Views: 222 Author: Amanda Publish Time: 2026-01-06 Origin: Site

Content Menu

● Understanding rapid prototyping in sports

● Why conditioning programs need rapid prototyping

● Step‑by‑step implementation of rapid prototyping

>> 1. Assessing needs in the conditioning program

>> 2. Designing concepts with CAD and simulation

>> 3. Building physical prototypes with mixed processes

>> 4. Testing prototypes in live training

>> 5. Iterating, refining, and scaling

● Role of a manufacturing partner like Shangchen

● Example applications inside a conditioning program

>> Custom cooling and recovery devices

>> Sensor mounts and camera fixtures

>> Strength equipment attachments and athlete‑specific supports

● Best practices for integrating rapid prototyping

● FAQ

>> Q1. How does rapid prototyping reduce risk in a conditioning program?

>> Q2. Which technologies are most useful for rapid prototyping in sports?

>> Q3. How fast can a rapid prototyping concept move into daily training?

>> Q4. What should coaches track when testing rapid prototyping equipment?

>> Q5. Why work with an external rapid prototyping factory instead of building everything in‑house?

Rapid prototyping is the process of quickly turning a digital design into a physical model or functional part so teams can validate ideas with real‑world testing instead of theory alone. In a conditioning program, rapid prototyping is used to build and test training accessories, sensor mounts, cooling devices, and recovery tools in days instead of months, dramatically speeding up innovation cycles.

- It relies on technologies such as 3D printing, CNC machining, sheet metal fabrication, and soft tooling to manufacture one‑off or low‑volume parts very quickly.

- For global OEM brands, rapid prototyping allows conditioning staff to collaborate with manufacturing partners to co‑develop hardware that perfectly matches their sport‑specific training philosophy.

Training staff can embed short instructional clips into internal education platforms to show how newly developed rapid prototyping tools are integrated into warm‑ups, main strength blocks, speed sessions, and recovery segments. These explanations help athletes understand why a rapid prototyping tool exists, what problem it solves, and how it fits into the larger conditioning strategy.

Conditioning programs face constant pressure to deliver better performance with fewer injuries, making rapid prototyping a strategic advantage rather than a luxury. Instead of relying on generic commercial equipment, coaches can quickly prototype customized grips, sled attachments, wearable mounts, and cooling tools that fit their environment and athlete profiles.

- Rapid prototyping cuts the risk of investing in full‑scale manufacturing before a concept is validated under training stress, saving time and cost.

- It also enables sport‑specific innovation, such as unique bar attachments for sprint mechanics, position‑specific shoulder supports, or custom fixtures for motion‑capture cameras.

Because rapid prototyping compresses the design–test–refine loop, hardware innovation starts to operate on the same time scale as program design changes, rather than lagging behind by months or seasons. That alignment allows coaches to quickly match physical tools to updated philosophies on load management, velocity‑based training, and return‑to‑play protocols.

The first stage is a structured needs analysis where coaches, sports scientists, and medical staff list pain points that rapid prototyping could solve, such as poor bar grip, inconsistent sled resistance, or sub‑optimal cooling during high‑heat sessions. This assessment uses video analysis of current drills, athlete feedback surveys, and injury reports to prioritize which rapid prototyping projects will have the biggest impact.

- Recording high‑frame‑rate training footage of current drills reveals technical flaws that might be corrected by new hardware such as alignment guides or foot positioning blocks.

- Annotated snapshots of movements help staff identify where a rapid prototyping solution, like a new handle shape or stabilizing bracket, could reduce unwanted joint stress.

Over time, this needs analysis evolves into a running backlog of rapid prototyping ideas, each tagged with expected impact, complexity, and cost. Conditioning directors can then decide which rapid prototyping projects to launch each training block based on available time, budget, and competition schedule.

Once priorities are clear, engineers or external manufacturing partners translate ideas into CAD models designed specifically for rapid prototyping processes like 3D printing or CNC machining. Simulation tools estimate stress, fatigue, and ergonomics so the first physical rapid prototyping iteration already aligns with performance and safety targets.

- Coaches can review 3D renderings and simple motion previews that simulate how the rapid prototyping design will move relative to the athlete during a lift or sprint.

- Screen walkthroughs of CAD models allow non‑technical staff to highlight edges, angles, or surfaces that may cause discomfort or limit real‑world usability.

At this stage, feedback loops are intentionally short: conditioning coaches, athletic trainers, and even athletes themselves are invited to comment on early rapid prototyping concepts before any material is cut. That collaborative approach reduces the chance of creating a technically perfect but practically useless rapid prototyping design.

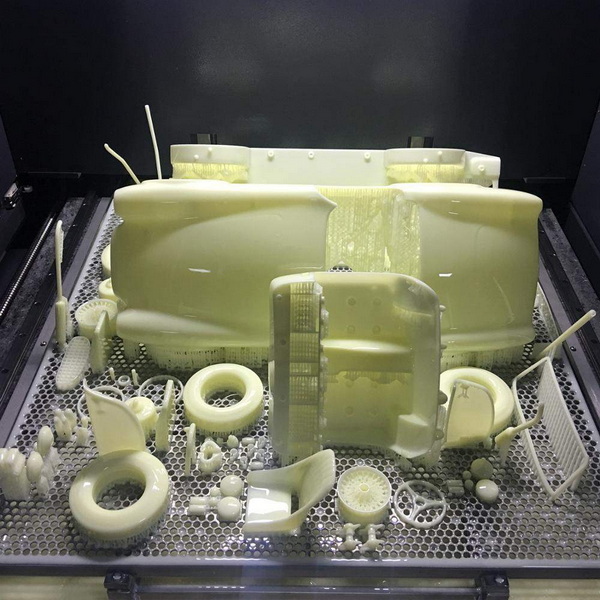

The next step is to manufacture physical prototypes using the best rapid prototyping process for each part, balancing cost, strength, and lead time. Typical workflows blend 3D printing for complex shapes, CNC machining for high‑strength metal components, and sheet metal fabrication or molding for parts that must survive repeated team‑wide use.

- Staff might start with 3D‑printed plastic attachments to validate geometry, then move to CNC‑machined aluminum versions once a rapid prototyping design has proven effective in load‑bearing drills.

- For device housings and protective covers, rapid prototyping via casting or soft tooling can create small pre‑production batches used across multiple athletes.

Using standardized templates for ordering and reviewing rapid prototyping parts keeps communication clean between conditioning departments and manufacturing partners. Clear documentation of dimensions, tolerances, and intended use cases helps ensure each rapid prototyping run matches functional expectations on the first try.

Every rapid prototyping iteration must be stress‑tested inside actual conditioning sessions, under the same loads, speeds, and fatigue levels the final product will see. Coaches track both subjective feedback (comfort, ease of use, perceived benefit) and objective data (bar velocity, ground contact time, heart rate, and core temperature) to judge whether the rapid prototyping concept is worth refining.

- Wearable sensors, tracking devices, and force plates can be mounted using special brackets produced through rapid prototyping so they can be repositioned quickly without expensive custom machining.

- A/B testing of drills with and without the rapid prototyping device shows whether movement patterns, stability, or speed improve in a measurable way.

Testing sessions are scheduled to minimize disruption to the overall training plan, often in secondary blocks or during lower‑priority days so the risk of performance interference is low. After each test, staff log results and impressions into a central rapid prototyping database that guides the next design decision.

Rapid prototyping shines when teams use short iteration cycles to refine a design before committing to mass production. Each training block generates new data and feedback that feed into updated CAD models and new rapid prototyping runs until the part meets performance, safety, and durability targets.

- Once validated, the same rapid prototyping geometry can be transitioned into precision batch production using CNC machining, injection molding, or sheet metal fabrication so the entire roster can use the new tool.

- Manufacturing partners then document specifications, tolerances, and finishing standards for long‑term repeatability, ensuring the rapid prototyping success becomes a stable product line.

Conditioning departments that adopt this mindset begin to treat rapid prototyping just like programming adjustments or sports science interventions: something that evolves continuously instead of once per year. This culture of ongoing rapid prototyping helps teams stay ahead of competitors who rely only on off‑the‑shelf solutions.

For many conditioning programs, partnering with an external rapid prototyping and CNC machining specialist is the most efficient way to turn ideas into high‑quality physical products. A provider such as Shangchen in China offers rapid prototyping, CNC machining, CNC lathe turning, sheet metal fabrication, 3D printing, casting, and molding under one roof, which streamlines every phase from prototype to precision batch production.

- International OEM brands rely on partners like this to translate rough sketches or CAD files into rapid prototyping parts with tight tolerances, consistent quality, and short lead times, even for complex geometries.

- This full‑service model allows conditioning staff to focus on program design while the manufacturing team handles material selection, machining strategy, surface finishing, and logistics for global delivery.

Having a single partner responsible for almost every rapid prototyping step also simplifies communication and quality control. Instead of coordinating separate vendors for 3D printing, CNC machining, and finishing, conditioning programs can manage rapid prototyping tasks through one integrated workflow.

One practical example is the development of a palm‑cooling or hand‑held device designed to manage athlete core temperature between high‑intensity sets. Rapid prototyping allows engineers to test different handle shapes, fluid channels, and surface textures quickly, ensuring the final design is comfortable, durable, and effective under real conditioning workloads.

- Staff can compare how different rapid prototyping versions influence heart‑rate recovery, perceived exertion, and readiness for the next working set.

- Once results are validated, the project scales up using rapid prototyping‑driven tooling to support small‑batch OEM production so every athlete on the roster can access the device.

These cooling and recovery tools can then be integrated into standardized protocols, such as between‑set routines or post‑session cooldown blocks, and monitored with basic performance and wellness questionnaires. Because rapid prototyping keeps development costs low, staff can continue experimenting with small geometry and material changes to fine‑tune the effect.

Another common use of rapid prototyping in a conditioning program is the creation of mounts for tracking devices and high‑speed cameras. With rapid prototyping, staff can quickly test different attachment methods on racks, sleds, turf, and wearable harnesses without damaging expensive equipment or facilities.

- Iterative rapid prototyping cycles optimize angle, stability, and ease of repositioning so staff can capture high‑quality footage and data from multiple training perspectives.

- Simple quick‑release mechanisms built with rapid prototyping parts allow coaches to move monitoring equipment between athletes or stations in seconds.

By reducing the friction of setting up monitoring tools, rapid prototyping helps make data collection part of everyday training rather than a rare, special event. Over time, this leads to richer datasets that support more precise program adjustments and long‑term athlete profiling.

Rapid prototyping also helps conditioning programs develop sport‑ or position‑specific attachments for bars, benches, and sleds to encourage better joint alignment and realistic game‑like loading. For example, custom handles for linemen, grip variations for throwers, or torso supports for injured athletes can all be created with rapid prototyping before deciding which designs to standardize.

- Comparisons between standard equipment and rapid prototyping‑enhanced attachments often show improvements in bar path, depth consistency, or joint stacking under load.

- Once a particular rapid prototyping design proves its value over several training cycles, OEM manufacturing partners can produce durable, branded versions ready for long‑term team use.

This approach is particularly useful for return‑to‑play or long‑term development cases where slight changes in support angle, grip thickness, or loading vector can make the difference between safe progress and repeated setbacks. Rapid prototyping allows staff to tailor equipment to individual needs without waiting for commercial solutions to appear.

To fully integrate rapid prototyping into a conditioning program, teams need clear processes, communication, and data discipline. Treat every rapid prototyping project as a mini R&D cycle with defined objectives, timelines, and criteria for success so athletes and staff understand why new tools are being tested.

- Maintain a digital log with photos, test notes, and key performance indicators for each rapid prototyping iteration so design decisions are traceable and repeatable.

- Align with a capable rapid prototyping partner that offers multiple manufacturing methods, design support, and consistent quality management, especially if your program serves international OEM teams.

It is also essential to manage expectations: not every rapid prototyping idea will produce a breakthrough, but the cumulative effect of many small improvements can significantly enhance performance and safety. By normalizing experimentation through rapid prototyping, organizations create a culture where innovation is encouraged but always grounded in real‑world data.

Rapid prototyping was implemented into conditioning programs by turning training hardware and monitoring tools into fast, low‑risk experiments that can be evaluated and refined in real time. By combining CAD design, 3D printing, CNC machining, data tracking, and structured on‑field testing, coaches and partners systematically evolved devices and attachments that improved performance, comfort, and safety before committing to full‑scale manufacturing. With the support of comprehensive rapid prototyping and OEM services from specialized manufacturers, conditioning departments now treat hardware innovation as an ongoing process rather than a one‑time purchase decision.

Rapid prototyping reduces risk because coaches can test new tools on a small scale, gather real data, and discard poor designs before investing in large production runs. This approach prevents wasted budget on ineffective equipment and limits athlete exposure to unproven devices by validating each rapid prototyping iteration step‑by‑step.

The most commonly used rapid prototyping technologies in sports conditioning are 3D printing for complex geometries, CNC machining for strong metal components, and sheet metal or molded parts for durable training equipment. When combined in a hybrid rapid prototyping workflow, these methods cover everything from sensor mounts and grips to full training tools and cooling devices.

With a mature rapid prototyping pipeline and an experienced manufacturing partner, a simple concept can move from CAD design to a usable prototype in days or a few weeks. After one or two rapid prototyping iterations in practice sessions, successful designs can then transition into precision batch production so that every athlete gains access within a single training cycle.

Coaches should track both subjective feedback, such as comfort and confidence, and objective performance or safety metrics like bar speed, jump height, heart rate, and joint angles when testing rapid prototyping equipment. Capturing training data and short athlete comments for each rapid prototyping iteration gives a complete picture of whether the new hardware delivers meaningful benefits.

An external rapid prototyping factory typically offers deeper manufacturing expertise, more advanced equipment, and multiple processes under one roof, which shortens development cycles and improves quality. For international OEM programs, partnering with a specialist in rapid prototyping and CNC machining also simplifies sourcing, quality control, and logistics from prototype through precision batch production.

content is empty!