Content Menu

● Is CNC Machining Really in Demand?

● Key Industries Driving CNC Machining Demand

>> General Industrial and Machinery

● Global Market Growth for CNC Machining

● Why CNC Machining Remains So Attractive

>> Precision and Repeatability

>> Complex Geometries with Multi‑Axis Machining

>> Scalability from Prototype to Production

● Technology Trends Shaping the Future of CNC Machining

>> Automation and Lights‑Out Machining

>> AI, Smart Tooling, and Predictive Maintenance

>> On‑Demand and Distributed Manufacturing

● Why Overseas OEM Buyers Choose Chinese CNC Machining

● How CNC Machining Compares to 3D Printing

● What This Means for CNC Machining Demand

● FAQ

>> 1. Why is CNC Machining still important when 3D printing is growing?

>> 2. Which industries rely most on CNC Machining?

>> 3. Is demand for CNC Machining growing or shrinking?

>> 4. How do multi‑axis and 5‑axis CNC Machining affect demand?

>> 5. Why do overseas OEM buyers often choose Chinese CNC Machining factories?

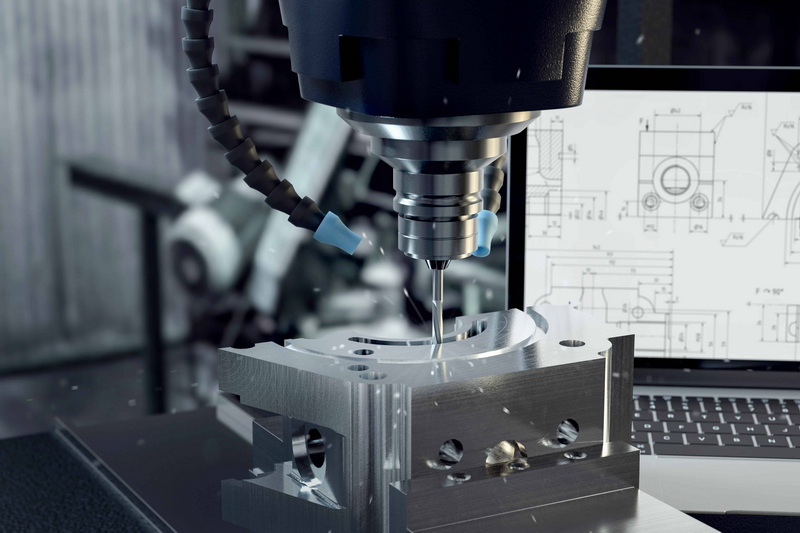

CNC Machining is in very high demand worldwide and continues to grow as more industries require precise, complex, and repeatable metal and plastic parts. For overseas brands, wholesalers, and manufacturers, CNC Machining has become a strategic manufacturing method rather than just a basic workshop process.[1][2]

CNC Machining is a subtractive manufacturing process where cutting tools are controlled by programmed computer code to remove material from a solid block (metal or plastic) and create precise components. Modern CNC Machining includes milling, turning, drilling, tapping, and boring, often combined on multi‑axis machining centers and turning centers.[3][4]

CNC Machining can achieve tight tolerances, excellent surface finishes, and consistent repeatability, which is why it is essential for critical parts in automotive, aerospace, medical, and electronics industries. For OEM buyers, CNC Machining also supports small‑batch prototyping, bridge production, and mass production using the same digital data, shortening the path from design to market.[5][1]

Global demand for CNC machining equipment and CNC Machining services is growing rapidly, supported by automotive, aerospace, medical, and general manufacturing industries. One forecast projects the CNC machine market to grow from about USD 79.2 billion in 2025 to around USD 194.3 billion by 2034, driven by precision machining and smart manufacturing.[2][1]

The CNC Machining Services market itself is expanding because more companies outsource precision parts instead of investing in their own machine shops. This outsourcing trend is especially strong among start‑ups, high‑mix low‑volume manufacturers, and foreign brands that rely on Chinese CNC Machining partners for cost‑effective production.[1][3]

Several industries are responsible for the strong demand for CNC Machining, each with its own technical requirements and volume patterns. Understanding these sectors helps OEM buyers see why CNC Machining is not only current but also future‑proof.[5][1]

