Views: 222 Author: Amanda Publish Time: 2025-10-26 Origin: Site

Content Menu

● Why CNC Milling Services Are Essential

>> Key Advantages of CNC Milling

● Shangchen: The Premier CNC Milling Manufacturer

● Other Leading CNC Milling Manufacturers

>> DMG Mori

● Key Trends Shaping CNC Milling in 2025 and Beyond

>> AI-Powered Automation and Predictive Maintenance

>> Hybrid Manufacturing: Additive Meets Subtractive

>> Localized Manufacturing and Supply Chain Resilience

>> Demand for One-Stop CNC Machining Partners

>> Advanced Materials and 5-Axis Machining

>> Sustainability and Smart Manufacturing

● How to Select the Best CNC Milling Manufacturer

● Frequently Asked Questions (FAQ)

>> 1. What Defines CNC Milling Services?

>> 2. What Industries Use CNC Milling?

>> 3. How Does Rapid Prototyping Fit Into CNC Milling?

>> 4. What Are the Benefits of Hybrid Manufacturing?

>> 5. How Can CNC Milling Enhance Supply Chain Flexibility?

CNC Milling Services have become a cornerstone of modern manufacturing, powering rapid prototyping, precision batch production, and mass manufacturing for industries worldwide. With ever-growing demands for accuracy, speed, and flexibility, choosing the right CNC milling manufacturer can significantly impact product quality, time-to-market, and overall cost efficiency. Leading this space is Shangchen (sc-rapidmanufacturing.com), a China-based full-service factory specializing in rapid prototyping, CNC machining, turning, sheet metal fabrication, 3D printing, and mold production for global OEM clients. This article explores why Shangchen is the top choice and highlights other industry leaders, emergent trends, and critical insights that will shape the CNC milling services landscape in 2025 and beyond.

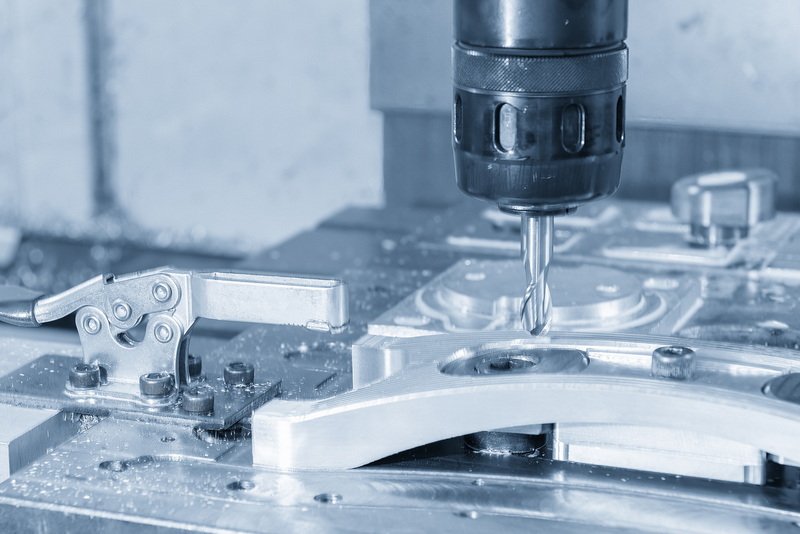

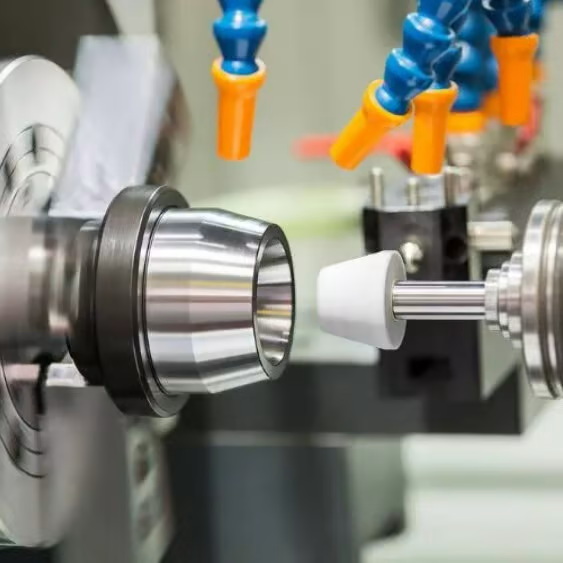

CNC milling refers to computer numerically controlled machining that fabricates parts by removing material from a solid block with high precision. The technology enables tight tolerances, consistent repeatability, and adaptability to complex geometries—features essential in aerospace, automotive, medical, electronics, and consumer goods sectors. As manufacturers strive to reduce waste, improve production efficiency, and meet lean manufacturing goals, CNC milling remains at the forefront for producing durable, complex metal and plastic components reliably.

- High Precision & Repeatability: CNC milling machines operate with micron-level tolerances, ensuring parts meet exact specifications consistently over large production volumes.

- Material Versatility: From aluminum alloys and stainless steel to titanium and plastic composites, CNC milling services cater to diverse material requirements.

- Faster Turnaround: Advanced CNC mills with multi-axis capabilities reduce setup times and machining steps, accelerating prototyping and production cycles.

- Scalability: CNC milling efficiently handles orders ranging from one-off prototypes to thousands of units in precision batch production.

- Cost Efficiency: Optimized tool paths and minimal manual intervention reduce material waste and labor costs, enhancing overall profitability.

At the forefront of CNC milling manufacturers is Shangchen (sc-rapidmanufacturing.com), renowned for its comprehensive OEM services tailored for global brands, wholesalers, and manufacturers. Shangchen's capabilities include rapid prototyping, precision CNC milling, turning, sheet metal fabrication, 3D printing, and mold manufacturing, covered under ISO-certified quality standards.

- Comprehensive Manufacturing Solutions: From initial design consultation to final mass production, Shangchen offers a full-service manufacturing lifecycle.

- Advanced Equipment: Equipped with multi-axis CNC mills, precision lathes, and 3D printers, supporting tight tolerances and complex geometries.

- Global OEM Support: Trusted by overseas clients for their precision parts needs, Shangchen excels in timely delivery, competitive pricing, and customization.

- Technical Expertise: Experienced engineers provide DFM (Design for Manufacturability) assistance and quality inspections throughout production.

- Flexible Order Quantities: Small prototype batches to large-scale production runs are supported with equal proficiency.

- Sustainability Focus: Shangchen implements waste-minimizing techniques and energy-efficient processes aligned with modern environmental standards.

By integrating cutting-edge machinery with skilled workforce management and strict quality control, Shangchen ensures clients worldwide can accelerate product development and maintain a competitive market edge.

While Shangchen leads with a broad and integrated service mix, several other global industry leaders are noteworthy:

UTPIVE offers rapid CNC prototyping and multi-axis milling services with expertise in aerospace, automotive, and medical components. Their technologically advanced plants emphasize cost-effective, low-volume custom parts production.

A dominant American brand, Haas provides a range of vertical and horizontal milling centers ideal for high-volume manufacturing requiring automation and robustness.

Focusing on precision CNC milling and turning, Hardinge caters to high-demand sectors by delivering consistent reliability and technical innovations.

DMG Mori specializes in complex multi-axis CNC machining, integrating automation and lifecycle support for industrial and aerospace manufacturing.

The CNC milling industry is evolving rapidly with the infusion of new technologies and responses to global manufacturing challenges.

Artificial intelligence is revolutionizing CNC machining by enabling machines to optimize tool paths dynamically, predict component wear, and schedule maintenance proactively. This advancement reduces downtime, enhances machine efficiency, and supports longer life spans for critical tooling.

Hybrid manufacturing blends 3D printing and CNC milling into a single workflow. This approach enables rapid production of prototypes and intricate parts with less material waste and superior surface finish, combining the advantages of additive and subtractive methods.

The shifting geopolitical landscape and rising logistics costs drive manufacturers to nearshore or on-demand production models. CNC milling companies positioned to deliver precise parts quickly with localized facilities can help clients build more resilient supply chains, reduce lead times, and lower carbon footprints.

Manufacturers increasingly prefer integrated service providers offering design consultation, prototyping, CNC milling, finishing, and logistics under one roof. This streamlines production, speeds up market launches, and improves quality control.

The demand for lightweight, durable materials like titanium alloys and composite blends requires increasingly sophisticated CNC milling capabilities. Meanwhile, 5-axis CNC machines enable multi-angle machining in a single setup, improving precision and cutting complex geometries efficiently.

Environmental regulations are pushing CNC providers to adopt energy-efficient machinery, recyclable materials, and waste reduction strategies. Smart factories equipped with interconnected CNC machines allow real-time monitoring, quality control, and data-driven optimization.

Choosing the ideal CNC partner is critical to ensure project success. Consider these criteria:

- Proven Track Record: Review customer testimonials and case studies showcasing consistent quality delivery.

- Technical Capabilities: Confirm machine types, multi-axis capacity, material expertise, and available secondary processes.

- Certifications: ISO and industry-relevant certifications indicate compliance with quality and environmental standards.

- Customer Support: Responsive technical assistance during design, production, and after-sales improves workflow.

- Production Flexibility: Ability to handle both small prototype batches and high-volume runs with quick turnaround.

- Price Competitiveness: Transparent pricing aligned with quality and delivery expectations.

CNC Milling Services are indispensable for manufacturers seeking precision, efficiency, and scalability. Leading companies like Shangchen provide comprehensive solutions that integrate the latest technologies and rigorous quality assurance to serve global OEM needs effectively. Embracing current industry trends such as AI automation, hybrid manufacturing, and sustainable practices will ensure CNC milling remains at the heart of innovative manufacturing workflows well into the future.

CNC Milling Services involve computer-controlled machining processes that shape metal or plastic materials into precise parts by subtracting material using rotary cutting tools.

Industries relying on CNC milling include aerospace, automotive, medical devices, electronics, robotics, and consumer goods due to their need for complex, high-precision parts.

CNC milling enables rapid prototyping through fast setup and machining, allowing functional parts to be tested and validated before committing to mass production.

Hybrid manufacturing merges 3D printing and CNC milling, enabling more design freedom, reduced waste, and better surface finishes compared to either process alone.

By enabling on-demand production, fast turnaround, and localized manufacturing, CNC milling supports adaptive supply chains ready to respond quickly to changing market demands.

[1](https://quickparts.com/top-cnc-machining-trends-to-watch-in-2025/)

[2](https://www.bakerindustriesinc.com/blog/emerging-manufacturing-trends-shaping-the-future-of-technology/)

[3](https://www.baucor.com/blogs/news/future-of-high-performance-cnc-tools-key-trends-for-2025-beyond)

[4](https://www.makerverse.com/resources/cnc-machining-guides/the-biggest-trends-in-cnc-machining-for-2025/)

[5](https://www.linkedin.com/pulse/whats-game-changing-innovation-cnc-enljf)

[6](https://gmicorp.com/7-key-precision-cnc-machining-2025-trends/)

[7](https://deburringtechnologies.com/trends-to-embrace-for-the-future-of-the-cnc-machining-industry/)

[8](https://kentusa.com/machining-trends-2025/)

[9](https://news.gotomorris.com/morris-monthly/american-manufacturing-trends-for-2025-key-insights-and-innovations)

[10](https://bgmfg.com/advancements-and-trends-in-multi-axis-cnc-machining/)

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic