Views: 222 Author: Amanda Publish Time: 2026-01-06 Origin: Site

Content Menu

● What Is Rapid Prototyping and Why Your Partner Matters

● Key Capabilities to Look for in a Rapid Prototyping Partner

>> Multi‑Process Rapid Prototyping Capabilities

>> Experience With Your Industry and Application

>> Material Options and Engineering Support

● Evaluating Technical Strength and Quality Systems

>> Equipment, Tolerances, and Process Control

>> Quality Management and Inspection Reports

● Lead Time, Flexibility, and Cost Transparency

>> Turnaround Time and Capacity

>> Transparent Quotation and Cost Structure

● Communication, Collaboration, and Project Management

>> Responsiveness and Technical Communication

>> Data Security and Confidentiality

● Global OEM Experience and One‑Stop Service

>> From Rapid Prototyping to Mass Production

>> Logistics, Export, and After‑Sales Support

● Practical Steps to Choose the Right Rapid Prototyping Partner

>> Define Your Rapid Prototyping Requirements Clearly

>> Shortlist and Compare Multiple Suppliers

>> Start With a Trial Rapid Prototyping Project

● FAQ

>> Q1. How does rapid prototyping reduce development risk?

>> Q2. What rapid prototyping services does Shangchen provide?

>> Q3. When should a company start using rapid prototyping?

>> Q4. What information should I send to a rapid prototyping partner for quotation?

>> Q5. How do I compare different rapid prototyping partners?

Rapid prototyping has become a core strategy for brands that want to move quickly from idea to market‑ready product with less risk and lower cost. Choosing the right rapid prototyping partner directly affects design quality, development speed, and long-term manufacturing success.[1][2]

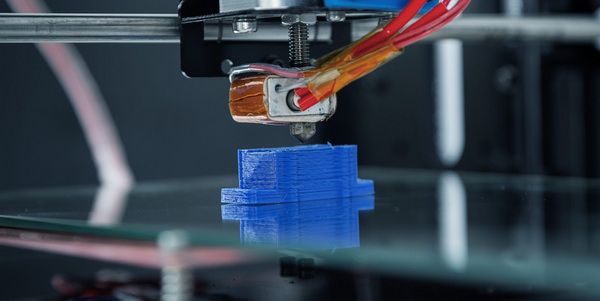

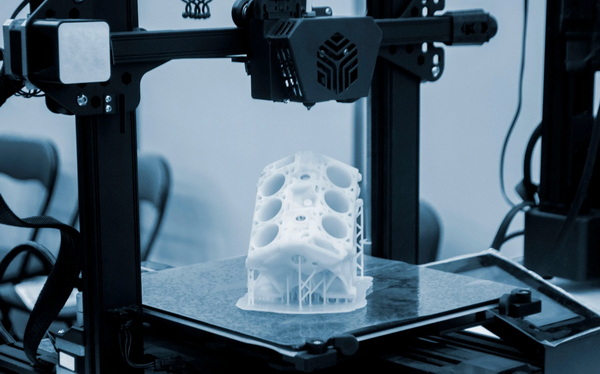

Rapid prototyping is a set of technologies and workflows that convert 3D CAD data into physical prototypes using processes such as 3D printing, CNC machining, and sheet metal fabrication. A professional rapid prototyping partner does more than simply make parts; the best teams provide engineering feedback, material suggestions, and DFM optimization that help you avoid mistakes before mass production.[3][4][5][1]

A strong rapid prototyping partner offers integrated services such as CNC machining, 3D printing, sheet metal fabrication, and mold manufacturing under one roof to support different stages from design validation to low‑volume production. For example, Shangchen (sc‑rapidmanufacturing.com) is a China‑based factory that combines rapid prototyping, CNC machining, turning, sheet metal fabrication, 3D printing, precision batch production, and mold manufacturing to support overseas OEM brands and wholesalers.[5][6][7][8][1][3]

A qualified rapid prototyping partner should demonstrate broad technical coverage so that you can select the best process for each development stage. When evaluating suppliers, focus on the following core capabilities that show whether they can handle your current and future projects.[4][3]

Rapid prototyping partners should provide both additive (3D printing) and subtractive (CNC machining) processes so that you can balance speed, cost, and material performance. For hardware, robotics, industrial equipment, and consumer products, it is helpful when one rapid prototyping supplier also offers sheet metal fabrication, turning, and rapid tooling for bridge production.[6][9][1][3]

Companies such as Shangchen integrate rapid prototyping with CNC machining, sheet metal, turning, 3D printing, and mold manufacturing, which simplifies communication and reduces transition time between prototype and production. This integrated structure allows engineers to try different rapid prototyping routes for the same part and quickly converge on the most suitable combination of processes and materials.[7][8][1][4][5]

Your rapid prototyping partner should understand the standards, safety requirements, and testing methods of your specific industry, whether it is automotive, medical, consumer electronics, industrial machinery, or IoT devices. Industry‑focused rapid prototyping teams can better anticipate practical challenges such as thermal load, fatigue, regulatory tests, or environmental exposure that your product must pass.[2][10][4]

Suppliers with long‑term rapid prototyping experience for OEM customers can anticipate common design issues such as weak snap‑fits, insufficient wall thickness, or tolerance stack‑ups in multi‑part assemblies. When a rapid prototyping factory regularly serves overseas brands and wholesalers, it usually has mature processes for DFM review, engineering communication in English, and export packaging.[11][1][2][5]

A strong rapid prototyping provider will offer a wide portfolio of plastics, metals, and elastomers, together with clear material data so that you can choose options based on mechanical strength, temperature resistance, chemical compatibility, and appearance. For example, rapid prototyping in CNC aluminum or stainless steel is ideal for structural parts, while polymer rapid prototyping using ABS, PC, or nylon suits housings and functional plastic components.[9][3][4]

During rapid prototyping, good partners proactively suggest more suitable materials or processes if they see risk in your original design or material choice, which can avoid failures during testing. Factories like Shangchen use rapid prototyping to create CNC‑machined metals, 3D‑printed plastics, and sheet‑metal components that match end‑use performance as closely as possible, enabling serious functional and assembly testing.[1][2][4][7]

Technical depth and quality control are critical when you rely on rapid prototyping to make engineering decisions and prepare for mass production. Even if you plan only a small batch of prototypes, your partner's approach to quality will influence measurement accuracy, reliability, and repeatability.[4][1]

Check what type of CNC centers, 3D printers, and sheet‑metal lines the rapid prototyping partner uses, and what tolerances they can realistically maintain on complex parts. Modern rapid prototyping factories combine multi‑axis CNC machining, industrial 3D printers, and advanced inspection tools to produce accurate prototypes for functional and dimensional validation.[12][3][6][1]

When a rapid prototyping supplier also supports precision batch production, you gain confidence that successful prototypes can quickly scale to pilot and low‑volume runs without changing vendors. Consistent rapid prototyping performance across multiple projects and materials indicates that their process control is stable and that they can handle more demanding production requirements.[5][6][1][4]

Professional rapid prototyping partners follow structured quality systems and provide inspection reports, measurement data, and visual checks before shipment, even for small orders. Look for rapid prototyping factories that use CMM inspection, digital calipers, hardness testing, and surface‑finish checks aligned with your drawing tolerances and material standards.[6][11][1]

Shangchen positions rapid prototyping at the center of its OEM model and combines process control with detailed inspections so international customers can rely on consistent quality from prototype to serial production. When your rapid prototyping supplier is willing to share sample inspection templates, control plans, and traceability records, it becomes much easier to integrate them into your own quality system.[11][1][5][6]

Rapid prototyping is successful only when your partner can deliver parts fast enough for iterative development cycles while still controlling costs. When you evaluate candidates, compare their standard lead times, express options, and pricing structure.[3][4]

Many rapid prototyping services can deliver simple 3D‑printed parts within a few days, while CNC‑machined or sheet‑metal parts typically require slightly longer lead times due to setup and finishing steps. A good rapid prototyping partner will clearly communicate realistic schedules for standard and rush orders, helping your engineering team align prototype delivery with testing and design reviews.[2][12][3][11]

Factories serving global OEM clients, such as Shangchen, design their rapid prototyping workflows to support tight development schedules and overlapping engineering phases. They can prioritize urgent rapid prototyping tasks, split batches, and coordinate multiple processes in parallel to keep your development milestones on track.[8][9][1][3][5]

A reliable rapid prototyping supplier explains how cost is affected by quantity, material, process choice, tolerances, and finishing, which makes it easier to optimize your design. During rapid prototyping it is common to order multiple iterations, so choose a partner who can offer cost‑effective pricing for repeated changes or multiple design variants.[9][3][4]

Integrated factories that combine rapid prototyping with batch production and tooling can quote both prototype and future production scenarios, giving OEM buyers a clearer total cost picture for the whole product lifecycle. This transparency lets you compare whether a slightly higher rapid prototyping price might still be justified because it reduces later tooling risk or scrap in mass production.[8][4][5][6]

Even with strong technical capabilities, your rapid prototyping project may fail if communication is slow or confusing. Effective collaboration ensures that design data is interpreted correctly and that problems are addressed before they turn into delays.[10][2]

When choosing a rapid prototyping partner, pay attention to response speed, clarity of questions, and the ability to understand engineering drawings, 3D files, and specifications in detail. Good rapid prototyping suppliers ask targeted questions about tolerances, critical dimensions, assembly interfaces, and end‑use conditions rather than quoting blindly.[13][2][11]

Companies such as Shangchen often assign project engineers who follow your rapid prototyping orders from quotation to shipment and keep overseas customers updated at each key step. This type of project management reduces miscommunication and ensures that every rapid prototyping iteration moves your design closer to a production‑ready state.[7][1][5][8][11]

Your rapid prototyping partner must demonstrate that CAD files, technical drawings, and product concepts are handled securely, especially for confidential OEM projects. Many professional rapid prototyping factories support NDAs, controlled data access, and secure communication channels to protect intellectual property.[14][13][1]

Long‑term OEM relationships with global brands indicate that a rapid prototyping supplier is accustomed to handling confidential designs and new product launches without information leakage. If necessary, you can request specific data‑handling procedures and limited‑access arrangements for sensitive rapid prototyping programs.[14][1][5][6]

For overseas brands, wholesalers, and industrial manufacturers, working with a rapid prototyping partner that also supports serial production can significantly simplify the supply chain. This one‑stop approach reduces handovers and keeps technical knowledge within a single team.[1][5]

An ideal rapid prototyping partner is also capable of taking successful prototypes into bridge production, tooling, and steady mass production using CNC machining, sheet metal, molding, or casting. When the same factory manages rapid prototyping, mold production, and batch machining, it can adjust designs quickly according to test results and maintain consistent quality across stages.[3][4][5][6][1]

Shangchen exemplifies this model by combining rapid prototyping services with precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing specifically for overseas OEM buyers. This makes it easier for customers to plan long‑term projects where early rapid prototyping work naturally transitions into stable, repeatable production.[5][7][8][1]

Experienced rapid prototyping factories for export business understand international shipping, customs documentation, and packaging requirements to protect sensitive parts during transit. After‑sales support should include feedback handling, engineering suggestions for the next rapid prototyping iteration, and readiness to modify fixtures, tools, or CNC programs based on test results.[2][6][11]

For long‑term OEM cooperation, many customers choose rapid prototyping partners in China like Shangchen because they combine competitive pricing, strong engineering, and reliable export logistics for global shipments. This combination allows rapid prototyping to become a continuous improvement loop that supports multiple product generations over time.[8][1][2][5]

Once you understand what to look for, follow a structured approach to select and verify your rapid prototyping partner. A systematic process helps reduce risk and builds a stable supply base for future projects.[14][2]

Before contacting suppliers, list your target materials, required quantities, tolerance levels, surface finishes, inspection needs, and expected lead times for each rapid prototyping phase. Clarifying whether you need visual models, functional prototypes, engineering samples, or pilot‑run parts will help the rapid prototyping partner recommend the best process mix.[12][4][1]

You should also define how many rapid prototyping iterations are likely, what tests will be performed, and what metrics will decide whether a prototype is successful. This information supports more accurate planning on both sides and avoids delays caused by unclear expectations around rapid prototyping deliverables.[4][12][2]

Create a shortlist of rapid prototyping companies that match your required processes and industries, using websites, case studies, and customer references as initial filters. Compare them on capabilities, rapid prototyping experience, quality systems, typical lead times, pricing, communication style, and their ability to transition from prototypes to production.[15][11][2][14]

It is useful to prepare a simple evaluation matrix that scores each rapid prototyping supplier across technical competence, quality, cost, delivery, and service. This method makes the decision more objective and helps your team justify the final choice of rapid prototyping partner internally.[15][2][14]

