Views: 222 Author: Amanda Publish Time: 2025-10-23 Origin: Site

Content Menu

● Introduction to Vacuum Mold Casting and Automation

● Understanding Vacuum Mold Casting

● The Role of Automation in Vacuum Mold Casting

>> Automated Mold Preparation and Material Handling

>> CNC Machining for Mold Creation

>> Automated Material Dispensing and Mixing

>> Intelligent Process Control and Monitoring

● Broader Benefits of Automation in Vacuum Mold Casting

>> Significantly Increased Production Speed

>> Enhanced Product Quality and Consistency

>> Cost Efficiency and Waste Reduction

>> Flexibility and Scalability in Production

>> Improved Safety and Working Conditions

● Real-World Application: Shangchen's Automated Vacuum Casting Line

● Challenges in Implementing Automation in Vacuum Mold Casting

● Future Trends Boosting Vacuum Mold Casting Automation

● Frequently Asked Questions (FAQs)

>> 1. What industries benefit the most from vacuum mold casting automation?

>> 2. How does automated dosing improve vacuum casting quality?

>> 3. Is automation suitable for small-scale vacuum mold casting operations?

>> 4. What are the key components of an automated vacuum mold casting line?

>> 5. How can manufacturers prepare for automation integration?

Vacuum mold casting is a highly specialized manufacturing process widely used in industries requiring precise, high-quality parts with complex shapes. This method involves creating molds and casting materials under vacuum conditions to reduce air entrapment, leading to superior surface finish and structural integrity. Automation advancements have drastically boosted the efficiency and speed of vacuum mold casting production, revolutionizing how manufacturers meet market demands.

This article explores the profound impact of automation on Vacuum Mold Casting production speed, detailing the technologies involved, their benefits, challenges, and practical applications. It is an essential read for industrial engineers, production managers, and businesses involved in precision manufacturing.

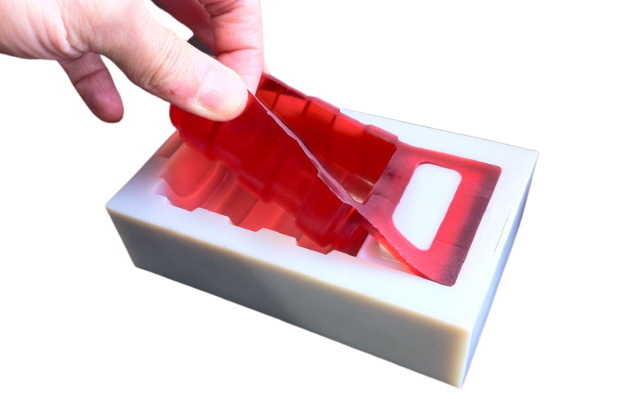

Vacuum mold casting, also known as vacuum casting, is a process where liquid polyurethane, silicone, or other materials are poured into molds under a vacuum. This method reduces defects caused by air bubbles and ensures detailed replication of the master pattern.

Vacuum casting is particularly advantageous for producing small to mid-sized runs of parts with complex geometries and fine surface finishes, often making it the preferred choice for prototyping and low-volume manufacturing.

Key advantages include:

- High dimensional accuracy

- Excellent surface quality

- Ability to produce intricate shapes

- Rapid prototype and small batch production

Despite its precision, traditional vacuum mold casting can be time-consuming and labor-intensive. This is where automation plays a transformative role.

Automation in vacuum mold casting combines robotics, computer numerical control (CNC), and integrated software systems to streamline the casting process. These technologies minimize human intervention, enhance precision, reduce errors, and dramatically accelerate production cycles.

Robotic arms equipped with sensors and manipulators can load and unload molds into vacuum chambers quickly and with exceptional consistency. Automated material handling frees human operators from repetitive tasks and ensures seamless transitions between production stages, minimizing delays.

Additionally, automated conveyors and handling systems maintain a smooth flow in high-volume environments, reducing bottlenecks and downtime.

The accuracy of molds directly impacts casting quality. CNC machining automates mold creation, carving molds with extreme precision and tight tolerances. This not only enhances the exactness of the mold but also shortens turnaround times from days to mere hours for prototype molds.

The ability to quickly manufacture, modify, or replicate molds is crucial for industries with fast iteration cycles.

Casting materials require precise mixing ratios to maintain mechanical properties and ensure quality. Automated dosing systems accurately measure and mix components, delivering consistent batches every time. This reduces material waste, lowers defect rates, and decreases the time spent on manual preparation.

Integrated dispensing further improves repeatability and supports multi-material casting without contamination risks.

State-of-the-art automation systems use sensors and software to continuously monitor vacuum levels, temperature, pressure, and casting duration. Real-time feedback allows for instant process adjustments, keeping parameters optimal and reducing scrap rates.

Moreover, these systems can log data for quality assurance and traceability, helping manufacturers adhere to industry standards and regulatory requirements.

By integrating automation across the vacuum mold casting workflow, manufacturers realize a spectrum of advantages:

Automated machinery completes tasks at a consistent pace without fatigue or variability, enabling shorter cycle times and faster throughput. For example, robotic mold handling can cut mold loading/unloading from minutes to seconds, while CNC mold fabrication accelerates mold availability.

Automation reduces human error and variability. CNC-machined molds maintain tight tolerances, and automated dispensing ensures precise material mixes, leading to fewer defects such as air bubbles, warping, or incomplete fills. This consistency supports repeatable high-quality production, vital for OEM partnerships.

While upfront investment in automation equipment might be significant, operational savings are realized through lowered labor requirements, reduced material waste, and minimized scrap. High automation levels also enable better resource planning and energy efficiency.

Automated systems can adapt quickly to different product designs or batch sizes through programmable controls, supporting both rapid prototyping and scaled manufacturing without major retooling. This flexibility is essential in industries with evolving product lines and customization needs.

Automation reduces the need for operators to engage in potentially hazardous steps such as handling chemicals or hot materials. This can lead to safer workplaces and compliance with health and safety regulations.

At Shangchen (sc-rapidmanufacturing.com), a prominent Chinese manufacturer specializing in rapid prototyping and precision production, automation has transformed their vacuum mold casting operations. By integrating robotic arms for automated mold handling, CNC machines for fast mold production, and computerized dosing for precise material mixing, Shangchen has reduced production cycles by approximately 40%.

The automated line operates with minimal human oversight, maintaining consistent product quality while handling large OEM orders for foreign brands and wholesalers. This setup has opened opportunities for faster market entry and reduced costs for clients demanding timely delivery.

While the advantages are clear, automation adoption is not without challenges:

- High Initial Investment: Advanced robotics, CNC machines, and control software require substantial capital expenditure.

- Technical Expertise: Skilled engineers and operators are needed to program, maintain, and troubleshoot automated systems.

- Integration Complexity: Seamlessly incorporating automation into existing workflows demands thoughtful planning and customization.

- Maintenance and Downtime: Automated systems require regular maintenance and may involve costly repairs if not properly managed.

- Process Adaptation: Automated processes need fine-tuning to handle diverse materials and part designs, necessitating ongoing development.

Manufacturers must carefully balance these factors against anticipated gains to ensure successful automation adoption.

Looking ahead, several innovations are set to further accelerate vacuum mold casting production speed:

- Artificial Intelligence (AI): Machine learning algorithms will optimize process parameters in real-time, reducing manual intervention and improving yields.

- Internet of Things (IoT): Networked sensors and devices will allow connected manufacturing floors, enabling predictive maintenance and remote process control.

- Hybrid Manufacturing: Integration of additive manufacturing (3D printing) with vacuum casting will streamline mold creation and customization.

- Advanced Robotics: More agile, multi-functional robots will handle complex tasks across multiple stages of the casting process.

- Sustainable Automation: Energy-efficient machinery and smart resource management will reduce environmental impacts while maintaining productivity.

These technologies will continue to make vacuum mold casting faster, more flexible, and more economical.

Automation profoundly enhances vacuum mold casting by speeding up production cycles, improving product quality, and reducing costs. Robotic handling, CNC mold fabrication, automated material dosing, and intelligent process control work synergistically to optimize every step of the vacuum casting process.

For manufacturing businesses and OEMs requiring precision, repeatable parts with rapid turnaround, integrating automation into vacuum mold casting is a strategic advantage. As technology advances, vacuum casting will become even more adaptable and efficient, supporting innovation in a range of industries from automotive to electronics.

Industries such as automotive, aerospace, electronics, consumer goods, and medical devices greatly benefit due to their need for precision parts, rapid prototyping, and low-volume production.

Automated dosing ensures accurate and consistent mixing ratios of casting materials, which reduces defects like bubbles and imperfections, leading to better mechanical properties and surface finish.

Yes, scalable automation solutions exist that can optimize small-batch production by minimizing manual labor and maximizing process stability.

Typical components include robotic mold handlers, CNC mold makers, automated material dispensers, vacuum chambers with sensors, and process control software.

They should evaluate current workflows, invest in employee training, plan phased upgrades, and collaborate with automation experts to ensure smooth implementation.

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal