Views: 222 Author: Amanda Publish Time: 2025-10-27 Origin: Site

Content Menu

● Why Choose CNC Milling Services

>> Fast Turnaround for Prototyping

>> Broad Material Compatibility

>> Scalability for Batch Production

● CNC Milling and Rapid Prototyping

● CNC Milling in Batch Production

>> Benefits for Batch Manufacturing

● Integration with Other Manufacturing Services

● Applications of CNC Milling Services

● Surface Finishing and Customization Options

● Quality Assurance in CNC Milling

● Innovations in CNC Milling Technology

>> Automation and Smart Manufacturing

● Environmental and Economic Impact

● Partnering with Shangchen for OEM CNC Milling Services

● FAQ

>> (1) What materials are best suited for CNC Milling Services?

>> (2) How accurate are CNC Milling Services?

>> (3) What is the turnaround time for CNC milling prototypes?

>> (4) Can CNC milling be used for both metal and plastic parts?

>> (5) How do CNC Milling Services compare with 3D printing?

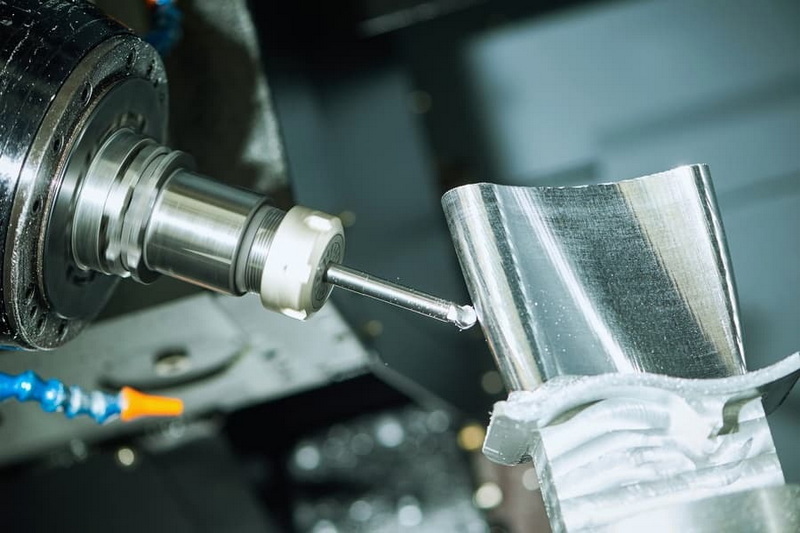

In today's competitive manufacturing environment, CNC Milling Services play a critical role in turning design concepts into tangible, high-precision components. For companies striving for innovation, speed, and quality, CNC milling stands as the backbone of both rapid prototyping and batch production.

At Shangchen (sc-rapidmanufacturing.com), our state-of-the-art CNC machining facility delivers tailor-made OEM manufacturing solutions for global brands and distributors. From precision prototype development to robust metal and plastic production runs, CNC Milling Services provide unmatched reliability, scalability, and accuracy.

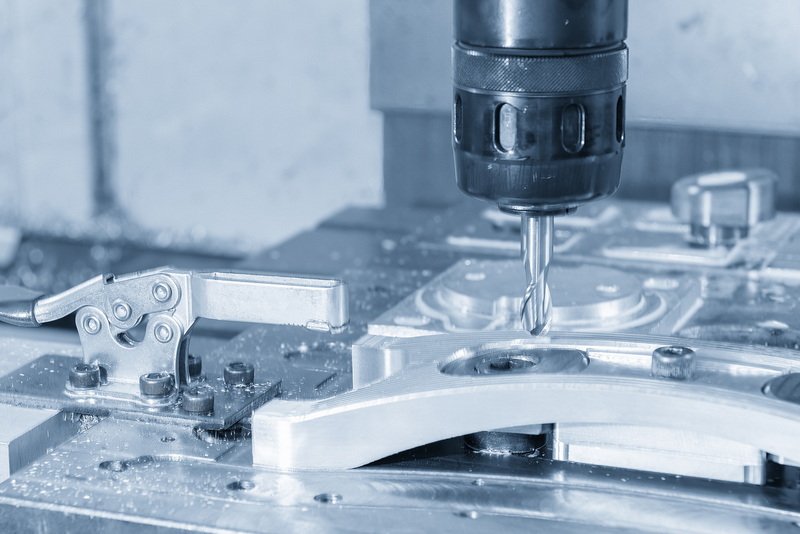

CNC milling is a subtractive manufacturing process that uses rotating multi-point cutting tools to remove material from a workpiece. Powered by computer numerical control (CNC) systems, this process converts complex 3D CAD models into real-world parts with exceptional dimensional accuracy.

1. Design Input: The product design begins with a CAD file that specifies geometries, tolerances, and dimensions.

2. Programming: The CAD file is converted into a CNC program (G-code) that the milling machine uses to control movement and tool paths.

3. Machining Process: The CNC machine executes the program to cut, drill, and shape the material into the final form.

4. Inspection: Each component is examined for dimensional accuracy using advanced metrology tools.

CNC machines can achieve tolerances as tight as ±0.005 mm, providing consistency across high-volume parts. With this level of precision, manufacturers can minimize rework, optimize performance, and maintain product integrity—even for complex geometries.

Rapid prototyping demands speed and flexibility. CNC Milling Services allow you to produce prototypes from actual material—such as aluminum, stainless steel, titanium, or ABS plastic—within hours or days. This accelerates design iterations and reduces the time-to-market.

CNC milling supports an extensive range of materials, enabling designers to explore varying thermal, mechanical, and aesthetic properties. Common materials include:

- Aluminum alloys (6061, 7075)

- Stainless steel (304, 316)

- Brass and copper

- Engineering plastics (POM, Nylon, ABS)

- Carbon fiber reinforced materials

Once a prototype meets all design specifications, scaling production is straightforward. CNC Milling Services allow seamless transition from one-off parts to batch production, ensuring consistency and efficiency.

Although initial tooling costs may be higher, CNC machining minimizes waste and reduces errors, which translates into long-term cost savings. For small to medium-scale production, CNC milling remains one of the most economical options available.

Rapid prototyping is about refining concepts and validating designs before full-scale production. With CNC Milling Services, designers can create realistic, fully functional prototypes that replicate final production parts in material and dimension.

- Functional testing: Check performance under real-world conditions.

- Design validation: Identify and fix design flaws early.

- Material simulation: Test the actual material used in final manufacturing.

- Surface finishing options: Sandblasting, anodizing, powder coating, or polishing can be applied to mimic final aesthetics.

CNC milling's speed and precision enable engineers to iterate quickly, helping companies shorten development cycles and gain a competitive edge.

Batch production requires consistency, efficiency, and reliability. CNC milling meets these requirements by automating repetitive machining processes.

- Consistent quality: Each part matches exact specifications.

- Reduced lead time: Automation accelerates output.

- Flexibility: Designs can be updated or modified easily between production runs.

- Traceability: Digital control ensures data-driven quality management.

By integrating CNC Milling Services into your supply chain, you gain complete control over production scalability—from dozens to thousands of identical components.

At Shangchen, CNC Milling Services complement several other advanced fabrication technologies, providing a one-stop manufacturing solution:

- CNC Turning: For cylindrical or rotational parts.

- Sheet Metal Fabrication: Ideal for housings, brackets, and structural components.

- 3D Printing: Useful for conceptual models and low-cost design testing.

- Injection Molding: Perfect for high-volume polymer production.

- Die Casting and Mold Production: Ensures high repeatability and aesthetics for mass manufacturing.

CNC milling often works alongside these methods to produce hybrid prototypes or assemble mixed-material components.

CNC milling is indispensable across multiple industries that demand efficiency and stringent quality standards.

- Aerospace: Turbine blades, structural supports, housings.

- Automotive: Engine components, custom fixtures, chassis parts.

- Medical Devices: Surgical instruments, implants, and diagnostic equipment.

- Electronics: Heat sinks, enclosures, and connectors.

- Robotics & Automation: Gearboxes, actuator mounts, structural plates.

Whether it's a single prototype or production run, precision and performance are paramount. CNC Milling Services make both possible.

To achieve the desired aesthetic and functional performance, CNC-milled components can undergo various finishing processes:

- Anodizing: Enhances corrosion resistance and color options.

- Powder Coating: Provides durable, uniform coatings.

- Electropolishing: Improves surface smoothness for stainless steel parts.

- Bead Blasting: Creates uniform matte textures.

- Laser Engraving: Ideal for part labeling and branding.

These surface treatments make CNC-milled parts production-ready for direct assembly or consumer applications.

At Shangchen, precision is a measurable commitment. Our CNC Milling Services integrate automated inspection systems and rigorous quality control steps:

- Coordinate Measuring Machines (CMMs) for precise dimensional inspection.

- In-process monitoring to detect errors during machining.

- Raw material traceability to meet international standards (ISO 9001, SGS).

- Performance reports delivered with each production batch.

These measures ensure that every component meets client expectations in both function and finish.

Continuous technological advancements have revolutionized CNC milling, increasing capabilities and reducing turnaround times.

The introduction of 4-axis and 5-axis CNC machines enables milling along multiple planes simultaneously. This allows the creation of complex geometries:

- Curved surfaces and deep cavities

- Undercuts that were previously impossible to achieve with traditional 3-axis machines

- Reduced setup time, since parts require fewer repositioning steps

Integration of robotics and AI-driven monitoring optimizes CNC milling by:

- Minimizing human error

- Enabling unattended, 24/7 operation for faster throughput

- Providing real-time diagnostics to predict tool wear and schedule maintenance before defects occur

Cutting tools now use super-hard materials like carbide, ceramics, and polycrystalline diamond (PCD). Benefits include:

- Longer tool life

- Higher cutting speeds

- Ability to machine tough materials efficiently

CNC Milling Services contribute positively to sustainable manufacturing practices.

- Material efficiency: Precise cutting reduces scrap and waste.

- Energy consumption: Modern CNC centers are more energy-efficient than older machines.

- Low emissions: Compared to casting or forging, CNC milling produces fewer pollutants and requires fewer chemical processes.

Economically, CNC milling lowers overall production costs by reducing error rates and accelerating time-to-market, giving companies a competitive advantage.

Our facility supports full OEM manufacturing from engineering design review to final production and logistics. By collaborating with global brands, suppliers, and product developers, we provide robust custom parts designed for your business needs.

- Multi-axis CNC milling centers

- Tight-tolerance machining for metals and plastics

- Rapid prototyping turnaround within 1–3 days

- Batch and mass production flexibility

- Global export and just-in-time delivery solutions

Your vision is our blueprint for precision.

CNC Milling Services have reshaped modern manufacturing by merging speed, flexibility, and precision. From rapid prototyping to batch production, this technology accelerates innovation and ensures consistent part quality. With advanced capabilities at Shangchen, businesses can confidently bring complex designs to life, streamline their supply chains, and achieve superior product performance across industries.

Partner with us at sc-rapidmanufacturing.com to explore how customized CNC Milling Services can power your next project.

Metals such as aluminum, brass, copper, and stainless steel offer excellent machinability, while engineering plastics like ABS, POM, and Nylon are equally popular for lightweight, corrosion-resistant parts.

CNC milling can achieve dimensional tolerances as tight as ±0.005 mm, ensuring reliable and repeatable precision even in mass production.

Most standard prototypes can be completed within 1–3 business days, depending on material, complexity, and finishing requirements.

Yes, CNC Milling Services handle a wide range of materials, making them ideal for functional prototypes and durable end-use products.

CNC milling provides stronger, more accurate parts from real materials, whereas 3D printing is ideal for quick concept models that may not require structural strength.

content is empty!

Top On Demand 3D Printing Manufacturers and Suppliers in Japan

Top On Demand 3D Printing Manufacturers and Suppliers in Italy

Top On Demand 3D Printing Manufacturers and Suppliers in Germany

Top On Demand 3D Printing Manufacturers and Suppliers in Russia

Top On Demand 3D Printing Manufacturers and Suppliers in Portugal

Top On Demand 3D Printing Manufacturers and Suppliers in Spain

Top On Demand 3D Printing Manufacturers and Suppliers in France

Top CNC Turning Manufacturers and Suppliers in Czech Republic