The automotive industry is one of the largest users of CNC Machining services, relying on CNC Machining for engine blocks, transmission housings, brackets, and structural parts. As electric vehicles grow, CNC Machining is increasingly used for battery housings, cooling plates, and lightweight structural components with tight tolerances.[3][1]

Automotive manufacturers also depend on CNC Machining for prototype parts when launching new vehicle models, since they must test and modify designs quickly before investing in high‑cost tooling. Tier‑1 and Tier‑2 suppliers frequently cooperate with CNC Machining factories in Asia to secure flexible capacity during peaks in development and pre‑production.[6][1]

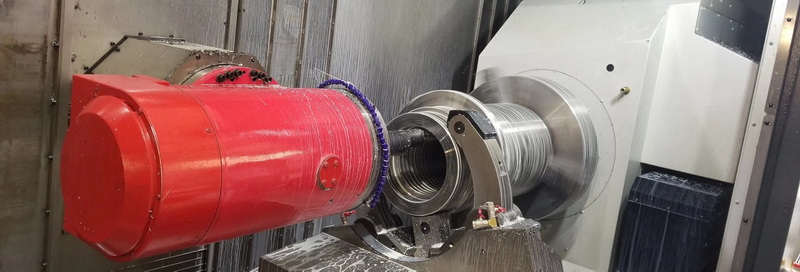

Aerospace and defense require extremely precise and reliable parts such as turbine blades, structural brackets, landing gear components, and hydraulic manifolds, all of which are ideal applications for CNC Machining. These components often involve complex geometries and difficult materials (titanium, Inconel, high‑strength aluminum), which demand advanced multi‑axis CNC Machining capabilities.[1][3]

This sector is a major driver of multi‑axis and 5‑axis CNC Machining technology, as it needs fewer setups, better surface finishes, and higher throughput on complex parts. Increased global demand for commercial aircraft and advanced defense systems continues to push the demand for precision CNC Machining capacity.[7][1]

The medical industry relies heavily on CNC Machining for implants, surgical instruments, dental components, and housings for diagnostic equipment. These parts require biocompatible materials, complex shapes, and extremely consistent quality, which CNC Machining delivers with repeatable accuracy.[8][1]

As populations age and personalized medical devices become more common, the demand for CNC Machining in this sector is expected to grow even faster than the average industrial market. High‑end CNC machine tools with micro‑machining capabilities are increasingly used to produce very small and intricate medical components.[8]

Electronics manufacturers use CNC Machining for heat sinks, housings, fixtures, molds, and precision mechanical parts in consumer electronics, communication equipment, and industrial controls. With continuing device miniaturization and higher integration, CNC Machining must achieve tighter tolerances and fine features on aluminum and copper alloys.[5][8]

High‑end CNC Machining is also widely used for semiconductor equipment and test fixtures, where stable accuracy over long production runs is essential. For overseas electronics brands working with Asian OEM factories, CNC Machining is a key link between rapid design changes and stable batch production.[6][3]

General machinery, construction equipment, and industrial automation all rely on CNC Machining for shafts, gears, frames, mounting plates, and custom mechanical parts. As more factories adopt automation, robots, and smart equipment, they require precision components and mounting solutions that are usually produced by CNC Machining.[2][5]

The shift from manual machining to CNC Machining improves quality, reduces human error, and supports standardized parts that fit easily into global supply chains. This structural upgrade in manufacturing regions such as Asia Pacific, Europe, and North America continues to create long‑term demand for CNC Machining.[9][10]

Several independent research reports confirm strong long‑term growth in the CNC machine and CNC Machining Services markets. Estimates indicate the global CNC machines market is growing at compound annual rates between about 7% and 10%, with total value potentially approaching or exceeding USD 190–200 billion in the early 2030s.[10][9][2]

Asia Pacific, especially China, leads the market with the largest share of CNC machine installations, supported by a strong base of OEM exporters, automotive suppliers, and electronics manufacturers. This concentration of equipment and technical talent helps Chinese CNC Machining factories offer competitive pricing and fast lead times to overseas buyers.[10][3]

Even with the rise of 3D printing and other digital manufacturing technologies, CNC Machining remains a central process because of several key strengths. For OEM buyers, these advantages translate directly into shorter lead times, lower risk, and better total cost of ownership.[3][1]

CNC Machining can consistently achieve tight tolerances, often in the micrometer range, which is essential for safety‑critical and high‑performance parts. Once a CNC program and process are validated, thousands of parts can be reproduced with minimal variation, supporting both batch and mass production.[1][3]

CNC Machining works with a wide range of metals and plastics, including aluminum, steel, stainless steel, titanium, brass, copper, engineering plastics, and composites. This material flexibility allows designers to optimize for strength, weight, conductivity, cost, or corrosion resistance while still using the same CNC Machining process chain.[3][1]

Multi‑axis and 5‑axis CNC Machining allow complex shapes to be produced in fewer setups, improving accuracy and reducing cycle times. The 5‑axis CNC machining centers market is expected to grow steadily, supported by demand for complex parts in medical, aerospace, and mold & die applications.[11][12]

Advanced 4‑axis and 5‑axis CNC machining centers have their own growing markets, with 4‑axis equipment alone expected to increase strongly over the coming years. This shows that demand is not just for basic 3‑axis tools but for higher‑end CNC Machining solutions capable of handling more sophisticated parts.[13][8]

CNC Machining is widely used for rapid prototyping because it can turn CAD data into functional metal or plastic parts quickly, often with production‑grade materials. Once a prototype is validated, the same CNC Machining program can be scaled to low‑ or mid‑volume production without changing the basic process.[1][3]

This smooth scaling is particularly valuable for overseas brands working with Chinese CNC Machining suppliers that can handle rapid prototypes, small orders, and larger batch production under one roof. It reduces coordination costs and simplifies quality control for OEM buyers.[3][1]

The future demand for CNC Machining is strongly linked to new technologies that make machining smarter, faster, and more connected. Many of these trends are already visible in modern 4‑axis and 5‑axis CNC machining centers and integrated production lines.[14][11]

Automation systems such as robotic loading, pallet pools, automatic tool changers, and in‑process measurement are now common in advanced CNC Machining workshops. These solutions reduce labor costs, extend machine runtime into nights and weekends, and make CNC Machining more competitive even in higher‑wage regions.[7][14]

For overseas OEM buyers, partnering with CNC Machining suppliers that use automation means more stable lead times and better consistency on large or repetitive orders. The combination of automation and CNC Machining also makes it easier to integrate with smart factory and Industry 4.0 systems.[14][8]

Artificial intelligence and machine learning tools are being used to optimize toolpaths, automatically adjust cutting parameters, and predict tool wear before it causes quality issues. Simulation software and digital twins can test CNC Machining programs virtually, reducing setup time and minimizing risk of collision or scrap.[15][11]

Predictive maintenance systems monitor vibration, spindle load, and temperature to prevent unexpected machine downtime, improving overall equipment effectiveness in CNC Machining workshops. These digital capabilities help CNC Machining providers deliver more reliable schedules and quality to demanding OEM clients.[8][14]

On‑demand manufacturing platforms rely heavily on CNC Machining because it can respond quickly to varying order sizes and a wide mix of part designs. Many global buyers now send CAD data directly to networks of CNC Machining partners and receive parts within days rather than weeks.[11][1]

This distributed model increases the practical demand for high‑quality CNC Machining capacity in regions like China, where there is a strong concentration of capable suppliers. Factories that combine CNC Machining with 3D printing, sheet metal fabrication, and molding can serve as one‑stop OEM partners for overseas brands.[3]

China has become a major hub for CNC Machining because of its dense supply chain, experienced engineers, and competitive cost structure. Many Chinese factories combine CNC Machining with rapid prototyping, turning, sheet metal fabrication, 3D printing, and mold manufacturing to serve overseas OEM clients.[10][3]

For foreign brands, wholesalers, and manufacturers, partnering with a Chinese CNC Machining factory helps to achieve fast sampling, flexible order quantities, and strong cost control. When a single supplier can handle CNC Machining plus related processes and assembly, project management and quality control become much easier for international buyers.[1][3]

While 3D printing is gaining popularity, CNC Machining still dominates many end‑use applications where mechanical strength, surface finish, and cost per unit at medium volume are critical. CNC Machining is particularly strong for metals and engineering plastics in structural and functional parts.[1][3]

3D printing is useful for highly complex internal geometries and very low quantities, but CNC Machining often delivers better dimensional stability and surface quality for load‑bearing components. In practice, many OEM projects combine 3D printed concept parts with CNC Machining for final prototypes and production.[11][3]

Considering the global market growth, the multi‑industry dependence, and the technology upgrades, CNC Machining demand is expected to remain strong for many years. High‑precision sectors such as aerospace, medical, automotive, and electronics will continue to invest in CNC Machining capacity because they cannot compromise on accuracy and reliability.[2][1]

At the same time, general manufacturing and new energy applications (such as EVs and renewable energy equipment) will add additional layers of demand for CNC Machining. For overseas OEM buyers, reliable CNC Machining partners in manufacturing hubs like China will remain essential for competitive product development and production.[10][3]

CNC Machining is clearly in strong and growing demand across the global manufacturing landscape, from automotive and aerospace to medical, electronics, and general industrial sectors. Market forecasts show that the CNC machine and CNC Machining Services markets are expanding steadily, driven by the need for precision engineering, automation, and multi‑axis capabilities.[2][1]

Technology trends such as 5‑axis machining, automation, AI‑driven optimization, and on‑demand manufacturing are making CNC Machining even more powerful and cost‑effective. For overseas brands, wholesalers, and manufacturers, partnering with a professional Chinese CNC Machining factory that also offers rapid prototyping, turning, sheet metal, 3D printing, and mold production is an effective way to stay competitive in demanding global markets.[15][3]

CNC Machining remains important because it offers high strength, excellent surface finish, and tight tolerances in production‑grade metals and plastics, which many 3D printing processes cannot yet match at scale. For medium‑ and high‑volume parts, CNC Machining is often more economical and faster per piece, especially when the same process is used from prototyping through mass production.[3][1]

The main industries using CNC Machining are aerospace, automotive, medical devices, electronics, and general manufacturing. These sectors rely on CNC Machining to produce complex, safety‑critical, and high‑precision parts with consistent quality and traceability.[5][1]

Demand for CNC Machining is growing, with multiple studies projecting strong growth in the CNC machine and services markets over the next decade. Growth is driven by automation, smart manufacturing, and expanding applications in EVs, aerospace, medical devices, and advanced industrial equipment that all depend on CNC Machining.[2][1]

Multi‑axis and 5‑axis CNC Machining allow more complex parts to be produced in fewer setups, which cuts cycle time and improves accuracy, making CNC Machining more attractive for high‑value projects. The 5‑axis CNC machining centers market is expected to grow, particularly in industries like medical, aerospace, and mold & die where complex surfaces and tight tolerances are critical.[12][11]

Overseas OEM buyers choose Chinese CNC Machining factories because they combine competitive pricing, wide process capability, and large installed bases of modern CNC equipment. Many Chinese suppliers also integrate CNC Machining with rapid prototyping, turning, sheet metal fabrication, 3D printing, and mold production, providing a one‑stop solution for foreign brands, wholesalers, and manufacturers.[10][3]

[1](https://dataintelo.com/report/cnc-machining-services-market)

[2](https://dimensionmarketresearch.com/report/cnc-machine-market/)

[3](https://tirapid.com/cnc-machining-industry/)

[4](https://www.grandviewresearch.com/industry-analysis/cnc-machining-turning-centers-market-report)

[5](https://www.ycmalliance.com/which-industries-use-cnc-machines-the-most/)

[6](https://www.kenresearch.com/industry-reports/north-america-cnc-milling-machines-market)

[7](https://www.yamazen.com/about/news/post/5-axis-cnc-trends-imts2026)

[8](https://www.congruencemarketinsights.com/report/high-end-cnc-machine-tool-market)

[9](https://www.psmarketresearch.com/market-analysis/computer-numerical-control-machines-market)

[10](https://www.fortunebusinessinsights.com/industry-reports/computer-numerical-controls-cnc-machine-tools-market-101707)

[11](https://www.makerverse.com/resources/cnc-machining-guides/the-biggest-trends-in-cnc-machining-for-2025/)

[12](https://www.prnewswire.com/news-releases/5-axis-cnc-machining-centers-market-to-grow-by-usd-792-5-million-2024-2028-driven-by-self-optimized-machine-cutting-ais-impact-on-market-evolution---technavio-302355135.html)

[13](https://www.linkedin.com/pulse/cnc-machining-center-4-axis-market-trends-technological-advancements-ebbaf)

[14](https://www.campro-usa.com/post/the-future-of-cnc-machining-trends-to-watch)

[15](https://jwmachinecorp.com/innovations-and-future-trends-in-cnc-5-axis-machining/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal