Views: 222 Author: Amanda Publish Time: 2025-10-23 Origin: Site

Content Menu

● What Is Vacuum Mold Casting?

● Advantages of Vacuum Mold Casting

● How Vacuum Mold Casting Addresses Common Manufacturing Challenges

● Industrial Applications of Vacuum Mold Casting

>> Electronics and Consumer Products

● Best Practices in Vacuum Mold Casting to Enhance Cost Savings and Quality

>> Mold Design and Maintenance

● Environmental and Sustainability Benefits

● FAQ

>> 1. What industries benefit most from vacuum mold casting?

>> 2. How does vacuum mold casting compare to injection molding?

>> 3. Can vacuum mold casting handle complex geometries?

>> 4. What types of materials are compatible with vacuum mold casting?

>> 5. Are there size limitations to parts made by vacuum mold casting?

Vacuum mold casting is an innovative manufacturing technique that has been gaining traction in various industries for its ability to reduce production costs while maintaining high quality. This method is particularly effective for rapid prototyping, precision batch production, and OEM services. If you are involved in manufacturing or product development, understanding how vacuum mold casting works can significantly benefit your business. This comprehensive article explores the process, advantages, and applications of Vacuum Mold Casting, helping you grasp why it is a cost-effective solution without compromising on quality.

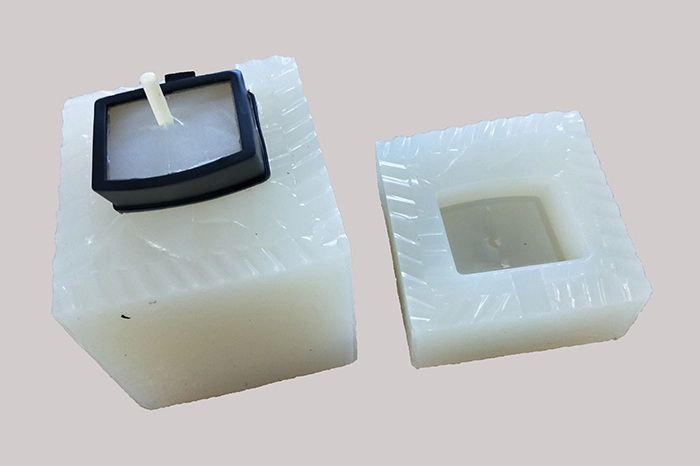

Vacuum mold casting is a manufacturing process where liquid material is poured into a mold under vacuum conditions. This technique helps eliminate air bubbles and prevents defects that commonly occur in traditional casting. The vacuum environment ensures that the material fills the mold completely, resulting in parts with superior surface finish and structural integrity.

1. Mold Preparation: The mold, often made from silicone or metal, is prepared and placed inside a vacuum chamber.

2. Material Mixing: The casting material (such as polyurethane, epoxy, or other resins) is mixed thoroughly to ensure consistency.

3. Vacuum Application: The mixture is poured into the mold while the chamber is evacuated of air to create a vacuum.

4. Curing: The material is allowed to cure inside the mold under vacuum, which minimizes voids.

5. Demolding: Once cured, the cast part is removed, ready for post-processing or use.

This vacuum-assisted filling ensures a high-quality mold casting with reduced defects.

Vacuum mold casting offers several benefits, especially when production costs and quality are critical factors.

The vacuum system eliminates air pockets that cause defects inside the cast. Consequently, less material is wasted due to rejected parts, which directly lowers raw material costs.

Compared to other molding processes, vacuum mold casting typically uses less expensive molds, such as silicone, which are cheaper and faster to produce than metal injection molds. This process requires less labor and energy as the vacuum reduces the need for additional steps to fix casting defects. It's particularly cost-effective for low to medium volume production runs.

Air bubbles commonly cause weaknesses and blemishes in cast parts. Vacuum mold casting virtually removes these problems by evacuating air during the pour. The result is a product with a consistent surface finish, higher mechanical strength, and superior dimensional accuracy. This quality improvement reduces scrap rates and the need for further finishing or repairs.

Vacuum mold casting is compatible with a wide range of materials including flexible and rigid polyurethane, epoxy resins, silicones, and some thermoplastics. This versatility allows manufacturers to customize product properties such as flexibility, hardness, chemical resistance, and color.

