Views: 222 Author: Amanda Publish Time: 2025-10-22 Origin: Site

Content Menu

● Understanding Vacuum Mold Casting

>> Step-by-Step Vacuum Mold Casting Process

>> Key Benefits of Vacuum Mold Casting for Electronics and Consumer Goods

>> Applications in Electronics and Consumer Products

● Designs Best Suited for Vacuum Mold Casting

● Material Options in Vacuum Mold Casting

● Cost and Lead Time Considerations

● Integrating Vacuum Mold Casting with Other Manufacturing Processes

● Overcoming Common Challenges

● Frequently Asked Questions (FAQ)

>> 1. What types of materials are typically used in Vacuum Mold Casting?

>> 2. How does Vacuum Mold Casting compare to injection molding?

>> 3. What is the usual turnaround time for Vacuum Mold Casting parts?

>> 4. Can Vacuum Mold Casting accommodate electronic functional parts?

>> 5. Is Vacuum Mold Casting environmentally sustainable?

In the fast-evolving electronics and consumer products industry, precision and efficiency in manufacturing are paramount. One process that has gained significant traction is Vacuum Mold Casting. This method offers rapid prototyping and small-batch production with excellent surface finish and material properties. As a leading Chinese factory specializing in rapid prototyping, CNC machining, precision batch production, turning, sheet metal fabrication, 3D printing, and mold manufacturing, Shangchen (sc-rapidmanufacturing.com) delivers outstanding OEM services globally.

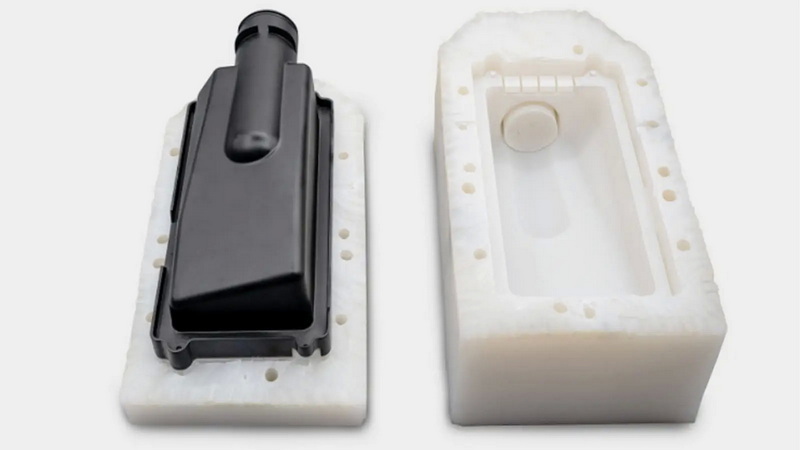

Vacuum Mold Casting is a sophisticated manufacturing process where liquid polyurethane resin is injected into a silicone mold under vacuum conditions. This process removes air bubbles and minimizes defects, producing parts with excellent surface quality and mechanical strength. It is particularly beneficial for producing functional prototypes and limited-run parts for electronics and consumer product applications.

The Vacuum Mold Casting process consists of multiple well-defined stages:

1. Creating the Master Model: The master pattern, representing the final product, is fabricated using 3D printing or CNC machining. This model defines the exact shape and detail of the parts.

2. Silicone Mold Fabrication: The master model is embedded in high-quality silicone rubber to create a flexible mold. This mold can be used for multiple casting cycles.

3. Resin Preparation: Polyurethane resins are prepared by mixing base compounds with hardeners and pigments to achieve the desired color and physical properties.

4. Vacuum Casting: The resin is poured into the silicone mold placed inside a vacuum chamber. The vacuum extracts trapped gases, preventing bubble formation inside the cast parts.

5. Curing Phase: The resin cures within the mold at room or slightly elevated temperatures, solidifying into the final product.

6. Demolding and Finishing: After curing, the parts are removed and cleaned. Optional post-processing such as sanding, painting, or assembly enhances the appearance and functionality.

Vacuum Mold Casting offers a suite of advantages that make it ideal for electronics and consumer products manufacturing:

- Exceptional Surface Finish: The vacuum ensures bubbles are removed, resulting in parts with smooth, flawless surfaces crucial for device housings.

- Material Variety: Different polyurethane formulations replicate the properties of plastics such as ABS, PC, PP, silicone rubber, or flexible elastomers.

- Rapid Prototyping: Production times are much faster compared to injection molding, allowing quick design iterations and market testing.

- Cost Efficiency: Low tooling costs and short turnaround make it economically viable for prototype runs and small production batches.

- Customizable Aesthetics: Molded parts can be finished with textures, colors, metallic coatings, and UV resistance to match product requirements.

Vacuum Mold Casting finds broad applications across electronics and consumer sectors due to its versatility:

- Electronic Enclosures: High-precision casings for smartphones, remote controls, IoT devices, and wearable tech.

- Buttons and Switches: Durable and tactile parts that require exact fit and finish.

- Connectors and Small Mechanical Assemblies: Custom components with fine features.

- Medical Device Housings: Lightweight, accurate prototypes and parts for medical electronics.

- Consumer Accessories: Cases, holders, and parts for home appliances and gadgets.

Designing for Vacuum Mold Casting requires attention to detail to optimize mold life and part quality:

- Wall Thickness: Uniform wall thickness prevents warping or incomplete filling.

- Draft Angles: Slight tapers ease demolding from flexible silicone molds.

- Details and Undercuts: Small undercuts are possible given silicone's flexibility, allowing intricate shapes.

- Assembly Features: Incorporate snap fits, slots, and bosses compatible with post-assembly processes.

The choice of resin is critical to meet mechanical and aesthetic requirements:

- Rigid Polyurethane: Mimics stiff plastics, ideal for enclosures and structural components.

- Flexible Polyurethane: Offers rubber-like flexibility for gaskets, seals, and ergonomic grips.

- High-Temperature Resistant Resins: Suitable where electronic components generate heat.

- Custom Pigmented Resins: Ensure brand-consistent colors or specific visual effects.

Maintaining strict quality standards is essential in electronics manufacturing:

- Dimensional Accuracy: Verified with 3D scanning and precision measurement tools.

- Surface Finish Inspection: Detects blemishes, bubbles, or defects.

- Mechanical Testing: Including tensile, impact resistance, and hardness tests.

- Electrical Compatibility: Non-conductive resins prevent interference with electronic circuits.

Vacuum Mold Casting balances speed and cost efficiently:

- Low Tooling Costs: Silicone molds are cheaper and faster to produce compared to metal injection molds.

- Batch Size Flexibility: Economically viable for tens to thousands of parts.

- Lead Time: Mold making and casting typically occur within 1–3 weeks, accelerating product development cycles.

Combining Vacuum Mold Casting with other techniques enhances overall product quality:

- CNC Machining: For metal components or master model creation.

- 3D Printing: Rapid prototyping and master patterns shorten the design-to-manufacture cycle.

- Sheet Metal Fabrication: For hybrid assemblies combining metal and plastic.

- Surface Treatments: Painting, coating, or plating applied after casting to meet specific durability or appearance standards.

While Vacuum Mold Casting is versatile, some challenges need to be managed:

- Mold Durability: Silicone molds wear with repeated use; planning for mold replacement or refurbishment is important.

- Complex Internal Features: May require additional mold design strategies like two-part molds.

- Material Limitations: Though versatile, some engineering plastics require injection molding for high-volume runs.

Vacuum Mold Casting is a powerful method for producing accurate, high-quality parts for electronics and consumer products, especially when rapid prototyping and small-to-medium production runs are required. By providing fine detail, excellent surface finish, and a variety of material options, this process greatly supports OEMs in launching innovative products quickly and cost-effectively. When integrated with services like CNC machining and 3D printing, manufacturers like Shangchen deliver comprehensive solutions tailored to the unique needs of global clients, helping them stay competitive in demanding markets.

Polyurethane resins are most common and can be formulated to mimic different plastics such as ABS, PC, PP, and silicone rubber, enabling flexibility in mechanical and aesthetic properties.

While injection molding suits high-volume production with faster per-piece cycle times but requires expensive tooling, Vacuum Mold Casting is better for lower volumes, rapid prototyping, and short lead times with reduced costs.

Typically, from mold making to finished parts, production takes between 1 and 3 weeks, depending on part complexity and finishing requirements.

Vacuum Mold Casting is excellent for producing enclosures and non-electronic mechanical parts, but electronic circuits and components are assembled separately.

The sustainability depends on the specific resins used and recycling practices. Some polyurethane materials are recyclable or biodegradable, and optimizing material use can reduce environmental impact.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Finland

Top 5 Axis CNC Machining Manufacturers and Suppliers in Greece

Top 5 Axis CNC Machining Manufacturers and Suppliers in Sweden

Top 5 Axis CNC Machining Manufacturers and Suppliers in Turkey

How Vacuum Mold Casting Compares to Silicone Mold Casting for Precision Parts

Vacuum Mold Casting vs. Resin Casting: Key Differences You Should Know

Vacuum Mold Casting vs. 3D Printing: Choosing the Best Rapid Prototyping Method

Best Vacuum Mold Casting Services for Precision Manufacturing in 2025

Top Vacuum Mold Casting Manufacturers Delivering High-Quality Prototypes