Views: 222 Author: Amanda Publish Time: 2025-10-26 Origin: Site

Content Menu

● What are CNC Milling Services?

>> Overview

>> Key Features and Capabilities

>> Overview

>> Key Features and Capabilities

● Mechanisms and Technical Distinctions

>> Cutting Tool and Workpiece Movement

>> Axes and Machining Complexity

● Advanced Technologies and Hybrid Systems

● Materials and Surface Finish

● Production Volume, Setup, and Efficiency

● Real-World Examples and Case Studies

● Innovations and Future Trends

● Frequently Asked Questions (FAQ)

>> 1. What products are best suited for CNC Milling Services?

>> 2. Can CNC Milling and CNC Turning be combined for one project?

>> 3. How does one choose between CNC Milling and CNC Turning?

>> 4. What tolerances and surface finishes are achievable with CNC Milling Services?

>> 5. Are CNC Milling Services applicable for prototypes and large-scale production?

CNC (Computer Numerical Control) machining is a core pillar of modern manufacturing, enabling manufacturers to achieve high accuracy, repeatability, and efficiency in fabricating metal, plastic, and composite components. The two most prominent machining styles are CNC milling services and CNC Turning, each providing unique benefits for different part geometries and production needs.[1][2][3]

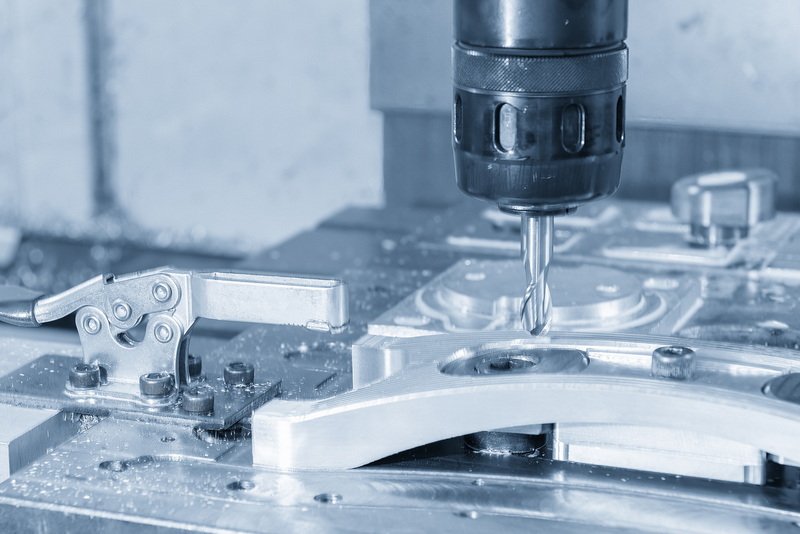

CNC Milling Services involve the removal of material from a stationary workpiece using rotary cutters. These multi-point tools, such as end mills and face mills, move along multiple axes, enabling the creation of complex 3D profiles, pockets, and contours. CNC mills range from basic three-axis machines to sophisticated five-axis equipment, capable of intricate multi-angle work.[3][4][1]

- Complex Geometries: CNC Milling can produce irregular shapes, pockets, and sophisticated structures that are difficult to manufacture using manual methods.[5][6]

- Material Flexibility: Milling is suitable for a wide variety of metals (aluminum, steel, titanium), plastics, and composite materials.[6][11]

- Precision: CNC Milling achieves repeatable tolerances as tight as ±0.004mm, which is critical for aerospace, medical, and automotive components.[11][12]

- Multi-Axis Movement: Advanced mills possess up to six axes, facilitating complex 3D surface machining and multi-face part fabrication.[5]

