Views: 222 Author: Amanda Publish Time: 2025-10-26 Origin: Site

Content Menu

● What Are CNC Milling Services?

● Key Criteria for Selecting CNC Milling Services

>> Assessing Expertise and Experience

>> Equipment Capabilities and Technology

>> Material Proficiency and Sourcing

>> Quality Assurance and Certifications

>> Lead Times, Responsiveness, and Scalability

>> Communication and Design Support

>> Transparent Pricing and Value

● Advanced Considerations for CNC Milling Services

>> Multi-Axis Machining for Complex Parts

>> Rapid Prototyping and Production Agility

>> Customization and Batch Flexibility

>> Digital Integration and Online Quoting

● Global Sourcing, Supply Chain, and Sustainability

>> Overseas and Domestic Suppliers

>> Sustainable Manufacturing Practices

● Managing the Supplier Relationship

● FAQ

>> 1. How do I verify a CNC Milling Services provider's expertise?

>> 2. Which certifications should a CNC Milling Services provider have?

>> 3. What are critical equipment features for quality CNC Milling Services?

>> 4. How can CNC Milling Services accelerate product development?

>> 5. What's the safest way to compare provider pricing?

Selecting the right CNC milling services provider is a strategic business decision that directly impacts quality, lead times, and competitiveness. With a global marketplace, prices and capabilities vary widely—making the supplier selection process both essential and complex. By understanding how to evaluate factors like expertise, equipment, material options, and communication, companies can build successful and lasting partnerships that drive innovation and profitability.[1][4][5][6][7]

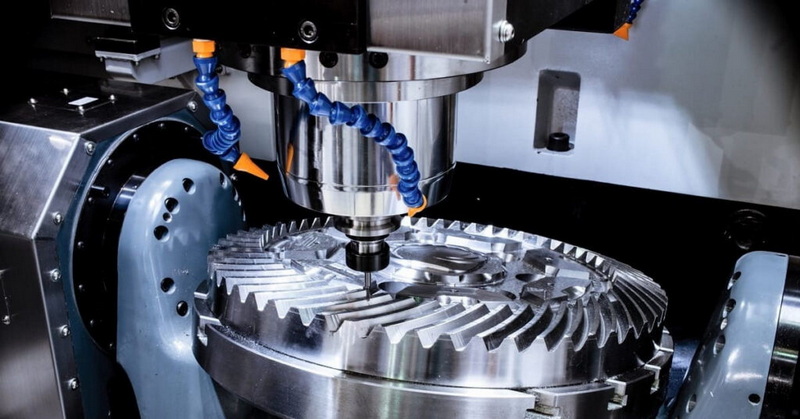

CNC Milling Services leverage computer-controlled mills to cut and shape materials into highly precise components. They cater to industries as varied as aerospace, automotive, medical devices, industrial automation, and consumer goods.

- CNC Milling enables intricate geometries and extremely tight tolerances.

- Services include prototyping, volume production, and specialized finishing.

- Leading providers support metals, plastics, composites, and exotic materials.[5][6][7]

A provider's expertise underpins every successful machining project.

- Evaluate the years spent in CNC Milling Services and track record in your industry.

- Review their familiarity with your target materials and complexity of required parts.

- Ask for customer references, technical portfolios, and case studies of past projects.[4][7][1][5]

State-of-the-art equipment ensures consistent, high-quality output.

- Confirm multi-axis CNC machine availability (3, 4, and 5-axis), which allows for precise and intricate part fabrication.[7][5]

- Assess in-house quality control equipment, such as coordinate measuring machines (CMMs) and advanced software solutions.

- Determine whether providers stay updated on technological advancements and invest in machinery upgrades.[1][4][7]

Matching your design and performance needs requires material versatility.

- Inquire about their ability to process your required materials—aluminum, steel, titanium, plastics, composites, or other specialty alloys.

- Assess the provider's experience machining your chosen materials and how they mitigate risks specific to those materials (e.g., warping, tool wear, burrs).[6][5][7]

- Check material sourcing reliability and inspection processes for incoming raw materials.

Rigorous quality standards deliver reliable, defect-free components.

- Seek providers with ISO 9001 certification, and look for additional industry-specific credentials such as AS9100 (aerospace) or IATF16949 (automotive) where needed.

- Scrutinize their quality control procedures—do they run inspections mid-process, or only at final stages?

- Leading CNC Milling Services document processes and offer traceability for every part.[8][1]

Lead time guarantees and production flexibility are critical.

- Compare quoted turnaround times to your schedule and ask for on-time delivery metrics.

- Determine capacity for urgent or rush orders, as well as ability to scale for larger batch production.

- Top providers communicate about scheduling constraints early and offer rapid prototyping support.[5][7][1]

Strong communication prevents mistakes and maximizes value.

- Providers should respond promptly, clarify technical details, and offer improvements or feedback on manufacturability.

- Value-added services may include design review and optimization for cost, performance, and ease of production.[7][5]

- Open channels reduce chances of misinterpretation, ensuring expectations are met at every project phase.

A transparent pricing structure demonstrates integrity.

- Request detailed quotes breaking down costs for materials, setup, machining, finishing, and logistics.

- Compare overall value, checking that competitive pricing comes with no hidden trade-offs in quality or dependability.

- Be cautious of providers whose pricing seems unusually low—they may cut corners on materials or quality assurance.[10][11]

Advanced multi-axis CNC Milling enables sophisticated part geometries and reduces the need for secondary operations.

- 4-axis and 5-axis systems improve precision and unlock previously impossible shapes.

- These capabilities are essential for aerospace, medical, and high-tech sectors.[5][7]

Speed to market is crucial in today's competitive environment.

- Leading providers offer both CNC prototyping and quick-turn production.

- Short prototyping cycles support design validation before major investment in tooling or large-batch manufacturing.[7][5]

Versatile shops can handle both bespoke parts and mass production.

- Ask about minimum order quantities and lot-size flexibility.

- True partners adjust their workflow to your project needs—from one-off prototypes to thousands of parts per production run.

Next-generation providers invest in digital customer experiences.

- Online RFQ (request for quote) systems streamline pricing and ordering, saving time on administrative tasks.[12]

- Digital process management tools allow real-time project tracking and easier collaboration.

Depending on your project requirements and budget, international CNC Milling Services—especially in China—may offer significant cost advantages.

- Evaluate overseas partners for export experience and communication skills.

- Balance price savings with lead time, shipping risk, aftermarket support, and intellectual property protection.

Environmental priorities are increasingly important in manufacturing.

- Choose providers committed to waste minimization, energy efficiency, and recycling.

- Ask about their initiatives to reduce their environmental footprint—this can strengthen your own ESG (Environmental, Social, Governance) positioning.[8][7]

Building the right relationship with your CNC Milling Services provider enhances trust and project outcomes.

- Schedule regular project reviews and feedback sessions.

- Consider long-term partnership opportunities for volume discounts, prioritized scheduling, and co-development of custom solutions.

A proactive relationship invites insights, innovation, and shared success.

Choosing the perfect CNC Milling Services provider is a high-stakes business process. Evaluate each provider through the lens of technical expertise, equipment sophistication, material proficiency, quality certifications, scalability, communication standards, pricing transparency, and ethical standards. Treat supplier selection as a partnership opportunity—your provider should show a commitment to reliability, technical guidance, and shared growth. Every successful venture starts with an informed decision; with these insights, your business can forge a sustainable, competitive edge in manufacturing.[6][1][5][7]

Ask for detailed case studies, client testimonials, and evidence of similar projects. Check for active participation in your industry sector and verify their technical staff's qualifications.[4][5]

Look for ISO 9001 as a minimum, with additional standards like AS9100 for aerospace or IATF16949 for automotive, as relevant. Certifications show adherence to robust quality and process controls.[1][8][7]

State-of-the-art multi-axis CNC mills, robust tooling options, advanced CAD/CAM software, and in-process as well as post-process metrology are key indicators of capability and quality.[4][5][7]

By integrating rapid prototyping setups, supporting design revision cycles, and offering expeditious quoting/order fulfillment, providers help speed up innovation while reducing risk.[5][7]

Request itemized quotes and scrutinize what is (and isn't) included in the price—materials, labor, finishing, inspection, and shipping. The best value comes from competitive rates paired with transparency and robust quality systems.[11][10]

[1](https://www.fisherbarton.com/factors-to-consider-when-choosing-a-cnc-machining-partner/)

[2](https://www.americanmicroinc.com/resources/choosing-cnc-manufacturing-partner/)

[3](https://revpart.com/seven-essentials-to-identify-cnc-machining-partner/)

[4](https://www.modusadvanced.com/resources/blog/how-to-select-a-cnc-machining-services-partner)

[5](https://www.norck.com/blogs/news/choosing-the-right-cnc-machining-services-5-key-considerations)

[6](https://www.ltc-proto.com/blog/what-is-cnc-machining-services-and-how-to-select-a-good-service-provider/)

[7](https://www.3erp.com/blog/factors-to-consider-when-choosing-cnc-machining-service/)

[8](https://www.soflomachining.com/choosing-the-right-cnc-machining-service-provider-key-considerations/)

[9](https://jlccnc.com/blog/10-key-factors-to-consider-when-choosing-a-cnc-machining-company)

[10](https://fadal.com/how-to-choose-the-right-cnc-machine-for-your-business-needs/)

[11](https://vesciomfg.com/what-to-look-for-in-a-commercial-cnc-machine-shop/)

[12](https://www.reddit.com/r/CNC/comments/15b6lz9/does_anyone_have_experience_using_online_chinese/)

content is empty!