Views: 222 Author: Amanda Publish Time: 2025-12-02 Origin: Site

Content Menu

● Understanding Rapid Prototyping

● Why Rapid Prototyping Matters Today

● Shangchen's Role in Rapid Prototyping

● Core Technologies in Rapid Prototyping

● 3D Printing for Rapid Prototyping

● CNC Machining in Rapid Prototyping

● Sheet Metal and Turning for Rapid Prototyping

● Molding and Low‑Volume Rapid Prototyping

● Applications of Rapid Prototyping Across the Product Lifecycle

● Industries Benefiting from Rapid Prototyping

● Benefits of Rapid Prototyping for OEM Clients

● How Shangchen Structures Rapid Prototyping Projects

● Choosing Materials for Rapid Prototyping

● Design Best Practices for Rapid Prototyping

● Digital Transformation and AI in Rapid Prototyping

● Rapid Prototyping vs Traditional Prototyping

● Future Outlook for Rapid Prototyping

● FAQs

>> 1. What is Rapid Prototyping in manufacturing?

>> 2. How does Rapid Prototyping reduce development cost?

>> 3. What Rapid Prototyping services does Shangchen offer?

>> 4. Which materials are commonly used in Rapid Prototyping?

>> 5. When should a company start using Rapid Prototyping?

Shangchen (sc-rapidmanufacturing.com) is a specialized Chinese factory providing Rapid Prototyping, CNC machining, precision batch production, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing services for global OEM brands, wholesalers, and manufacturers. With integrated engineering and production capabilities, Shangchen uses Rapid Prototyping to transform 3D concepts into real, testable parts quickly and reliably for overseas customers.[11][12][13][14]

Rapid Prototyping is a set of modern manufacturing techniques that convert 3D CAD designs into physical parts in a short time, often in days instead of weeks. These processes allow design teams to visualize, test, and refine ideas repeatedly before committing to expensive tooling or large-scale production.[2][10][15][16]

Instead of relying on slow, manual prototyping, Rapid Prototyping uses digital workflows and flexible equipment to produce multiple design iterations with minimal setup. This accelerates decision‑making, improves product performance, and reduces the risk of costly changes late in the project.[16][17][18][11]

In competitive markets, product life cycles are shorter and customer expectations are higher, making speed and flexibility crucial. Rapid Prototyping helps companies bring better products to market faster by enabling more experimentation and validation in the same development window.[3][5][18][2]

Rapid Prototyping also supports cross‑functional collaboration, since engineers, marketers, and decision‑makers can all interact with realistic parts early in the process. This shared understanding reduces miscommunication and keeps development aligned with real user needs and technical constraints.[4][9][19][20]

Shangchen places Rapid Prototyping at the center of its OEM service model, providing overseas clients with a one‑stop solution from concept validation to stable production. By combining CNC machining, 3D printing, turning, sheet metal, and mold making in a single facility, Shangchen ensures consistent quality and fast communication throughout the Rapid Prototyping cycle.[12][13][14][11]

Foreign brands and wholesalers benefit from Shangchen's engineering support, where design for manufacturability (DFM) suggestions are integrated into each Rapid Prototyping iteration. This partnership approach helps optimize cost, performance, and reliability before moving to mass production.[14][21][3][11]

The Rapid Prototyping process usually follows a repeatable, digital‑first workflow:

1. 3D CAD modeling of the product concept or assembly.[1][16]

2. Selection of the most suitable Rapid Prototyping technology based on material, geometry, and purpose.[10][3]

3. Process preparation such as slicing for 3D printing or toolpath generation for CNC.[8][16]

4. Physical manufacturing of the Rapid Prototyping part.[7][1]

5. Testing, measurement, and collection of feedback from engineering and stakeholders.[5][9]

6. Design updates and repeat Rapid Prototyping cycles until requirements are met.[2][4]

This loop can run many times, allowing Rapid Prototyping to refine ergonomics, strength, assembly steps, and aesthetics step by step.[5][2]

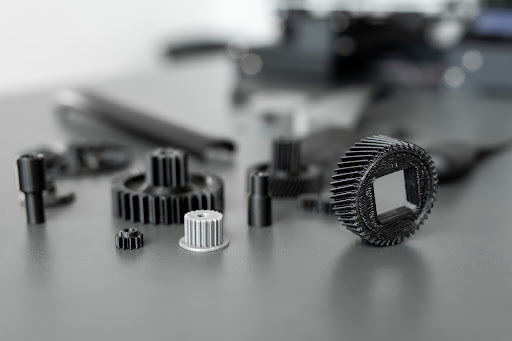

Rapid Prototyping is not a single method but a family of manufacturing technologies, each with strengths for specific tasks. Selecting the right combination allows Shangchen and its clients to balance speed, cost, and performance at different project stages.[3][7][10][16]

