Views: 222 Author: Amanda Publish Time: 2025-09-30 Origin: Site

Content Menu

● Why Post-Processing Is Crucial for 3D Prints

● Post-Processing Techniques for Polymer 3D Printing

>> Fused Deposition Modeling (FDM)

>> Vat Photopolymerization (SLA/DLP)

>> Selective Laser Sintering (SLS)

● Post-Processing in Metal 3D Printing

>> Direct Energy Deposition (DED)

>> Binder Jetting and Metal Extrusion

● Advanced Post-Processing Techniques

● Practical Tips for Efficient Post-Processing

● Frequently Asked Questions (FAQ)

>> 1. What is 3D printing post-processing?

>> 2. Why is support removal important?

>> 3. How can I smooth FDM printed parts effectively?

>> 4. Are post-processing methods different for metal 3D prints?

>> 5. Can post-processing enhance mechanical properties?

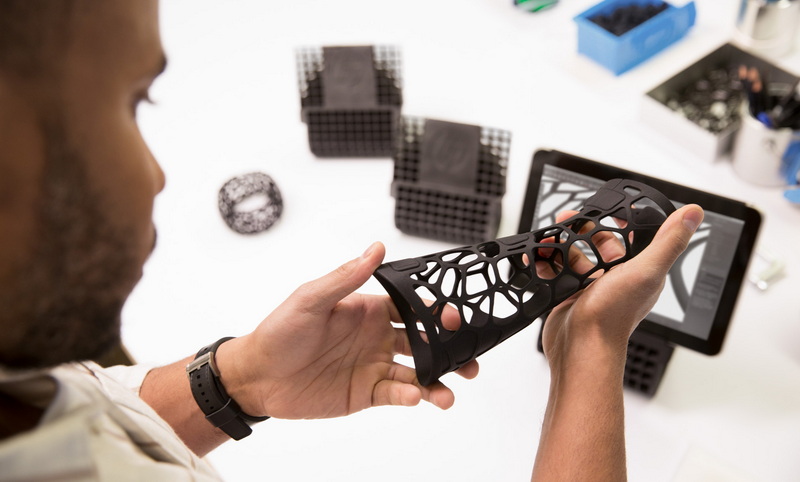

3D printing has transformed modern manufacturing by allowing rapid production of intricate and customized parts. However, to achieve the high-quality finish, functional performance, and professional aesthetics demanded by OEM manufacturers and global clients, post-processing of 3D printed parts is essential. This stage includes a variety of techniques that improve surface smoothness, mechanical properties, and dimensional accuracy, tailored to the specific printing technology and material used.

For factories like Shangchen providing rapid prototyping, CNC machining, precision batch production, and OEM services, mastering post-processing ensures parts meet rigorous industrial standards while enhancing customer satisfaction. This article discusses comprehensive best practices for post-processing across polymer and metal 3D printing, covering everything from manual finishing to advanced heat treatments and coatings. The focus will be on practical methods to optimize the quality of 3D printed parts, especially for service providers working with international brands, wholesalers, and manufacturers.

3D printed parts inherently exhibit surface imperfections: visible layer lines, rough textures, residual support marks, and slight dimensional deviations. These flaws result from the layer-by-layer deposition process and the use of supports for complex geometries. Post-processing is pivotal to address these issues by:

- Enhancing Aesthetic Appeal: Smoothing surfaces and removing visible defects gives parts a professional, polished look.

- Improving Mechanical Strength: Heat treatments and infiltration can relieve internal stresses and strengthen materials.

- Ensuring Dimensional Accuracy: Machining and finishing refine critical dimensions for proper fit and function.

- Adding Functional Properties: Coatings can confer UV resistance, chemical protection, or electrical conductivity.

Thus, post-processing transforms raw prints into market-ready components that satisfy quality, performance, and regulatory requirements.

Polymer 3D printing technologies—Fused Deposition Modeling (FDM), Vat Photopolymerization (SLA/DLP), and Selective Laser Sintering (SLS)—mandate distinct finishing workflows.

FDM builds parts by extruding melted thermoplastic filament in layers, resulting in visible print lines and support marks.

- Support Removal: Supports are typically snapped off manually using pliers or cutters. For dual extrusion prints, soluble supports (like PVA) dissolve in water, preserving delicate features.

- Sanding: Starting with coarse grit and progressing to fine grit sandpaper, sanding reduces layer lines and smooths surfaces. This labor-intensive process is essential for visual and tactile improvement.

- Filling and Priming: Application of fillers or primers masks minute imperfections and prepares the surface for painting.

- Chemical Smoothing: Acetone vapor treatment (for ABS) melts the outer layer to create a glossy, smooth finish. Adequate safety precautions are required due to chemical exposure.

- Annealing: Controlled heating processes relieve layer-induced stress, improving strength and dimensional stability.

These methods cure liquid resin with UV light, producing high-resolution parts that require:

- Washing: Parts are submerged in solvents like isopropyl alcohol to remove uncured resin residues.

- Post-Curing: UV exposure completes curing to achieve optimal mechanical properties.

- Support Removal: Resin supports are carefully clipped away; sanding or filing removes marks.

- Sanding and Polishing: Fine sanding and polishing enhance the surface finish, perfecting highly detailed and delicate parts.

SLS uses a laser to fuse polymer powder particles, resulting in strong but rough, porous parts.

- Powder Removal: Excess unsintered powder is brushed or blown off with compressed air.

- Media Blasting: Fine abrasive media such as glass beads smooth the surface and prepare it for finishing.

- Media Tumbling: Vibration or rotary tumblers with abrasive media uniformly polish batches of parts.

- Dyeing and Coating: Porous SLS parts readily absorb dyes; subsequent sealing in epoxy or polyurethane enhances durability and aesthetics.

- Machining: For precise dimensions, CNC machining may be applied.

Metal 3D printing technologies, such as Powder Bed Fusion (PBF), Direct Energy Deposition (DED), and Binder Jetting, require rigorous post-processing to meet demanding industrial standards.

- Support Removal: Mechanical removal using wire EDM or manual tools protects part integrity.

- Heat Treatment: Stress relieving and annealing optimize microstructure and mechanical properties.

- Hot Isostatic Pressing (HIP): High-pressure, high-temperature treatment removes internal porosity, enhancing fatigue life.

- Surface Finishing: Bead blasting, electropolishing, or CNC machining achieves smooth, corrosion-resistant surfaces.

- Precision Machining: CNC operations refine dimensions and surface flatness.

- Machining: High-precision CNC machining after deposition produces exact geometries.

- Heat Treatment: Enhances grain structure and mechanical performance.

- Grinding and Polishing: Address coarse surface finishes to meet functional or aesthetic requirements.

- Surface Coatings: Thermal spray coatings add wear protection.

- Debinding and Sintering: Remove binders and fuse powder into dense metal parts.

- Machining: Precision CNC machining attains critical dimensions.

- Electropolishing and Coating: Provide corrosion resistance and mirror finishes where needed.

To push the boundaries of finish quality and functionality, advanced techniques are increasingly adopted:

- Electropolishing: An electrochemical process that produces ultra-smooth, mirror-like metal surfaces with enhanced corrosion resistance.

- Hydrographics (Water Transfer Printing): Transfers complex patterns onto parts for aesthetic customization.

- Electroplating: Applies metal layers to polymer parts, boosting mechanical strength and adding conductive or protective surfaces.

- Dyeing and Infiltration: Porous polymer parts can be colored or infiltrated with epoxy to enhance appearance and mechanical properties.

- Plan for Minimal Supports: Design parts to minimize support requirements, reducing post-processing time and marks.

- Select Compatible Materials: Material choice affects post-processing options; ABS lends itself well to chemical smoothing, while PLA benefits from epoxy coatings.

- Use Automation Where Possible: Tumbling, media blasting, and robotic sanding reduce labor and improve consistency.

- Safety First: Ensure proper ventilation, personal protective equipment, and safe handling of chemicals and powders.

- Iterate and Test: Develop tailored finishing workflows based on specific client requirements and part performance.

Post-processing is a vital phase in the 3D printing workflow that transforms rough prints into high-quality, functional, and visually appealing parts. By employing a blend of support removal, sanding, chemical treatments, heat processes, and advanced finishing, manufacturers can meet stringent OEM standards and fulfill the expectations of global clients. Mastery of post-processing techniques enables companies like Shangchen to deliver outstanding 3D printed components with improved mechanical strength, dimensional accuracy, and surface aesthetics, solidifying their position in the competitive manufacturing landscape.

Post-processing refers to all finishing steps after printing that improve appearance, strength, and functionality, including support removal, sanding, polishing, and coating.

Supports provide stability during printing but leave marks; careful removal prevents damage and prepares the surface for further finishing.

Gradual sanding, chemical smoothing (e.g., acetone vapor for ABS), priming, and painting are effective to reduce layer lines and improve surface finish.

Yes, metal prints require specific procedures like heat treatments, HIP, machining, and electropolishing to meet performance and finish requirements.

Yes, processes like annealing, infiltration, and electroplating reinforce and extend the durability of 3D printed parts.

[1](https://bigrep.com/post-processing/)

[2](https://www.wevolver.com/article/the-ultimate-guide-to-3d-printing-post-processing-techniques)

[3](https://www.unionfab.com/blog/2025/09/3d-printing-post-processing)

[4](https://jlc3dp.com/blog/a-comprehensive-introduction-to-3d-printing-post-processing-techniques)

[5](https://formlabs.com/blog/post-processing-and-finishing-sla-prints/)

[6](https://www.prusa3d.com/ja/product/complete-guide-to-3d-print-postprocessing-painting-and-detailing/)

[7](https://www.crealitycloud.com/blog/tutorials/3d-printing-post-processing)

[8](https://blog.geeetech.com/3d-printing-trouble-shooting-guide/post-processing-guides/3d-printing-post-processing-guide-petg-vs-pla/)

[9](https://all3dp.com/2/fdm-3d-printing-post-processing-an-overview-for-beginners/)

content is empty!