Views: 222 Author: Amanda Publish Time: 2025-10-23 Origin: Site

Content Menu

● Understanding Vacuum Mold Casting

● Benefits of Vacuum Mold Casting for Small to Medium Batch Production

>> Reduced Lead Times and Increased Flexibility

● Detailed Vacuum Mold Casting Process

>> Step 1: Design Finalization and Mold Fabrication

>> Step 2: Mixing and Degassing of Resin

>> Step 3: Pouring Under Vacuum Conditions

>> Step 5: Post-Processing and Quality Assurance

● Applications and Industry Use Cases

● Integrating Vacuum Mold Casting into Comprehensive Manufacturing Workflows

● Key Considerations and Best Practices

>> Mold Longevity and Batch Size

>> Achieving Optimal Surface Finish

● Environmental Impact and Sustainability

>> 1. How is vacuum mold casting different from traditional injection molding?

>> 2. What materials are compatible with vacuum mold casting?

>> 3. What is the typical lifespan of a silicone mold in vacuum casting?

>> 4. Can vacuum mold casting handle complex or intricate part designs?

>> 5. Which industries benefit most from vacuum mold casting?

Vacuum mold casting has transformed the way manufacturers approach small to medium batch production, particularly for industries requiring precision and cost-efficiency. At Shangchen, a leading Chinese factory specializing in rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing, we offer top-tier OEM services to international brands, wholesalers, and producers through Vacuum Mold Casting. This article explores the advantages, applications, and process details of vacuum mold casting, highlighting why it is an ideal choice for cost-effective manufacturing.

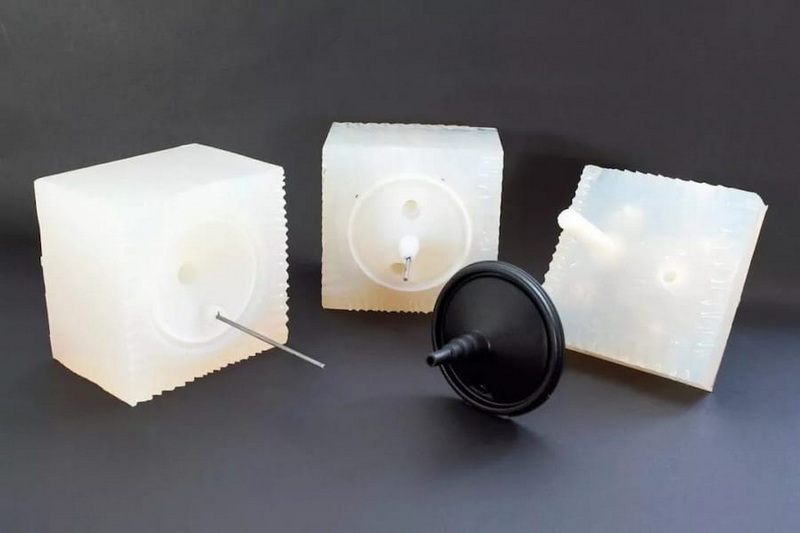

Vacuum mold casting is a specialized manufacturing process where liquid silicone or resin is poured into a mold under vacuum pressure. This technique removes air bubbles and minimizes defects, resulting in highly durable, accurate parts with excellent surface finishes. Typically, the molds used are made from silicone or metal, depending on production volume and complexity.

This process is predominantly used for prototype development and small to medium-scale manufacturing because it allows for quicker turnaround times and lower setup costs compared to traditional molding methods like injection molding.

Vacuum mold casting offers a highly cost-efficient solution for small to medium batch runs. Instead of investing in expensive steel molds required for injection molding, manufacturers use silicone molds, which are much cheaper and faster to create. This significantly reduces the initial tooling costs and allows for economically producing limited quantities.

The application of vacuum pressure eliminates trapped air within the resin, preventing bubbles and other flaws that can compromise part integrity. Parts produced via vacuum casting exhibit excellent dimensional accuracy and smooth surface finishes. This quality makes it especially suitable for prototype validation and functional components that demand consistency.

A wide range of materials can be used in vacuum mold casting, including polyurethane resins, epoxy resins, and other specialized silicones. This versatility enables the creation of parts with different mechanical properties such as flexibility, hardness, or heat resistance. Manufacturers can also achieve different finishes, textures, and colors tailored to specific product requirements.

Vacuum molding eliminates long machining cycles and complex tooling setups, leading to faster lead times. This speed is advantageous for brands that need rapid prototyping and quick adjustments before final production. Since silicone molds are easier to modify or remake, vacuum casting supports agile, iterative development processes.

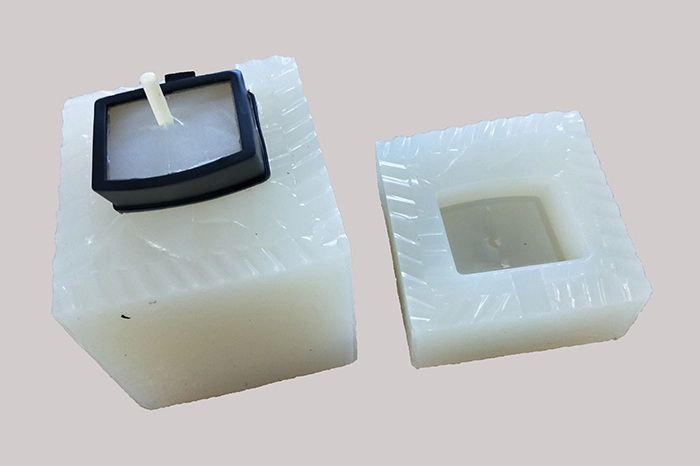

The process begins with creating a precise CAD model of the part. At Shangchen, our engineers optimize designs for vacuum mold casting to ensure manufacturability and quality. Using CNC machining or 3D printing, master models are produced as patterns for silicone mold fabrication.

Resin materials are prepared by mixing base polymers with colorants, hardeners, or additives. The mixture is then placed inside a vacuum chamber to remove trapped gases. Degassing ensures the resin will flow smoothly and form flawless parts during casting.

The degassed resin is carefully poured into the silicone mold while inside the vacuum chamber. Maintaining vacuum conditions during pouring prevents air entrapment and ensures the material fills every corner of the mold.

After filling, the mold is left to cure. Cure times vary depending on resin type, typically ranging from minutes to hours. Once solidified, the part is demolded gently to preserve surface quality.

The finished parts may undergo finishing procedures such as trimming, sanding, painting, or assembling. Rigorous inspections check for defects and verify dimensional tolerances to ensure the parts meet client specifications.

Vacuum mold casting has become integral to many industries due to its adaptability, including:

- Automotive: Producing components like interior panels, custom trims, and functional prototypes.

- Consumer Electronics: Manufacturing housings and button covers with fine optical properties.

- Medical Devices: Crafting precision parts with biocompatible resins and complex geometries.

- Industrial Machinery: Fabricating replacement parts and customized machine components.

- Toys and Collectibles: Creating detailed models and limited edition products with realistic finishes.

Shangchen not only offers vacuum mold casting but also a full range of complementary manufacturing services. These include rapid prototyping to help clients visualize and test product concepts quickly, CNC machining to produce precise tooling and metal parts, sheet metal fabrication for enclosures and frames, and 3D printing to shorten lead times for mold masters.

Leveraging this complete ecosystem accelerates product development and ensures consistency across manufacturing stages. It also enables easy adjustments and iterations, which are often necessary in product innovation cycles.

Silicone molds have a limited useful life, generally suitable for up to 30 production cycles. Proper maintenance and careful handling can extend this lifespan but anticipating mold replacement costs is crucial when planning batch sizes.

While vacuum mold casting accommodates a variety of resins, some materials with very high thermal or mechanical requirements may be unsuitable. Careful selection based on product specifications and intended use cases ensures optimal performance.

Though vacuum casting delivers superior surface quality, finishing processes like polishing or coating may still be necessary, especially for aesthetic or tactile demands.

Compared to metal tooling and injection molding, vacuum mold casting tends to have a smaller environmental footprint, owing to reduced energy consumption and less material waste. Shangchen is committed to sustainable manufacturing practices, including recycling silicone mold materials when feasible and using eco-friendly resins to minimize environmental impact.

Companies choosing vacuum mold casting can highlight sustainability benefits alongside cost and quality advantages.

Vacuum mold casting stands out as a practical and economical manufacturing method for small to medium batch production. By combining low tooling costs, high precision, material flexibility, and fast lead times, it empowers businesses—from startups to established brands—to innovate without the heavy expense of traditional molding methods.

At Shangchen, our expertise spans vacuum mold casting and a comprehensive suite of manufacturing services tailored to diverse industry needs. Partnering with us gives you access to advanced technology, skilled craftsmanship, and a streamlined production process, helping you bring your products to market efficiently and with superior quality.

Vacuum mold casting uses silicone molds and employs vacuum pressure to prevent air bubbles in the resin, making it cost-effective for small to medium batch runs. Injection molding relies on expensive steel molds suited for high-volume manufacturing, offering quicker per-piece production once tooling is made.

Common materials include polyurethane and epoxy resins, as well as specialized silicones. These can emulate the properties of plastic, rubber, or even metal finishes depending on additives and curing methods.

Silicone molds generally last for about 20 to 30 production cycles, depending on factors like resin type and mold care. Once the mold degrades, it needs replacement to maintain product quality.

Yes, vacuum mold casting is well suited for complex geometries and detailed features because the vacuum environment reduces air entrapment and improves mold filling.

Automotive, consumer electronics, medical devices, industrial equipment, and collectibles are key industries that leverage vacuum mold casting's flexibility, low cost, and high detail fidelity.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Lithuania

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Czech Republic

Top 5 Axis CNC Machining Manufacturers and Suppliers in Denmark

Top 5 Axis CNC Machining Manufacturers and Suppliers in Hungary