these issues, buyers should:

- Mark only critical features with tight tolerances and keep non‑critical areas more relaxed.

- Confirm material standards and acceptable equivalents before production.

- Ask CNC Machining partners to share manufacturing feedback early, including DFM suggestions.

- Define packaging, labeling, and inspection standards clearly at the quotation stage.

Rapid CNC Machining services for custom parts are available from local shops, online manufacturing platforms, and overseas OEM factories, giving buyers a wide choice of suppliers and pricing levels. By clearly defining requirements, evaluating CNC Machining capabilities and certifications, and leveraging integrated prototyping‑to‑production partners, OEM brands, wholesalers, and manufacturers can secure fast, precise, and cost‑effective custom parts for demanding applications. Choosing the right rapid CNC Machining partner ultimately helps reduce risk, shorten development cycles, and support a smoother path from prototype to mass production.

Suppliers typically require 3D CAD files, 2D drawings with critical dimensions and tolerances, material selection, quantities, surface finish, and target lead time to quote CNC Machining accurately. Providing this data up front speeds up pricing and reduces clarification emails.

Depending on part complexity and quantity, rapid CNC Machining providers can ship custom parts in as little as 2–14 days when materials are in stock and designs are stable. Larger or more complex CNC Machining projects may require phased deliveries for prototypes, pilot runs, and final production.

Common materials for rapid CNC Machining include aluminum, stainless steel, mild steel, brass, copper, and engineering plastics such as POM, nylon, and PEEK. The best choice depends on strength, weight, temperature resistance, and cost targets for the final application.

CNC Machining produces stronger, more accurate parts in production‑grade materials and is ideal for functional testing and final validation. 3D printing is typically faster and more economical for very complex shapes and early design iterations, especially when final material properties are less critical.

Reliable CNC Machining partners follow formal quality systems, provide inspection reports or CMM data, and track materials with certificates where required. They also define clear procedures for handling nonconformities, rework, and engineering change requests so projects remain traceable and controlled.

content is empty!