Key Rapid Prototyping technologies include:

- Additive manufacturing (3D printing) for free‑form geometries and fast functional or visual models.[15][1]

- CNC machining for high‑precision Rapid Prototyping in metals and engineering plastics.[22][23]

- Sheet metal fabrication for structural frames, enclosures, and brackets.[21][5]

- Turning (lathe) for accurate rotational parts in Rapid Prototyping assemblies.[24][22]

- Molding and casting for low‑volume Rapid Prototyping close to production conditions.[17][16]

3D printing has become one of the most recognizable Rapid Prototyping methods because it builds complex shapes directly from CAD without dedicated tooling. By adding material layer by layer, 3D printing enables lightweight structures, internal channels, and organic surfaces that would be expensive or impossible with traditional methods.[6][1][7][15]

Different 3D printing techniques support various Rapid Prototyping goals:

- FDM for cost‑effective, early-stage Rapid Prototyping and conceptual models.[1][6]

- SLA for high‑detail Rapid Prototyping with fine surface finish and intricate features.[1][5]

- SLS for robust Rapid Prototyping components with functional strength and complex internal geometries.[7][1]

By choosing the appropriate printing process and material, designers can align Rapid Prototyping output with the required level of realism, from appearance prototypes to functional parts.[8][2]

CNC machining is essential when Rapid Prototyping must closely match final production performance, especially in metals and high‑performance plastics. Computer-controlled mills and lathes cut material from solid stock, achieving tight tolerances, consistent surfaces, and repeatable quality.[23][25][22]

For Rapid Prototyping, CNC machining is ideal for:

- Structural components that will carry real loads in testing.[6][22]

- Precision housings, fixtures, and tooling used in broader validation setups.[22][23]

- Parts where specific alloys or engineering plastics are required to validate thermal or mechanical behavior.[7][22]

Because the same CNC platforms can transition from Rapid Prototyping to small‑batch and full production, validated designs can scale with minimal process changes.[26][22]

Sheet metal processes are widely used in Rapid Prototyping for enclosures, boxes, and mechanical supports that must combine stiffness and light weight. Bending, cutting, and welding techniques allow fast, repeatable creation of parts that resemble final production versions in both form and function.[10][21][3][5]

Lathe turning complements Rapid Prototyping by enabling accurate production of shafts, bushings, pins, and threaded components. These rotational parts are critical for assemblies in automotive, robotics, and industrial equipment, where Rapid Prototyping must verify alignment, concentricity, and smooth motion.[24][6][22]

When projects move beyond single samples, Rapid Prototyping often uses temporary or soft tooling, silicone molds, and low‑volume injection molds. These approaches create small batches of parts in production‑like materials, bridging the gap between one‑off prototypes and mass production.[16][17][5][10]

Such low‑volume Rapid Prototyping is valuable for:

- Pre‑production testing under real environmental and mechanical loads.[17][6]

- Certification, regulatory, or pilot market runs where realistic parts are mandatory.[3][10]

- Early customer trials and sample shipments for OEM and wholesale partners.[11][14]

Rapid Prototyping supports every stage of product development, not only early design. It can be applied at multiple points to reduce uncertainty and refine the product step by step.[9][4][5][3]

Typical Rapid Prototyping applications include:

- Concept and early design: basic models to communicate size, shape, and layout.[4][3]

- Functional verification: prototypes that validate mechanical strength, movement, and assembly.[8][10]

- Aesthetic mock‑ups: parts with near‑final surfaces and colors for marketing and user feedback.[2][6]

- User testing: Rapid Prototyping versions for ergonomic trials, usability studies, and packaging checks.[9][3]

- Pre‑production validation: near‑production Rapid Prototyping batches to check process capability and quality before scaling.[5][6]

Many sectors rely on Rapid Prototyping to remain competitive and compliant with regulations. Rapid Prototyping is especially important where safety, comfort, and performance are tightly controlled.[18][11][17][3]

Examples of industries using Rapid Prototyping include:

- Automotive and aerospace for structural, aerodynamic, and engine components.[6][1]

- Medical and biomedical fields for custom implants, guides, and medical device housings.[4][1]

- Consumer electronics for ergonomic enclosures, connectors, and internal component layouts.[3][6]

- Robotics and automation for grippers, brackets, and complex mechanical linkages.[9][6]

For OEM brands and wholesalers working with manufacturing partners, Rapid Prototyping provides powerful advantages. These benefits become even greater when paired with a full‑service factory like Shangchen.[12][14][21][11]

Key benefits of Rapid Prototyping include:

- Faster time‑to‑market through compressed development cycles and more efficient decision‑making.[18][2]

- Lower risk by discovering design flaws and production challenges early.[10][11]

- Better product‑market fit through multiple Rapid Prototyping rounds of customer and user testing.[19][9]

- Improved manufacturability by integrating DFM feedback directly into Rapid Prototyping iterations.[10][3]

Shangchen typically organizes Rapid Prototyping projects into clear phases aligned with customer goals. Each phase uses appropriate technologies and materials to balance cost, speed, and data quality.[21][11][12][5]

A typical Shangchen Rapid Prototyping workflow might look like:

- Phase 1: Fast 3D printing Rapid Prototyping for visual and ergonomic evaluation.[1][2]

- Phase 2: CNC and sheet metal Rapid Prototyping for functional and assembly verification.[21][22]

- Phase 3: Low‑volume tooling and trial production to confirm material properties, process stability, and quality.[16][17]

Throughout these phases, Shangchen's engineers collaborate with international customers on tolerance targets, surface requirements, and cost optimization.[14][11]

Material selection is a strategic decision in Rapid Prototyping because it affects performance, test validity, and budget. The right material choice depends on whether the prototype is for appearance, functional testing, or pre‑production verification.[7][21][3][10]

Common Rapid Prototyping materials include:

- Plastics such as ABS, PLA, nylon, and polycarbonate for many 3D printing and CNC applications.[22][1]

- Resins for SLA and related processes, offering specialized optical and mechanical characteristics.[5][1]

- Metals such as aluminum, stainless steel, and tool steel for strong, precise Rapid Prototyping parts.[23][22]

Combining different materials across multiple Rapid Prototyping rounds can give a full picture of real‑world performance before production.[6][21]

Designing with Rapid Prototyping in mind can significantly improve outcomes and reduce iteration cost. Each process has guidelines that help prevent failures and quality issues.[3][5][7][10]

Good practices for Rapid Prototyping include:

- Respecting minimum feature sizes, wall thicknesses, and hole diameters for each technology.[7][10]

- Considering support structures and orientation in 3D printing to improve surfaces and reduce post‑processing.[8][1]

- Ensuring tool access, radii, and draft angles for CNC machining and molding Rapid Prototyping.[5][10]

- Clearly specifying critical dimensions and tolerances, while keeping non‑critical areas more relaxed to control cost.[22][3]

Digital tools are expanding what Rapid Prototyping can achieve, especially with AI and advanced simulation. These technologies help generate, evaluate, and optimize designs before a physical prototype is produced.[9][16][1][5]

AI‑assisted Rapid Prototyping can:

- Propose geometry alternatives that meet strength and weight targets automatically.[1][5]

- Detect potential stress concentrations or manufacturability issues early in the design.[1][7]

- Streamline scheduling and resource usage across multiple Rapid Prototyping machines in a smart factory.[16][8]

This digital evolution strengthens the value of Rapid Prototyping for OEMs seeking higher performance and lower costs.[18][6]

Traditional prototyping often requires custom tooling, significant manual labor, and long setup times for each design change. This makes it difficult to explore multiple design options or respond quickly to market feedback.[17][4][16][3]

Rapid Prototyping, by contrast, relies on flexible equipment that can switch between versions with only a CAD update. This difference allows many more iterations and leads to final products that have been thoroughly tested and optimized.[2][18][10][5]

Rapid Prototyping will continue to grow as machines become faster, more accurate, and more affordable. New materials and hybrid processes will further blur the line between prototype and production, supporting direct manufacturing in some cases.[6][16][7][1]

For OEM partners working with factories like Shangchen, the future of Rapid Prototyping means even closer integration between design, simulation, and manufacturing. This integration will help companies launch complex products confidently, backed by comprehensive Rapid Prototyping data and real‑world testing.[11][12][18][5]

Rapid Prototyping technology has become a cornerstone of modern product development by turning digital concepts into physical parts quickly and repeatedly. Through 3D printing, CNC machining, sheet metal, turning, and low‑volume molding, Rapid Prototyping enables more iterations, better decisions, and smoother transitions into production.[15][2][10][16]

For global OEM brands, wholesalers, and industrial manufacturers, partnering with Shangchen (sc-rapidmanufacturing.com) provides an integrated Rapid Prototyping and manufacturing solution from initial idea to long‑term mass production. As markets evolve and competition intensifies, leveraging professional Rapid Prototyping services will be a critical factor in achieving fast innovation, reliable quality, and commercial success.[12][11][17][18]

Rapid Prototyping in manufacturing is the fast creation of physical parts or assemblies from 3D CAD data using technologies such as 3D printing, CNC machining, and molding. It allows teams to validate form, fit, and function early, reducing risk before investing in full-scale tooling and production.[15][17][2][5]

Rapid Prototyping reduces development cost by identifying design and manufacturing issues at an early stage, when changes are cheaper and easier. It also minimizes the need for multiple tool modifications and shortens time‑to‑market, which can significantly improve overall project ROI.[11][18][10][6]

Shangchen offers a comprehensive range of Rapid Prototyping services including CNC machining, lathe turning, sheet metal fabrication, 3D printing, and mold manufacturing for international OEM clients. These capabilities support single prototypes, small batches, and full production within one coordinated supply chain.[13][14][12][21]

Rapid Prototyping commonly uses plastics like ABS, PLA, nylon, polycarbonate, and various resins, as well as metals such as aluminum, stainless steel, and tool steel. The specific material is selected according to the goal of each Rapid Prototyping phase, whether visual appearance, functional performance, or pre‑production validation.[21][22][7][1]

A company should start using Rapid Prototyping as early as the concept and initial design stages to explore ideas and compare multiple options efficiently. Continuing to apply Rapid Prototyping through functional testing, certification, and pilot runs ensures a smoother ramp‑up to mass production and more reliable product launches.[10][3][5][6]

[1](https://bigrep.com/posts/rapid-prototyping-3d-printing/)

[2](https://formlabs.com/blog/ultimate-guide-to-rapid-prototyping/)

[3](https://www.weerg.com/guides/what-is-rapid-prototyping)

[4](https://www.hlhprototypes.com/a-guide-to-rapid-prototyping/)

[5](https://www.monarch-innovation.com/rapid-prototyping-guide)

[6](https://www.fictiv.com/articles/rapid-prototyping-guide)

[7](https://www.additive-x.com/blog/rapid-prototyping-guide-2022)

[8](https://www.stratasys.com/en/resources/blog/guide-to-rapid-prototyping/)

[9](https://www.dailybot.com/insights/the-ultimate-guide-to-rapid-prototyping)

[10](https://www.protolabs.com/resources/guides-and-trend-reports/rapid-prototyping-processes/)

[11](https://www.sc-rapidmanufacturing.com/what-are-the-advantages-of-rapid-prototyping.html)

[12](https://www.sc-rapidmanufacturing.com)

[13](https://www.sc-rapidmanufacturing.com/rapid-prototyping.html)

[14](https://www.sc-rapidmanufacturing.com/top-10-rapid-prototyping-manufacturers-in-china.html)

[15](https://en.wikipedia.org/wiki/Rapid_prototyping)

[16](https://www.autodesk.com/solutions/rapid-prototyping)

[17](https://www.twi-global.com/technical-knowledge/faqs/faq-manufacturing-what-is-rapid-prototyping)

[18](https://prototek.com/article/rapid-prototyping-bridging-ideas-and-reality/)

[19](https://www.figma.com/resource-library/what-is-rapid-prototyping/)

[20](https://www.geeksforgeeks.org/software-engineering/what-is-rapid-prototyping/)

[21](https://www.sc-rapidmanufacturing.com/best-materials-for-rapid-prototyping-what-works-best.html)

[22](https://fastradius.com/capabilities/cnc-machining/prototyping/)

[23](https://www.pcbway.com/rapid-prototyping/cnc-machining/)

[24](https://schantzfab.com/rapid-prototyping-services/)

[25](https://www.protolabs.com/services/cnc-machining/cnc-milling/)

[26](https://www.xometry.com/rapid-prototyping-service/)

content is empty!

Top CNC Machining Parts Manufacturers and Suppliers in Japan

Top CNC Machining Parts Manufacturers and Suppliers in Germany

Top CNC Machining Parts Manufacturers and Suppliers in Italy

Top CNC Machining Parts Manufacturers and Suppliers in Russia

Top CNC Machining Parts Manufacturers and Suppliers in Portugal