Views: 222 Author: Amanda Publish Time: 2025-10-22 Origin: Site

Content Menu

● Understanding Vacuum Mold Casting

● Why Vacuum Mold Casting is Ideal for Medical Device Prototyping

● The Vacuum Mold Casting Process for Medical Prototypes

>> Step 1: Master Model Creation

>> Step 3: Degassing and Casting

>> Step 4: Curing and Demolding

● Advantages of Vacuum Mold Casting for Medical Components

● Applications in Medical Device Development

● Integration with Other Manufacturing Services

● Best Practices for Vacuum Mold Casting Medical Prototypes

● Challenges and Limitations to Consider

● FAQs

>> 1. What materials are commonly used in vacuum mold casting for medical prototyping?

>> 2. How does vacuum mold casting improve surface finish?

>> 3. Can vacuum mold casting be used for functional testing of medical parts?

>> 4. What are the size limitations for vacuum mold casting components?

>> 5. How quickly can prototypes be produced using vacuum mold casting?

Vacuum mold casting is rapidly becoming a cornerstone process in medical device prototyping due to its ability to produce highly precise and reliable parts. For manufacturers and designers working in the medical field, where safety and accuracy are paramount, Vacuum Mold Casting offers significant advantages over traditional methods. This article explores the key benefits, processes, and applications of vacuum mold casting in medical device prototyping, providing detailed insights to help companies make informed decisions about adopting this technology.

Vacuum mold casting is a manufacturing technique that involves creating detailed molds under vacuum conditions to eliminate air bubbles and impurities. This process helps achieve exceptional surface quality and dimensional accuracy, critical for medical components that must meet stringent standards.

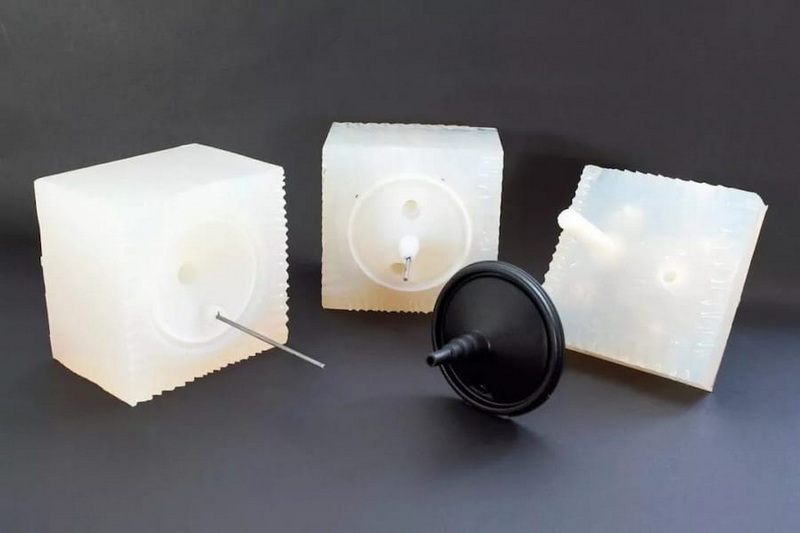

The technique generally uses silicone molds made from master models, enabling rapid production of prototype parts in a variety of materials that simulate final product properties. By evacuating air around the resin as it fills the mold, vacuum mold casting minimizes defects and improves the mechanical integrity of the prototypes.

Medical devices require prototypes that replicate the final products not only in form but also in function and durability. Here are some reasons vacuum mold casting excels in this niche:

- High Precision: The vacuum process removes trapped air, ensuring smooth and bubble-free surfaces. This is crucial for devices like surgical instruments or implantable parts where accuracy impacts performance.

- Material Versatility: Vacuum mold casting supports a wide range of resins and silicones, allowing simulation of various final product materials such as flexible polymers or hard plastics.

- Cost Efficiency: Compared to CNC machining or injection molding, it reduces tooling costs and turnaround time, enabling rapid iteration during design validation.

- Small Batch Production: Ideal for limited runs required in early development or clinical trials without high setup expenses.

- Improved Prototype Durability: The reduced presence of air bubbles and defects in the vacuum-cast parts leads to prototypes that better withstand handling and functional testing.

Initially, a master model is designed and created using high-precision CNC machining, 3D printing, or other prototyping methods. This model represents the exact geometry of the medical component. Design considerations include ensuring that the model can easily be released from the silicone mold, minimizing undercuts.

A silicone mold is crafted by carefully encasing the master model, capturing intricate details down to microns. The flexibility of silicone molds allows the easy demolding of complex and delicate shapes without damage.

The silicone mold is placed inside a vacuum chamber where air is evacuated to minimize voids. The selected resin is also degassed separately to ensure the elimination of bubbles before being poured. Resin is then introduced into the mold under vacuum conditions, helping it fill every cavity perfectly.

After the resin cures—which may take minutes to hours, depending on the material—the part is demolded carefully. Because of the vacuum process, the resulting prototype exhibits excellent clarity, surface finish, and structural integrity.

Post-processing steps might include sanding, painting, assembly, or sterilization preparation depending on the prototype's function. These final touches prepare the prototype for clinical evaluation or design reviews.

Vacuum mold casting offers multiple benefits that address the specific needs in medical device development:

- Air Bubble Elimination: The vacuum environment removes trapped air, preventing defects such as voids or weak spots that can jeopardize prototype reliability.

- High Detail Reproduction: This method can reproduce extremely fine details, essential for small and intricate medical devices.

- Fast Turnaround Time: The process allows for rapid production and iteration, speeding up the development cycle.

- Mixed Material Options: Different resin formulations help mimic the mechanical, thermal, and chemical properties of final materials.

- Lower Production Costs: Unlike injection molding, vacuum mold casting requires minimal tooling investment, making it cost-effective for prototype and low-volume production.

Vacuum mold casting fits a wide variety of applications, especially where precision and material performance are critical:

- Surgical Instruments: Producing ergonomic handles, custom grips, and other detailed components that require smooth surfaces and strong mechanical properties.

- Implants and Biocompatible Devices: Creating shapes and structures that simulate properties of biocompatible materials for fit and functionality testing before final manufacturing.

- Diagnostic Devices: Manufacturing clear, smooth parts such as casings and optical plastics essential for devices like endoscopes or sensors.

- Wearable Health Monitors: Prototyping flexible, lightweight components with similar feel and durability to final products.

- Dental Applications: Rapid manufacturing of dental molds, models, and aligners requiring high resolution and surface quality.

At Shangchen (sc-rapidmanufacturing.com), vacuum mold casting is integrated with various complementary manufacturing technologies. This approach enables complete prototyping and production solutions including:

- Rapid Prototyping and 3D Printing: For creating master models used in mold making.

- CNC Machining: To produce precise masters or functional components.

- Precision Batch Production: To support small to medium production runs of quality medical components.

- Sheet Metal Fabrication: For enclosing parts or creating hybrid assemblies.

This combined offering streamlines development workflows and helps clients go from concept to clinical evaluation faster and more cost-effectively.

- Design with Moldability in Mind: Ensure draft angles facilitate easy removal from flexible molds, minimizing damage.

- Choose Appropriate Resin Materials: Match resin mechanical and chemical properties to intended functional tests or use cases.

- Thorough Degassing: Use quality vacuum chambers for both mold and resin degassing to prevent voids.

- Quality Control: Inspect prototypes meticulously for dimensional accuracy and surface defects.

- Regulatory Compliance: Work with suppliers knowledgeable in medical standards and materials compliant with regulations such as ISO 13485 or FDA guidelines.

While vacuum mold casting excels in many areas, it has limitations:

- Size Constraints: Typically limited to small and medium-sized parts due to mold flexibility and vacuum chamber dimensions.

- Material Restrictions: Some materials used in final medical devices may not yet be compatible with vacuum casting resins.

- Mechanical Property Differences: Cast prototypes may not fully replicate the strength or elasticity of injection molded production parts.

- Post-Processing Requirements: Additional finishing may be needed to match the aesthetics or sterilization requirements of final devices.

Despite these, vacuum mold casting remains an excellent and cost-effective solution for early-stage prototyping and functional testing.

Vacuum mold casting offers a precise, reliable, and cost-effective solution for medical device prototyping. Its ability to reproduce fine details and maintain structural integrity under vacuum conditions makes it superior for early product development and pre-clinical evaluation. With rapid turnaround times and versatile material options, it empowers medical manufacturers and designers to innovate confidently while reducing risks. Integrating this technology with complementary manufacturing services creates a streamlined development cycle that accelerates innovation and commercial readiness.

Common materials include polyurethane resins, silicone rubbers, and epoxy resins that simulate the mechanical properties of final medical-grade plastics.

The vacuum environment removes trapped air bubbles and gases during resin pouring, resulting in smoother, defect-free surfaces essential for medical devices.

Yes, prototypes produced by this method often have mechanical properties close enough to final materials to be used for fit, form, and limited functional testing.

Typically, components range from small intricate parts to medium-sized assemblies. Extremely large parts may require alternative manufacturing methods.

Depending on design complexity, materials, and curing times, prototypes can often be delivered within a few days to a week.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes