Views: 222 Author: Amanda Publish Time: 2026-01-07 Origin: Site

Content Menu

● Why CNC Machining Cost Matters

● Main Types of CNC Machining Cost Calculators

● Standalone CNC Machining Cost Estimators

● Online CNC Machining Instant Quote Platforms

>> Benefits of Instant Quote CNC Machining Calculators

● Machine Hourly Rate Calculators for CNC Shops

>> How Hourly Rate Affects CNC Machining Cost

● Technical Calculators vs. Cost Calculators

● How Professional Platforms Use CNC Machining Cost Calculators

● Using Online CNC Machining Calculators for OEM Sourcing

● Why Work With a CNC Machining Partner Like Shangchen

● Practical Steps to Estimate CNC Machining Cost

● Reducing CNC Machining Cost Through Design

● When a Custom CNC Machining Quote Is Better Than a Calculator

● How to Choose the Right CNC Machining Cost Calculator

● Common Mistakes When Using CNC Machining Cost Calculators

● Best Practices for Sharing CNC Machining Estimates With Suppliers

● FAQ About CNC Machining Cost Calculators

>> (1) How accurate are online CNC Machining cost calculators?

>> (2) What information is needed to use a CNC Machining cost calculator?

>> (3) Can calculators help reduce CNC Machining costs?

>> (4) Do I still need a manual CNC Machining quote?

>> (5) How can Shangchen support CNC Machining cost estimation?

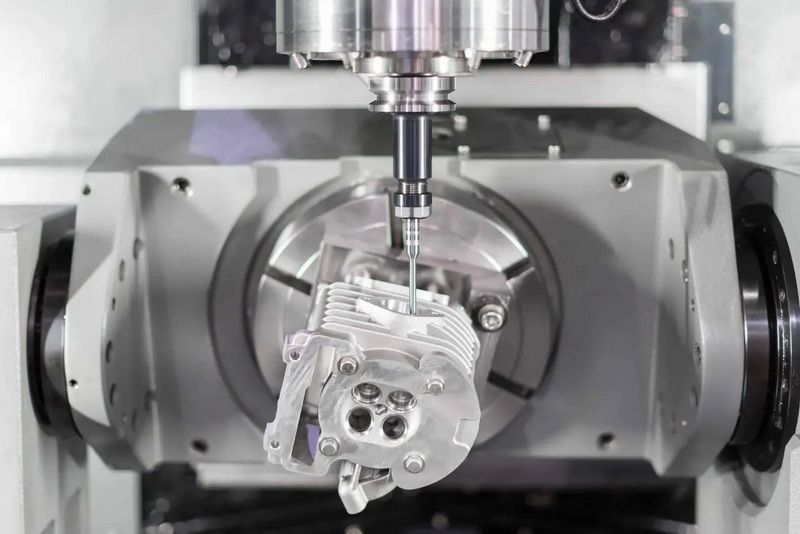

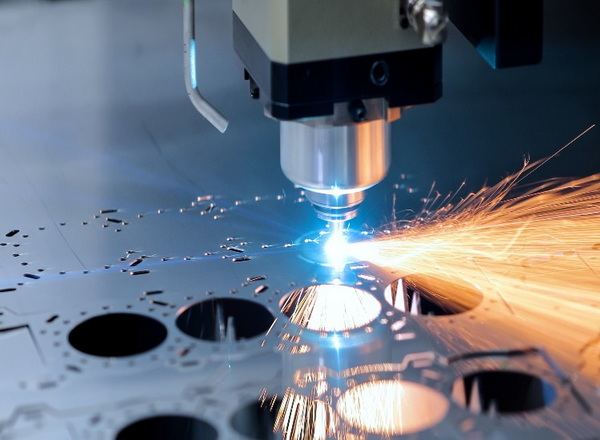

CNC Machining has become the backbone of modern manufacturing, but estimating a realistic CNC Machining cost is still challenging for many engineers, buyers, and startup founders. An accurate CNC Machining cost calculator helps you compare design options, choose the right supplier, and keep your project on budget without endless emails and manual quotes.[1][2]

CNC Machining cost is not just an hourly machine rate; it is a combination of materials, machine time, setup, tooling, labor, overhead, and profit margin. Using a reliable CNC Machining calculator allows you to simulate different material choices, quantities, and tolerances before you finalize drawings or place orders.[3][1]

- CNC Machining costs are influenced by part geometry, tolerances, surface finish, and order volume.

- A good CNC Machining cost calculator lets you estimate how each change (e.g., thicker wall, tighter tolerance) may increase cycle time and price.

There are several categories of CNC Machining cost calculators, each designed for a different use case. Understanding them helps you choose the right tool instead of relying on a single generic formula.[1]

- Standalone machining cost estimators (browser-based calculators).

- Instant quote platforms for online CNC Machining services.

- Machine hourly rate and shop-rate calculators for internal costing.

- Specialized CNC Machining calculators focused on cutting parameters, not price.

Dedicated cost estimator tools are popular for early-stage CNC Machining budget planning. These tools ask you for dimensions, materials, and basic process data, then output an approximate CNC Machining cost.[4]

- CustomPartNet offers a Machining Cost Estimator where you can input CNC Machining operations and estimate manufacturing costs for different processes and part quantities.[4]

- General CNC project estimators help you structure material cost, machine time, setup, tooling, and overhead into a single CNC Machining cost figure.

A strong CNC Machining cost calculator should help both technical and nontechnical users quickly understand cost drivers.

- Ability to enter material type and unit cost for realistic CNC Machining material estimates.

- Separate input fields for machine time, hourly CNC Machining rate, setup cost, tooling cost, and optional labor or overhead.

- Support for different CNC Machining operations such as milling, turning, drilling, and tapping.

Many digital manufacturing platforms now embed sophisticated CNC Machining cost calculators directly into their quoting tools. These systems read your 3D CAD model and automatically calculate CNC Machining pricing based on real production data and networked machine capacity.[2]

- Protolabs Network (formerly Hubs) provides an online CNC Machining service where you upload a CAD file, select material and quantity, and receive instant CNC Machining quotes for various lead times.[2]

- Protolabs offers an instant CNC Machining quote system that analyzes your CAD design and updates pricing in real time as you change materials, quantities, or features.[5]

Instant quote platforms combine CNC Machining cost calculation with manufacturability feedback and supplier selection.

- Engineers can iterate designs and see CNC Machining price changes instantly, which supports design-for-manufacturing decisions during development.[2]

- Buyers get transparent CNC Machining pricing for different quantities and delivery options without building complex spreadsheets or waiting days for responses.[5]

If you run a CNC Machining workshop or in-house machining department, you need to know the real hourly rate of each CNC machine, not just a guess. Machine hourly rate calculators help you turn equipment cost, maintenance, and labor into a usable CNC Machining shop rate.[3]

- CNC Cookbook provides a CNC Machine Hourly Rate Calculator that factors ownership cost, depreciation, maintenance, operator wages, and utilization into a per-hour CNC Machining rate.[3]

- Similar tools allow CNC Machining shops to standardize how they quote jobs and ensure that hourly rates cover true operating costs.

Once you know the hourly rate of a machine, you can multiply it by the estimated CNC Machining cycle time per part.[3]

- CNC Machining cost often follows the formula: machine time × hourly rate + setup + tooling + handling.

- The same part can have very different CNC Machining prices at different shops because their machines, labor costs, and utilization levels differ.

Not every CNC Machining calculator is designed for pricing; many tools focus purely on cutting parameters and machining physics. These calculators still indirectly help you optimize CNC Machining cost by improving efficiency and tool life.[6]

- MachiningDoctor provides online calculators for milling feed, speed, chip thinning, and other technical parameters used in CNC Machining.[6]

- When engineers refine feeds and speeds using these calculators, they can lower CNC Machining cycle times and tool wear, which reduces cost per part over the long term.

Large digital manufacturing networks and advanced OEM factories combine automated CNC Machining cost engines with manual engineering review. This approach balances speed with realistic pricing and manufacturability.[2]

- Some platforms use algorithms to instantly generate CNC Machining quotes from CAD files and then allow engineers to fine-tune pricing for complex projects, high-value materials, or tight tolerances.[2]

- These systems often integrate collaboration tools so customers can discuss CNC Machining cost trade-offs directly with manufacturing experts.

For sourcing managers, CNC Machining cost calculators are practical tools to compare regional suppliers and sourcing models.[2]

- You can upload the same CAD file to several CNC Machining platforms and compare instant quote results to understand market price levels across regions.

- OEM brands often combine local CNC Machining suppliers for urgent jobs with cost-effective overseas partners for larger volumes, using calculators to plan budgets and negotiations.

Beyond online calculators, partnering with a dedicated CNC Machining supplier gives you real-world production data and engineering feedback. Shangchen in China focuses on integrated services such as rapid prototyping, CNC Machining, CNC lathe turning, sheet metal fabrication, 3D printing, and injection molding for overseas OEM clients.[7]

- Shangchen's CNC Machining team supports both low-volume prototypes and precision batch production, helping brands reduce development risk and scale smoothly.[7]

- By combining CNC Machining with complementary processes and quality control, Shangchen can suggest cost-saving design changes that online calculators alone cannot provide.[7]

You can build a more reliable CNC Machining cost estimation workflow by combining several tools and supplier inputs.

- Start with a public CNC Machining cost estimator to define a preliminary budget and understand rough cost ranges.

- Upload the CAD to instant quote CNC Machining platforms and compare results with quotations from trusted OEM partners like Shangchen to validate pricing.

CNC Machining calculators show cost, but designers still control many of the most important price drivers.[1]

- Simplifying geometries, relaxing unnecessary tight tolerances, and minimizing deep narrow pockets can significantly lower CNC Machining time and price.

- Choosing materials that are easier to machine, such as common aluminum or mild steel grades, often decreases CNC Machining cycle time and tool wear.[1]

For complex parts, multi-process assemblies, or demanding materials, purely automated CNC Machining calculators may not capture all the risks and costs.[2]

- Projects with multiple setups, critical GD&T requirements, or hybrid processes (CNC Machining plus welding, heat treatment, or finishing) usually require a custom quote from an experienced supplier.

- Working with a factory like Shangchen lets you combine initial calculator estimates with detailed process planning, ensuring that CNC Machining cost and quality targets are realistic.[7]

With so many CNC Machining tools available, choosing the right calculator depends on your role, project stage, and information needs.

- Designers and engineers often benefit most from instant quote platforms that connect CAD-based CNC Machining analysis with automatic pricing and manufacturability feedback.

- Purchasing managers and business owners may prefer standalone CNC Machining cost estimators and machine-rate tools that help them model long-term cost structures and supplier comparisons.

For early concept work, a simple browser-based CNC Machining cost calculator is usually enough to check feasibility. During detailed design and sourcing, instant quote platforms and OEM supplier quotes become more important for accurate CNC Machining budgeting.

Even the best CNC Machining calculator can give misleading results if the inputs are wrong or incomplete.

- Underestimating setup complexity, fixture design, or inspection requirements can lead to CNC Machining cost gaps between estimates and final quotes.

- Ignoring tolerances and surface finish in the calculator may produce optimistic CNC Machining prices that do not reflect real production challenges.

To avoid these issues, always include notes about tolerance ranges, critical surfaces, and special processes when using or sharing CNC Machining cost estimates. Treat calculator results as a starting point for discussion with CNC Machining suppliers, not a final contract price.

When you move from internal estimation to actual CNC Machining sourcing, communication quality can make a big difference.

- Provide clean 3D models, detailed 2D drawings, and any internal CNC Machining cost assumptions, so suppliers understand how you arrived at a target price.

- Ask suppliers like Shangchen for feedback on which design features drive CNC Machining cost and whether small modifications could unlock better pricing or lead times.

Many OEM buyers use calculator results as “target prices” but remain open to supplier feedback. This collaborative approach often produces more realistic CNC Machining offers and stronger long-term partnerships.

CNC Machining cost calculators have evolved from simple spreadsheets into powerful online tools that combine CAD analysis, machine data, and real-time pricing. By using standalone estimators, instant quote platforms, and machine hourly rate calculators together, you gain a clearer picture of CNC Machining costs across different designs, materials, and suppliers.[4][3]

For serious OEM work, however, the most reliable strategy is to treat CNC Machining calculators as decision-support tools rather than final answers. Combining these calculators with expert guidance and tailored quotations from a specialized CNC Machining partner such as Shangchen ensures that your projects stay on schedule, within budget, and aligned with long-term quality goals.[7]

Most online CNC Machining calculators provide ballpark estimates that are reasonably accurate for simple parts and standard materials at moderate quantities. They can deviate more on complex geometries, exotic alloys, or projects requiring special certifications or multiple secondary operations.

Typically you need basic geometry (dimensions or a CAD file), material type, quantity, and sometimes surface finish and tolerance requirements. Advanced CNC Machining cost calculators may also ask for estimated machine time, setup time, and tooling or fixture costs for better accuracy.

Yes, by iterating designs and immediately seeing price differences, you can identify which features have the biggest cost impact. Using CNC Machining calculators to compare materials, tolerances, and volumes supports more informed design-for-manufacturing decisions that reduce overall cost.

For prototypes or simple parts, instant quote CNC Machining platforms may be enough. For critical components, multi-step processes, or long-term production, a manual CNC Machining quote from an experienced supplier is recommended to validate assumptions and optimize cost.

Shangchen combines online communication with engineering review to provide CNC Machining quotations backed by real production experience. Overseas brands can share CAD data, initial calculator estimates, and project targets so Shangchen's team can propose practical CNC Machining solutions with competitive pricing and stable quality.

[1](https://www.xometry.com/resources/machining/cnc-machining-cost-calculation/)

[2](https://www.hubs.com/cnc-machining/)

[3](https://www.cnccookbook.com/cnc-machine-hourly-rate-calculator/)

[4](https://www.custompartnet.com/estimate/machining)

[5](https://www.protolabs.com/services/cnc-machining/)

[6](https://www.machiningdoctor.com/calculators/)

[7](https://www.sc-rapidmanufacturing.com/cnc-machining.html)

content is empty!