- Medical devices

- Aircraft parts

- Automotive engine blocks and brackets

- Electronic housings and custom enclosures

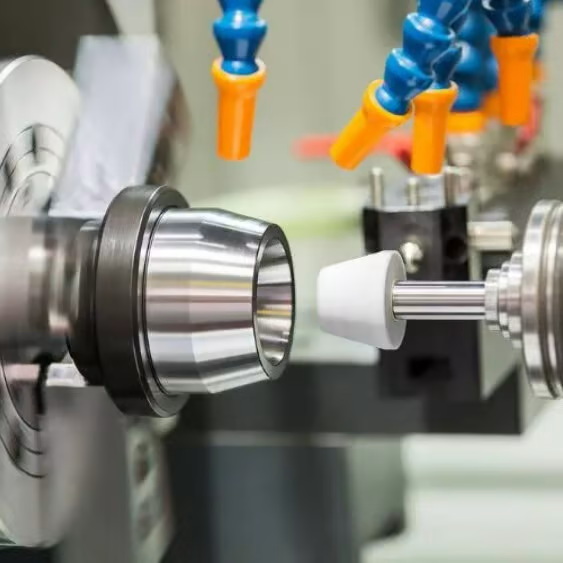

CNC Turning is defined by a rotational approach: the workpiece spins rapidly while a stationary, single-point cutting tool removes material. This method excels at creating cylindrical, tubular, or conical components such as shafts, bushings, rings, and pins.[4][13][3]

- Simple, Efficient Production of Symmetrical Parts: Turning is perfect for high-volume, axis-symmetric parts, delivering superior surface finish and concentricity.[3][5]

- Speed and Consistency: CNC lathes can produce large quantities of round parts swiftly and with excellent repeatability.[4][5]

- Variety of Operations: Including threading, grooving, boring, drilling, and knurling, which add functional details to cylindrical parts.[6][4]

- Material Versatility: CNC turning efficiently machines metals, plastics, and selected woods.[6]

- Automotive drive shafts and connectors

- Medical implant components

- Electronic connectors and housings

- CNC Milling Services: The workpiece remains stationary (or moves slowly), and the cutting tool rotates and traverses in multiple directions to machine features.[2][7][3]

- CNC Turning: The workpiece rotates while the cutting tool remains fixed, removing material along the part's surface or length.[8][3]

- Milling: Utilizes 3, 4, 5, or even 6 axes for complex contouring and multi-dimensional parts.[5]

- Turning: Usually involves two primary axes (X and Z): creates cylindrical or conical shapes with maximum efficiency.[4][5]

- Milling: Multi-point cutting tools (end mills, face mills).[3][6]

- Turning: Single-point cutting tool (lathe tool bits and inserts).[3][6]

A significant advancement in CNC manufacturing is the development of hybrid turn-mill machines. These combine both processes, enabling a single setup for parts needing cylindrical features and complex geometries, thus minimizing work handling, reducing lead times, and increasing productivity.[5]

Multi-axis capabilities in both milling and turning permit more complex features, off-center drilling, and compound operations, essential for aerospace, medical, and advanced industrial applications.[5]

- CNC Milling Services: Can handle harder and denser materials like titanium, carbon steel, stainless steel, and advanced plastics. It's flexible enough for composites and less abrasive materials, enabling a wide application range.[11][6]

- CNC Turning: Often preferred for softer metals such as brass and aluminum, but modern lathes are fully capable of processing tough alloys.[4][6]

- Milling: Produces flat and contoured surfaces with smooth or patterned finishes, depending on the toolpath and cutter.[3][4]

- Turning: Delivers excellent finish for round surfaces, crucial for parts requiring high concentricity and minimal friction, such as shafts and bushings.[4][3]

- CNC Milling Services: Most advantageous for low to medium production runs, rapid prototyping, and complex custom parts. Setup time may be longer due to complicated fixtures, but the method allows for exceptional detail.[4][5]

- CNC Turning: Ideal for high-volume production of cylindrical components. Setup is generally simpler, and the process is more cost-effective for repetitive, symmetrical part geometries.[5][4]

Selecting between CNC Milling Services and CNC Turning often depends on several critical factors:

- Part geometry and complexity

- Material type

- Required tolerances and surface finish

- Production volume and lead time

- Budget constraints

Hybrid machines and advanced tooling can sometimes bridge the gap, allowing manufacturers to benefit from both processes in a unified workflow for advanced parts. Consulting with engineering experts or your CNC services supplier can help determine the most effective solution for your needs.[1][5]

- Aerospace turbine blades: Machined on multi-axis milling centers to achieve complex airfoil contours.

- Medical joint implants: Produced using a combination of turning (for round shaft features) and milling (for recessed and contoured mating areas).

- Automotive shafts: Finished with CNC turning for concentricity, then precisely milled to add slots, keyways, or surface features.

The CNC machining landscape continues to evolve with ongoing advancements:

- CAD/CAM Integration: Enhances the design-to-production pipeline, reduces errors, and speeds up prototyping and manufacturing.

- Automation and Robotics: Picks, loads, and changes tools automatically, further minimizing setup time and labor costs.

- Smart Monitoring: Real-time feedback and predictive maintenance improve machine uptime and reduce faults.

- Eco-Friendly Coolants and Processes: Help reduce environmental impact without compromising quality.

CNC Milling Services and CNC Turning are foundational technologies in manufacturing, each offering specialized advantages for particular part types, production volumes, and material requirements. CNC Milling excels at complex, multi-angled structures, high precision, and batch production of intricate parts. CNC Turning, meanwhile, provides speed, economy, and accuracy for cylindrical and symmetric components. The emergence of hybrid machines and advanced tooling means manufacturers can increasingly combine processes for superior flexibility and efficiency. By understanding the distinct characteristics of each method—and leveraging expert consultation—brands, manufacturers, and engineers can unlock the full potential of CNC machining for any project in today's global supply chains.[1][3][4][5]

CNC Milling Services are perfect for complex-shaped components such as brackets, housings, molds, custom gears, and aerospace parts, where multiple dimensions and features are required.[3][4]

Yes, many modern machining centers combine both processes, allowing for parts that have both cylindrical and intricate prismatic features to be completed in a single setup.[3][5]

It depends on part geometry, material, production volume, lead time, and cost. Seek expert advice from your CNC machining service provider to optimize the process.[1][3]

Tolerances can reach as tight as ±0.004mm, and surface finishes range from matte to polished, depending on cutter type, settings, and post-processing.[11][3]

Absolutely. Milling is commonly used for prototyping one-off designs and for batch production, offering flexibility and responsiveness from design to final delivery.[12][5]

[1](https://www.rapiddirect.com/blog/cnc-turning-vs-milling-differences/)

[2](https://www.mastercam.com/news/blog/what-is-the-difference-between-cnc-milling-and-cnc-turning/)

[3](https://www.3erp.com/blog/turning-vs-milling/)

[4](https://www.komacut.com/blog/cnc-milling-vs-cnc-turning/)

[5](https://www.unionfab.com/blog/2023/09/cnc-milling-vs-turning-processes-applications-pros-cons)

[6](https://waykenrm.com/blogs/cnc-turning-and-milling/)

[7](https://www.fluorotec.com/news/blog/cnc-milling-vs-cnc-turning/)

[8](https://www.pmpa.org/turning-vs-milling-whats-the-difference-for-precision-machining/)

[9](https://demmermanufacturing.com/news/difference-between-cnc-milling-drilling-and-turning/)

[10](https://www.autodesk.com/products/fusion-360/blog/milling-vs-turning-what-should-i-use-for-my-part/)

[11](https://www.china-machining.com/blog/cnc-milling-advantages-and-disadvantages/)

[12](https://www.makerverse.com/resources/cnc-machining-guides/10-big-benefits-of-cnc-milling/)

[13](https://acmefoundry.net/cnc-turning-vs-cnc-milling-whats-the-difference-for-precision-machining-services/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal