Views: 222 Author: Amanda Publish Time: 2025-08-20 Origin: Site

Content Menu

>> The Importance of CNC Machining

● Factors Influencing Cost in CNC Machining Services

>> 4. Tolerances and Surface Finish

>> 5. Machine Type and Technology

>> 6. Labor and Operator Expertise

● Factors Affecting Quality in CNC Machining

>> 4. Inspection and Quality Control

● Strategies to Balance Cost and Quality in CNC Machining

>> Value Engineering Early in Design

>> Prioritize Features for Tight Tolerances

>> Optimize Batch Size and Production Planning

>> Use Advanced CNC Techniques Wisely

>> Lean Manufacturing and Process Control

>> Partner with Experienced Providers

● CNC Machining and OEM Services for Overseas Brands

● Frequently Asked Questions (FAQ)

>> 1. What materials can be used in CNC machining?

>> 2. How does complexity affect CNC machining costs?

>> 3. What is the typical turnaround time for CNC machining projects?

>> 4. How are tolerances specified and measured in CNC machining?

>> 5. Can CNC machining be combined with other manufacturing processes?

In the manufacturing landscape, CNC machining stands out as a pivotal technology for producing precise, reliable, and complex components. From rapid prototyping to mass production, CNC machining services enable businesses to achieve exceptional accuracy and repeatability. However, one of the critical challenges manufacturers and clients face is balancing cost and quality. How do you ensure you get high-quality CNC machined parts without spiraling expenses? This article dives deep into the key factors affecting both cost and quality in CNC machining, offering insights to help you find the optimal balance for your next project.

c

c

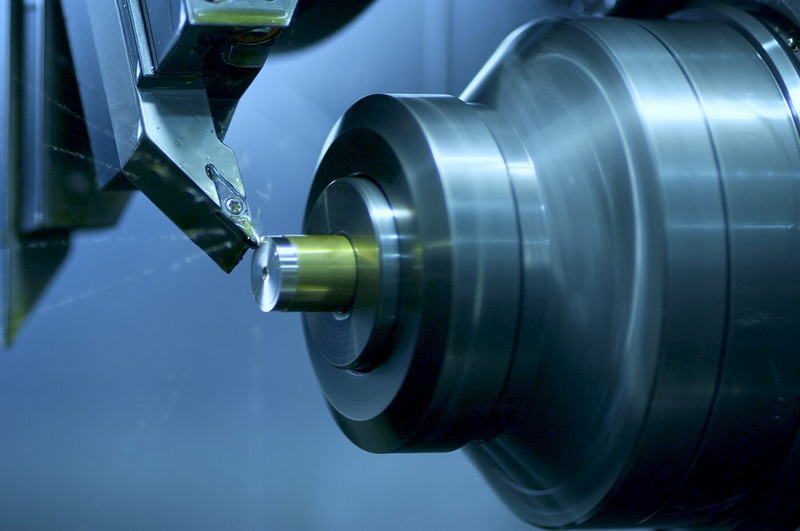

CNC machining (Computer Numerical Control) is a subtractive manufacturing process where pre-programmed computer software dictates the movement of factory tools and machinery. This process executes cutting, turning, drilling, and milling operations on raw materials like metal, plastic, or composites to shape precise components.

- Produces consistent, high-precision parts

- Suitable for both simple and complex designs

- Supports various materials including aluminum, stainless steel, brass, and plastics

- Enables rapid prototyping and efficient small to medium batch production

By automating machining tasks, CNC offers unmatched efficiency and repeatability, making it indispensable in industries such as aerospace, automotive, electronics, and medical devices.

Cost is often the first consideration when choosing CNC machining services. It's important to understand the underlying factors that drive costs up or down.

Different materials vary widely in price and machinability:

- Aluminum: Cost-effective and easy to machine; commonly used.

- Stainless Steel: More durable but harder to machine, requiring more tool wear and time.

- Titanium: High strength-to-weight ratio but expensive and difficult to machine.

- Engineering Plastics: Such as PEEK or Nylon can offer cost advantages but may require different tooling and considerations.

Choosing the right material impacts both cost and final product quality. Sometimes opting for a slightly cheaper material may compromise durability or performance. Conversely, investing in premium materials can increase upfront costs but may result in longer-lasting parts and greater value over time.

Complex parts with intricate geometries, tight tolerances, or multiple features need longer machining time and more specialized tooling, increasing costs. For example, parts requiring multi-axis machining or internal cavities typically require more setup and expertise.

On the other hand, simple geometries such as flat plates or cylindrical parts generally are faster and less expensive to produce. Optimizing the design for manufacturability by reducing unnecessary features or using standard shapes can significantly lower cost without compromising function.

- Larger parts require longer machining cycles and more raw material. They also often need larger machines capable of handling bigger workpieces.

- Higher production volumes benefit from economies of scale, reducing per-unit costs. CNC machining setups typically have upfront programming and tooling costs, which spread out over larger orders.

Low volume or prototype runs tend to be costly on a per-piece basis, but necessary for development and testing. Medium batch sizes often represent a good compromise between cost efficiency and customized production.

Tolerances define how much a dimension can deviate from its nominal value. Tight tolerances require more precise machine calibration, slower cutting speeds, and frequent quality checks — all of which add to cost.

Similarly, surface finish requirements influence costs. A rough surface finish may be acceptable for internal parts or prototype tests, while visible or functional surfaces may require polishing, grinding, or coating. Post-machining processes like anodizing or painting increase lead time and expenses but improve appearance and durability.

Basic 3-axis CNC machines excel at simple flat or prismatic parts and tend to be cost-effective. More advanced 4-axis and 5-axis machines can machine complex parts with multiple faces without repositioning, improving accuracy and reducing handling time, but they come with higher operation and maintenance costs.

Additionally, automation and integration of CNC machines with robotics or quality inspection systems can improve throughput and consistency but represent higher capital investments that may reflect in pricing.

Highly skilled machinists and engineers improve programming efficiency, reduce waste, and minimize errors during production. Their expertise allows for faster problem-solving and helps optimize cutting strategies for cost-effective production.

However, specialized labor commands higher wages. Balancing experienced operators with standardized processes helps control labor expenses while maintaining quality.

Quality in CNC machining is multi-dimensional and goes beyond just tolerances.

Achieving close dimensional accuracy depends on the condition of the CNC machines, calibration schedules, tooling sharpness, and stability of the machining environment. Precision components must be fabricated under controlled conditions to ensure consistency.

Manufacturers with stringent quality control and advanced equipment can produce complex parts meeting micrometer tolerances, which is essential in industries like aerospace and medical devices.

The quality of the surface affects part performance and longevity. For instance, smoother surfaces reduce friction and wear in moving parts. Achieving specific finishes requires careful selection of tooling paths, speeds, and possibly secondary polishing or coating operations.

Quality raw materials significantly impact machining outcomes. Variations in material hardness, grain structure, or composition can cause tool wear, surface defects, or dimensional inconsistencies, jeopardizing overall part quality.

Robust inspection methods like Coordinate Measuring Machines (CMM), optical comparators, and visual inspection ensure parts comply with specifications before delivery. Inline monitoring during machining can also detect deviations early.

Documentation such as First Article Inspection (FAI) reports provides traceability and quality assurance for clients.

Secondary operations like heat treatment enhance strength or hardness, while coatings add corrosion resistance or aesthetics. Though these processes increase costs, they may be essential for meeting performance requirements.

Balancing cost and quality entails deliberate trade-offs and strategic planning.

Engage your CNC machining partner at the design stage to apply value engineering principles. This means:

- Simplifying geometrical features where possible.

- Choosing standard hole sizes and thread specifications.

- Relaxing tolerances where functionally acceptable.

- Selecting machinable materials that meet performance goals but reduce costs.

This collaborative approach can lower machining time and tool wear and reduce scrap rates.

Not all features require the same precision. Identify critical dimensions affecting assembly, fit, or function and maintain tight tolerances there. Other less critical areas can have relaxed specs to save machining time.

Large batch runs reduce per-piece programming and setup costs but increase inventory risks. Smaller batches offer flexibility but at higher per-unit costs. Forecast demand accurately and find an equilibrium that balances cash flow and cost efficiency.

Invest in multi-axis machining or automated tooling changes for complex parts if volume justifies the cost. For low volume or prototypes, simpler machining centers may be more economical.

Adopt lean manufacturing principles to minimize waste, reduce machine downtime, and enhance process repeatability. Continuous improvement efforts enhance quality without rising costs.

Choose CNC machining services with proven expertise in your industry, supported by quality certifications (ISO 9001, AS9100, etc.) and state-of-the-art equipment. Experienced providers anticipate challenges and optimize production plans, ultimately delivering better value.

For foreign brands, manufacturers, and wholesalers, finding a trustworthy CNC machining and OEM partner is essential to maintain competitiveness. Our factory excels in providing comprehensive services, including:

- Rapid Prototyping: Quick turnaround for testing and validation.

- CNC Milling and Turning: Precision manufacturing of complex components.

- Sheet Metal Fabrication: Custom bends, cuts, and assemblies.

- 3D Printing: Hybrid approaches to create prototypes or tooling.

- Mold Making: Injection molding and casting molds for mass production.

- Precision Batch Production: Scalable and repeatable manufacturing runs.

By consolidating these capabilities, manufacturers reduce supply chain complexity and improve quality oversight. Outsourcing to reliable CNC machining factories like ours combines cost benefits with advanced manufacturing standards, enabling foreign brands to deliver high-quality products at competitive prices.

Balancing cost and quality in CNC machining is an intricate process shaped by various factors such as material choice, design complexity, machine technology, and production volume. High-quality parts demand precision, superior materials, and diligent quality control, which increase costs. Conversely, cost reduction requires thoughtful compromises in design and materials without undermining functional requirements.

Collaborative partnerships with trusted CNC machining providers, thorough early-stage design reviews, and strategic prioritization of critical features pave the way to optimized manufacturing solutions. These efforts enable OEMs and brand owners to secure affordable, high-quality CNC machined parts essential for competitiveness in demanding markets.

Investing in suitable machinery, advanced technologies, and skilled labor further bridges the gap between cost and quality, ensuring consistent and reliable outcomes. Ultimately, a clear understanding of your project's requirements, combined with flexible manufacturing strategies, will allow you to strike the perfect balance.

CNC machining supports a wide range of materials including metals such as aluminum, stainless steel, titanium, brass, and plastics like ABS, Nylon, and PEEK. Material choice depends on application requirements and cost considerations.

Complex parts with intricate features or tight tolerances require longer machining time, advanced tool setups, and expert programming, all of which increase costs. Simplifying designs and relaxing non-critical tolerances can reduce expenses.

Turnaround varies by complexity, batch size, and material. Rapid prototypes may be delivered in days, while larger batch production could take weeks. Early communication with the supplier helps establish accurate timelines.

Tolerances define allowable dimensional variation, specified on engineering drawings. They are measured using precision tools like calipers, micrometers, and coordinate measuring machines (CMM) to verify compliance.

Yes. CNC machining can be integrated with 3D printing, sheet metal fabrication, molding, and finishing operations to produce complex assemblies or improve performance and aesthetics.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal