Views: 222 Author: Amanda Publish Time: 2025-10-24 Origin: Site

Content Menu

● What is Vacuum Mold Casting?

● How Does Vacuum Mold Casting Work?

● Advantages of Vacuum Mold Casting

● Common Applications of Vacuum Mold Casting

● Materials Used in Vacuum Mold Casting

● Design Tips for Vacuum Mold Casting

● Quality Control in Vacuum Mold Casting

● Environmental and Cost Considerations

>> 1. What kinds of products benefit most from vacuum mold casting?

>> 2. How many parts can be made from one silicone mold?

>> 3. What materials are used in vacuum mold casting?

>> 4. How long does the vacuum mold casting process take?

>> 5. What are the limitations of vacuum mold casting compared to injection molding?

Vacuum Mold Casting is an advanced manufacturing process widely used for rapid prototyping, precision parts, and small batch production. This article aims to give you a thorough understanding of Vacuum Mold Casting, explaining its process, advantages, applications, materials used, and critical tips for success. The content is structured with clear headings and includes a conclusion and a frequently asked questions section to help enrich your knowledge.

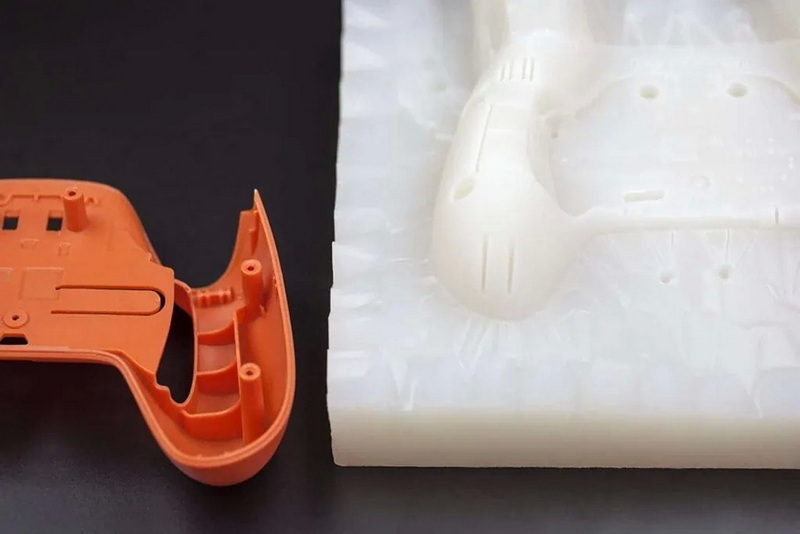

Vacuum Mold Casting, also known as urethane or vacuum casting, is a manufacturing technique where liquid casting materials, usually polyurethane resins, are drawn into silicone molds under vacuum. This process produces highly detailed, precise parts that are free from air bubbles and surface imperfections.

Unlike traditional injection molding, which uses pressure to inject molten material, vacuum casting relies on creating a vacuum to eliminate air and ensure even resin flow. This enables the production of parts with excellent surface finishes and fine detail replication, making it ideal for prototypes, functional parts, and small production batches.

Vacuum mold casting involves several meticulous steps:

The process begins with creating a master model, which acts as the original prototype. This model can be made through high-precision CNC machining or 3D printing methods such as stereolithography (SLA). The master model requires careful surface preparation—sanding, polishing, and sometimes painting—to provide the desired quality for the final part.

Once the master model is ready, it is suspended in a mold box using support structures. Liquid silicone rubber is poured over the model under vacuum conditions to prevent air pockets. The silicone is then cured, typically in an oven at 40°C for 8-16 hours. After curing, the mold is carefully cut open, and the master model is removed, leaving a flexible negative cavity.

The silicone mold is prepared for casting by assembling it and attaching risers and gates for proper flow and air release. Two-component polyurethane resin, often pigmented for color, is mixed and degassed inside a vacuum chamber to remove trapped bubbles. The resin is poured into the mold within the vacuum chamber, where the vacuum aids in filling intricate features without air entrapment.

After filling, the vacuum is released, and atmospheric pressure helps compress any residual bubbles. The mold is then placed in an oven at around 70°C to cure the resin, typically taking about one hour.

The cured parts are removed from the mold and trimmed to remove any flash or excess material from gates and risers. Additional post-processing such as sanding, polishing, or painting can be applied to enhance surface finish and aesthetics. Typically, silicone molds can be reused approximately 20 to 30 times before losing accuracy.

Vacuum Mold Casting offers several benefits that make it popular for prototyping and limited production:

- Precision and Detail: The silicone mold captures intricate details from the master model, producing accurate parts.

- Flawless Surface Finish: The vacuum process eliminates air bubbles, resulting in smooth, high-quality surfaces.

- Material Versatility: A variety of polyurethane resins can mimic plastics with different softness, hardness, and colors.

- Rapid Production Turnaround: Vacuum casting allows quick turnaround times, often within a week.

- Cost-Effective for Small Runs: Silicone molds are less expensive and faster to produce than metal molds, suitable for small to medium batch sizes.

- Versatile Use Cases: Can be used for functional parts, prototypes, display models, and even limited production components.

Due to its precision and flexibility, vacuum mold casting is used in industries such as:

- Electronics: For producing housings, functional prototypes, and small batches of components.

- Automotive: Rapid prototyping of car parts or limited edition components.

- Medical Devices: High-detail, accurate models for testing and limited use.

- Consumer Products: Prototypes, concept models, or low-volume runs for product launch.

- Aerospace: Functional and display parts for testing aerodynamics or assembly.

The most common materials are two-part polyurethane resins available in rigid or flexible grades, which allow simulating different mechanical properties. Silicone rubber is the preferred mold material due to its flexibility, heat resistance, and excellent detail reproduction. Pigments and fillers can be added to customize color and mechanical properties.

- Ensure uniform wall thickness in the master model to avoid warping or uneven curing.

- Design gentle tapers for easy demolding.

- Include runners and risers in mold design for better resin flow and air escape.

- Avoid sharp corners or deep undercuts that complicate mold release.

- Select appropriate resin type based on required mechanical and thermal properties.

Following these design principles enhances the quality and manufacturability of cast parts.

Quality checks are performed after demolding, examining parts for:

- Dimensional accuracy relative to CAD models.

- Surface defects such as bubbles, voids, or roughness.

- Mechanical properties according to material specifications.

- Visual defects including color consistency and finish smoothness.

Quality control ensures the final parts meet required standards before assembly or delivery.

While vacuum mold casting is cost-effective for low volumes, it is less suitable for mass production primarily due to limited mold reusability compared to metal molds. The silicone molds degrade after multiple uses, which may increase cost per part for larger orders.

Additionally, polyurethane resins and silicones must be properly handled and disposed of to meet environmental regulations. Many manufacturers aim to optimize processes to minimize waste and energy consumption.

Vacuum Mold Casting is a highly versatile and efficient manufacturing method ideal for producing precise prototypes and small batches of functional parts. The process combines the use of high-quality silicone molds and vacuum-assisted casting to achieve superior surface finish and detail accuracy. Its advantages include lower mold costs, fast turnaround, and material versatility, making it a preferred choice across industries from automotive to electronics and medical devices.

With careful design and quality control, vacuum mold casting can deliver parts that meet stringent specifications without the high upfront costs of injection molding. This flexibility supports rapid product development and market testing, ultimately accelerating innovation.

Vacuum mold casting is ideal for prototypes, limited production runs, and parts requiring high detail and smooth finishes, like consumer electronics, automotive components, and medical device models.

A typical silicone mold can produce between 20 to 30 castings before its accuracy and surface quality degrade, depending on part complexity and material.

Most commonly, two-part polyurethane resins are used, offering various mechanical properties and colors. Silicone rubber is the mold material.

From master model creation to finished parts, the entire process usually takes about 7 to 10 days, making it suitable for rapid prototyping.

Vacuum mold casting is not suited for high-volume production due to mold durability limits and slower cycle times. Injection molding is preferred for mass manufacturing.

[1](https://formlabs.com/blog/vacuum-casting-urethane-casting-polyurethane-casting/)

[2](https://www.immould.com/vacuum-casting/)

[3](https://an-prototype.com/ultimate-guide-to-vacuum-casting/)

[4](https://xdmining.in/2024/10/02/elementor-11005/)

[5](https://objectify.co.in/a-comprehensive-guide-to-vacuum-casting-everything-you-need-to-know/uncategorized/)

[6](https://ame-3d.co.uk/news/a-complete-guide-to-vacuum-casting-polyurethane-casting)

[7](https://blog.isa.org/what-are-vacuum-casting-factories-a-comprehensive-guide-to-the-manufacturing-process)

[8](https://leadrp.net/blog/overview-of-vacuum-casting/)

[9](https://www.kemalmfg.com/complete-guide-to-vacuum-casting/)

[10](https://www.rapiddirect.com/blog/vacuum-casting-design-guide/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal