Views: 222 Author: Amanda Publish Time: 2025-10-27 Origin: Site

Content Menu

● What Are CNC Milling Services?

>> Key Features of CNC Milling

>> Key Features of 3D Printing

● Comparing CNC Milling Services and 3D Printing

>> Surface Finish and Mechanical Properties

>> Materials and Structural Strength

● Applications and Industry Use Cases

>> CNC Milling Services in Practice

● Integration: Hybrid Approaches

● Future Trends and Innovations

● How to Choose the Right Technology

● Frequently Asked Questions (FAQ)

>> 1. What materials can be processed with CNC Milling Services?

>> 2. What are the main limitations of 3D Printing in industrial applications?

>> 3. How do lead times compare between CNC Milling Services and 3D Printing?

>> 4. Is it possible to combine both processes for one project?

>> 5. Which process is more economical for complex projects?

The rapid evolution of manufacturing technologies has created unprecedented opportunities for businesses around the world to innovate, reduce time-to-market, and customize at scale. Among the most impactful advances are CNC Milling Services and 3D Printing. Both technologies drive the prototyping and manufacturing sectors, each with its own strengths, challenges, and best-use scenarios. This comprehensive guide provides an in-depth comparison of CNC Milling Services and 3D Printing, helping you determine the optimal technology for your next project.

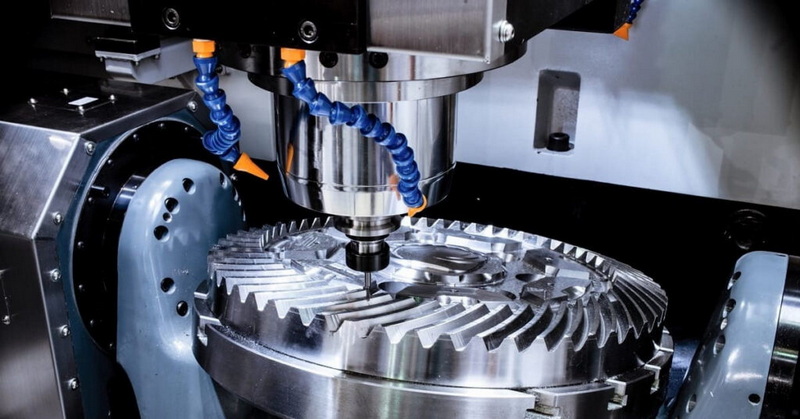

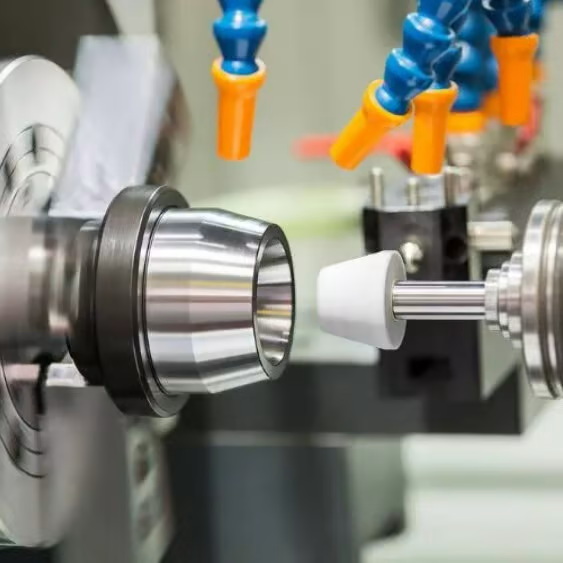

CNC Milling Services refer to the use of computer numerical control (CNC) machines that remove material from a solid block (called a workpiece) by means of programmed cutting and drilling operations. Guided by CAD models and G-code instructions, CNC equipment—such as mills, routers, and lathes—deliver extremely accurate results across a vast range of materials, including metals, plastics, and composites. This subtractive manufacturing technique excels at producing durable, precise parts on demand.

- Extreme accuracy, with tolerances as tight as ±0.01 mm achievable on finished components.

- Broad material compatibility encompassing metals (including aluminum, steel, and titanium alloys), engineering plastics, wood, and more.

- Robust performance, rendering end-use industrial parts suitable for high-stress conditions and repetitive loads.

- Excellent surface finishes, enabling medical, aerospace, or electronics-ready production.

- Scalability from one-off prototypes to full-scale production batches with little loss in quality.

3D Printing, also known as additive manufacturing, builds objects from digital files by layering materials in precise increments. Different processes—such as fused deposition modeling (FDM), selective laser melting (SLM), stereolithography (SLA), or direct metal laser sintering (DMLS)—enable almost any geometry previously imaginable only in concept.

- Geometric freedom, unlocking the creation of intricate internal channels, lattices, or lightweight structures not possible by traditional machining.

- Direct-from-digital manufacturing, which dramatically reduces the lead time and setup for custom projects or iterations.

- Minimal material waste, as only the required substance is deposited layer by layer.

- Rapid prototyping, allowing multiple design versions to be produced and validated overnight.

- Expanding material choices, including not only plastics and resins but also advanced metals, ceramics, and composites with specialized printers.

CNC Milling Services reliably achieve much tighter tolerances than most commercial 3D printers. While some professional 3D Printing methods can approach fine resolutions, surface quality often requires post-processing, and internal flaws may remain in lower-cost equipment.

- CNC-milled parts feature crisp edges, clear features, and near-mirror surface finishes when needed, ideal for both functional prototypes and end-use items.

- 3D Printed parts vary by method: SLA and PolyJet printing produce smooth, detailed surfaces, but FDM prints generally look layered and rougher.

- Subtractive machining imparts excellent isotropic mechanical properties, meaning strength and consistency in all directions.

- Most 3D Printed items have anisotropic properties; that is, strength varies depending on print direction due to the nature of fused or layered construction.

CNC Milling Services maintain a clear advantage in material selection and finished part strength. Industrial parts made from solid billet aluminum or stainless steel via CNC have superior load-bearing capacity compared to most printed alternatives.

Although cutting-edge 3D Printing techniques now permit steel, titanium, or aluminum printing, their cost and the need for finishing operations still restrict them compared to the scale and reliability of CNC-milled metals. For highly functional or safety-critical components, CNC remains the standard.

- 3D Printing is unrivaled for single, complex prototypes or one-time custom shapes, producing parts directly from digital models in a matter of hours.

- CNC Milling Services require programming, workholding setup, and tool changes, but batch runs can greatly outperform 3D Printing for production quantities due to faster cycle times and simultaneous milling on multi-axis machines.

3D Printing shines where intricate, lightweight, and internal features are needed—such as custom cooling channels, lattice structures, or impossible-overhangs. CNC Milling Services, while still capable of impressive complexity, are limited by tool reach and angles, making certain internal shapes or sharp undercuts impractical.

- For prototypes, single parts, or a handful of custom models, 3D Printing is generally much more cost-effective since it bypasses the need for custom tools or labor-intensive setups.

- CNC Milling Services excel in per-part cost for larger-volume production runs; once programmed, the marginal cost per unit decreases rapidly.

- Post-processing costs (support removal, surface finishing) can be higher for 3D Printing, especially if parts are to be functional or aesthetically demanding.

CNC Milling Services are inherently wasteful by virtue of being subtractive, but recycling metal chips or plastic shavings is standard practice in modern facilities. 3D Printing produces almost no waste, but certain photopolymer and powder-based systems come with their own health and disposal considerations. Energy usage varies widely for both, depending on the process and part geometry.

- Aerospace: Machining high-tolerance, flight-critical brackets and housings.

- Automotive: Crafting everything from concept engine parts to working gear assemblies.

- Medical: Creating surgical tools, orthopedic devices, and custom prosthetic components.

- Consumer electronics: Mil-spec enclosures, heat-dissipating interfaces, and mounting brackets.

- Architecture: Presenting detailed 3D models for client review or construction planning.

- Healthcare: Manufacturing patient-specific implants, dental crowns, and even bioprinted tissue scaffolds.

- Robotics and drone technology: Prototyping assemblies, mounts, and custom mechanisms.

- Fashion and jewelry: Creating intricate, fully-custom accessories or bespoke pieces with high detail.

Increasingly, OEMs and contract manufacturers combine the strengths of both CNC Milling Services and 3D Printing for best results. A common workflow starts with 3D Printing for rapid iteration, concept validation, or internal structures, and finishes with CNC Milling Services for high-stress or dimensionally-critical components made from advanced materials.

Hybrid strategies also use printed parts as casting patterns or fixtures for CNC operations, dramatically reducing time and cost while maximizing efficiency.

- Advanced CNC Milling Services are incorporating AI-powered process optimization, real-time monitoring, and 5-axis simultaneous machining to reduce cycle times and ensure zero-defect production.

- 3D Printing is evolving toward mass customization and large-volume additive manufacturing with breakthroughs in multi-material printing, high-strength filament, and post-processing automation.

- Sustainability is becoming a focal point: both sectors focus on smarter energy use, better recycling, and minimizing waste.

Selecting between CNC Milling Services and 3D Printing depends on multiple variables:

- Material: If high-performance metals or heat-resistant plastics are required, CNC Milling Services could be the answer.

- Geometry: For complex geometries with internal voids or organic structures, 3D Printing offers unique advantages.

- Lead Time: Prototyping urgency favors 3D Printing; large batch production usually suits CNC Milling Services.

- Budget: Factor in material, machine time, setup, post-processing, and volume to determine the best fit.

- End Use: Load-bearing and safety-critical parts call for the strength and consistency of CNC-milled items.

Many manufacturers benefit from consulting with experienced providers who offer both CNC Milling Services and 3D Printing, ensuring the most effective and economical production strategy.

Both CNC Milling Services and 3D Printing represent the best in digital manufacturing, supporting everything from visionary product development to industrial-scale production. CNC Milling Services are essential when durability, finish quality, and proven material performance are required for demanding applications. 3D Printing revolutionizes the prototyping process, speeds up R&D, and enables geometric freedom unavailable to traditional processes. Industry leaders increasingly combine both to unlock speed, flexibility, and superior manufacturing outcomes.

The technology you choose should align with your project's functional requirements, deadlines, materials, production scale, and cost targets. Shangchen specializes in both CNC Milling Services and advanced 3D Printing, empowering global brands, wholesalers, and manufacturers to bring innovations to life rapidly and reliably.

CNC Milling Services support a wide array of metals (such as aluminum, steel, copper, brass), engineering plastics (such as ABS, POM, nylon), composites, and certain woods. This diverse compatibility enables their use across nearly all demanding industries.

Despite significant progress, 3D Printing may fall short in producing high-strength, wear-resistant parts or meeting extremely tight tolerances compared to CNC Milling Services. Some industrial metals are costly to print, and many printed thermoplastics are not suitable for high-temperature or high-stress use-cases.

3D Printing is usually faster for one-off parts and design validation since it skips the setup required for CNC. For larger quantities, CNC Milling Services often achieve quicker turnaround due to batch processing and reduced post-processing needs.

Absolutely. Many companies prototype designs using 3D Printing before switching to CNC Milling Services for functional parts. Printed components can also serve as molds or fixtures, optimizing costs and speeding up timelines.

For low-volume, high-complexity designs, 3D Printing typically offers better economies. CNC Milling Services become increasingly cost-effective as part volume increases and complexity decreases, especially when precise tolerances and advanced materials are priorities.

content is empty!

What Are The Benefits of Rapid Prototyping to The Manufacturer?

What Are The Advantages of Using Pytorch for Rapid Prototyping?

What Are The Advantages and Disadvantages of Rapid Prototyping?

Top On Demand 3D Printing Manufacturers and Suppliers in Netherlands

Top On Demand 3D Printing Manufacturers and Suppliers in Norway

Top On Demand 3D Printing Manufacturers and Suppliers in Turkey

Top On Demand 3D Printing Manufacturers and Suppliers in Poland

Top On Demand 3D Printing Manufacturers and Suppliers in Vietnam