Since vacuum mold casting uses simpler molds and a streamlined curing process, production time shrinks compared to traditional manufacturing methods. The quick turnaround makes it ideal for rapid prototyping, small production batches, and design iteration during product development.

Manufacturers often face the challenge of balancing quality with cost efficiency. Defects like porosity, incomplete filling, or warping are common in casting, driving up expenses through rework and delays. Vacuum mold casting provides solutions to these issues.

- Porosity and Air Pockets: By creating a vacuum, air and gases trapped inside the mold or resin are forced out, preventing bubbles.

- Incomplete Mold Filling: The vacuum also helps pull the resin deeply into intricate parts of the mold, even in thin-walled or detailed sections.

- Warping & Shrinkage: Controlled curing under vacuum limits stresses and shrinkage, ensuring dimensional stability.

Many automotive parts require strong mechanical properties and excellent surface finishes at low costs. Vacuum mold casting is ideal for prototypes, interior panels, and even some functional exterior components. The process helps manufacturers quickly develop and iterate designs, reducing time to market.

Precision is critical in electronics enclosures, connectors, and other components. Vacuum mold casting produces smooth, defect-free surfaces necessary for aesthetic and functional purposes. The ability to easily change materials for different electrical or thermal properties is another advantage.

Vacuum mold casting supports the creation of accurate, biocompatible prototypes and devices. Low volume medical tools benefit from this cost-efficient production route without sacrificing hygiene or tolerances.

Part complexity and material performance requirements in aerospace demand reliable, defect-free parts. Vacuum mold casting is used for prototype testing and small runs of specialized components, combining quality and cost-effectiveness.

Beyond industrial manufacturing, vacuum casting excels in art reproductions, jewelry manufacturing, and decorative objects. Its surface accuracy and ability to replicate fine details make it a favored method for these precision applications.

Investing in high-quality molds suitable for vacuum casting guarantees clean parts and longevity. Proper mold maintenance ensures continued vacuum tightness, reducing downtime and defective parts.

Choosing the right resin or material based on the product's intended use and compatibility with vacuum casting is crucial. Testing various formulations can optimize physical properties and cost.

Maintaining consistent vacuum pressure and curing conditions helps avoid defects. Automation and monitoring technologies improve repeatability and throughput.

Although vacuum mold casting yields high-quality parts, light post-processing such as trimming, polishing, or coating can enhance aesthetics and functionality without excessive costs.

Vacuum mold casting often uses lower energy than injection molding or machining. Reduced material waste and fewer rejected parts contribute to sustainability goals. Additionally, some casting materials are recyclable or biodegradable, making the process environmentally friendlier.

Vacuum mold casting bridges the gap between cost-efficiency and quality in manufacturing. By thoroughly removing air bubbles and providing precision casting, it lowers waste and shortens production cycles without compromising product standards. For OEM services or batch production, this method offers flexibility, speed, and material versatility, making it an excellent choice in today's competitive industry. Whether for prototyping or small to medium volume manufacturing, vacuum mold casting supports businesses in delivering superior products while controlling costs.

Vacuum mold casting is widely used in prototyping, automotive, consumer goods, electronics, medical devices, and aerospace industries where precision and cost control are crucial.

Injection molding is better suited for very high volume production with high upfront tooling costs, while vacuum mold casting is more economical for low to medium volumes, offering faster setup and lower mold costs.

Yes, the vacuum environment helps fill intricate molds completely, capturing fine details and thin walls effectively with minimal defects.

Materials commonly used include polyurethane resins, epoxy, silicones, and some thermoplastics, giving manufacturers flexibility in product characteristics.

Vacuum mold casting is generally more suitable for small to medium parts due to vacuum chamber size constraints, though some setups can handle larger components with specialized equipment.

content is empty!

Top 5 Axis CNC Machining Manufacturers and Suppliers in Lithuania

Top 5 Axis CNC Machining Manufacturers and Suppliers in Norway

Top 5 Axis CNC Machining Manufacturers and Suppliers in Czech Republic

Top 5 Axis CNC Machining Manufacturers and Suppliers in Denmark

Top 5 Axis CNC Machining Manufacturers and Suppliers in Hungary