Before committing to large volumes or complex tooling, place a smaller rapid prototyping order with your preferred partner and evaluate the full experience from quotation to delivery. Assess dimensional accuracy, surface quality, packaging, documentation, and the willingness of the team to discuss improvements openly during and after the rapid prototyping run.[13][11][1][2]

If the trial rapid prototyping order goes well, you can gradually expand to more complex parts, multi‑process assemblies, and eventually tooling or batch production under the same partner. This phased approach reduces risk and lets you build trust with the rapid prototyping supplier step by step.[6][11][2][5]

Selecting a partner experienced in rapid prototyping is not only about price; it is about finding an engineering‑driven factory that can translate your CAD models into reliable parts quickly, repeatedly, and securely. Look for multi‑process capabilities, strong quality systems, responsive communication, and a clear track record with global OEM customers so that rapid prototyping becomes a strategic tool in your development process rather than a bottleneck. By collaborating with an integrated manufacturer such as Shangchen (sc‑rapidmanufacturing.com), overseas brands and wholesalers gain a one‑stop rapid prototyping and production partner that supports them from first concept to stable mass production.[7][11][1][2][5][8]

Rapid prototyping allows engineers to test form, fit, and function early, so design problems are discovered before expensive tooling and large‑scale production. Multiple rapid prototyping iterations make it easier to optimize ergonomics, assembly, and performance based on real‑world testing and customer feedback.[12][1][4]

Shangchen provides rapid prototyping through CNC machining, 3D printing, sheet metal fabrication, lathe turning, and related processes for metal and plastic parts. The factory also offers precision batch production and mold manufacturing, allowing customers to move smoothly from rapid prototyping to mass production using one supplier.[1][5][7][8]

Companies should start rapid prototyping as soon as CAD designs are stable enough to be tested physically, often immediately after initial concept and simulation stages. Early rapid prototyping shortens development cycles and reduces later design changes, which saves time and cost during tooling and production.[4][5][1]

For accurate rapid prototyping quotations, provide 3D CAD files, 2D drawings with critical dimensions and tolerances, target materials, quantities, and required finishes. It is also helpful to describe product application, testing conditions, and any special certification or inspection requirements linked to your rapid prototyping stage.[11][2][4]

Compare rapid prototyping partners by capability range, industry experience, equipment, quality systems, lead times, pricing transparency, and communication quality. Running a small trial rapid prototyping project with each shortlisted supplier provides practical insight into their reliability, flexibility, and engineering support.[13][15][2][14]

[1](https://www.sc-rapidmanufacturing.com/rapid-prototyping-knowledge.html)

[2](https://havokjournal.com/nation/business/key-factors-to-consider-when-selecting-a-rapid-prototyping-partner/)

[3](https://www.xometry.com/rapid-prototyping-service/)

[4](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

[5](https://www.sc-rapidmanufacturing.com/what-is-rapid-prototyping-technology.html)

[6](https://elimold.com)

[7](https://www.sc-rapidmanufacturing.com/what-is-rapid-prototyping-in-software-development.html)

[8](https://www.sc-rapidmanufacturing.com)

[9](https://www.partmfg.com)

[10](https://digitalpivot.co.nz/key-considerations-for-choosing-the-right-rapid-prototyping-partner/)

[11](https://kenvox.com/prototyping-services-partnering-expectations/)

[12](https://www.manufacturinghub.io/prototyping/7-rapid-prototyping-methods-you-need-for-your-hardware-startup/)

[13](https://www.linkedin.com/posts/ame-3d_5-questions-to-ask-before-choosing-a-prototyping-activity-7373302065193984001-h8Zs)

[14](https://plastic-it.co.uk/choosing-the-right-prototyping-partner/)

[15](https://www.hlhprototypes.com/our-tips-on-selecting-the-perfect-rapid-prototyping-company/)

content is empty!

How Was Rapid Prototyping Implemented Into a Conditioning Program?

Top CNC Cutting Machine Manufacturers and Suppliers in Denmark

Top CNC Cutting Machine Manufacturers and Suppliers in Hungary

Top CNC Cutting Machine Manufacturers and Suppliers in Czech Republic

Top CNC Cutting Machine Manufacturers and Suppliers in Lithuania

Top CNC Cutting Machine Manufacturers and Suppliers in Ireland