Views: 222 Author: Amanda Publish Time: 2026-01-25 Origin: Site

Content Menu

● Hungary's Growing 3D Printing Ecosystem

● Representative 3D Printing Companies in Hungary

● Why Overseas OEMs Look Beyond Local Hungarian Capacity

● Shangchen as a Strategic OEM Partner

● Typical Services Offered to Global OEMs

● Applications of On‑Demand 3D Printing in Hungary

● How Overseas Buyers Can Use Hungarian and Chinese Partners Together

● Design and Engineering Support for OEM Customers

● Logistics, Lead Time, and Cost Considerations

● Quality Assurance and Certifications

● Example Collaboration Workflow: Hungary + Shangchen

● Marketing Content Ideas for On‑Demand 3D Printing

● FAQ

>> 1. How many 3D printing companies operate in Hungary?

>> 2. What sectors most commonly use on‑demand 3D printing in Hungary?

>> 3. Why should overseas OEMs consider a Chinese factory like Shangchen alongside Hungarian suppliers?

>> 4. What quality standards can global buyers expect from Shangchen?

>> 5. How can I start a project with Shangchen if I currently buy from Hungary?

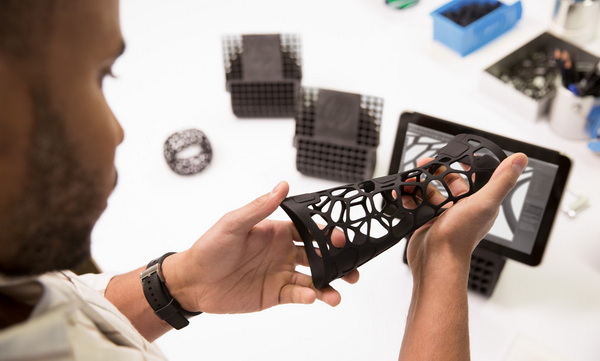

Hungary is becoming an attractive destination for overseas OEM brands looking for reliable on demand 3D printing manufacturers and suppliers, especially in automotive, medical, electronics, and industrial equipment. For foreign buyers, combining local Hungarian 3D printing service bureaus with powerful Chinese OEM partners like Shangchen is often the most cost‑effective and flexible sourcing strategy.

Hungary hosts a diverse range of professional 3D printing companies, from metal additive manufacturing specialists to desktop printer manufacturers and hybrid rapid prototyping workshops. These On Demand 3D Printing Manufacturers and Suppliers support both one‑off prototypes and small‑to‑medium batch production runs for European and global customers.

Many companies focus on industrial applications such as automotive, machine building, and medical implants. Others develop and manufacture 3D printers and software, selling complete solutions to universities, hospitals, and engineering firms. Well‑chosen partners in Hungary can reduce logistics time to EU markets while maintaining high technical quality and engineering support.

Several Hungarian businesses illustrate the range of capabilities available from On Demand 3D Printing Manufacturers and Suppliers in the country. Some metal‑focused companies offer high‑precision stainless steel and cobalt‑chrome parts with tight tolerances and robust mechanical performance. These are suitable for demanding sectors such as aerospace components, powertrain parts, and high‑load mechanical structures.

Hungary also has companies that develop and manufacture their own 3D printers and related software. These solutions are widely used in medical and dental applications, educational institutions, and general industrial design departments. Innovative technologies such as two‑directional printing or volumetric printing are emerging from local innovators, providing faster build times and reduced support structure requirements for complex geometries.

Large‑format and volumetric solutions exist to create 3D elements for visual communication, exhibitions, and automotive rapid prototyping. Service providers in this segment often bridge the gap between traditional advertising, industrial design, and advanced manufacturing, making 3D printing a practical tool for marketing agencies and design studios.

Even though Hungary has many capable On Demand 3D Printing Manufacturers and Suppliers, European and American OEM buyers frequently supplement local sourcing with China‑based partners. This hybrid model helps balance speed, cost, and capacity for different project stages.

Hungarian partners provide fast engineering communication, local language support, and convenient EU logistics for urgent prototypes and small batches. For early‑stage design iterations, having a nearby supplier reduces time‑to‑feedback and encourages face‑to‑face collaboration when needed. This is particularly valuable for complex assemblies that require close communication between design, testing, and manufacturing.

Chinese OEM factories, on the other hand, offer lower unit costs, comprehensive technologies (3D printing, CNC, sheet metal, molds), and strong scalability for larger batches or complex multi‑process projects. As volumes grow or when parts demand multiple manufacturing technologies in one project, a capable Chinese factory can become the backbone of a cost‑efficient global supply chain. For many brands, the optimal approach is to use Hungary for immediate regional needs and trusted Chinese factories for cost‑optimized production and overflow capacity.

Shangchen is a China‑based OEM factory specializing in rapid prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing for overseas brands, wholesalers, and manufacturers. This broad portfolio of capabilities makes Shangchen an ideal extension to On Demand 3D Printing Manufacturers and Suppliers in Hungary that need extra capacity or advanced processes not available in‑house.

Shangchen supports applications across automotive, medical devices, electronics, consumer goods, industrial automation, robotics, and other specialized sectors. The company helps turn 3D geometry data into functional parts, whether for one‑off prototypes, bridge production, or long‑term OEM contracts. With professional project management and engineering support, overseas customers can move from concept to validated prototypes and then into stable production with one integrated partner.

The factory operates with robust quality systems, tight machining tolerances, and comprehensive inspection equipment such as coordinate measuring machines and 3D scanners. This ensures that critical dimensions, surface finishes, and mechanical properties meet the standards required by global OEM customers. By partnering with Shangchen, Hungarian and other European businesses can maintain local engineering relationships while leveraging competitive Chinese pricing, flexible lead times, and a broad range of manufacturing technologies.

Modern On Demand 3D Printing Manufacturers and Suppliers, whether in Hungary or China, increasingly serve as multi‑process solution providers rather than pure print houses. Key services often include:

- Industrial 3D printing in plastics and metals for prototypes, jigs, fixtures, and end‑use parts.

- CNC machining for high‑precision milling and turning in materials such as aluminum, steel, stainless steel, brass, titanium, and engineering plastics.

- Sheet metal fabrication for housings, brackets, enclosures, panels, and structural components.

- Mold and tooling production, including rapid tooling and production molds for plastic injection, die casting, and polyurethane vacuum casting.

- Surface finishing and post‑processing, such as polishing, anodizing, plating, painting, bead blasting, heat treatment, and laser engraving.

For overseas OEM customers, using one provider that can integrate 3D printing with CNC, sheet metal, and molds reduces hand‑offs between multiple suppliers. This approach improves quality consistency, shortens project timelines, and simplifies communication. It also helps ensure that design‑for‑manufacturing feedback considers all relevant processes in a single workflow.

In Hungary, On Demand 3D Printing Manufacturers and Suppliers support a wide range of industrial and commercial applications. The technology has moved beyond simple mock‑ups to become a core tool for functional parts, fixtures, and production‑grade components.

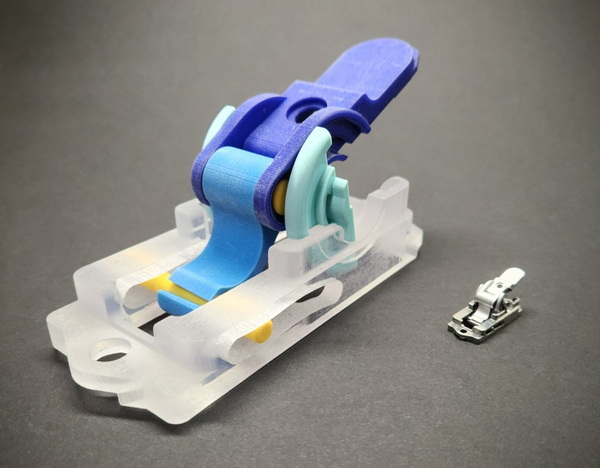

In the automotive and transportation sectors, companies use on‑demand 3D printing for functional prototypes, custom jigs and fixtures, and limited‑run components. This includes parts for motorsport applications, restoration projects, and low‑volume specialty vehicles. Manufacturers benefit from shorter lead times, easier design iterations, and the ability to consolidate multiple parts into single printed components.

Medical and dental applications are another strong area for Hungary. Local printer manufacturers and service bureaus supply customized surgical guides, dental models, orthodontic appliances, device housings, and training models. The combination of 3D printing with biocompatible materials and precision post‑processing allows doctors, surgeons, and technicians to work with highly accurate, patient‑specific models.

Visual communications, exhibitions, and interior design also rely on on‑demand 3D printing. Large volumetric prints are used for exhibition stands, advertising installations, film props, architectural models, and artistic projects. This allows agencies and designers to translate creative concepts into physical objects quickly, without relying on expensive traditional sculpting or complex manual fabrication.

For foreign brand owners, wholesalers, and manufacturers, a dual‑sourcing strategy often delivers the strongest results when working with On Demand 3D Printing Manufacturers and Suppliers in Hungary and China. Such a strategy allows companies to adjust their sourcing approach based on project phase, volume, and cost targets.

Hungarian service bureaus are ideal for early‑stage design validation prototypes and urgent iterations. Their proximity to European customers means faster shipping, easier communication in regional languages, and the possibility of on‑site meetings. When development timelines are tight and engineering changes are frequent, these advantages can be decisive.

Shangchen is well‑suited for larger prototype batches, bridge production, and full production runs. When a design has matured and the focus shifts to cost, repeatability, and scalability, Chinese OEM factories provide significant advantages. Shangchen's ability to combine 3D printing, CNC machining, sheet metal, and mold making in one workflow is particularly useful for complex assemblies or multi‑material products.

By using both types of On Demand 3D Printing Manufacturers and Suppliers, OEM buyers gain the responsiveness of local partners in Hungary plus the cost efficiency and capacity of a Chinese factory. This blended model also improves supply chain resilience, because production can shift between regions in response to demand spikes, transportation disruptions, or regulatory changes.

Another important advantage when working with experienced On Demand 3D Printing Manufacturers and Suppliers is access to design and engineering support. Many Hungarian service providers and Chinese factories like Shangchen employ in‑house engineers who can review 3D models, suggest design improvements, and optimize parts for specific manufacturing technologies.

Design‑for‑additive‑manufacturing services help optimize lattice structures, wall thickness, and support strategies for 3D printed parts. For CNC machined components, engineers can adjust tolerances, radii, and machining strategies to reduce cycle times and improve tool life. In sheet metal projects, design adjustments can eliminate unnecessary bends, reduce welding distances, and improve flatness.

For international OEMs, this engineering collaboration is essential to avoid costly iterations and ensure that prototypes translate smoothly into stable mass production. By engaging both Hungarian and Chinese partners early in the design stage, customers can identify the best combination of processes and materials, and avoid late‑stage surprises.

When choosing On Demand 3D Printing Manufacturers and Suppliers, OEMs must carefully weigh logistics, lead time, and overall cost. Hungary offers clear advantages for European customers when it comes to shipping times and customs procedures within the EU. This is valuable for urgent prototypes or service parts that must reach end customers quickly.

However, for larger batches and repeat orders, total landed cost often favors production in China, especially when using an integrated OEM factory like Shangchen. Even after accounting for international freight, unit prices can remain highly competitive due to economies of scale, labor cost differences, and optimized manufacturing workflows.

A practical approach is to use Hungary for extremely urgent parts and early development runs, while relying on Shangchen for cost‑optimized production and long‑term supply. As designs stabilize, production can gradually shift from rapid local providers to high‑capacity Chinese manufacturing, while still keeping some local capacity for emergency needs and market‑specific variants.

Global OEM buyers place strong emphasis on the quality systems of their On Demand 3D Printing Manufacturers and Suppliers. Many professional suppliers in Hungary and China operate under recognized standards such as ISO9001 and other industry‑specific certifications. Documented procedures, traceability, and regular audits help ensure consistent performance.

An OEM partner like Shangchen typically complements these systems with advanced inspection equipment and clear quality control workflows. Incoming materials inspection, in‑process checks, final inspection, and packaging control are integrated into a unified quality management framework. For critical components, customers can request full inspection reports, material certificates, and dimensional measurement data.

Hungarian partners also contribute to quality assurance through local testing, fit checks, and functional validation. By combining the strengths of both regions, OEMs can maintain high quality standards from prototype through series production.

A typical cooperation between a Hungarian service bureau and Shangchen, acting together as On Demand 3D Printing Manufacturers and Suppliers, might follow a practical sequence that supports the complete product lifecycle.

In the concept and early prototype phase, the Hungarian partner prints plastic or metal prototypes that allow designers to evaluate ergonomics, assembly, and basic function. Adjustments can be made quickly, often within days, based on feedback from engineering, marketing, and end users.

During design optimization, both the local engineering team and Shangchen's manufacturing engineers review the models. They collaborate to improve manufacturability, reduce weight, minimize cost, and select the best combination of processes. This stage may involve additional 3D printed prototypes, CNC‑machined samples, and small sheet metal assemblies.

For bridge production, Shangchen produces low‑volume runs using 3D printing, CNC machining, and sheet metal fabrication, depending on part requirements. These parts support pilot launches, test markets, internal validation, and pre‑series builds. Lessons learned in this phase feed into final tool design for mass production.

In mass production, Shangchen's mold and tooling capabilities enable efficient large‑scale manufacturing. Injection‑molded plastic parts, die‑cast components, and stamped sheet metal parts are produced at scale, while Hungarian partners continue to handle local support, modifications, and service parts. This creates a flexible, stable, and scalable supply chain for global OEMs.

Because 3D printing and rapid prototyping are visually appealing and technically rich, marketing content for On Demand 3D Printing Manufacturers and Suppliers performs best when it explains real‑world applications clearly. Blogs, case studies, and landing pages can highlight industry‑specific solutions, such as rapid tooling for consumer products, lightweight fixtures for automotive plants, or custom anatomical models for surgeons.

Step‑by‑step project stories help potential customers understand how a part moves from design to finished product. Describing material choices, surface finishing options, and cost trade‑offs builds trust and positions suppliers as knowledgeable partners rather than simple job shops. When combined with clear call‑to‑action messages, these stories can turn website visitors into qualified leads.

For companies like Shangchen and their Hungarian partners, emphasizing the combined value of local responsiveness and global manufacturing strength is especially compelling. Framing the partnership as a comprehensive solution—rather than two separate suppliers—helps overseas OEMs visualize how the joint model fits into their own product development roadmap.

Hungary has built a dynamic ecosystem of On Demand 3D Printing Manufacturers and Suppliers, including metal additive specialists, printer manufacturers, and multi‑process service bureaus. These companies support a wide variety of sectors such as automotive, medical, industrial equipment, and visual communications, providing local engineering support and fast turnaround for European customers.

When combined with an experienced Chinese OEM factory like Shangchen, overseas brands, wholesalers, and manufacturers gain a powerful, flexible supply chain for rapid prototyping, precision batch production, and long‑term OEM manufacturing. Shangchen's integration of 3D printing, CNC machining, sheet metal fabrication, and mold production, together with strong quality systems and engineering support, makes it a valuable partner for complex and high‑volume projects.

By carefully selecting partners in both Hungary and China, buyers can achieve faster development cycles, robust quality, and competitive total cost across their entire product portfolio. A blended sourcing strategy that leverages the strengths of local Hungarian providers and Shangchen as a global OEM factory is often the most resilient and efficient approach for modern product development and manufacturing.

Contact us to get more information!

Hungary hosts dozens of professional 3D printing‑related companies, including service bureaus, metal printing specialists, and 3D printer manufacturers. The ecosystem continues to expand as industrial additive manufacturing gains momentum across Central Europe. Many of these On Demand 3D Printing Manufacturers and Suppliers focus on high‑value applications for automotive, medical, and industrial customers.

The most active sectors for on‑demand 3D printing in Hungary are automotive, medical and dental, industrial machinery, and visual communications. Companies in these fields rely on On Demand 3D Printing Manufacturers and Suppliers for rapid prototyping, functional testing, customized tooling, fixtures, and low‑volume production components. Educational institutions and research labs are also important users, particularly for experimental designs and technology development.

Hungarian partners provide regional support, short shipping times within the EU, and fast response for early prototypes and urgent parts. A Chinese factory like Shangchen complements this by offering lower unit costs, broader process capability, and greater production capacity for larger orders. Working with both types of On Demand 3D Printing Manufacturers and Suppliers allows OEMs to optimize speed, cost, and flexibility at each stage of the product lifecycle.

Shangchen operates under strict quality management systems, supported by advanced inspection equipment and documented procedures. The company routinely works with tight machining tolerances and controlled surface finishes suitable for demanding industries such as automotive and medical devices. Overseas OEM customers can expect comprehensive quality documentation, stable process control, and consistent performance across repeated batches.

OEM buyers who already work with Hungarian On Demand 3D Printing Manufacturers and Suppliers can easily add Shangchen as a complementary partner. The usual first step is to send 3D CAD files and basic project requirements for quotation and manufacturability review. Many customers begin with small sample orders, compare quality and lead time with existing suppliers, and then decide how best to divide prototype, bridge, and mass production between Hungary and Shangchen.

1. https://ensun.io/search/3d-printing/hungary

2. https://ensun.io/search/3d-metal-printing/hungary

3. https://www.bigprint.eu/volumetric-3D-printing

4. https://www.sc-rapidmanufacturing.com

5. https://www.sc-rapidmanufacturing.com/top-metal-cnc-machining-manufacturers-and-suppliers-in-hungary.html

6. https://shangchencnc.en.made-in-china.com/product/BFbGmPgEJNrf/China-Rapid-Plastic-Prototyping-Services-with-3D-Printing-and-CNC

7. https://anebonmetal.com/top-rapid-prototyping-manufacturers-and-suppliers-in-hungary/

8. https://tirapid.com/rapid-prototyping-services-china/

9. https://seekmake.com/mfg/3d-printing/hungary/gy%C3%85%E2%80%98r-moson-sopron

10. https://www.varinex.hu/tdk-at-the-forefront-of-industrial-3d-printing/

content is empty!